Validation and improvement of gamma heating calculation methods for the G.A. Siwabessy multipurpose reactor

2020-12-08AnisRohandaAbdulWarisRizalKurniadiSyaifulBakhriPardiPardiDwiHaryanto

Anis Rohanda· Abdul Waris · Rizal Kurniadi · Syaiful Bakhri ·Pardi Pardi · Dwi Haryanto

Abstract Gamma heating,which is deposited in irradiated targets or samples, is an important issue in research reactors because it affects the safety of samples and the reactor operation.Gamma heating in the Reaktor Serba Guna G.A.Siwabessy (RSG GAS) can be measured or calculated using computer code. In this paper, we present the results obtained by using gamma calorimeters to measure the gamma heating in the central irradiation position in RSG GAS. The measurement results were verified and then compared with the calculation results obtained using the Gamset code. However, the accuracy of the calculation results obtained using Gamset was inadequate, with more than 20% error. Moreover, Gamset was initially created to calculate gamma heating in 35 MWth reactors, and the RSG GAS reactor has an operating power level of 30 MWth. To address these issues, we developed a new program called NewGamset, built with an informative graphical user interface-based display. NewGamset can employ new analytical approaches as it utilizes a calculation base that comprises 18 energy groups and can provide updated physical parameters of RSG GAS. The results of gamma heating measurements obtained using gamma calorimeters made of graphite, aluminum, iron, and zirconium were 2.20 ± 0.03 W/g, 2.25 ± 0.02 W/g,2.58 ± 0.03 W/g, and 2.91 ± 0.10 W/g, respectively. In general, the calculation results were larger than the measurement results, and the average ratio of calculation to measurement result was 1.37 for Gamset and 1.02 for NewGamset. Hence, it can be concluded that NewGamset provides more accurate results than Gamset.We also report the gamma heating estimation for common elements irradiated in the RSG GAS silicide core, with an operating power level of 15 MWth and 30 MWth. We highly recommend that NewGamset be used for validating the gamma heating data of various target materials in RSG GAS.

Keywords Gamma heating · RSG GAS · Calorimeter ·NewGamset

1 Introduction

The 30 MWth Multipurpose Reactor or Reaktor Serba Guna G.A. Siwabessy (RSG GAS) is a multipurpose research reactor located in the Serpong Nuclear Area,South Tangerang, Indonesia. It has been operated by the Indonesian Nuclear Energy Agency (BATAN) since 1987.At present, the RSG GAS is mainly utilized for radioisotope production,material irradiation,and research.In 1996,the fuel elements used in RSG GAS were converted from oxides to silicides. Some advantages of using a silicide as the fuel element (silicide core) are that it can improve reactor availability,reduce costs,and has a high loading of fissile material, which can make the operating cycle last longer[1].The silicide core has better thermal conductivity and can reduce the risk of rising fuel temperatures and thermal pressures that trigger swelling and cracking [2].However,after operating for approximately 30 years,aging of the structures and components of RSG GAS is inevitable. Hence, to ensure safe operation, the operational condition and parameters of RSG GAS should be evaluated.

One important issue in the operation of RSG GAS is the gamma heating that is deposited in materials or samples irradiated in the core of the research reactor. In the reactor core, various types of material are exposed to high radiation fields, one of which primarily arises from gamma radiation. The interaction of gamma rays with materials can reduce the intensity of the gamma rays and increase the temperature of the material; this is known as gamma heating. Information on gamma heating is crucial to material and reactor safety.Lemaire et al.[3]reported that neglecting to predict gamma heating during irradiation could lead to overheating of the irradiated material. Various studies on gamma heating have been conducted globally.For instance,Guardini[4]measured gamma heating in the ESSOR reactor and Fourmentel et al.[5]in the OSIRIS Material Testing Reactor using a differential calorimeter.Reilly and Peters [6] used materials such as graphite, aluminum, and zirconium as the irradiated materials to estimate the gamma heating. In addition to measurement,gamma heating can be determined through calculation.Lee et al. [7] developed a new method for the calculation of gamma heating in a research reactor considering the effects of gamma prompt and gamma decay factors. Moreover,Varvayanni et al. [8] developed a simple analytical model to evaluate the results of gamma heating measurement in the Greek Research Reactor.

