旋耕刀Fe/WC/CeO2等离子堆焊层制备及其组织性能

2021-03-17郝建军占志国侯俊英赵建国刘敬春殷常峰

郝建军,占志国,侯俊英,2,赵建国,刘敬春,2,殷常峰

·农业装备工程与机械化·

旋耕刀Fe/WC/CeO2等离子堆焊层制备及其组织性能

郝建军1,2,3,占志国1,侯俊英1,2,赵建国1,2,3,刘敬春1,2,殷常峰4

(1. 河北农业大学机电工程学院,保定 071001;2. 河北省智慧农业装备技术创新中心,保定 071001;3. 河北省农业机械作业刀具重点实验室,定州 073000;4. 山东旭拓新材料科技有限公司,潍坊 261000)

针对农业触土部件因耐磨性能差、冲击韧性低而导致刀具寿命短、失效频繁等问题,采用等离子堆焊技术在Q235钢基材上成功制备了Fe/WC/CeO2金属陶瓷复合涂层,分析了CeO2对Fe/WC/CeO2金属陶瓷复合涂层性能的影响及其对涂层的作用机理。以堆焊电流、堆焊速度、送粉速率、堆焊距离为试验因素,磨损量为评价指标,通过正交试验优化了Fe/WC/CeO2等离子堆焊层制备工艺参数:堆焊电流50 A,堆焊距离5 mm,堆焊速度15 cm/min,送粉速率25 g/min。利用扫描电子显微镜、X射线衍射仪、能谱仪分析了堆焊层显微组织、物相组成,采用维氏显微硬度计、摩擦磨损试验机、冲击试验机、土槽试验台等测试了堆焊层显微硬度、耐磨性和冲击韧性,利用电化学工作站分析了堆焊层的耐蚀性。结果表明,堆焊层与基体呈良好的冶金结合,涂层主要有鱼骨状、长杆状、球状、六方形状等组织构成,堆焊层主要由γ-Fe、Fe-Cr-Ni固溶体、WC、M7C3、Cr7C3、Cr23C6、W2C等物相组成。与Fe/WC堆焊层相比,Fe/WC/CeO2堆焊层平均显微硬度提高22%,冲击韧性提高29%。土槽试验与田间试验表明,与65Mn旋耕刀相比,Fe/WC/CeO2堆焊层旋耕刀的磨损量分别降低71%和65%;与Fe/WC堆焊层旋耕刀相比,Fe/WC/CeO2堆焊层旋耕刀的磨损量分别降低17%和15%。Fe/WC/CeO2堆焊层具有较好的耐磨、耐蚀和耐冲击综合性能,研究结果可为犁铧、深松铲等农业触土部件强化提供参考。

显微结构;性能;等离子堆焊;堆焊层;旋耕刀

0 引 言

中国农业机械化的快速发展,对农机装备关键部件的综合性能及使用寿命要求也越来越高[1-2]。农业机械是实现农业机械化的基本物质保证,是现代农业的有力支撑。耕整地机械作为农业机械化的首要和基础环节,对于提高耕地产能、保障粮食安全,具有十分重要的意义。农业触土部件长期承受土壤中砂石、作物秸秆等的摩擦极易发生磨损失效,严重影响了农业机械的使用寿命和工作可靠性[3-6]。改善农业机械触土部件的耐磨性,延长其使用寿命,是加快农业机械化及农机装备产业转型升级亟待解决的问题之一。

为提高农业触土部件的使用寿命,张旭等[7]采用氧乙炔火焰喷焊在灭茬刀上制备了耐磨性优异的Fe6涂层。郝建军等[8]采用等离子堆焊技术在旋耕刀上制备了较65Mn旋耕刀平均磨损量减小50%的Fe-Cr-C-V复合涂层。赵建国等[9]采用火焰喷焊技术在深松铲尖制备铁基合金涂层,并利用喷焊余温进行淬火处理,结果表明涂层深松铲尖耐磨性明显提高。张校珩[10]利用等离子堆焊在割草刀上制备了Fe基合金堆焊层,并对其进行微波热处理,结果表明割草刀耐磨性和使用寿命明显提高。上述方法制备的涂层均在不同程度上提高了农机触土部件的耐磨性,延长了使用寿命,但上述涂层大多存在韧性低、易发生脆断等不足,难以满足旋耕机大型化、复式化、高速化发展需求。

稀土改性是改善涂层性能的常用手段,它能有效消除涂层材料分布不均及晶粒粗大,使涂层具有硬度高、强度高、韧性高、耐蚀性好等优异性能[11-12]。赵运才等[13]以稀土氧化物CeO2为添加剂,利用等离子喷涂技术在45钢表面制备了Ti-Al/WC金属陶瓷复合涂层,结果表明,CeO2的加入使涂层内部晶粒得到细化,颗粒物含量大幅度减少,孔洞变小,裂纹数量显著降低。Chen等[14]以稀土氧化物CeO2为添加剂,采用激光熔覆制备了Fe基合金涂层,分析表明CeO2可减少涂层裂纹倾向和孔隙率,显著提高涂层与基体的结合强度。本文采用等离子堆焊制备Fe/WC/CeO2堆焊层,分析CeO2稀土氧化物对涂层性能的影响,以期为深松铲、犁铧、割草刀等农业触土部件表面强化提供参考。

