Design and fabrication of GeAsSeS chalcogenide waveguides with thermal annealing∗

2021-03-19LimengZhang张李萌JinboChen陈锦波JierongGu顾杰荣YixiaoGao高一骁XiangShen沈祥YiminChen陈益敏andTiefengXu徐铁峰

Limeng Zhang(张李萌), Jinbo Chen(陈锦波), Jierong Gu(顾杰荣), Yixiao Gao(高一骁),Xiang Shen(沈祥),†, Yimin Chen(陈益敏), and Tiefeng Xu(徐铁峰),

1Laboratory of Infrared Materials and Devices&Key Laboratory of Photoelectric Detection Materials and Devices of Zhejiang Province,Research Institute of Advanced Technology,Ningbo University,Ningbo 315211,China

2Ningbo Institute of Oceanography,Ningbo 315832,China

3Department of Microelectronic Science and Engineering,School of Physical Science and Technology,Ningbo University,Ningbo 315211,China

Keywords: chalcogenide film,dispersion engineering,optical waveguide,thermal annealing

1. Introduction

Supercontinuum (SC) generation is realized via dispersion and a series of nonlinear effects.[1]Broadband midinfrared SC light source has been found to be applicable to optical coherence tomography, bio-imaging, molecular fingerprinting spectroscopy, and high precision frequency metrology.[2-5]Recently,SC generation has been widely studied in optical fiber as well as planar waveguide devices.[6,7]Generally, it requires the fiber or waveguide to be pumped at a waveguide close to its zero-dispersion wavelength in order to achieve the maximum expansion of the SC spectrum. In addition,it is preferable to choose materials with a large Kerr nonlinearity[8]since SC generation is typical nonlinear interaction processes including self-phase modulation,cross-phase modulation, soliton dynamics, Raman scattering, four-wave mixing,and so on.[9,10]

ChGs have emerged as promising nonlinear materials with a number of distinct properties that make them attractive for mid-IR applications, ChGs consist of one or more of chalcogen elements S, Se, and Te that are covalently bonded with glass forming materials such as As, Sb, Ge, and Ga.[11]Compared to other glass materials, ChGs exhibit higher optical Kerr nonlinearity, high refractive index, and wide midinfrared transparency window.[12]ChGs can provide a wide infrared transmission spectrum with sulfides exceeding 8.5µm,selenides up to 14 µm, and tellurites to around 20 µm. Silicon has some disadvantages in high-speed nonlinear optical signal processing. In 1550 nm band,silicon would be affected by two-photon absorption (TPA) and free carrier absorption(FCA), thereby reducing the performance.[13]Chalcogenide glasses are chosen because they have some unique properties,including low TPA and no FCA.[14-17]The third-order nonlinearity of ChGs up to ~10−13cm2/W is 100-1000 times higher than that of silica.[18,19]Recently,Karim et al. reported a numerical study of the air clad Ge11.5As24Se64.5rib waveguide with a SC spanning from 2µm to 6µm when the waveguide was pumped with a peak power of 500 W at a wavelength of 3.1 µm.[20]Further theoretical studies by Karim have shown a supercontinuum output from 1.8 µm to beyond 8 µm in a Ge11.5As24Se64.5rib waveguide on MgF2.[21]Zhang et al. reported SC spectrum ranging from 1µm to 7µm in As2S3glass rib waveguide pumped by pulses with a peak power of 2 kW,and duration of 50 fs at a wavelength of 1.55 µm.[22]Moreover, Yu et al. also presented experimental results showing a linearly polarized SC spectrum extending from 2µm to 10µm over highly nonlinear rib waveguide employing 4.5 kW peak power 330 fs pulses pumped at 4.184µm.[7]The width of the SC spectrum generated in the planar chalcogenide waveguide is smaller than that in the fibers. However, the advantage of the waveguide platform is that all the functions can be integrated on a single chip,which can ultimately be used for more powerful lab-on-chip systems.[23]

In this paper,we fabricated Ge11As29S25Se35waveguide by UV-lithography and dry etching, and determined appropriate etching parameters and thermal annealing temperature(220◦C) to reduce the scattering loss of the surface and sidewalls of the waveguide.[24,25]We chose Ge11As29S25Se35glass component because the Ge11.5As24Se64.5(MCN≈2.67)component in the Ge-As-Se glass system has been demonstrated to be the most stable composition,[26]and the replacement of Se with a certain amount of S can significantly increase the laser damage threshold in Ge-As-Se glass system.[27]GeAsSeS glass exhibits relatively good thermal stability (Tg=237◦C) and a third-order nonlinearity around 2.82-5.46×10−14cm2/W at 1550 nm.[14]The surface roughness of the as-deposited and annealed films, the morphologies, and the propagation loss of the waveguide were characterized. In addition, the two ChG materials are thermally matched which are highly suitable for preparing step-index waveguides.