Energy generated owing to gamma heating in RSG GAS can be measured or calculated using computer code.Research on gamma heating was pioneered in Indonesia by Setiyanto, who adopted a method for calculating the gamma radiation heat used in the SILOE reactor at Grenoble (France); this method is called the Gamset code[9]. The Gamset has not been modified significantly to improve the accuracy of the calculation results since 1992,and there is no other program or code that can be used directly to calculating gamma heat in RSG GAS.Setiyanto et al.[10]designed and fabricated a gamma calorimeter for measuring the gamma heating in RSG GAS, and the last measurement was performed more than 25 years ago. In this study, gamma heating was re-measured to obtain the latest data on gamma heating in the silicide core. These data are used as a gamma heating benchmark in the current RSG GAS core.Additionally,the measurement is a part of the safety evaluation of irradiation facilities and the revitalization of nuclear instrumentations.

In the present study, gamma heating was measured in the central irradiation position(CIP)at a nominal power of 15 MWth and verified by using Gamset to calculate the heat (owing to gamma heating) absorbed by materials placed in the core of RSG GAS. Gamset is currently used as an alternative when direct gamma heating measurement with a calorimeter is difficult. However, the measurement results obtained using Gamset have low accuracy (more than 20% error) because the calculation base used in Gamset is limited to only three energy groups (0.5 MeV,1 MeV, and 1.5 MeV), whereas the gamma energy spectrum has a widerange, from low to high energy [9].Moreover, the calculation parameters in Gamset were created for reactors with a power level of 35 MWth;hence,they are not optimal for RSG GAS as it has a maximum power level of 30 MWth [11]. Currently, the aging of reactor components must be considered, and following advice from the regulatory agency, RSG GAS mainly operates at a power level of 15 MWth. Therefore, in this study, we have developed a novel program called NewGamset, which is equipped with an informative graphical user interface (GUI)-based display, to calculate gamma heating and also provide the updated physical parameters of RSG GAS.NewGamset utilizes a calculation base that comprises 18 energy groups, with the mean gamma energy ranging from 0.01 to 9.5 MeV. Results obtained using NewGamset are used to validate the measurement results and as the latest gamma heating database to complete the safety assessment report of RSG GAS.

2 Experimental setup

2.1 Gamma calorimeter

Gamma heating is measured using a gamma calorimeter.As part of nuclear instrumentation, a gamma calorimeter can measure the heat produced by an object or material due to gamma radiation. In general, a gamma calorimeter consists of target materials/samples, insulating gases, a thermocouple, and an insulated cylinder. A schematic diagram of a gamma calorimeter is shown in Fig. 1.

RSG GAS has a 10 × 10 fuel zone grid and a beryllium block reflector with a central irradiation position(CIP)and irradiation position(IP).Gamma heating measurement was performed in the CIP or IP with an operating power level of 15 MWth. The configuration of the RSG GAS core is shown in Fig. 2. Only four available types of gamma calorimeter are used in RSG GAS; these are calorimeters made of graphite (C), aluminum (Al), iron (Fe), and zirconium (Zr). Difficulties in production and elevated costs are the main obstacles to developing other types of gamma calorimeter.

2.2 Experimental procedures

The gamma calorimeter was inserted into the reactor core in the CIP/IP position under a stable condition, at a power level of 15 MWth. The temperature data measured using the thermocouple were recorded using a data acquisition system (DAS). Figure 3 illustrates the gamma calorimeter insertion.

Two variables were measured through the experiment.The first variable was the maximum temperature of the sample material measured using the thermocouple. The calorimeter was embedded in the reactor core in the CIP/IP until it reached the bottom part of the fuel grid. Then, it was raised slowly at intervals of 5 cm.After being raised at each step, the data of sample material temperature were recorded using a data acquisition device once the temperature became constant.Thereafter,the same procedure was repeated until the calorimeter reached the upper part of thefuel grid. Through this procedure, we determined the position (the height measured from the bottom of the fuel)where the thermocouple measured the maximum temperature of the sample material.