1 堆焊层制备

1.1 试验材料

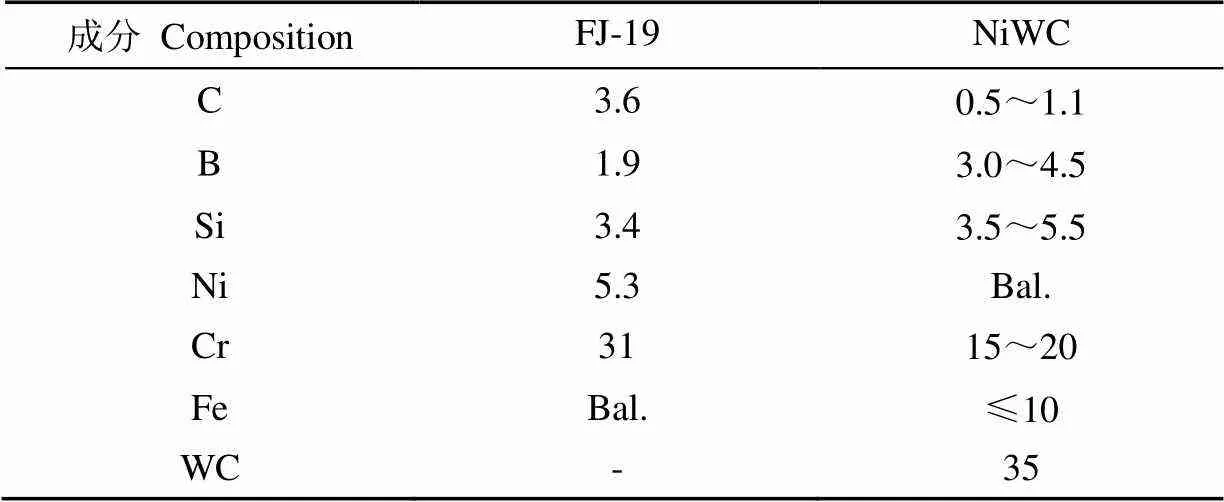

基体为100 mm×40 mm×10 mm的Q235钢,堆焊粉末为上海铸宇材料科技有限公司生产的纯度99.5%,粒度分别为48~100m与45~100m的FJ-19和NiWC粉末,化学成分组成见表1。纯度为99.99%,粒度为15~20m的CeO2粉由中诺新材(北京)科技有限公司生产。

表1 堆焊粉末化学成分及质量分数

混合粉末中CeO2含量对涂层组织和性能具有显著影响。CeO2含量太小,堆焊层硬度与耐磨性提升效果不明显,而CeO2含量过高,则会降低堆焊过程中熔池液态金属的流动性,导致堆焊层成分偏析严重、应力集中加剧、组织缺陷增多、耐磨性降低[14]。本研究前期试验表明,等离子堆焊制备Fe/WC/CeO2时,CeO2质量分数为3%时,CeO2对改善Fe/WC堆焊层耐磨性能效果明显(如图1)。

参考相关文献[15-16]并结合前期预试验结果,本研究试验用堆焊粉末分别按70%FJ-19+30%NiWC、67%FJ-19+ 30%NiWC+3%CeO2配制。混合粉末分别用QM-3SP2型行星式球磨机球磨混合。球磨工艺参数:转速200 r/min,球磨时间8 h,球料比7∶1,磨球材质氧化锆。

1.2 设备及工艺参数选取

采用GP-1喷砂机对Q235试件的100 mm×40 mm任一面进行喷砂处理,喷砂工艺参数为:喷砂压力0.7 MPa,G16钢砂,喷砂角75°,喷砂距离100 mm。喷砂完毕后用丙酮溶液清洗以去除试件表面的杂质与油污,清洗完毕后用冷风吹干,待用。

等离子堆焊工艺参数中,堆焊电流、堆焊速度、送粉速率、堆焊距离是影响堆焊层质量的主要因素[17-18]。工艺参数选取不当均会导致堆焊粉末熔化不良或过度熔化,堆焊层成型差,堆焊层耐磨性能变差。

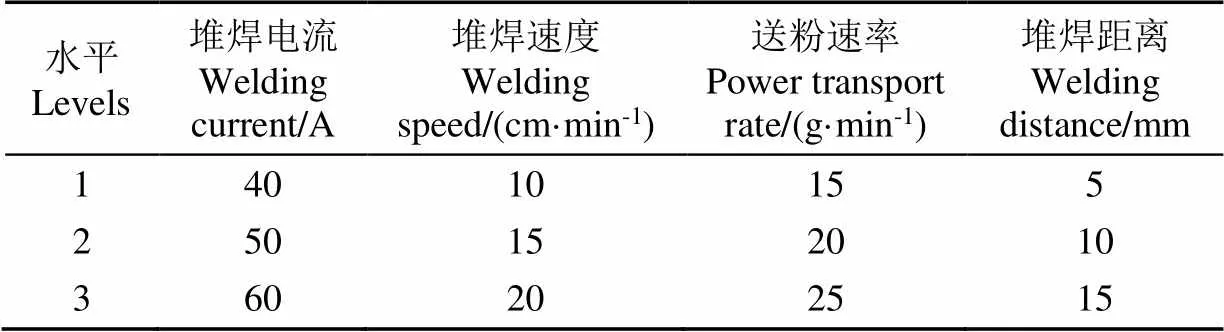

采用DML-V02BD等离子堆焊机(离子气1.5 L/min,送粉气2.5 L/min,保护气0.5 L/min,堆焊角度90°±5°)在经表面预处理后的2组基体试件表面分别制备Fe/WC、Fe/WC/CeO2等离子堆焊层。采用HSR-2M型往复式摩擦磨损试验机测试堆焊层耐磨性,利用FA2204B型电子分析天平称量磨损量(每组试样重复3次,结果取平均值)。以堆焊电流、堆焊速度、送粉速率、堆焊距离为试验因素,堆焊层磨损量为评价指标,采用四因素三水平L27(34)正交试验优化堆焊工艺参数。根据经验[19-22]和设备允许范围,试验因素与水平设计见表2。

