Cross-linking density and aging constitutive model of HTPB coating under prestrain thermal accelerated aging

2020-05-23YongqiangDuJianZhengChaoXiong

Yong-qiang Du, Jian Zheng, Chao Xiong

Shijiazhuang Campus, Army Engineering University, Shijiazhuang 050003, China

Keywords:Prestrain thermal accelerated aging Low-field 1H NMR Cross-linking density Aging constitutive model

ABSTRACT In order to study the cross-linking density and aging constitutive relationship of HTPB coating during storage, the thermal accelerated aging tests at 0%, 3%, 6% and 9% prestrains were carried out. The crosslinking density of HTPB coating at different aging stages were tested using low-field 1H NMR and the variation of cross-linking density was analyzed.The aging model of cross-linking density considering the chemical aging and the physical stretching factors was established.The uniaxial tensile tests were carried out on HTPB coating at different aging stages and the cross-linking density was introduced into Ogden hyperelastic constitutive model as a characterization parameter of correction coefficient.Combined with uniaxial tensile test results, a prestrain aging constitutive model of HTPB coating was established. The results show that the cross-linking density of HTPB coating increases rapidly at first and then slowly with the increase of thermal accelerated aging time without prestrain. Under prestrain conditions, the crosslinking density of HTPB coating decreases at the early stage,and increases rapidly at first and then slowly at the middle and late stages of thermal accelerated aging.The correlation coefficients of aging model of cross-linking density and aging constitutive model with test results are R > 0.9500 and R > 0.9900 respectively, which can be used to accurately describe the cross-linking density and aging constitutive relationship of HTPB coating under prestrain accelerated thermal aging conditions.

1. Introduction

At present, most of the coatings used in domestic solid rocket motors are thermal curing systems consisting of hydroxylterminated polybutadiene (HTPB) and isocyanate. The main functions are bonding and cushioning stress,which have the functions of heat insulation and flame limiting [1,2]. As one of the most important components of solid rocket motor, the microstructure and mechanical properties of HTPB coating will deteriorate caused by environment/load spectrum during the long-term storage process, which will directly lead to the fire, overload and even explosion hazards. The normal service life of solid rocket motor will be affected and serious safety and economic problems will be caused[3,4].

As a molecular structure parameter of HTPB coating, crosslinking density can quantitatively characterize the molecular structure of materials under environmental/load spectrum. At the same time, the change of cross-linking density will directly affect the mechanical properties such as elongation,tensile strength and stress relaxation modulus of the material, therefore the crosslinking density can be used as the performance characterization parameters of the material.Valanis[5]and Peng[6]established the deformation kinetics equation of aging polymer materials by using cross-linking density as the aging parameter and Peng [6] qualitatively explained the effect of aging on the relaxation process of crosslinked polymer materials by using this model. For the first time,the effect of material aging on mechanical properties is based on molecular motion, which has the reasonable physical and chemical basis. Zhang [7] used cross-linking density as an important criterion to evaluate the aging properties of HTPB.The results showed that the cross-linking density increased with the increase of storage aging time and temperature, and proved that oxidative cross-linking played a dominant role in the aging process. Howse[8] found that the cross-inking density of polymer materials has a strong correlation with the change of macro-mechanical properties before and after aging.

Traditional methods for measuring cross-linking density of materials mainly include equilibrium swelling method and mechanical testing method [9], but both of them have shortcomings such as long testing period and large error. Nuclear magnetic resonance (NMR) is an effective method to measure the crosslinking density of HTPB coating. The cross-linking density of HTPB coating can be calculated according to the change of low-field1H NMR transverse relaxation parameters, which has the advantages of short test cycle, small error and good reproducibility [9].The NMR-based cross-linking density measurement method was first reported by de Gennes [10] in 1971. Kuhn [11,12] studied the network structure and cross-linking density of vulcanizates in detail. The results showed that there was a good correlation between the transverse relaxation parameters and the traditional methods to characterize the cross-linking density of vulcanizates.The relationship between the transverse relaxation parameters and the structure of vulcanizates was also established.Jiang[13]found that there was a strong correlation between the results of low-field1H NMR and equilibrium swelling method. By comparing the transverse relaxation parameters with the mechanical properties,the changing trend of mechanical properties with the increase of cross-linking density was pointed out. Low-field1H NMR transverse relaxation parameters can be used to analyze the network structure of cross-linked polymers in detail, and the transverse relaxation time is also sensitive to the cross-linking density[14,15].Therefore, the network structure can be characterized by measuring the transverse relaxation time [16,17].