At the final step,the gamma heating(P)produced in the sample material in the calorimeter could be determined using the equation below [9]:

where P is the gamma heating (Watt/gram), C θ( ) is the specific heat capacity of the sample material in the calorimeter (J/g °C), T θ( ) is the calorimeter period as a function of temperature (s), θiis the temperature of the coolant in the reactor core (°C), and θfis the maximum temperature of the fuel (°C).

The above equation could be solved using a definite integral or by calculating the area under the curve,with the calorimeter and coolant temperature as the upper and lower limit of integration, respectively.

3 Simulation

3.1 Gamma heat generation in reactor core

When a reactor is being operated,gamma radiations can be generated in different ways, such as fission reaction,neutron capture, and decay [13]. High-intensity gamma radiation with will interact with materials placed in the reactor core. It will heat the material through the photoelectric effect, Compton scattering, and pair production.The heat produced is commonly referred to as gamma heating.During fixed-power reactor operation,the intensity of the gamma rays is constant and directly proportional to the power of the reactor, and varies as a function of the position in the core. The interaction of gamma rays with materials reduces the intensity of the gamma rays and induces heating in materials due to absorption of the gamma ray energy. The greater this attenuation effect, the higher the temperature of the material.According to Jaeger et al. [14], the production of gamma heat at any point on the reactor core can be expressed using the following equation:

where P(r)is the gamma heating (W/g),C = 1.6 × 10-23(Ws/MeV),E is the energy of gamma rays(MeV),μais the macroscopic absorption coefficient(cm-1),ρ is the density of absorbent materials (g/cm3), and φ(E, r) is the gamma flux as energy and position function (gamma/cm2s MeV).

The above equation shows that gamma heating in materials is affected by the energy of the gamma rays and the type of material.

3.2 Gamma heating calculation using Gamset code

Adapted from the gamma heating calculation code for the 35-MWth SILOE reactor because of the similar geometry, Gamset is a code specifically designed to calculate the gamma heat absorbed by samples or materials heated in the core of RSG GAS. Gamma radiations in the reactor core originate from different sources, prompt fission reactions, capture reactions, and decay reactions.Before being absorbed by sample materials, gamma radiation propagates through several objects in the core, such as the coolant, fuel, fuel cladding, and other core structures;hence,the intensity of the gamma radiation becomes weak. Gamset calculates gamma heating by utilizing the attenuation of gamma ray intensity, which is expressed in the following formula:

where I is the absorbed intensity,Iiis the initial intensity,μ is the coefficient of absorption, and x is the distance covered by the gamma radiation.

Gamma rays produced in the reactor core emit energy with different spectra. Sample materials irradiated in the reactor core differ in type; thus, the gamma energy (i) and type of material (j) must be included in the attenuation equation. Hence, Eq. (3) is transformed into the following equation [15]:

where ρ is the material density(g/cm3),k is the conversion factor (1.6021892 × 10-13J/MeV), and Eγ,iis the gamma ray energy.

Gamset can calculate the amount of heat in each layer of cylindrical material inserted into the reactor core. The Gamset code’s main program utilizes three data files to calculate gamma heating, which are the reactor core parameters (COEUR), calorimeter target material data(DISPO), and empirical constants used in the program(CONSTANT) [15]. In general, the COEUR file contains information about the core configuration and irradiation targets. The CONSTANT file contains data on the empirical constants,while the DISPO file contains the irradiation operation parameters. The three data files are sequentially read and then stored in the main memory when the Gamset application is running. The calculation performed by Gamset yields output data, including data on the heat absorbed by each sample material in W/g,W/cm, or rad/h.The parts that are revised include the distribution of the power peaking factor (PPF), the material properties in 18 groups (mass absorption coefficient, number of prompts and differs gamma), and the thermal neutron flux as a function of the position of the irradiation target selected in the application(CIP/IP),based on the measurement results.