表2 试验因素与水平

1.3 优化结果

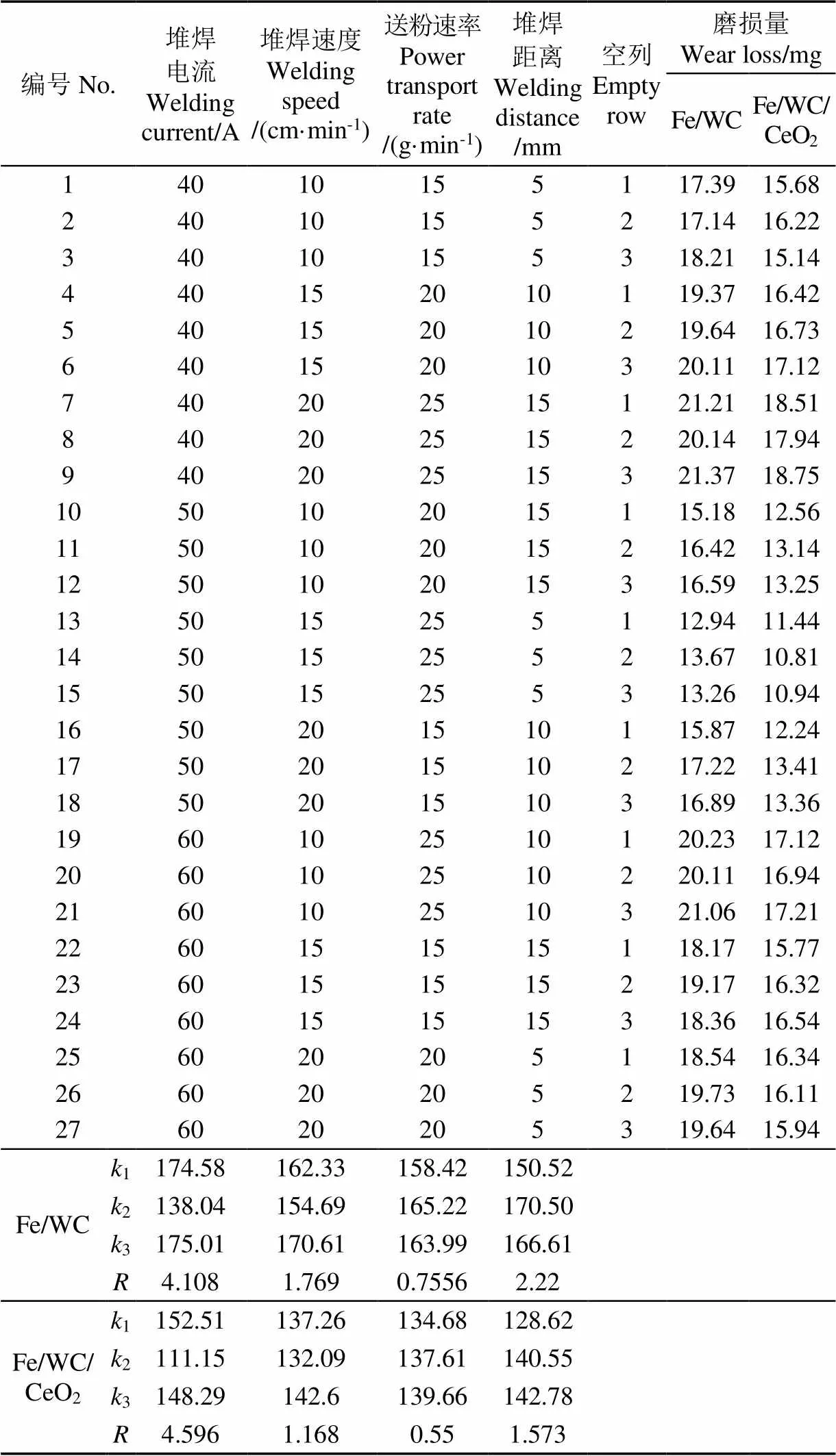

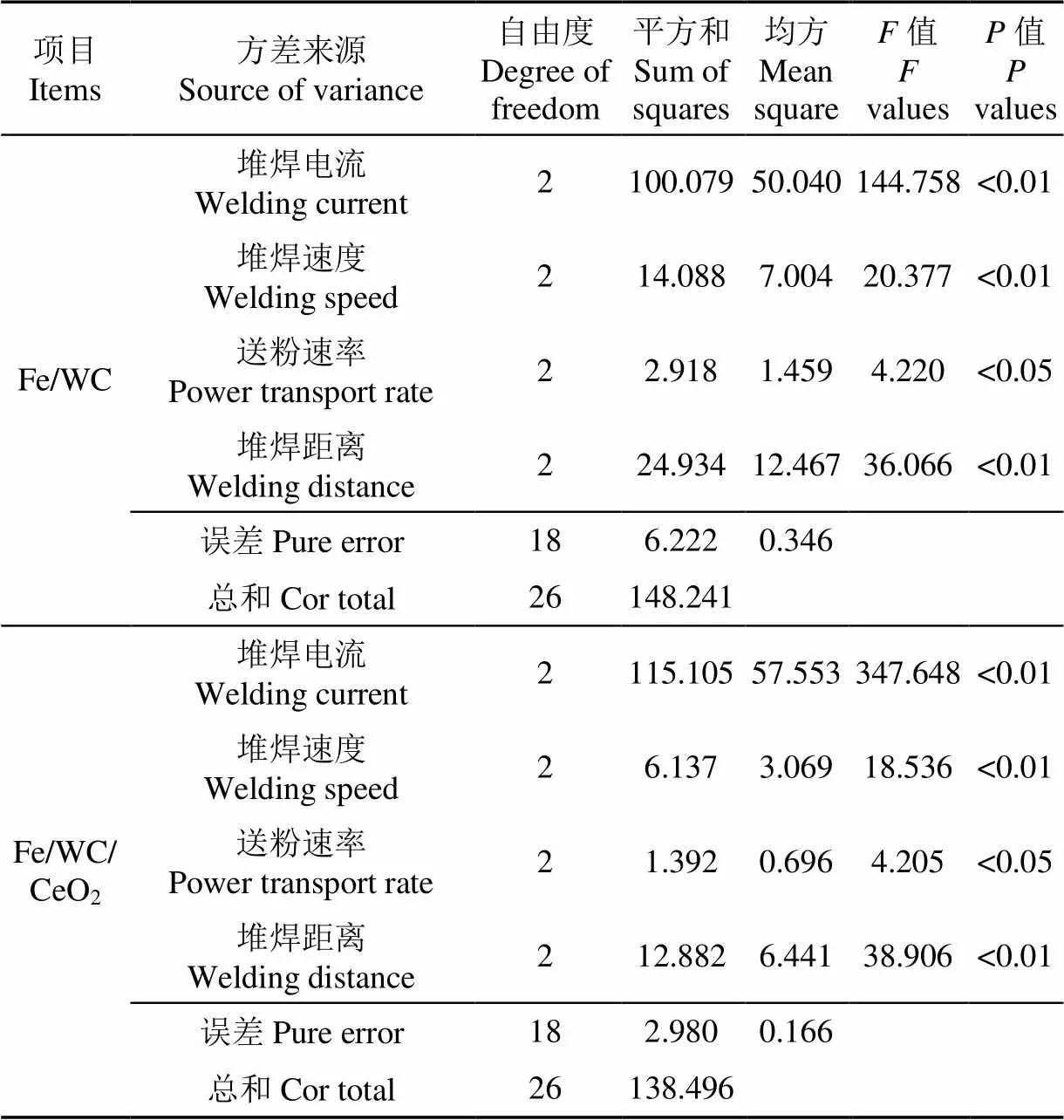

正交试验结果及极差分析见表3,方差分析见表4。

表3 正交试验结果及极差分析

表4 方差分析

注:<0.01(极显著);0.01<<0.05(显著);>0.05(不显著)。

Note:<0.01 (very significance), 0.01<<0.05 (significance)>0.05 (no significance).