The HTPB coating is continuously affected by strain during storage, which will result in the decrease of its mechanical properties[18,19].Kergourlay[20]analyzed the effect of static prestrain on the dynamic properties of viscoelastic thin films through experiments, but the author did not propose an effective model to describe the constitutive relationship.The viscoelastic constitutive model was introduced to study coating by Leu for the first time in 1994 [21].Yang et al.[22-26] proposed a viscoelastic-hyperelastic constitutive model for rubber materials,which was mostly used to describe the dynamic mechanical properties of materials at high strain rates. Shu [27] and Liu [28] neglected the viscous characteristics of polyurethane materials when they studied the static mechanical response of polyurethane isolators, and assumed that polyurethane materials were hyperelastic materials. The hyperelastic model with strain energy was used to represent the mechanical properties of materials, but the model could not adapt to the description of the mechanical properties of polyurethane materials under dynamic conditions. Yang [29,30] analyzed the applicability and accuracy of hyperelastic models such as Neo-Hookean, Yeoh, Mooney-Rivilin and Ogden, and described the viscoelastic properties of materials with linear viscoelastic model,which has certain reference value. As a single-use and long-term storage material, HTPB coating is continuously affected by environment/load spectrum during storage. There are few reports on the aging constitutive model of HTPB coating considering strain conditions.

In this paper, the prestrain thermal accelerated aging test of HTPB coating was carried out. The cross-linking density and uniaxial tension test of HTPB coating at different aging stages were carried out. The change regular of cross-linking density was analyzed, and the cross-linking density aging model considering chemical aging and physical stretching factors was established.The cross-linking density was introduced into the Ogden model as a modified parameter, and the prestrain thermal accelerated aging constitutive model of HTPB coating was established. Finally, the accuracy of the model was analyzed.

2. Materials and methods

2.1. Materials

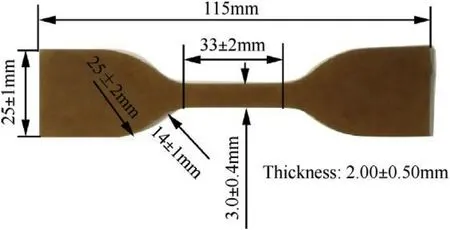

The HTPB coating used in this paper was the polyurethane(cured), which was provided by the State-owned No.845 Factory,China. The main components include hydroxyl-terminated polybutadiene, toluene diisocyanate (TDI), diisooctyl sebacate (DOS),zinc oxide, silicon dioxide and molecular sieve. The curing temperature of the HTPB coating was 70°C and the curing time was 5 days. The HTPB coating was cut into dumbbell-shaped specimens according to QJ 916-85 I standard after curing. The diagram of the HTPB coating was shown in Fig.1.

2.2. Prestrain thermal accelerated aging test

The thermal accelerated aging test of HTPB coating was carried out in an electrothermal oil bath thermostat.The test temperature is set to 70°C, and the range of temperature fluctuation is ±1°C.The relative humidity is less than 50% RH. Ref. [31] shows that under the combined action of gravity load and thermal load, the maximum strain of coating is about 10%. Therefore, the HTPB coating specimens were fixed on the clamping device and stretched to 0%, 3%, 6% and 9% strain levels respectively for thermal accelerated aging. The aging specimens were sampled and tested according to the principle of “short interval time at first and long interval time afterwards”.

2.3. Low-field 1H NMR cross-linking density test

The cross-linking density test of HTPB coating was carried out on VTMR20-010V-T NMR cross-linking density tester, which with resonance frequency of 22.35 MHz, magnet strength of 0.5 T, coil diameter of 10 mm, and magnet temperature of 32.00°C. In the low-field1H NMR method, the hydrogen(1H) protons of the HTPB coating were monitored and according to the state of hydrogen protons in the material, the cross-linking density of the material can be calculated. In the test, the HTPB coating specimens at different aging stages were cut into rectangular strips of 10 mm×6 mm×2 mm and loaded into the bottom of the test tube with 10 mm outer diameter. The test temperature is set to 90°C,120°C above the HTPB coating's Tg,and the specimens were treated at 90°C for 30 min before the test. The cross-linking density of HTPB coating was measured using CPMG sequence [17].

