Effect of operating temperature on aged single lap bonded joints

2020-05-23CostanzoBelliniGianlucaParodoLucaSorrentino

Costanzo Bellini, Gianluca Parodo, Luca Sorrentino

Department of Civil and Mechanical Engineering, University of Cassino and Southern Lazio, Cassino FR, 03043, Italy

Keywords:Temperature tests Hydrothermal ageing Adhesive bonding Single lap joint Experimental tests

ABSTRACT In recent decades, designers have increasingly focused on the stability of assemblies in composite materials over time,particularly when used in structural applications.The use of structural adhesives allows for realising assemblies without mechanical fasteners. In fact, bonding is an assembly technique that prevent corrosion, ensures uniform stresses in the joint, and grows the specific resistance of the assembly. The knowledge of the behaviour of bonded joint is necessary to ensure the reliability of this technique over time,especially in aggressive environments.The aim of this work consists in investigating the combined effect of hydrothermal ageing and temperature test on the lap shear strength of single lap joints realised in CFRP.The results showed a higher influence of the ageing on paste adhesive compared to film adhesive.However, the ageing, combined with the operating temperature,played a fundamental role on the shear strength of the bonded joints.

1. Introduction

In the industrial sector, in particular aeronautical and defence,composite materials are increasingly used for realising vehicle structures with complex geometry because of their high strength to weight ratio.However,for their realisation, it is often necessary to produce simpler parts and, subsequently, to assemble them.Nevertheless, in an assembled component, the joints usually represent the weaknesses so it is necessary to understanding their stability. For guarantee reliability over time, innovative systems of junctions are under development[1].However,the use of adhesive for assembly CFRPs is recommended respect traditional techniques as mechanical fastener.In fact,it leads to benefit like the increase of the specific strength, the use of materials free from corrosion and the reduction of delamination of the adherend due to drilling, as stated in Refs. [2-4]. However, the designer must know how the adhesive properties may vary in all the possible operating condition [5]. Unfortunately, the adhesive technical datasheet does not always report the influence of all the types of environments on the stability of the bonded joint. Generally,temperature and humidity represent the major factors of influence,but the combined effect is not completely known.Tucker et al.[6]have studied the behaviour of a graphite/polymer composite material coupled with mild steel in seawater. They observed forms of damage in composite adherends like swelling and bubbles in addiction to corrosion on the steel adherends. The carbon fibres in the composite and the steel of adherends immersed in salt water generate a galvanic coupling result of the different nobility of these materials.Because of it,the fibre-matrix interface can be subject to a locally more aggressive environment. Armstrong [7,8] noted that the degradation of aluminium bonded joints realised with epoxy adhesives and immersed in water was directly proportional to the solubility and the diffusibility of the same water into the adhesive.Zhou et al.[9]have studied the effect of long time immersion of composite laminate in water. They observed that the diffusion could not be described with the Fick's law:in fact, if the temperature exceeded the 25% of theTga partial dissolution of the matrix occurs. The benefits in the use of structural adhesives in hybrid joints were studied by Moroni et al.[10].They observed an increase of strength,energy absorption and stiffness respect simple fastened joints. In particular,they investigate the effects of salt spray environment on hybrid and simple bonded joints,observing similar effects of ageing on both. Zanni et al. [11] observed that the diffusion of water into the adhesive decreased its stiffness and mechanical resistance. In fact,the diffusion process had an important role on the durability of the bonded joint.Wilken et al.[12]stated that the presence of the adherend/adhesive interface increased the diffusion of water into the joint.

The diffusion process depended on the temperature of the environment. Odegard [13] stated that the temperature could physically change the molecular structure of the adhesive, influencing its reliability. Although they do not present corrosion problems, composite materials are also subject to degradation if immersed in water for a long period. McConnell et al. [14] stated that composite materials used for the adherends in bonded joints presented more complex mechanisms respect to metallic ones. In fact, the water penetrated also into the composite adherends,affecting their mechanical properties.Stazi et al.[15]observed that single lap joint and butt joints bonded with various type of adhesives presented an increase of their elongation and a decrease of their load carrying capacity if subjected to ageing treatments, i.e.UV exposure or temperature/moisture changes.In particular,epoxy adhesive has showed the highest performance for bonding GFRP in structural application.

The aim of this work is to investigate the effect of operating temperature on the mechanical strength of single lap bonded joints in CFRP and epoxy adhesives subjected to different ageing conditions. The simplicity of realisation of this type of joint combined with its ability to compare various influence factors has involved the choice of their use in this work.This analysis was carried out on two different types of adhesive: film (AF 163-2K) and paste (EA 9309NA).