3.3 Development and validation of NewGamset program

An overview of the spectra of gamma energy emitted in a pool-type research reactor, such as RSG GAS, is shown in Fig. 4. The energy is broadly distributed from lowest to highest. The calculation base in the Gamset code is only divided into three groups of gamma ray energy—0.1 MeV(for the 0–0.25 MeV range), 0.5 MeV (for the 0.25–0.90 MeV range),and 1.0 MeV(for the >0.90 MeV range)—as shown in the table in the inset of Fig. 4.Gamma radiation has a wide spectrum,ranging from low to high energy. Mathematical detailing of the calculation of the area under the gamma energy spectrum curve can improve the accuracy of the calculation of gamma heating.In this study, a new gamma heating simulator, a program called NewGamset, was developed by applying a calculation base that comprises 18 energy groups with mean energies ranging from 0.01 to 9.5 MeV; this range is the same as the energy spectrum used in the ORIGEN2 code[17], a popular tool for core inventory.

NewGamset is equipped with previously used libraries of the RSG GAS core (U oxides), the current core library(U silicides), future core candidates (U molybdenum), and new data on target materials for all single elements and topaz stone(Al2SiO4(OH4)2),which are usually used as the irradiated target in the RSG GAS core. This program uses the latest physical parameters, which correspond to the 15 MWth and 30 MWth RSG GAS. The parameters include power peaking factor (PPF), mass attenuation coefficients based on the NIST Standard Reference Database 126 [18],and the number of prompt gamma rays [19] and delayed gamma rays [20], thereby providing better calculation results, which are comparable to experimental results[21].Moreover, NewGamset is equipped with a graphical user interface (GUI) developed using NetBeans 8.0, a free and open-source integrated development environment(IDE)for the Java and HTML5 platforms. NetBeans can be run on Windows, macOS, Linux, and Solaris [22]. Hence,NewGamset is more informative and user-friendly than Gamset (a DOS-based program), in which the code has never been modified since 1992.The layout of NewGamset is shown in Fig. 5.