由表3可知,各因素对堆焊层磨损量的影响主次排序均为:堆焊电流、堆焊距离、堆焊速度、送粉速率。由表4可知,堆焊电流、堆焊速度、送粉速率、堆焊距离对堆焊层的磨损量影响显著。获得磨损量最小的堆焊层最优工艺参数组合为:堆焊电流50 A,堆焊距离5 mm,堆焊速度15 cm/min,送粉速率25 g/min。采用DML-V02BD等离子堆焊机以上述最优工艺参数制备Fe/WC、Fe/WC/CeO2堆焊层,并对堆焊层组织与性能进行分析。

2 堆焊层组织

2.1 堆焊层显微组织

图2为堆焊层扫描电镜(Scanning Electron Microscope,SEM)形貌。由图2a、2b可以看出,堆焊层成型较好,无明显气孔、裂纹等缺陷,堆焊层与基体结合区界面明显,说明堆焊层与基体相互渗透形成了良好的冶金结合。与Fe/WC堆焊层相比,Fe/WC/CeO2堆焊层结合区部位出现了WC颗粒,说明CeO2的净化作用可使WC等硬质颗粒移向堆焊层边缘,提高堆焊层结合部的硬度。

由图2c、2d可知,Fe/WC堆焊层中硬质相主要呈鱼骨状、长杆状、球状,硬质相尺寸粗大(长杆状硬质相可达200m)且分布杂乱;与Fe/WC堆焊层相比,Fe/WC/CeO2堆焊层中长杆状硬质相尺寸明显减小(尺寸约100m)且呈弥散分布,硬质相呈鱼骨状、长杆状、球状、六方形状。稀土氧化物CeO2不仅可使熔池中的WC等未熔颗粒移向堆焊层边缘,同时,还可细化晶粒、净化晶界,二者的共同作用使得堆焊层中硬质相细小且弥散分布。

2.2 堆焊层物相

图3为堆焊层X射线衍射图(X-Ray Diffraction, XRD)。由图3可见,Fe/WC堆焊层主要由γ-Fe、Fe-Cr-Ni固溶体及WC、M7C3、Cr7C3、Cr23C6等碳化物硬质相组成。与Fe/WC相比,Fe/WC/CeO2堆焊层中的碳化物与固溶体峰值有所增加,说明CeO2有助于碳化物增加和固溶体析出。另外,Fe/WC/CeO2堆焊层中出现了W2C硬质相,这是由于CeO2的使堆焊层中WC硬质相脱碳,分解形成W2C。与标准PDF(Powder Diffraction File)卡片比对发现Fe/WC/CeO2堆焊层的物相衍射峰有较弱偏移,这是由于等离子堆焊快速凝固导致的固溶扩展和热收缩产生的拉应变畸变[23-25]致使衍射峰发生了偏移。

因CeO2添加量较少,在Fe/WC/CeO2堆焊层XRD中未发现CeO2衍射峰。为进一步分析CeO2对涂层组织的影响,采用EDS分析Fe/WC/CeO2堆焊层中元素分布(如图4)。由图4可以看出,块状物质W元素含量较高,可能为未熔的WC颗粒。Ni、W、Ce元素均匀,说明CeO2的添加可使堆焊层中各组织呈弥散分布。

3 堆焊层性能

3.1 堆焊层显微硬度

利用MH-6维氏显微硬度仪测试Fe/WC、Fe/WC/CeO2试件截面显微硬度。测试时,试验载荷0.5 kg,加载时间15 s,每组试样重复3次,结果取平均值。图5为试件截面显微硬度图。

由图5可知,Fe/WC、Fe/WC/CeO2堆焊层显微硬度分布较均匀,硬度自涂层至基体方向逐渐降低,Fe/WC/CeO2堆焊层平均显微硬度(HV0.5870)较Fe/WC堆焊层显微硬度(HV0.5710)提高了22%。CeO2使堆焊层WC增强相和Cr23C6、M7C3等硬质相的分布更加均匀,从而提高了堆焊层的显微硬度。与本课题组前期制备的Fe-Cr-C-V堆焊层(HV0.5810)[8]相比,Fe/WC/CeO2堆焊层硬度提高了7%。

3.2 堆焊层耐磨性

利用HSR-2M型往复式摩擦磨损试验机,测试Fe/WC、Fe/WC/CeO2堆焊层磨损量及摩擦系数。磨损量测试时,加载载荷50 N,往复距离4 mm,磨球为直径6 mm的Si3N4陶瓷球,试验时间5 h,试验中每隔1 h利用FA2204B型电子天平(精度为0.1 mg)称量一次磨损量,每个试样重复3次,结果取平均值;摩擦系数测试时间60 min,其他测试参数与磨损量测试相同。

3.2.1 磨损量

试件磨损量如图6所示。由图6可知,Fe/WC试件总磨损量为12.94 mg,Fe/WC/CeO2试件总磨损量为10.81 mg,Fe/WC/CeO2试件总磨损量较Fe/WC降低了16%。

3.2.2 摩擦系数

图7为试件摩擦系数随时间变化图。由图7可知,Fe/WC堆焊层平均摩擦系数为0.56,Fe/WC/CeO2堆焊层平均摩擦系数为0.45。与Fe/WC堆焊层相比,Fe/WC/CeO2堆焊层摩擦系数变化范围较小,磨损曲线更加稳定,具有更优良的耐磨性能。CeO2提高了堆焊层熔池中流动性,提高了堆焊层致密性,改善堆焊层表面粗糙度,降低了堆焊层摩擦系数[26-27]。

分析认为,加入的CeO2稀土氧化物,提高了熔池中液态金属流动性,一方面可使熔池中的气体充分逸出,减小堆焊层中气孔、夹杂等缺陷产生倾向,另一方面还可缓解堆焊快速升温—快速冷却产生的应力集中,从而减小堆焊层裂纹产生倾向;CeO2的细化晶粒和净化晶界作用,可促进WC、M7C3、Cr23C6等硬质相颗粒在堆焊层中的扩散并使其弥散分布,从而使得堆焊层致密性好、硬度高、表面粗糙度小、摩擦系数小、耐磨性高。