2.4. Uniaxial tensile test

The uniaxial tensile test of HTPB coating was carried out on Instron 5982 material testing machine. The test temperature is controlled at 25°C, the range of temperature fluctuation is ±2°C,the environmental relative humidity is less than 50% RH, and the tensile rate is set to 50 mm/min.Uniaxial tension tests were carried out on specimens at different aging stages until the specimens were broken. The stress and strain changes of HTPB coating specimens during tension were recorded.

Fig.1. Dumbbell-shaped polyurethane of the HTPB coating.

3. Results and discussion

3.1. Cross-linking density

As shown in Fig. 2 is the cross-linking density curves of HTPB coating under the condition of prestrain thermal accelerated aging tested by low-field1H NMR.

The cross-linking density of HTPB coating increased with the increase of thermal accelerated aging time under 0% prestrain condition. In the initial stage (0-3 days), the increase was large,which mainly because the post-curing effect of HTPB coating increased the cross-linking and entanglement of molecular chains,resulting in the increase of the cross-linking density of materials.In the middle and late stages(more than 3 days),the increase of crosslinking density appeared in the platform area.The main reason was that oxidative cross-linking and degradative chain scission [6-9,19] were basically the same during thermal accelerated aging, but oxidative cross-linking was slightly stronger than degradative chain scission, and the speed of molecular chain cross-linking and entanglement was slower, so the increase of cross-linking density of the HTPB coating was slower at this stage [32].

When HTPB coating was subjected to thermal accelerated aging with 3%, 6% and 9% prestrain, the cross-linking density first decreased, then increased rapidly, and finally increased steadily.The test results showed that the cross-linking density of HTPB coating decreased rapidly at the initial stage of prestrain thermal accelerated aging (0-3 days), and the larger the prestrain, the larger the decline. The cross-linking density of HTPB coating decreased slightly at the initial stage of thermal accelerated aging when the prestrain was 3%,while the cross-linking density of HTPB coating decreased significantly when the prestrain were 6%and 9%.This was mainly due to the fact that under prestrain,the molecular chains of HTPB coating first showed the orientation of segments,and then gradually developed into the orientation of the whole molecular chain. The molecular chains were reordered, entangled,unentangled,crystallized and destroyed under different stretching conditions[33].At the same time,the post-curing effect existed in the early stage of thermal accelerated aging,which resulted in the increase of the cross-linking density to a certain extent. However,compared with the effect of prestrain,the post-curing effect can be neglected temporarily.When the prestrain was 3%,the existence of low strain lead to the stretching and entanglement of HTPB coating molecular chains to a certain extent, so the cross-linking density will decrease slightly, while the larger prestrain lead to the disentanglement,crystallization distortion and destruction of molecular chains when the prestrain were 6% and 9%, therefore the crosslinking density reduced greatly. In the middle stage of prestrain thermal accelerated aging(3%prestrain was 3-20 days,6%and 9%prestrain were 3-30 days), the cross-linking density of HTPB coating increased rapidly. The main reason was that with the increase of aging time, stress relaxation occurred under prestrain storage conditions, and the effect of prestrain on the cross-linking density of materials decreased gradually, then curing and oxidative cross-linking played a dominant role, which leading to a significant increase in the cross-linking density of HTPB coating.In the late stage of prestrain thermal accelerated aging(3%prestrain was 20-40 days,6%and 9%prestrain were 30-40 days),the increase of cross-linking density of HTPB coating appeared the platform area.The main reason was that oxidative cross-linking and degradative chain scission were basically the same, and the degradation chain scission was slightly weaker than oxidative cross-linking, so the cross-linking density increased slowly[6-9,19].

Fig. 2. Cross-linking density curves of HTPB coating under prestrain thermal accelerated aging.

It can be seen from the test results that the prestrain had a significant effect on the cross-linking density of HTPB coating in the early stage of aging, and oxidative cross-linking plays a dominant role in the middle and late stages of aging. With the increase of prestrain, the cross-linking density of HTPB coating showed a downward trend at the same aging time. The existence of strain should be avoided or reduced as much as possible in actual storage.