2. Waveguide design and simulation

The waveguide structure was optimized by changing the height and width of the waveguide to obtain a good distribution of the optical modes. The rib waveguide was applied because it can effectively reduce the interaction between the mode and the sidewall of the waveguide,which is beneficial to the fabrication of low-loss waveguides. The optimized structure of the waveguide was obtained using a commercial software(COMSOL Multiphysics). The structure diagram of the waveguide is shown in Fig.1. A 1.1µm GeAsS film was deposited on a silicon(TOX)substrate with 2µm thermal oxide layer by thermal evaporation, such a thin film could be used as the bottom cladding layer to reduce light leaks into the substrate. Then a 4.5µm-thick GeAsSeS film with 3.5µm etching depth was used as the optical transmission layer. Another layer of GeAsS was used to cover the top of the waveguide to prevent the core layer from absorbing moisture and other impurities in the air. The width of the waveguide was fixed at 2µm,4µm,and 6µm,respectively.

Fig.1. Schematic of the waveguide cross section.

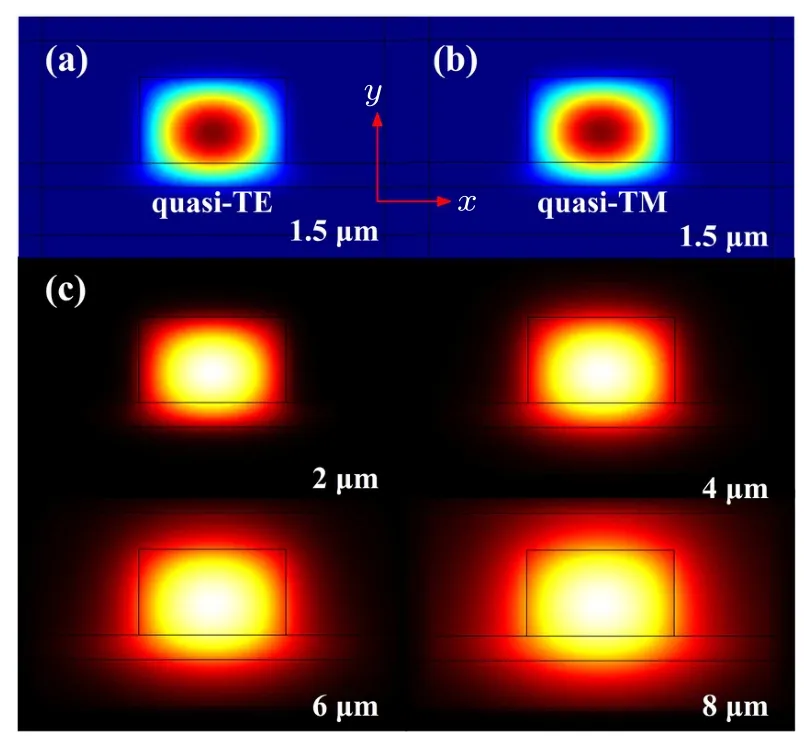

Figure 2 show the electric field distributions at different wavelengths. Figures 2(a)and 2(b)show the electric field distributions of quasi-TE and quasi-TM modes at 1550 nm, respectively. It is evident that quasi-TE and quasi-TM modes are well confined in the waveguide. The field distributions of the quasi-TE mode at wavelengths of 2µm,4µm,6µm,and 8µm in the waveguide are shown in Fig.2(c). We found that even at long wavelengths,the mode field could be effectively confined in the rib structure. The width and height of the designed waveguide are 6µm and 3.5µm,respectively.

Fig.2. (a) and (b) Electrical field distributions of the quasi-TE and quasi-TM modes at 1550 nm. (c)Electric field distribution of the quasi-TE mode at 2µm,4µm,6µm,and 8µm,respectively.