3.3 堆焊层冲击韧性

利用JB-300B型冲击试验机测试Fe/WC、Fe/WC/CeO2堆焊层冲击韧性。冲击韧性测试时,冲击能量150 J,摆锤预仰角150°,摆锤半径750 mm,冲击速度5.2 m/s,每种堆焊层取3个试样。

图8为试件冲击韧性测试结果。由图8可知,Fe/WC堆焊层的冲击韧性约为6.1 J/cm2,Fe/WC/CeO2堆焊层冲击韧性约为7.9 J/cm2。与Fe/WC堆焊层相比Fe/WC/CeO2堆焊层冲击韧性提高了29%。CeO2作为稀土元素,可有效细化晶粒,使堆焊层中WC颗粒呈弥散分布,缓解因位错滑移产生的位错堆积[28-30],有效避免堆焊层在冲击力作用下产生的应力集中。此外,堆焊层中被细化的晶粒会形成密集分布的晶界,在晶界与共晶区聚集的WC颗粒,可阻碍裂纹沿晶扩展,改变裂纹扩展方向,增加裂纹扩展路径,从而提高了Fe/WC/CeO2堆焊层的冲击韧性。与本课题组前期制备的Fe-Cr-C-V堆焊层(7.5 J/cm2)[8]相比,Fe/WC/CeO2堆焊层冲击韧性提高了7%。

3.4 堆焊层耐蚀性

利用CS350型电化学工作站测试Fe/WC、Fe/WC/ CeO2堆焊层的电化学极化曲线来表征堆焊层耐蚀性。测试时,参比电极为饱和甘汞电极,辅助电极为铂片,工作电极为暴露面积1 cm2的试样,其他区域采用环氧树脂进行密封,扫描速率1 mV/s,频率为5 Hz。

图9为Fe/WC、Fe/WC/CeO2试件动电位极化曲线图。由图9可知,Fe/WC试件腐蚀电位为-0.54 V,Fe/WC/CeO2试件腐蚀电位为-0.46 V,Fe/WC/CeO2堆焊层腐蚀电位明显大于Fe/WC堆焊层,腐蚀电位越大说明发生腐蚀的难度越大,受到腐蚀倾向较小,不易遭受腐蚀。与添加CeO2的堆焊层相比,未添加CeO2堆焊层孔隙较多,孔隙周围产生一定腐蚀坑。缝隙腐蚀产物堆积在孔隙口,氧很难进入缝隙,而缝内的氧难以得到补充,从而缝内缝外就形成了一个小阳极大阴极的腐蚀电池[31-33],表现为孔内的金属持续腐蚀,孔隙内酸化,促使Cl离子进一步向缝隙内迁移,由于自催化作用和酸化作用,腐蚀速度很快,耐腐蚀性能降低。CeO2的添加提高了堆焊层中碳化物硬质相与粘结相的粘结性,提高涂层的致密性,降低了缝隙腐蚀产物生成,减少自催化和酸化作用提高了堆焊层耐腐蚀性能。

4 堆焊层使用性能评价

4.1 土槽试验

利用自制的模拟土槽摩擦磨损试验台(如图10)对比等离子堆焊Fe/WC、Fe/WC/CeO2旋耕刀与65Mn旋耕刀的耐磨性。

试验时,各取40把65Mn(840℃淬火,540℃回火)材质旋耕刀和等离子堆焊Fe/WC/CeO2旋耕刀,分5次(每次各8把)称量后交错装夹在试验机上。试验机电机转速60 r/min,旋耕刀回转半径110 cm。连续运转24 h后将16把旋耕刀取下,洗净吹干后利用珠恒ACS工业计数秤(15 kg/0.1 g)称量。之后再各取40把等离子堆焊Fe/WC旋耕刀与等离子堆焊Fe/WC/CeO2旋耕刀称量后分5次(每次各8把)交错装夹在试验机上重复上述试验。结果表明,Fe/WC/CeO2堆焊层旋耕刀的平均磨损量(14.8 g)较65Mn 旋耕刀的磨损量(52.3 g)降低约71%,较Fe/WC堆焊层旋耕刀平均磨损质量(17.8 g)降低了17%。

4.2 田间试验

各取160把65Mn(840 ℃淬火,540 ℃回火)材质的旋耕刀、等离子堆焊Fe/WC/CeO2旋耕刀,称量后分5次(每次各32把)称量后交错安装在1GKN-220 型旋耕机(每次装夹64把)上进行田间试验(如图11),每次作业面积21.4 hm2后,取下旋耕刀并洗净吹干后称量计算磨损量平均值。然后再各取160把Fe/WC堆焊层旋耕刀、Fe/WC/CeO2堆焊层旋耕刀按照上述方法进行田间试验并计算磨损量平均值。试验地点:河北农业大学试验基地,机具前进速度4~5 km/h,土壤性质为砂壤土,土壤坚实度308.82 kg/cm2,土壤含水率19%。

图12为田间试验前后的刀具磨损形貌,Fe/WC堆焊层旋耕刀与Fe/WC/CeO2堆焊层旋耕刀磨损形貌无明显差别。由图12可见,65Mn旋耕刀的切刃部磨痕密集、明显磨损;Fe/WC/CeO2堆焊层旋耕刀表面光洁,未发现明显磨痕,堆焊层无脱落现象。Fe/WC/CeO2堆焊层旋耕刀平均磨损量(25 g)较65Mn旋耕刀(71 g)相比降低了65%,较Fe/WC堆焊层旋耕刀平均磨损质量(29.5 g)降低了15%。添加的CeO2提高了堆焊层液态金属流动性,降低了气孔、裂纹等缺陷产生倾向,使堆焊层中硬质相分布均匀,从而提高了Fe/WC/CeO2堆焊层旋耕刀耐磨性能。

土槽试验和田间试验结果表明,较65Mn旋耕刀相比,Fe/WC/CeO2涂层旋耕刀耐磨性能更优异。与本课题组前期制备的Fe-Cr-C-V堆焊层旋耕刀(32 g)相比[8],平均磨损量降低了21%,Fe/WC/CeO2堆焊层具有更加优良的综合性能。