2. Materials and methods

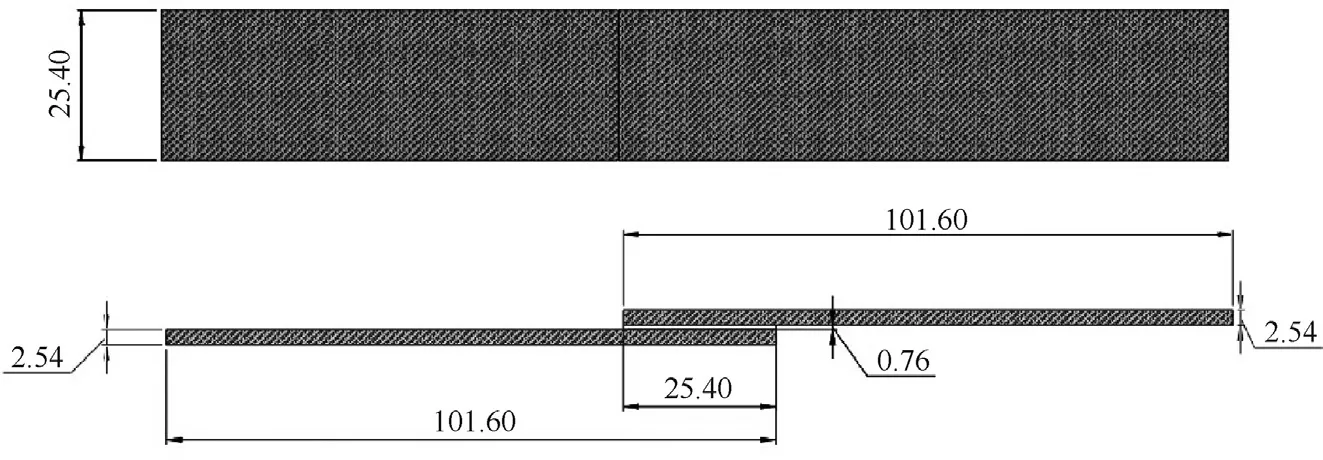

The specimens were realised according to ASTM D1002 and ASTM D5868.The dimension of the specimen are reported in Fig.1.

The adherends were made with an ER450-CC289 5H satin weave prepreg produced by SAATI S.p.A. The cure happened at 135°C for 2 h in autoclave under vacuum. The surface treatment consist in the use of a 51789 nylon peel ply manufactured by Precision Fabric Group.The peel ply treatment consists in adding itself at the end of the stacking sequence prior to polymerization and removing it after polymerization.

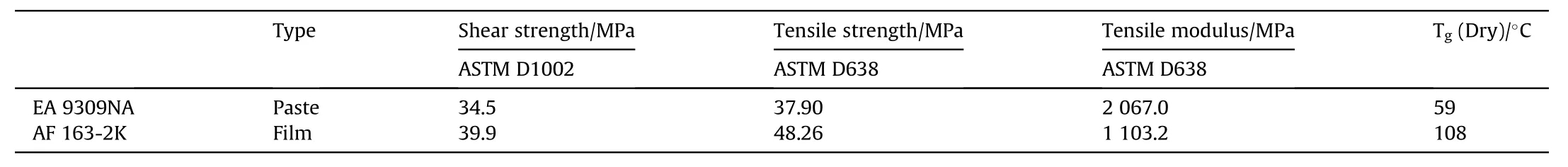

The adhesives used in this work are AF 163-2K and EA 9309NA.AF 163-2K is produced by 3 M Scotch-Weld and is a film adhesive with a knit supporting carrier inside.It presents a film thickness of approximately 0.2 mm in uncured state. The cure process took place in autoclave at 125°C for 1 h at a pressure of 0.27 MPa, according to prepreg technical datasheet. Manufactured by LOCTITE,EA 9309NA is a two-part paste adhesive. The mixture of the parts was done according to the technical datasheet.The adhesive cured at room temperature for 7 d according to technical datasheet. In order to have a defined bonding surface dimension, a Teflon tape was used, as shown in Ref. [16]. The main properties of the used adhesives are reported in Table 1 [17].