4 Results and discussion

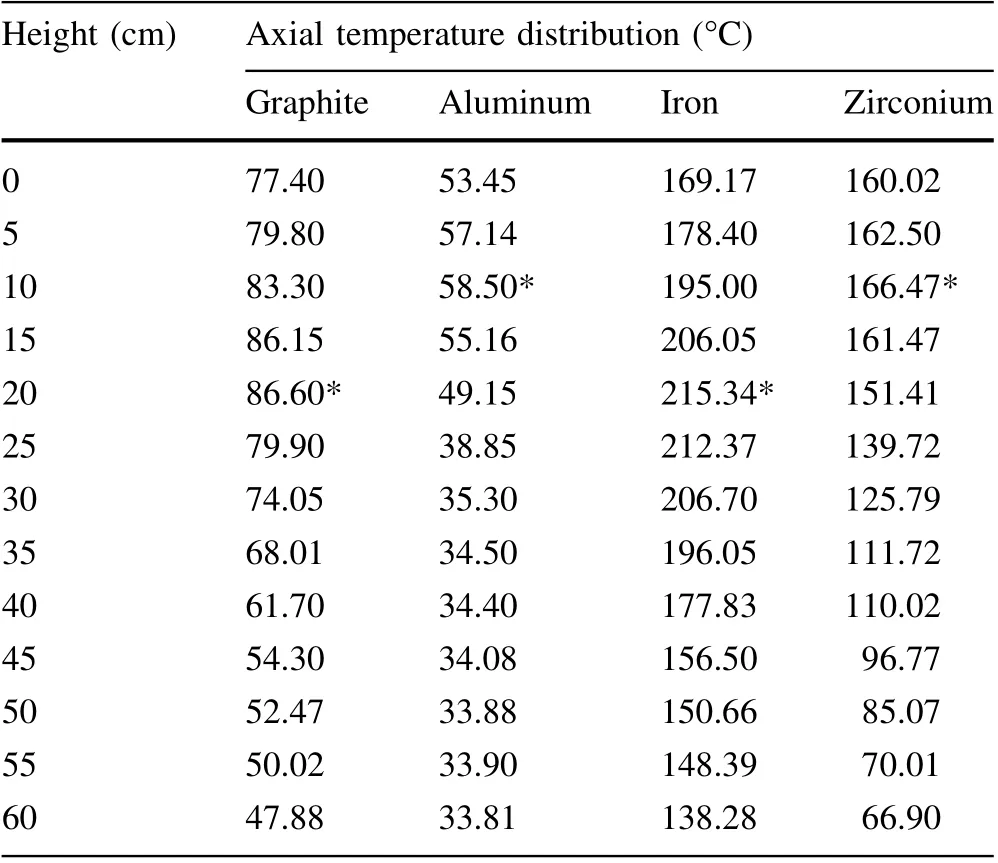

Gamma heating is determined based on the results of the axial temperature distribution and period of the calorimeter. Table 1 lists the axial temperature distribution for thefour types of calorimeters used. The measurements were performed in 2019:January 28–29(Core 97),March 18–19(Core 98), and July 2 (Core 99). Measurements were performed at[E,7]CIP in the RSG GAS silicide core,with an operating power of 15 MWth and height ranging from 0 to 60 cm from the bottom of the reactor core (as the reference). The height was adjusted according to the length of the calorimeter.The length of the calorimeter was equal to the length of the fuel element used in RSG GAS.

Table 1 Axial temperature distribution of various gamma calorimeters

As summarized in Table 1, it can be observed that the maximum axial temperatures were obtained at heights ranging from 10 to 20 cm. This height is approximately one-third of the height of the fuel element.This result is in accordance with the pattern of neutron thermal flux distribution of RSG GAS, in the axial direction, measured by Hamzah et al. [23], in which the maximum temperature was obtained at one-third of the height measured from the bottom of the reactor core.The maximum temperature acts as the upper limit of integration in the gamma heating calculation using Eq. 1.

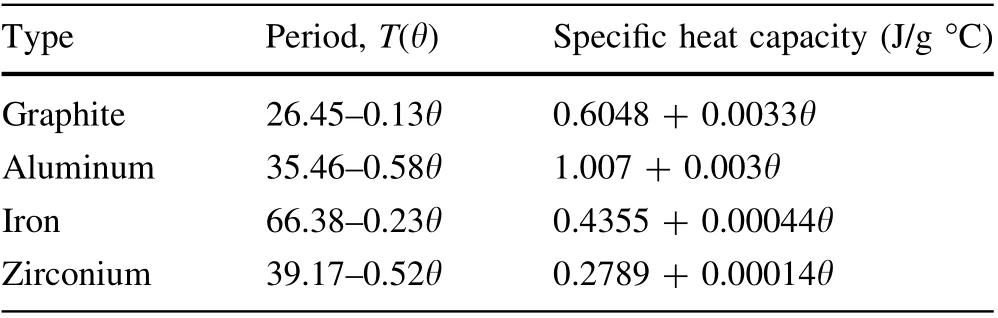

Table 2 lists the specific heat capacity of the calorimeter and the calorimeter period obtained by applying linear regression. The specific heat capacity expresses the deposition of heat in the target material to change the material temperature per mass of the material.