5 结 论

1)采用正交试验分析了堆焊电流、堆焊距离、堆焊速度、送粉速率对Fe/WC/、Fe/WC/CeO2堆焊层磨损量的影响,优化了等离子堆焊工艺参数为:堆焊电流50 A,堆焊距离5 mm,堆焊速度15 cm/min,送粉速率25 g/min。

2)Fe/WC/CeO2等离子堆焊层与基体呈良好的冶金结合,堆焊层无明显气孔、裂纹等缺陷。与Fe/WC等离子堆焊层相比,Fe/WC/CeO2堆焊层中硬质相尺寸明显减小,且呈弥散分布。

3)与Fe/WC等离子堆焊层相比,Fe/WC/CeO2等离子堆焊层的硬度提高了22%、磨损量降低了16%、冲击韧性提高了29%。田间试验表明Fe/WC/CeO2堆焊层旋耕刀较常用65Mn旋耕刀平均磨损量降低了65%,较Fe/WC堆焊层旋耕刀平均磨损质量降低了15%。

[1] 张兆同,陈瑶,魏瑜,等. 区域农机化高质量发展评价指标体系构建与应用[J]. 农业工程学报,2021,37(3):64-72.

Zhang Zhaotong, Chen Yao, Wei Yu, et al. Construction and application of the evaluation index system for high quality development of regional agricultural mechanization[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(3): 64-72. (in Chinese with English abstract)

[2] 贾洪雷,王万鹏,陈志,等. 农业机械触土部件优化研究现状与展望[J]. 农业机械学报,2017,48(7):1-13.

Jia Honglei, Wang Wanpeng, Chen Zhi, et al. Research Status and Prospect of Soil-engaging Components Optimization for Agricultural Machinery[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(7): 1-13. (in Chinese with English abstract)

[3] 宋月鹏,王伟,高东升,等. 基于表面工程技术装备农机刃具的研究现状[J]. 中国农机化学报,2018,39(1):27-31.

Song Yuepeng, Wang Wei, Gao Dongshen, et al. Research status of agricultural machine cutting tools treated by surface engineering technology[J]. Journal of Chinese Agricultural Mechanization, 2018, 39(1): 27-31. (in Chinese with English abstract)

[4] 屈平,马跃进,李建昌,等. 铝热剂法原位合成农机刀具 Al2O3-Ti(C, N)复合涂层组织结构及性能[J]. 农业工程学报,2016,32(6):65-72.

Qu Ping, Ma Yuejin, Li Jianchang, et al. Microstructure and properties of in-situ synthesis Al2O3-Ti (C, N) composite coatings of agricultural machinery tool by thermit process[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(6): 65-72. (in Chinese with English abstract)

[5] 张有强,王伟,廖结安. 采棉机摘锭磨损失效分析[J]. 农业工程学报,2017,33(18):45-50.

Zhang Youqiang, Wang Wei, Liao Jiean. Wear failure analysis on spindle of cotton picker[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(18): 45-50. (in Chinese with English abstract)

[6] 孟亮,李雄,黄永俊,等. 激光淬火及熔覆技术提高柑橘枝粉碎机65Mn钢锤片耐磨性[J]. 农业工程学报,2018,34(17):54-60.

Meng Liang, Li Xiong, Huang Yongjun, et al. Improvement on wear resistance of citrus twig grinding hammer of 65Mn steel by laser quenching and laser cladding[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(17): 54-60. (in Chinese with English abstract)

[7] 张旭,马跃进,赵建国,等. 灭茬刀火焰喷焊 Fe6 涂层组织及耐磨性能[J]. 表面技术,2015,44(10):40-45.

Zhang Xu, Ma Yuejin, Zhao Jianguo, et al. Microsturcture and wear-ability of the stubble-cleaning cutter with flame spray welding Fe6 coating[J]. Surface Technology, 2015, 44(10): 40-45. (in Chinese with English abstract)

[8] 郝建军,杨泽宇,马璐萍,等. Fe-Cr-C-V 等离子堆焊层改善旋耕刀耐磨性和冲击韧性[J]. 农业工程学报,2019,35(3):24-30.

Hao Jianjun, Yang Zeyu, Ma Luping, et al. Fe-Cr-C-V plasma surfacing layer improving wear resistance and impact toughness of rotary blade[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(3): 24-30. (in Chinese with English abstract)

[9] 赵建国,李建昌,王安,等. 喷焊余温淬火改善深松铲尖铁基涂层耐磨性[J]. 农业工程学报,2018,34(3):65-71.

Zhao Jianguo, Li Jianchang, Wang An, et al. Improvement of wear resistance of deep-shovel tip with Fe-based alloy coating by flame spray welding residual temperature quenching[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(3): 65-71. (in Chinese with English abstract)

[10] 张校珩. 果园割草机刀片等离子堆焊层组织和耐磨研究[D]. 保定:河北农业大学,2018.

Zhang Xiaoheng. Microstructure and Wear Resistance of Plasma Surfacing Coatings on Orchard Mower Blades[D]. Baoding: Hebei Agricultural University, 2018. (in Chinese with English abstract)

[11] 贺星,孔德军,宋仁国. 激光熔覆 Al-Ni-TiC-CeO2复合涂层的组织与耐腐蚀磨损性能[J]. 材料工程,2019,47(10):68-75. He Xing, Kong Dejun, Song Renguo. Microstructure and corrosion–wear resistance of laser cladding Al-Ni-TiC-CeO2composite coatings[J]. Journal of Matcrials Engineering, 2019, 47(10): 68-75. (in Chinese with English abstract)

[12] Han B, Lin J Y, Han X R, et al. Effect of CeO2on high-temperature wear resistance of WC/Fe-based coatings[J]. Surface Engineering, 2021, 37(8): 982-990.

[13] 赵运才,刘克. CeO2和Y2O3对Ti-Al/WC金属陶瓷复合涂层摩擦学性能的影响[J]. 润滑与密封,2019,44(7):78-84.

Zhao Yuncai, Liu Ke. Effect of CeO2and Y2O3on Tribological Properties of Ti-Al /WC Cermet Composite Coatings[J]. Lubrication Engineering, 2019, 44(7): 78-84. (in Chinese with English abstract)

[14] Chen L Y, Zhao Y, Guan C, et al. Effects of CeO2addition on microstructure and properties of ceramics reinforced Fe-based coatings by laser cladding[J]. The International Journal of Advanced Manufacturing Technology, 2021, 115, 2581-2593.