3.2. Prestrain aging model of cross-linking density

The cross-linking density of HTPB coating during thermal accelerated aging was the result of physical stretching and chemical aging.Therefore,the prestrain aging model of cross-linking density can be expressed as follows:

wherev(t,ε)is the total prestrain aging cross-linking density;vc(t)is the chemical cross-linking density;vp(t,ε) is the physical crossinking density due to prestrain.

The chemical cross-linking density evolution equation is derived from the chemical reaction kinetics [34]:

wherekBis the Boltzmann constant;his the Planck constant;Ecis the activation energy of aging reaction;f[vc(t)] is the partition function.

Takef[vc(t)] as a quadratic function:

whereAandCare material constants;vcmis the maximum value of cross-linking density.

Combining Eq. (2) and Eq. (3) and integrating over time from 0 to t gives:

where

Since the temperature of thermal accelerated aging is constant,there gives

that is β2is also the constant.

The physical cross-linking density induced by prestrain can be expressed by Boltzmann function [34]:

wherea,b,c,dare material parameters.

The Levenberg-Marquardt algorithm was used to iteratively fit the results of prestrain aging of cross-linking density. The parameters of prestrain aging model of cross-linking density were obtained as shown in Table 1 and Table 2. The fitting curves of the prestrain aging model of cross-linking density were shown in Fig.3.

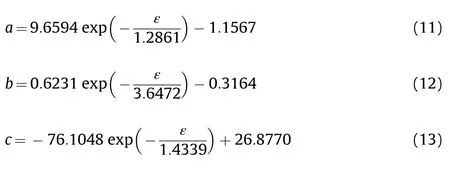

The parametersa,b,canddin physical cross-linking density model are related to prestrain. Considering the existence of stress relaxation under prestrain storage conditions, the relationship between model parameters and prestrain is expressed as an exponential function:

Table 1 Parameters fitting results of chemical cross-linking density model.

Table 2 Parameters fitting results of physical cross-linking density model.

Combining Eq.(1),Eq.(4)and Eq.(10),the prestrain aging model of cross-linking density of HTPB coating can be obtained.

3.3. Prestrain aging constitutive model

HTPB coating is a kind of hyperelastic material. In order to accurately describe the constitutive relationship of the material,aging and prestrain factors should be taken into account in the aging constitutive model of HTPB coating.As a molecular structure parameter, cross-linking density can accurately describe the molecular structure of HTPB coating during prestrain thermal accelerated aging. Therefore, cross-linking density was added to the constitutive model as a characterization parameter of correction factor [35].

where σ(ν,ε)is the uniaxial tensile stress; σ(ε)is the hyperelastic constitutive equation of HTPB coating;f(ν)is the modification factor characterized by cross-linking density.

In order not to make the equation too complicated, the correction factor was expressed as:

where ε0is the prestrain applied during aging, ε0=0%, 3%, 6%, 9%.HTPB coating is deformed by the stretching of molecular chains.The volume change of HTPB coating under external forces is relatively small and almost incompressible. Therefore, HTPB coating has mechanical properties such as incompressibility, large deformation and hyperelasticity. The hyperelastic constitutive model of HTPB coating can be derived from the relationship between strain energy function and engineering stress-strain. The strain energy functionWof material can be expressed as the invariant of Green tensor B:

whereI1,I2andI3are the invariants of the Green tensor B,λiis the principal elongation ratio in directioniandi=1, 2, 3, F is the deformation gradient, FTis the transposition of F,xis a spatial coordinate, X is a material coordinate, andJis the ratio of the total volume after deformation to that before deformation. For purely uniform strain the relationship between the principal stress σtiof the material in directioniand its' principal elongation ratio λiin directioniis:

Fig. 3. Fitting curves of prestrain aging model of cross-linking density.

wherepis the hydrostatic pressure,σiis the engineering stress,εiis engineering strain andi=1, 2, 3.

The principal stress differences obtained from Eq. (24) is

Under uniaxial loading conditions, when the material is incompressible and the 1 direction is the direction of stretching,then we concluded that:

Substituting Eq. (25) and Eq. (26) into Eq. (27), the following is obtained:

where σ =σ1, ε= ε1.

For the Ogden model,the strain energy function model is based on the principal elongation ratio.