For ChG glass, the ZDW is usually larger than 4.5 µm,reducing the ZDW of the waveguide structure is crucial for SC applications,[28]since most of the commercially available lasers operate at short pump wavelengths less than 2µm. The ZDW of the waveguide could be shifted to a shorter wavelength through dispersion engineering. The dispersion curves of the two modes are calculated by

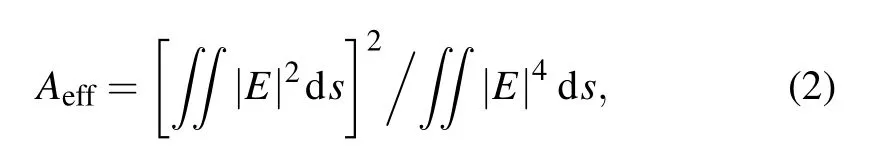

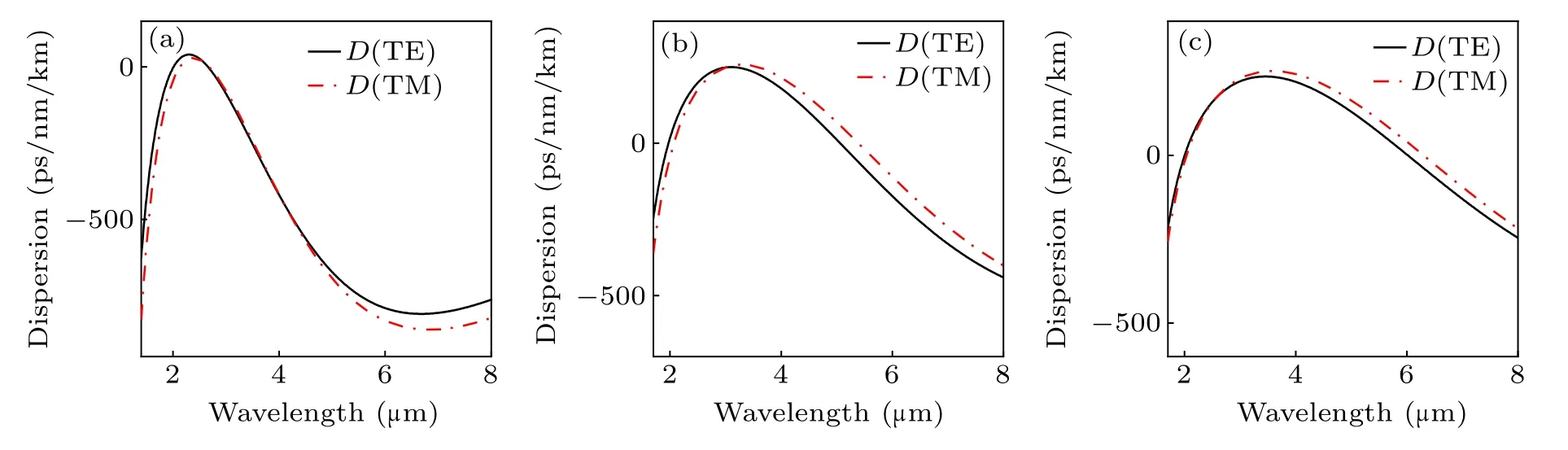

The dispersion of the transmission mode is determined by the wavelength λ and the speed of light c, as well as the second derivative of the mode effective index (neff) relative to the wavelength. The calculated results of the designed waveguides with different widths are shown in Fig.3. It can be seen from Fig.3(a) that a 2 µm wide waveguide exhibits a close double-zero dispersion point,which limits the broadening of SC.Although in the short wavelength region,for 4µm and 6µm wide waveguides,quasi-TE and quasi-TM have almost the same influence on the dispersion of the waveguide.However,it is obvious that the effect of the quasi-TE mode on the waveguide dispersion is smaller than that of the quasi-TM mode as the wavelength increases. The ZDW of the quasi-TE mode and the quasi-TM mode in waveguides with widths of 4 µm and 6 µm is around 2.1 µm, which is shorter than the ZDW reported in Refs.[29-31]The effective mode area(Aeff)is given by

where E represents the electric field transverse component propagating inside the waveguide. The integration is performed on the whole waveguide cross-section calculation region. The Aeffof the waveguide with 6 µm width (14.3 µm2for TE mode and 14.5µm2for TM mode)is obviously larger than that of the waveguide with 4µm width(9.6µm2for TE mode and 9.9 µm2for TM mode). The smaller the Aeff, the higher the nonlinear coefficient of the waveguide, which can enhance the nonlinear effect.

Fig.3. Calculated dispersion curves of the quasi-TE and quasi-TM modes with the waveguide width of 2µm,4µm,and 6µm,respectively.