[15] 朱继祥,雷声,李帅,等. WC含量对铁基复合涂层组织与磨损性能的研究[J]. 南京师大学报:自然科学版,2021,44(1):28-34.

Zhu Jixiang, Lei Sheng, Li Shuai, et al. Research on the microstructure and wear properties of iron-based composite coating with WC[J]. Journal of Nanjing Normal University: Natural Science Edition, 2021, 44(1): 28-34. (in Chinese with English abstract).

[16] 路王珂,李亚敏,张喜冬,等. WC含量对真空熔覆镍基合金涂层组织及性能的影响[J]. 材料保护,2018,51(5):94-97, 102.

Lu Wangke, Li Yamin, Zhang Xidong, et al. Effect of WC Content on Microstructure and Properties of Ni -Based Alloy Coating by Vacuum Cladding[J]. Materials Protection, 2018, 51(5): 94-97, 102. (in Chinese with English abstract).

[17] Wei Y, Wei X S, Chen B et al. Parameter optimization for tungsten carbide/Ni-based composite coating deposited by plasma transferred arc hardfacing[J]. Transactions of Nonferrous Metals Society of China, 2018, 28(12), 2511-2519.

[18] 杨泽宇. 旋耕刀等离子堆焊Fe-Cr-C-V涂层组织与性能研究[D]. 保定:河北农业大学,2019.

Yang Zeyu. Research on Microstructure and Properties of Fe-Cr-C-V Coating Prepared by Plasma Surfacing with Rotary Blade[D]. Baoding: Hebei Agricultural University, 2019. (in Chinese with English abstract)

[19] 王俊杰,杨军,邹德宁,等. 堆焊工艺参数与碳化钨含量对镍基碳化钨涂层性能的影响研究[J]. 矿冶工程,2020,40(4):130-134.

Wang Junjie, Yang Jun, Zou Dening, et al. Influence of surfacing process parameters and tungsten carbide content on properties of nickel-based tungsten carbide coatings[J]. Mining And Metallurgical Engineering, 2020, 20(4): 130-134. (in Chinese with English abstract)

[20] Ahmad R R. Plasma enhanced paste aluminizing of Ti-45Al-2Nb-2Mn-1B with Al-Si alloys[J]. Surface and Coatings Technology, 2015, 283: 10-21.

[21] 刘统治. 等离子堆焊/熔注复合法制备WC增强镍基涂层及其性能研究[D]. 武汉:武汉理工大学,2020. Liu Tongzhi. Preparation and Properties of WC Reinforced Nickel-Base Coating by Plasma Surfacing/Injection Composite Method[D]. Wuhan: Wuhan University of Technology, 2020. (in Chinese with English abstract)

[22] 赵建国,李建昌,郝建军,等. 氮弧熔覆TiCN/Fe金属陶瓷涂层对农业刀具耐磨性的影响[J]. 农业工程学报,2013,29(3):84-89.

Zhao Jianguo, Li Jianchang, Hao Jianjun, et al. Influence of TiCN/Fe metal ceramic coating by reaction nitrogen arccladding on wear resistance of agricultural tools[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(3): 84-89. (in Chinese with English abstract)

[23] Peng J Q, Chen Y, Yan G Q, et al. Solid solubility extension and microstructure evolution of cast zirconium yttrium alloy[J]. Rare Metals, 2016, 35(4): 325-330.

[24] 胡天时. CeO2对Ni-Cr-WC涂层耐磨性影响的理论计算和实验研究[D]. 秦皇岛:燕山大学,2020.

Hu Tianshi. Effect of CeO2on Wear Resistance of Ni-Cr-WC Coatings by Theoretical Calculation and Experimental Investigation[D], Qinhuangdao: Yanshan University, 2020. (in Chinese with English abstract)

[25] 肖奇,孙文磊,刘金朵,等. Ni60A/WC激光熔覆涂层表面抗蚀行为[J]. 材料导报,2021,35(8):8146-8150.

Xiao qi, Sun Wenlei, Liu Jinduo, et al. Surface Corrosion Behavior of Ni60A /WC Laser Cladding Coating[J]. Material review, 2021, 35(8), 8146-8150. (in Chinese with English abstract)

[26] 徐欢欢,林晨,刘佳,等. CeO2加入含量对激光熔覆WC增强镍基合金涂层组织与性能的影响[J]. 机械工程材料,2021,45(7):27-34.

Xu Huanhuan, Lin Chen, Liu Jia, et al. Effect of CeO2adding content on microstructure and properties of laser cladding WC reinforced Nickel–based alloy coating[J]. Materials for Mechanical Engineering, 2021, 45(7): 27-34. (in Chinese with English abstract).

[27] 张蕾涛,段理,刘德鑫,等. 稀土CeO2改性Ni60/50%WC涂层的制备及性能[J]. 金属热处理,2021,46(4):167-171.

Zhang Leitao, Duan Li, Liu Dexin, et al. Preparation and properties of rare earth CeO2 modified Ni60/50%WC coating[J]. Heat Treatment of Metals, 2021, 46(4): 167-171. (in Chinese with English abstract).

[28] Perevezentsev V N, Kirikov S V, Svirina Yu V, et al. Conditions of strain-induced facet formation during interaction between a lattice dislocation pile-up and a grain boundary[J]. The Physics of Metals and Metallography, 2020, 121, 929-935.

[29] 李云峰,石岩. WC对激光熔覆层组织及耐磨耐冲击性的影响[J]. 中国表面工程,2021, 34(2):104-113.

Li Yunfeng, Shi Yan. Effect of WC on microstructure, wear resistance and impact resistance of laser cladding layer[J]. China Surface Engineering. 2021, 34(2): 104-113. (in Chinese with English abstract)

[30] 王原琛,周剑秋,王蒙晰. 多级纳米孪晶金属在孪晶界处的堆积位错密度的本构模型和裂纹成核的准则[J]. 热加工工艺,2021,50(8):38-44.