Table 3 Parameters Fitting results of prestrain aging constitutive model(ε0=0%).

Table 4 Parameters Fitting results of prestrain aging constitutive model(ε0=3%).

whereJ=1 when the material is not compressible, μi, αi,Diarematerial parameters andNis the order number of the strain energy function modelWfor the Ogden model.

Table 5 Parameters Fitting results of prestrain aging constitutive model(ε0=6%).

Table 6 Parameters Fitting results of prestrain aging constitutive model(ε0=9%).

Substituting Eqs. (25) and (33) into Eq. (32), the engineering stress-strain relationships in the uniaxial stretching can be obtained as

By combining Eq. (15), Eq. (16) with Eq. (34), the prestrain constitutive models of the HTPB films can be obtained as shown in Eq. (35)

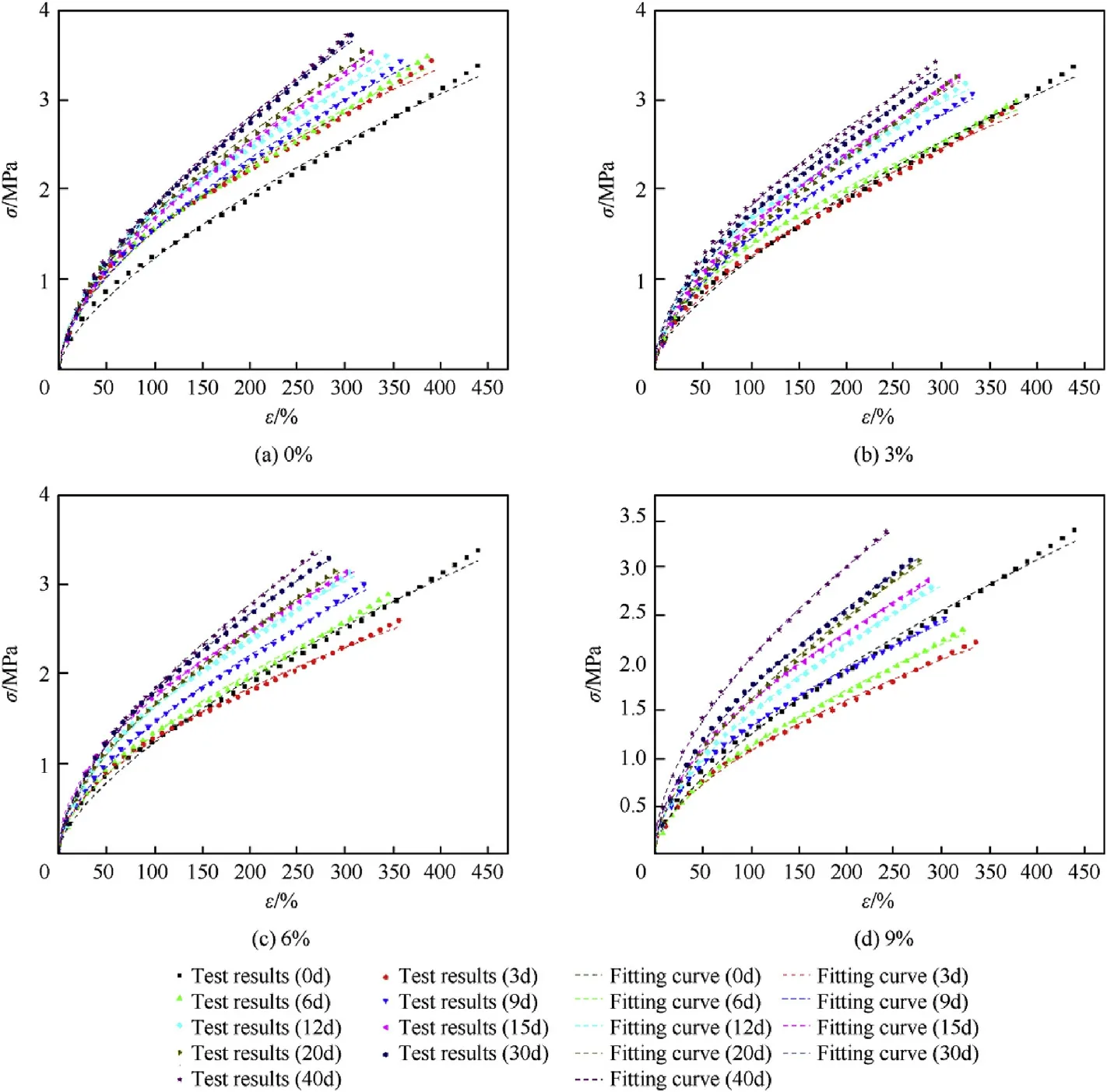

The parameters fitting results of the prestrain aging constitutive model were obtained as shown in Tables 3-6 using Levenberg-Marquardt algorithm. The uniaxial tensile test results of HTPB coating and the fitting curves of the model were shown in Fig. 4.

From the stress-strain curves in Fig. 4, it can be seen that the change of tensile strength and maximum elongation of HTPB coating showed the same trend as the cross-linking density with the thermal accelerated aging time,which indicated that the crosslinking density had a high correlation with the macro-mechanical properties of HTPB coating. Under the condition of 0% prestrain,the tensile strength of HTPB coating showed an increasing trend,and decreased slightly at last.The maximum elongation decreased rapidly at first, and then decreased slowly. Under 3%, 6% and 9%prestrain conditions, the tensile strength of HTPB coating firstly decreased and then increased,and the maximum elongation firstly decreased rapidly, then decreased slowly.

Fig. 4. The uniaxial tensile test results of HTPB coating and the fitting curves of the model.

Within the range of medium and small tensile strain,the fitting curves of the prestrain aging constitutive model was in good agreement with the test results,which can accurately described the change trend of stress-strain curves of HTPB coating at different aging stages.When the tensile strain was large,the fitting results of the model were slightly smaller than that of the test results, and there were errors between the fitting results and the test results.However, considering the overall fitting situations and combined with the results of Tables 3-6, it can be seen that whenN=1, the fitting results of the prestrain aging constitutive model were highly correlated with the test results (R>0.9900), and the fitting curves of the model were also in good agreement with the test results.