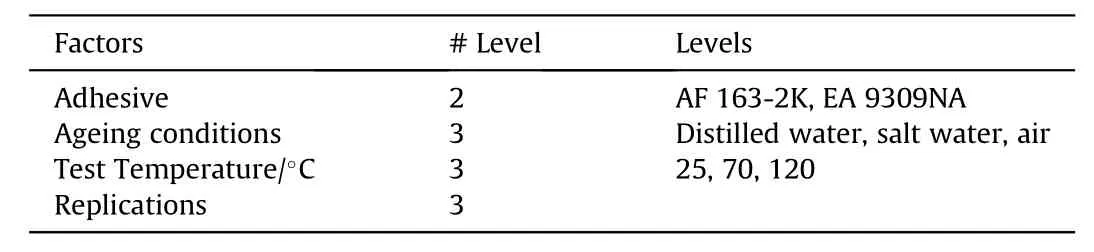

In total 54 specimens were manufactured and subdivided into 18 lots in a stochastic way,each one made up of 3 specimens.In this way, statistical errors due to the presence of possible defects in specimens related to the production process can be avoided,as seen in Ref.[18].These lots have been separated in accordance with the experimental plan (Table 2).

In order to realise the ageing conditioning, it has been used a ventilated oven model 125/45HA manufactured by Nabertherm GmbH. The temperatures were controlled using K-type thermocouples. The ageing treatments are the same reported in Ref. [19].Once completed the ageing treatments, the specimens were dried for a week at room temperature. For the test it has been used an INSTRON 5586 with climate chamber,as reported in Fig.2.The tests were carried out at 25°C, 70°C and 120°C. The thermal stabilization before tests were realised maintained the specimen inside the climate chamber for about 15 min. The test was carried out at 1.3 mm/min.