3. Waveguide fabrication

The GeAsSeS and GeAsS targets were fabricated using melting-quench method and then used as the source materials for the thermal evaporation.Figure 4 displays the flow chart of the fabrication process of the chalcogenide waveguide.1.1µm thick Ge30As15S55and 4.5µm thick Ge11As29S25Se35chalcogenide films were deposited on a TOX substrate successively.The films were annealed at 220◦C for 3 hours to reduce residual stress and scattering loss.[32]GeAsSeS waveguides were fabricated through UV-lithographic patterning and dry etching by employing a positive AZ series photoresist.[33]The photoresist with a thickness of 1-2µm was spin-coated on the film and then the film was baked for 6 min at 90◦C to survive development and subsequent etching without peeling. After UV exposure,the photoresist was developed followed by hard baking.After a contact ultraviolet lithography for 8 s,the photoresist was developed followed by 0.5 h post-baking at 120◦C.During etching, the ICP power was 500 W, HF was 100 W,the reaction chamber pressure was 6 mTorr, and the etch rate was ~1600 nm/min. The optimized CHF3:CF4etching ratio allowed us to obtain a rib waveguide with smooth surface and high sidewall verticality. Finally, a 1 µm-thick GeAsS layer was covered as a protective layer on the core layer.

Fig.4. Schematic fabrication process of the waveguide.

4. Results and discussion

The composition of the films was measured by using energy-dispersive x-ray spectroscopy (EDX). The refractive index curves of the Ge11As29S25Se35and Ge30As15S55films are shown in Fig.5. The linear refractive indexes of the films annealed at different temperatures below Tg(237◦C)were measured by an ellipsometer (J. A. Woollam IR-Vase II).Compared with Ge18Se82and As2S3films,[34,35]GeAsSeS films show the better stability of refractive index. The difference in refractive index between the annealed film and the deposited film is less than 0.04 in Fig.5(b).The increase in refractive index caused by the densification of the film could be explained by the increase in the number of heteropolar bonds after annealing,thereby increasing the effective polarizability of the material. The film thickness shows the opposite trend,i.e.,it decreases with the annealing temperature.By raising the temperature to reach 240◦C,the film thickness drops sharply by ~7 % due to the high temperature causing the material to evaporate from the surface, which is also reflected by the increase in surface roughness.

Fig.5. (a)Refractive index of as-deposited films. (b)Variation in relative thickness and refractive index at 1550 nm of GeAsSeS films annealed at different temperatures.

The first and crucial step in low-loss waveguide fabrication is to prepare high quality films with stable physical properties. The glass material needs to be added several times during thermal evaporation coating,which would cause delamination of the film. Thermal annealing is a simple method to accelerate the relaxation of the film to its equilibrium state. The density of the film could be improved by the proper thermal annealing.[36]In Fig.6,the morphology AFM images for the as-deposited and annealed GeAsSeS films show the fine particles on the surfaces of the films. Each group is processed with identical fabrication schemes but with different temperatures below Tg(237◦C). By performing thermal annealing treatment on the as-deposited film at a temperature from 180◦C to 240◦C with a step of 20◦C(Table 1),the change in root mean square roughness(RMS)of the film surface was measured by AFM.For the as-deposited film,the RMS is 2.98 nm and decreases with the increased temperature up to 220◦C,although the change is not obvious. The mean square error(MSE)decreases significantly as the temperature increases to 220◦C.The measurement results show that the roughness of the film annealed at 220◦C is reduced by 18%compared to that of the as-deposited film. By raising the temperature to over 240◦C,small cracks and bubbles were observed in the film through a microscopy, which is attributed to the thermal mismatch between the film and the silicon-based substrate. We thus conclude that the best thermal annealing temperature is 220◦C.The previous studies have shown that an annealing treatment can reduce the Rayleigh scattering of the films via the suppression of homopolar bonds, voids, and dangling bonds in the deposited film.[35]Compared with the as-deposited state,the annealing treated film has smaller nanoparticles, and thus could be used to prepare low-loss waveguides.

Fig.6. AFM topographical image of Ge-As-Se-S film surfaces taken at 5×5µm scanning area: (a)as-deposited film,(b)220 ◦C annealed film.

Table 1. Surface amplitude parameter for GeAsSeS films.