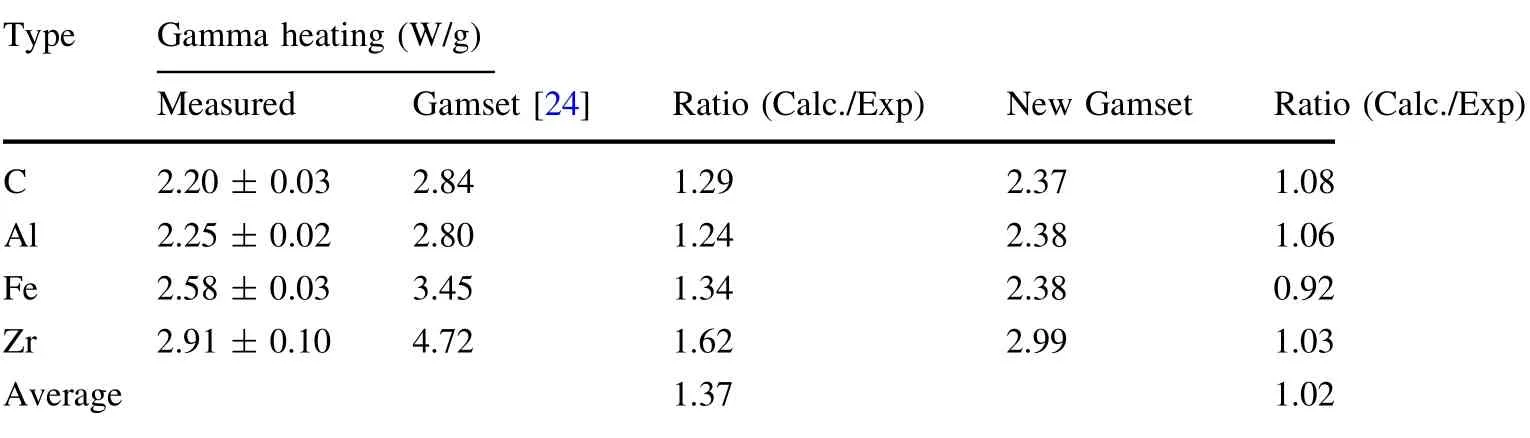

By applying the axial temperature distribution, period,and specific heat capacity of each calorimeter in Eq. 1,gamma heating can be determined. Table 3 shows a comparison of gamma heating at a position of CIP obtained through measurement, Gamset simulation, and NewGamset.

Table 2 Period and specific heat capacity of the calorimeters

Generally, the gamma heating obtained using the Gamset or NewGamset program were greater than that obtained through measurements. This pattern is in accordance with the benchmark of gamma heating in the 30 MWth reactor examined by Setiyanto [25], which states that the calculation results obtained through simulation are 18% greater than the measurement results or on average has a ratio of calculation to experiment of 1.18. As summarized in Table 3, by comparing these two different ratios, it can be said that NewGamset provides better calculation results than Gamset. By adding more groups (18 groups) to the calculation base, the calculated area under the function of the gamma spectrum becomes more realistic, thus resulting in more accurate data. Besides,NewGamset has been equipped with the latest data of reactor physical parameters so that the calculation results are comparable to the direct measurement results.

The calculation results,as summarized in Table 4,were classified based on the type of radiation sources that induce gamma heating. The sources of the gamma rays were mainly the fuel element, fast neutrons produced in the reactor core, and neutron reaction in the sample materials itself (auto-irradiation).

Table 4 lists the various types of heat sources that contribute toward gamma heating. The fuel element is the major contributor toward gamma heating because the fuel element is the main source of radiation in the reactor. The Gamset or NewGamset program calculates heat on the sides around a target.Targets placed in the CIP/IP position are surrounded by box-shaped fuel element plates in half or all directions.According to Lee et al.[7],heat deposited on the irradiation target and temperature distribution at the irradiation facility must be determined to obtain optimal irradiation conditions. Table 4 also lists the estimated temperature increases for each gram of the irradiated target. By correlating the gamma heating data with the specific heat capacity of the calorimeter, we could determine the estimated temperature. For example, the estimated increase in temperature of 1 g of carbon element(graphite) induced by 2.37 W of gamma heating is approximately 3.92 °C/s, with a graphite specific heat capacity of the calorimeter of 0.6048 J/g °C.However,the increase in temperature only occurs in the core of the target material, which is much lower, because the target material is covered by many protective layers and placed in a cooling area, with water acting as the cooling agent. The increase in temperature has to be evaluated and compared with the melting point of the irradiated target to meet the safety requirement.