3. Experimental results

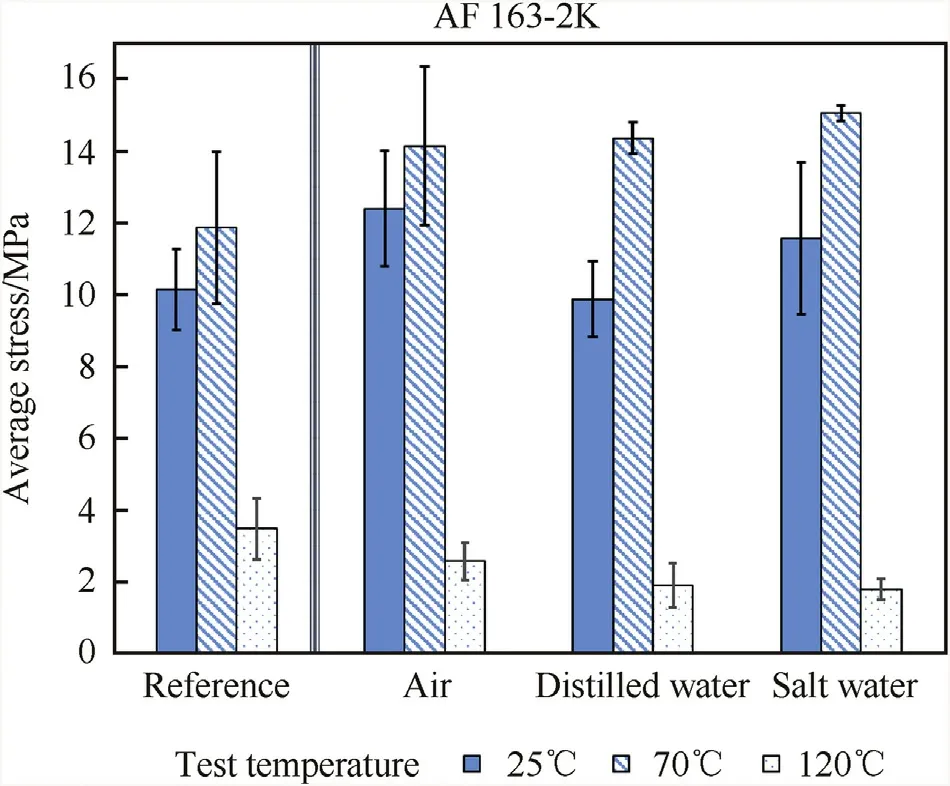

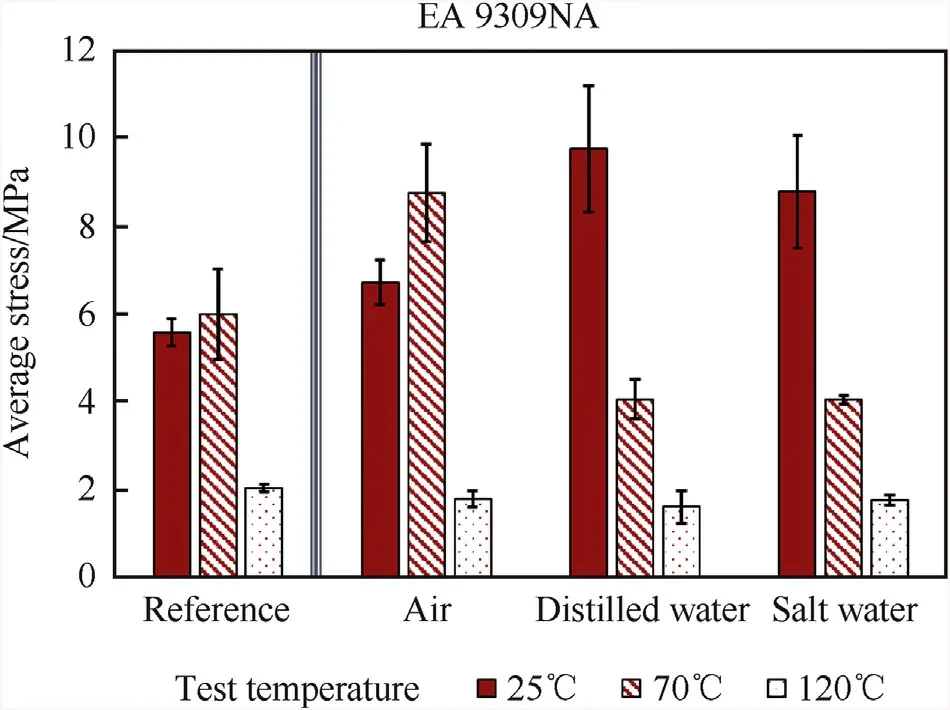

The results of lap shear tests are reported in Fig.3 and Fig.4;the values obtained for specimens tested at 25°C are taken from Ref. [20]. Analysing the results between the reference tested at room temperature and 70°C, it is possible to observe a slight increase in performance, which substantially highlights a greater ductility of both the adhesives at 70°C in unaged state.However,a statistical analysis is necessary to highlight any correlations between the factors of interest.