To obtain high-quality GeAsSeS waveguides, we chose a mixed gas of CF4and CHF3for etching. The gases in the reaction chamber of ICP form a plasma including ions,molecular mixtures,electrons,CFx(x=1,2,3)groups,and fluorine radicals. The main factor affecting the etching behavior is the relative density of the fluorine radicals. The etching strength increases as the density of fluorine radicals rises.The inert fluorocarbon polymer formed by the CFxgroups is deposited on the surface and sidewalls of the etched film. This fluorocarbon polymer protective layer can prevent further etching by fluorine radicals. Although the fluorocarbon polymer deposition and fluoride radical etching are isotropic, the lateral etching rate is lower than the vertical polymer removal rate. Enhanced anisotropy can reduce the occurrence of trenches and sidewall cuts in lateral etching.[37]We have previously tried using CF4and O2as etching gases,but some undesirable phenomena occurred, such as rough etched surfaces, curved sidewalls, and large etching deviation,due to a large number of fluorine radicals and relatively few CFxgroups in the etching environment.

Scanning electron microscopy (SEM) and optical microscopy were used to observe the morphology of GeAsSeS waveguides. It can be seen from Figs. 7(a) and 7(b) that the waveguide fabricated by the preparation process herein exhibits a vertical sidewall and excellent morphology. The vertical sidewalls of the rib waveguide can reduce the loss due to scattering and effectively confine the light in the mode field.Figures 7(c)and 7(d)show the cross-sectional morphology of the waveguide prepared by the as-deposited film and the annealed film. The waveguide prepared by the 220◦C annealed film exhibits better compactness on all levels, which is beneficial to the subsequent preparation of the waveguide without the problem of falling off.

Fig.7. (a)SEM image of the waveguide. (b)Optical microscopy image of the waveguide. (c)and(d)Cross-sectional view images of GeAsSeS rib waveguide before and after annealing.

The transmission properties of the waveguide samples were measured using an automated alignment system with lens fibers to couple light into and out of the waveguide and the output light was detected using a power meter(Newport 1918-R).

The propagation loss in dB/cm is defined by

Figure 8 shows the propagation loss measured at 1550 nm of the rib waveguide samples fabricated from the as-deposited and annealed films with different lengths(12 mm,7 mm,and 3 mm). To avoid the experimental uncertainty and statistical error in the loss measurement, several runs of the measurements were carried out on the waveguide samples and the data of the loss were averaged. The calculated propagation losses in 6µm wide and 4µm wide annealed waveguides are 1.91±0.21 dB/cm and 2.13±0.26 dB/cm, respectively. The approximate measurement error indicates that the annealed waveguide exhibits more than 0.4 dB/cm lower propagation losses compared to the waveguide before annealing.The propagation loss increase could be primarily attributed to increasing sidewall scattering as the width decreased from 6 µm to 4 µm. In addition, the coupling losses between lensed fibers and the waveguide could be determined by the intercepts of the fitting line, which was ~7 dB/facet for the waveguide. Presumably, the relatively large coupling loss is the mode mismatch between the waveguide and the lens fiber. The coupling loss can be reduced via several approaches, like polishing the waveguide end surface and adding anti reflection coating.[38-40]

Fig.8. Insertion loss and propagation loss of waveguides fabricated from the as-deposited and annealed films.

5. Conclusions

In this paper, Ge11As29S25Se35waveguides were fabricated by photolithography and dry etching. The ZDW of the obtained waveguide could be shifted to ~2.1µm through appropriate dispersion engineering,which provides great convenience for the laser pump wavelength required for SC generation. The experiments demonstrated that thermal annealing is an effective way to reduce film roughness and reduce optical loss. Without changing the geometry of the waveguide crosssection, thermal treatment can reduce film roughness (up to 18%) and reduce optical loss (up to 19%). The corresponding propagation losses of the annealed waveguides of 6 µm(width)×3.5µm(height)and 4µm(width)×3.5µm(height)are 1.9±0.21 dB/cm and 2.13±0.26 dB/cm at 1550 nm, respectively.Based on the optimized design and fabrication process of the waveguide,GeAsSeS chalcogenide waveguides are suitable for potential applications related with SC sources.

杂志排行

Chinese Physics B的其它文章

- Transport property of inhomogeneous strained graphene∗

- Beam steering characteristics in high-power quantum-cascade lasers emitting at ~4.6µm∗

- Multi-scale molecular dynamics simulations and applications on mechanosensitive proteins of integrins∗

- Enhanced spin-orbit torque efficiency in Pt100−xNix alloy based magnetic bilayer∗

- Soliton interactions and asymptotic state analysis in a discrete nonlocal nonlinear self-dual network equation of reverse-space type∗

- Discontinuous event-trigger scheme for global stabilization of state-dependent switching neural networks with communication delay∗