Therefore,the prestrain aging constitutive model established in this paper can effectively describe the constitutive relationship of HTPB coating under the condition of prestrain thermal accelerated aging. Moreover, the constitutive relation of different cured HTPB polyurethane and other systems which has the mechanical properties of incompressibility, large deformation and hyperelasticity can be described using this model.

4. Conclusions

In this paper, the thermal accelerated aging tests of HTPB coating under four prestrain conditions of 0%, 3%, 6% and 9%respectively were carried out.The relationship between the crosslinking density of HTPB coating was analyzed and the prestrain aging model of cross-linking density was established.According to the uniaxial tensile test results, the prestrain aging constitutive model of HTPB coating was established. The specific conclusions are as follows:

(1) Without prestrain,the cross-linking density of HTPB coating increased rapidly at first and then slowly with the increase of thermal accelerated aging time. Under prestrain condition,the cross-linking density of HTPB coating tended to decrease in the early stage of thermal accelerated aging,and the larger the prestrain applied, the greater the decrease of the crosslinking density in the early stage. The cross-linking density increased rapidly at first and then slowly at the middle and late stages of thermal accelerated aging;

(2) A prestrain aging model of cross-linking density considering chemical aging and physical stretching was established. The correlation coefficient between model fitting results and test results was greater than 0.9500;

(3) The cross-linking density was introduced into the Ogden hyperelastic constitutive model as the characterization parameter of the correction factor,and the prestrain thermal accelerated aging constitutive model of HTPB coating was established. The correlation between the model fitting results and the test results was greater than 0.9900.Therefore,the model can be used to accurately describe the constitutive relationship of HTPB coating under the prestrain thermal accelerated aging condition.

Acknowledgements

This work was supported by the National Defense Pre-Research Foundation of China [grant number ZS2015070132A12002].

杂志排行

Defence Technology的其它文章

- A comparison of the ballistic behaviour of conventionally sintered and additively manufactured alumina

- Effect of operating temperature on aged single lap bonded joints

- Investigation on energy output structure of explosives near-ground explosion

- Characteristics structure analysis on debris cloud in the hypervelocity impact of disk projectile on thin plate

- A fast-running method for blast load prediction shielding by a protective barrier

- Coating processes towards selective laser sintering of energetic material composites