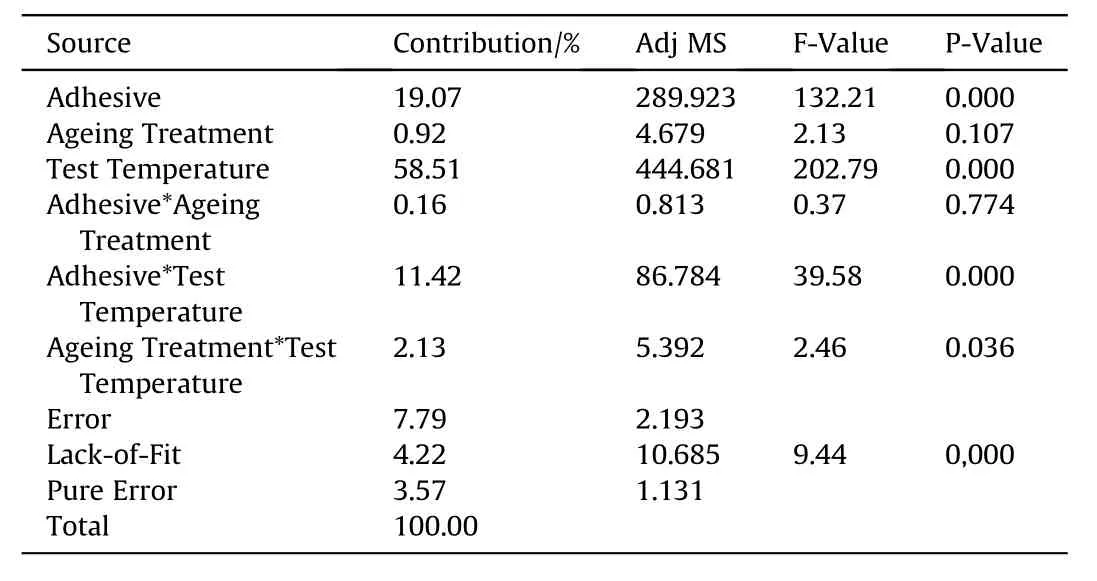

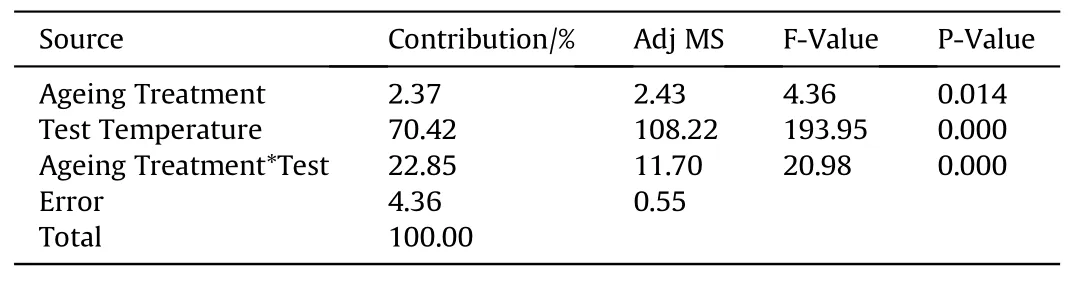

In particular,an analysis of variance on the entire population of specimen tested was carried out in order to investigate the presence of significant differences between the results obtained with the related factors. The results are reported in Table 3.

To determine whether any of the differences between the means are statistically significant, the p-value was compared with the significance level,in order to evaluate the null hypothesis.The null hypothesis affirms that the means of the population are all equal.In this analysis, a significance level of 0.05 has been used: the probability of rejecting the null hypothesis when it is true is 5.00%.Observing the results from ANOVA (Table 3), the more characterizing factor of the lap shear strength of the joint is the test temperature: it has a higher influence, appreciable through a contribution value of 58.51%.The process is strongly influenced by the test temperature and the type of adhesive.In order to study the combined effects of degradation and test temperature for each adhesive,two ANOVA have been made fixing the adhesive type.

3.1. AF 163-2K

Fig.1. Sketch of a single lap joint with relative dimensions.

Table 1 Adhesive properties.

Table 2 Experimental plan.

Fig. 2. Climate chamber used for high temperature tests.

Fig. 3. Lap shear test results for AF 163-2K.

Analysing the data of the joints made with the AF 163-2K adhesive(Table 4)it is possible to state that for the test at 25°C the lap shear strength values are very similar to the reference value regardless of ageing,therefore the cycles of ageing did not produce deleterious effects for this type of adhesive. According to ASTM D5573, the failure modes showed from these specimens are all Light-Fibre-Tear, as shown in Fig. 5. At this temperature, the resistance of the last ply of the adherend (near the adherend/adhesive interface) is lower than the resistance of the bulk adhesive.