Table 3 Gamma heating (W/g)in different types of calorimeter used in 15 MWth RSG GAS silicide core

Table 4 Gamma heating (W/g) in calorimeter inserted in 15 MWth RSG GAS silicide core

Owing to difficulties in making calorimeters that use other target elements, limitations associated with performing a direct measurement, and to not interfere with irradiation service schedules, gamma heating in the calorimeter with different target materials would be more convenient if calculated using the NewGamset program,whose results have been proven to be comparable with the direct measurement and are more accurate than the calculation results obtained by Gamset. The difference between the measurement results and Gamset’s calculation results and limitations in indirect measurement are reasons for developing the NewGamset program.This work provides a means of estimating gamma heating deposited on a common single element irradiated in the RSG GAS core at a normal operating power of 15 MWth and maximum operating power of 30 MWth. These data can be used for analyzing the safety of sample elements.The estimation of gamma heating for a common single element by the NewGamset program in the silicide core of RSG GAS is shown in Fig. 6.

Figure 6 shows the correlation between gamma heating in the silicide core and the atomic number of the target material.For other elements that have not been determined,gamma heating can be estimated using the obtained polynomial equation. Besides being affected by the mass energy-absorption coefficient, the calculated gamma heating is affected by prompt gamma rays and delayed gamma rays constants. The researchers in Highflux Advanced Neutron Application Reactor (HANARO) used the Monte Carlo method and the ORIGEN 2.1 code to correct the emission rates of delayed-gamma rays that affect gamma heating [26, 27]. Based on the semi-empirical equation formulated by Valentine TE(2000 and 2001),the constants of the prompt and delayed-gamma rays are proportional to the deposited gamma ray energy, atomic number (Z), and mass number(A)of a material[19,20].In Fig. 6,the curve of gamma heating is slightly skewed for Z <20 and significantly increases for Z >20. This change is because of effect of the coefficient of the mass energy absorption.For Z <20,the mass energy-absorption coefficient is relatively constant; however, it significantly increases for Z >20,especially at the mean low energy of ¯Eγ = 0.1 MeV(¯Eγ = 0–0.25 MeV). Different coefficients data can be compared by sampling coefficients data at three different levels of energy groups, as shown in the inset of Fig. 6.