Wang Yuanchen, Zhou Jianqiu, Wang Mengxi. Constitutive model of pile-up dislocations density and crack nucleation criteria at twinboundary in hierarchically nanotwinned metals[J]. Hot Working Technology 2021, 50(8): 38-44. (in Chinese with English abstract)

[31] 杨效田,李秀倩,李霞,等. WC含量对定向结构Ni60涂层耐蚀性能的影响[J]. 稀有金属材料与工程,2020,49(10):3604-3611.

Yang Xiaotian, Li Xiuqian, Li Xia, et al. Effect of WC content on corrosion resistance of directional structure Ni60 coating[J]. Rare Metal Materials And Engineering, 2020, 49(10): 3604-3611. (in Chinese with English abstract)

[32] 陈艺文,柏洪武,巩秀芳,等. 氧乙炔火焰喷焊镍基复合涂层的显微组织和腐蚀性能研究[J]. 表面技术,2021,50(5):295-302.

Chen Yiwen, Bai Hongwu, Kong Xiufang, et al. Study on microstructure and corrosion performance of Nickel base composite coatings prepared by Oxy-Acetylene flame spray welding[J]. Surface Technology, 2021, 50(5): 295-302. (in Chinese with English abstract)

[33] 屈平,马跃进,赵建国,等. 适宜碳化钨含量提高 Ti(C, N)-WC 涂层耐磨耐蚀性[J]. 农业工程学报,2014,30(16):33-40.

Qu Ping, Ma Yuejin, Zhao Jianguo, et al. Appropriate WC content improving wear and corrosion resistance of Ti(C, N)-WC coating[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(16): 33-40. (in Chinese with English abstract)

Preparation and microstructure properties of Fe/WC/CeO2plasma surfacing layer for rotary blades

Hao Jianjun1,2,3, Zhan Zhiguo1, Hou Junying1,2, Zhao Jianguo1,2,3, Liu Jingchun1,2, Yin Changfeng4

(1.,,071001,; 2.,,g 071001,a; 3.,,g073000,a; 4..,.,261000,)

This study aims to improve the wear resistance, impact toughness, and free of frequent failure of contacting parts with soil in the agricultural machinery. A Fe/WC/CeO2ceramic composite coating was prepared on the Q235 steel substrate by plasma surfacing technology. An analysis was also made to clarify the influence of the CeO2compound on the wear resistance of Fe/WC cermet composite coating and the action mechanism. An orthogonal test was used to optimize the preparation process parameters of the Fe/WC/CeO2plasma surfacing layer, where the surfacing current, surfacing speed, powder feeding rate, and powder feeding distance were taken as the test factors and the wear quality as the evaluation index. Specifically, the welding current was 50 A, welding distance 5 mm, welding speed 15 cm/min, and power transport rate 25 g/min. The microstructure and phase composition of the surfacing layer were characterized by a scanning electron microscope, energy dispersive spectrometer (EDS), and X-ray diffractometer (XRD). The results showed that there was an outstanding interface between the surfacing layer and the matrix bonding zone, indicating that the surfacing layer and matrix permeated each other to form an excellent metallurgical bonding. The size of the hard phase in the surfacing layer decreased outstandingly in presence of a dispersion distribution, particularly with the shape like a fishbone, long rod, ball, and hexagonal. The surfacing layer was composed of γ-Fe, Fe-Cr-Ni solid solution, WC, M7C3, Cr7C3, Cr23C6, and W2C. The carbide hard phase (such as WC, Cr7C3,and Cr23C6) was effectively improved the hardness and wear resistance of the surfacing layer. In addition, the addition of CeO2decarbonized the WC hard phase to form W2C hard phase for better wear resistance. The Vickers microhardness tester, friction and wear testing machine and impact testing machine were used to measure the microhardness, wear resistance, and impact toughness of the surfacing layer. The corrosion resistance was also analyzed by an electrochemical workstation. It was found that there was a uniform distribution of microhardness with a gradual decrease from the coating to substrate along the section of the surfacing layer. The average microhardness of the Fe/WC/CeO2surfacing layer (HV0.5870) was much higher, indicating less wear quality, smaller friction coefficient, and better wear resistance, compared with the Fe/WC (HV0.5710). The reason was that the CeO2phase was evenly distributed to enhance the anti-wear properties, due to the refined hard phase, such as WC, M7C3,and Cr23C6in the surfacing layer. The impact toughness values of Fe/WC and Fe/WC/CeO2surfacing layers were about 6.1 J/cm2and 7.9 J/cm2, respectively. The average microhardness, impact toughness, and corrosion resistance of the Fe/WC/CeO2surfacing layer increased by 22%, 29%, and 15%, respectively, compared with Fe/WC. The soil groove test showed that the average wear of the Fe/WC/CeO2rotary blade was 71% lower than that of the commonly-used 65Mn rotary blade, and 17% lower than that of Fe/WC. The field experiments showed that the surface of the Fe/WC/CeO2layer was smooth with serious abrasion marks or falling off. The Fe/WC/CeO2coated rotary tillage knife (25 g) decreased by 65% and 15%, compared with the 65Mn rotary tillage knife (71 g), and Fe/WC coated rotary blade (29.5 g), respectively. Consequently, the Fe/WC/CeO2coating was prepared on the surface of agricultural machinery in contact with the soil by plasma surfacing, indicating a high application value with low cost, high efficiency, flexibility, and convenience. Anyway, the rotary tillage knife with the Fe/WC/CeO2coating surfacing layer can be expected to present an excellent wear resistance and comprehensive mechanical properties for agriculture production.

microstructure; performance; plasmasurfacing; surfacing layer; rotary blade

郝建军,占志国,侯俊英,等. 旋耕刀Fe/WC/CeO2等离子堆焊层制备及其组织性能[J]. 农业工程学报,2021,37(24):1-8.doi:10.11975/j.issn.1002-6819.2021.24.001 http://www.tcsae.org

Hao Jianjun, Zhan Zhiguo, Hou Junying, et al. Preparation and microstructure properties of Fe/WC/CeO2plasma surfacing layer for rotary blades[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(24): 1-8. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2021.24.001 http://www.tcsae.org

2021-08-26

2021-12-09

国家重点研发计划(2017YFD0300907)

郝建军,博士,教授,博士生导师,研究方向为农业生产机械化自动化技术及装备研发。Email:hjjpaper@163.com

10.11975/j.issn.1002-6819.2021.24.001

TG174.4

A

1002-6819(2021)-24-0001-08