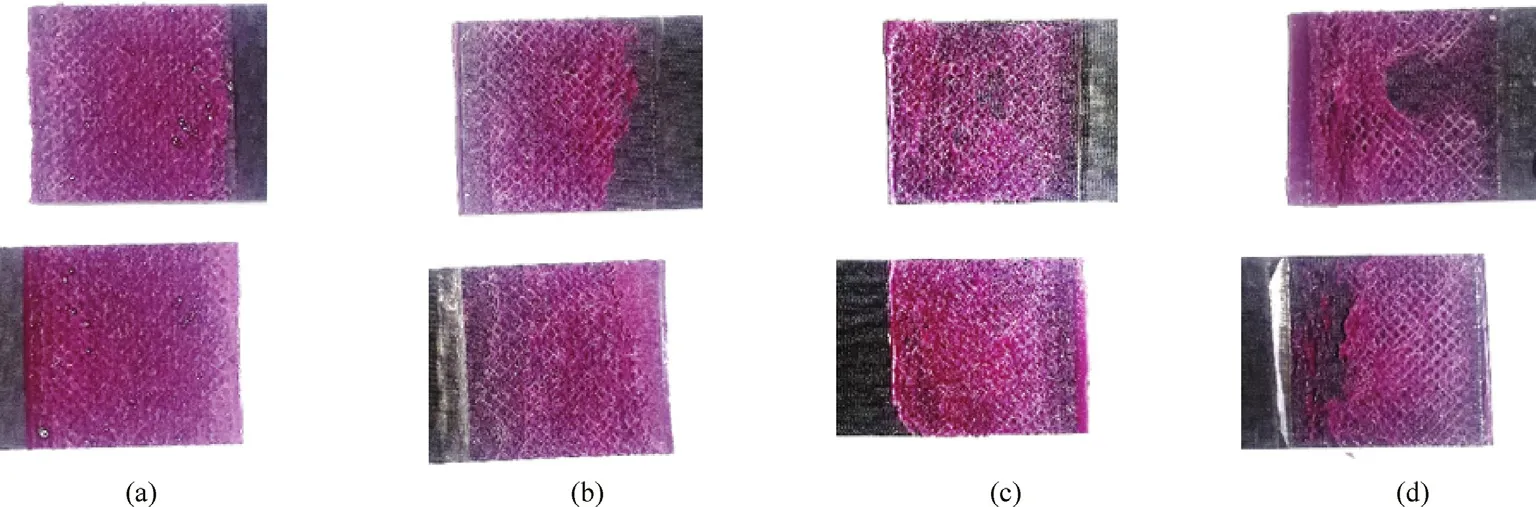

Referring to the tests carried out at 70°C, the results show the same trend for all ageing conditions, recording an increase in average resistance of about 20% respect the reference tested at 70°C. In particular specimens aged in water have shown a less dispersion of the results, as observed in Ref. [21] with this type of adhesive.Probably the highTgof this adhesive,combined with the presence of the support,has led to an increase in the ductility due to degradation without penalizing the mechanical resistance.Fig.6 shows the failure surfaces of these specimens: it is possible to observe that the specimens aged in air show light-fibre tear failures while the references and the specimens aged in water show mixed light-fibre tear/cohesive failures. This is probably due to a greater degradation of the adhesives aged in water,which has affected the resistances of the adhesive in a negligible way.