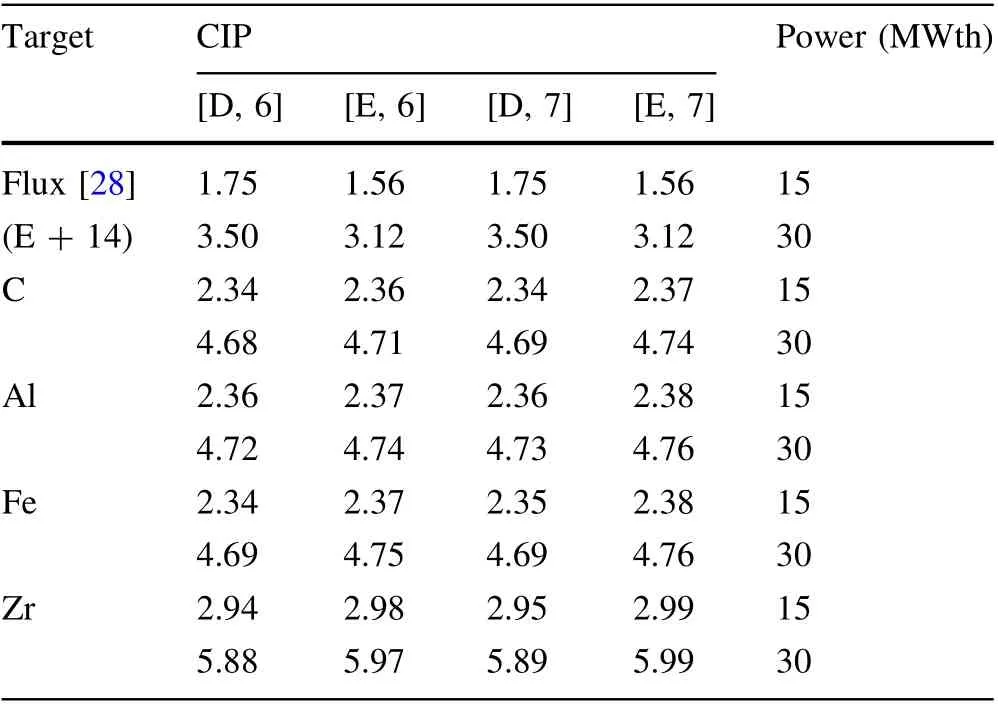

Moreover, Fig. 6 shows that the results of gamma heating calculation at an operating power of 30 MWth are almost double those at 15 MWth. These trends are summarized in detail in Tables 5 and 6. Jaeger [14] found that the gamma heating at any point in the reactor is highly dependent on and proportional to the reactor power or flux(Eq. 2). Thus, the greater the neutron flux (power reactor),the greater the energy deposited in the sample (target material). The correlation between the results of gammaheating calculation in various irradiation positions and its flux is summarized in Tables 5 (CIP) and 6 (IP).

Table 5 Gamma heating(W/g)in position of CIP in RSG GAS core

Table 6 Gamma heating (W/g) in position of IP in RSG GAS core

Tables 5 and 6 show that the gamma heating in the CIP is generally lower than that in the IP. This could occur because the target material in the closed IP position (D9,G7, B6, E4) was surrounded by nine fuel elements, as the sources of heat, in all directions. In contrast, the target material in the CIP position was surrounded by the fuel elements only in some directions (see Figs. 2, 5). Besides,the presence of material around the irradiation position could affect the backscattering of the deposited gamma radiation energy, whose interaction probability depends on the energy and type of material and affects gamma heating results.To improve the calculation of gamma heating using NewGamset, the dynamic flux data can be applied as a function of position in the reactor core,which refers to the results of routine flux measurements done by the operator.In the Gamset code,the flux is static,with only one certain flux (refers to SILOE reactor data). The power peaking factor also affects the final calculation results. In the NewGamset program, we adjusted the power peaking factor used in 35 MWth reactor (SILOE reactor), so it can be used in our 30 MWth RSG GAS. Thus, the obtained results are more accurate and comparable to the measurement results.

5 Conclusion

The results of the gamma heating measurement in the RSG GAS were generally lower than the calculation results. Gamma heating in different calorimeters made of graphite (C), Al, Fe, and Zr, obtained through measurements, were 2.20 ± 0.03 W/g, 2.25 ± 0.02 W/g,2.58 ± 0.03 W/g, and 2.91 ± 0.10 W/g, respectively. The gamma heating is proportional to the atomic number of the irradiated target material and the reactor power level. We developed a new program, called NewGamset, to improve the calculation methods used in Gamset. NewGamset utilizes a calculation base that comprises 18 energy groups,and it can deliver updated physical parameters of RSG GAS. The results of the gamma heating calculation obtained by Gamset and NewGamset were greater than those obtained through measurements.The average ratio of the calculation to measurement result was 1.37 for Gamset and 1.02 for NewGamset. Thus, NewGamset is more accurate than Gamset in calculating gamma heating.Hence, our program is highly recommended for validating and evaluating gamma heating data of various target materials irradiated in RSG GAS. However, additional measurements are required at the IP position to complement the validation results; this should be addressed in a future study. The obtained gamma heating data, as a function of atomic number, irradiation position (CIP/IP),and power of the reactor, will be used comprehensively as the main input data for analyzing the safety of irradiation targets and the performance of the cooling system of the reactor.

杂志排行

Nuclear Science and Techniques的其它文章

- Analytic RF design of a linear accelerator with a SLED-I type RF pulse compressor

- Preliminary analysis of fuel cycle performance for a small modular heavy water-moderated thorium molten salt reactor

- Effective (kinetic freeze-out) temperature, transverse flow velocity, and kinetic freeze-out volume in high energy collisions

- Design, assembly, and pre-commissioning of cryostat for 3W1 superconducting wiggler magnet

- Simulation-based correction of dose enhancement factor values in photon brachytherapy with metal nanoparticle targeting

- Preliminary evaluation of the radiotherapeutic efficacy of 131I-atorvastatin in rats with hepatocellular carcinoma