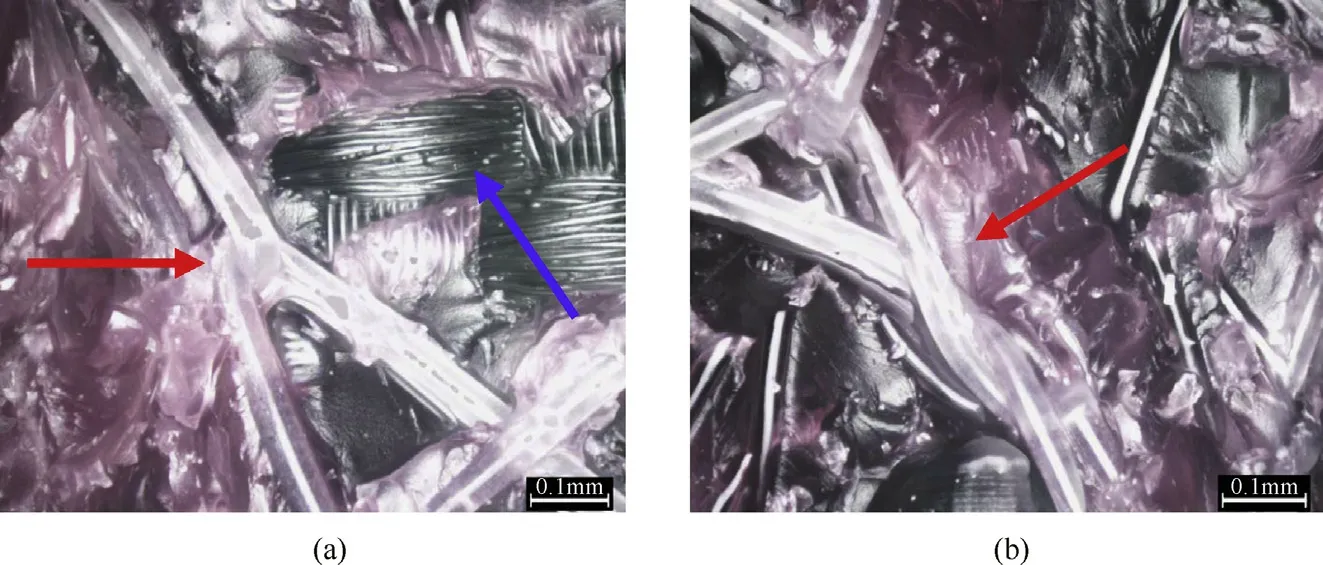

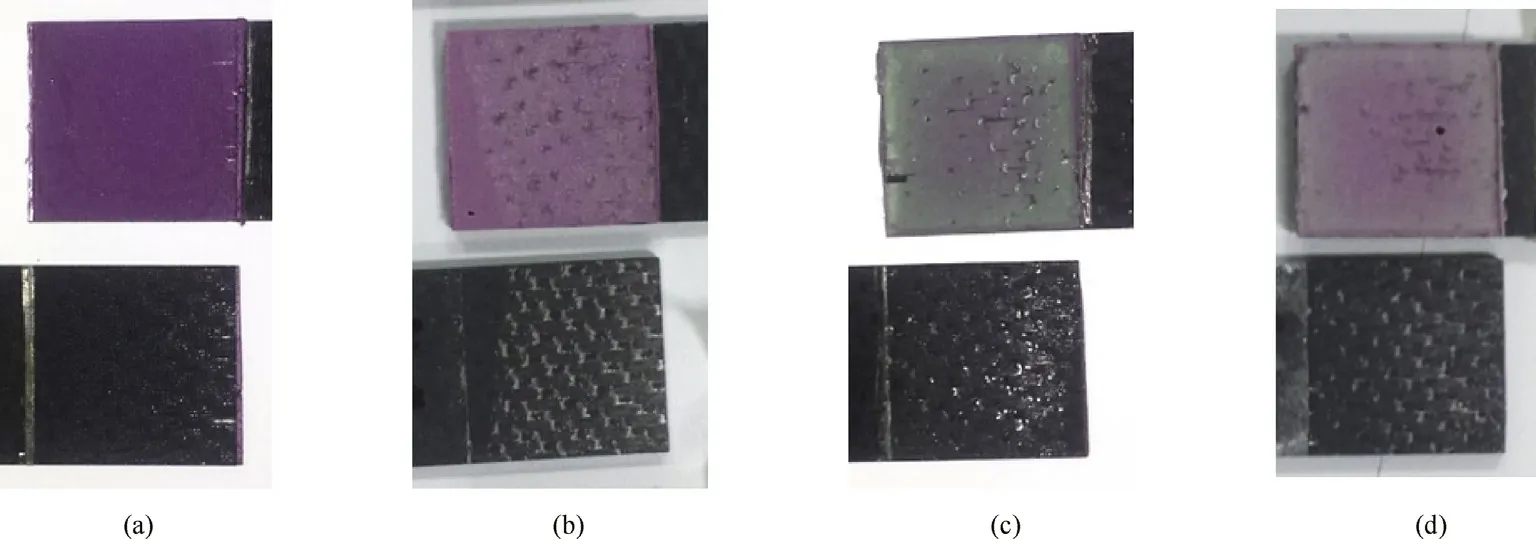

For the results of the tests carried out at 120°C,a strong decay of performance of about 65% respect the reference at room temperature was observed combined with cohesive failures:it is possible to state that the low performance was induced by the softening of the adhesive since the test temperature was higher than theTgof the same. However, comparing the data obtained with the reference at 120°C, the decay is on average 20% for specimens aged in air, and 45% in the case of specimens aged in water. Probably the presence of the carrier inside the adhesive has improved the mechanical resistance of the joint at this temperature. In fact, the reference presents a higher average resistance respect aged specimen.This is probably due to an influence of the ageing treatment on the integrity of the adhesive/carrier interface. In fact, at this temperature,the bulk resistance of the adhesive is very low and the carrier has a major effect on the mechanical resistance of the joint.Fig. 7 shows the stretching of the carrier fibres of the support observed on failure surface of AF 163-2K specimen aged in distilled water and tested at 120°C. The load is transferred from an adherend to the other through the carrier: further investigations are needed to investigate the effect of the knit support carrier at high temperatures(see Fig. 8).

Fig. 4. Lap shear test results for EA 9309.NA.

Table 3 Anova on the entire population of tested specimens.

Table 4 ANOVA for AF 163-2K

As noted in Ref.[19],it is possible to state that for the specimens made with AF 163-2K adhesive,the ageing process did not involve substantial changes, showing a slight improvement in the tests at 70°C, but for very high test temperatures the adhesive has immediately softening such as to result in cohesive failures.

3.2. EA 9309NA

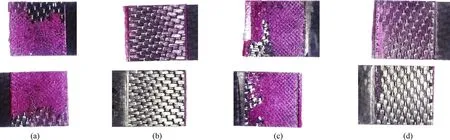

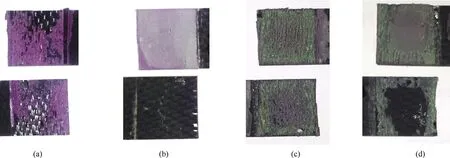

Analysing the data referenced to the joints realised with EA 9309NA (Fig. 4 and Table 5), it is possible to affirm that the behaviour of the specimens has been severely influenced by the ageing conditions and,in particular,the test temperature,showing variable morphologies of failure depending on the ageing treatment and test temperature. At 25°C the joints aged in water undergo a strong increase in performance,achieving performances of about 75%higher than the reference ones;also for samples aged in air there was an increase in performance(due to a post-cure effect induced by the maximum temperature reached during ageing)but less significant(about 35%).Probably the specimen aged in air have undergone the effects of damage due to the thermal shock suffered during the transient from -28°C to 85°C lasting a few minutes,while the specimens aged in water have suffered a softer transient duration of about 2 h.This difference between the two groups may be due to a higher ductility and lower resistance of the edges of the adhesive due to degradation in the water-aged specimens, which may have resulted in a higher apparent shear strength of the joint respect the non-aged ones. In fact, it is known that the stress field that is generated inside a single-lap joint presents a singularity into the adhesive/adherend interface localized near the edges [22,23],so the overlap ends of the bonding tend to be stressed more respect the central area of the interface.A greater ductility of the adhesive localized to the extremes allows attenuating the presence of this singularity and in this way generating a more uniform load,allowing an increase in the apparent shear strength of the joint[24]. In Fig. 9f it is possible to observe the chromatic variation on the green that occurs in the joints aged in water compared to the other joints tested, which tends to concentrate near the edges of the glue. From the analysis of the failure surfaces, it is possible to observe how the failure mode passes from adhesive to mixed adhesive-light fibre tear:this is probably due to an improvement of the resistance of the adhesive/adherend interface due to ageing(Fig. 9).

Fig. 6. Failure surfaces of AF 163-2K specimens tested at 70°C: a) unaged; b) aged in air; c) aged in distilled water; d) aged in salt water.

Fig. 7. Stretching of carrier fibres (red arrows) of the support on failure surface from AF 163-2K specimen aged in distilled water and tested at 120°C, observed with optical microscope. It is possible to observe the imprint of the peel ply (blue arrow) on the adherend surface.

Fig. 8. Failure surfaces of AF 163-2K specimens tested at 120°C: a) unaged; b) aged in air; c) aged in distilled water; d) aged in salt water.

For the test carried out at 70°C,the specimens aged in air have increased the performance of about 50%and the specimens aged in water have undergone a performance decay of about 30% respect the reference. This degradation in water has resulted in some failure modes classified according to ASTM D5573 as cohesive failure(COH)and mixed adhesive/cohesive failure,as shown in Fig.10.It is possible to hypothesize that the ageing of the adhesive in water has lowered the thermal stability of the same such as to affect the mechanical resistance of the adhesive at this test temperature.

At the test temperature of 120°C there was a performance decay of about 65%for all three types of ageing respect the reference at RT.In this case, the justification lies only in the high test temperature that softened the adhesive,weakening the intermolecular chemical bonds, already degraded by ageing. In fact, there is no sensible difference between the results obtained with EA 9309NAspecimens tested at 120°C.

Table 5 ANOVA for EA 9309NA.

In conclusion,it can be stated that the mechanical resistance of the joints made with EA 9309NA paste adhesive have been strongly influenced by ageing. In particular, in the case of the tests carried out at 25°C the effects of post-cure induced by the thermal cycle and the most localized degradation in the edges of the bonded joint are noted.For the test carried out at 70°C the specimens aged in air present better performances respect the specimens aged in water.For the tests carried out at 120°C, it can be stated that the strong degradation of the joint performance is due only to the test temperature, far above theTgof the adhesive.

4. Conclusion

In this work single lap joints in composite material were made with two types of adhesive: film (AF 163-2K) and paste (EA 9309NA). The specimens were subjected to ageing cycles in water and air between -28°C and 85°C, then tested at 25°C, 70°C and 120°C respectively.

Regarding the joints made with the AF 163-2K, ageing did not particularly affect the apparent shear strength. The specimens tested at 25°C show a behaviour compatible with the nondegraded joints. The specimens tested at 70°C show a slight increase in performance and a lower dispersion of the specimens aged in water. Instead, the specimens tested at 120°C show a collapse of the shear strength: at this temperature, the ageing conditions of the specimen are negligible.

Fig. 9. Failure surfaces of EA 9309NA specimens tested at 25°C: a) unaged; b) aged in air; c) aged in distilled water; d) aged in salt water.

Fig.10. Failure surfaces of EA 9309NA specimens tested at 70°C: a) unaged; b) aged in air; c) aged in distilled water; d) aged in salt water.

As for the specimens made with the EA 9309NA, ageing has played a fundamental role in the apparent shear strength of the joints.Tests at 25°C show an increase in the apparent resistance of the joint aged in air,due in part to a post-cure effect of ageing on the adhesive; while in the case of joints aged in water the apparent resistance is directly proportional to the degradation of the adhesive.This has occurred because the degradation is more localized in the edges of the bonding that is where this type of specimen has a stress singularity: in this way, the adhesive presents a lower resistance but a greater ductility where such properties are required.In tests at 70°C,it was observed that ageing in air resulted in improved performances, while ageing in water led to a deterioration. This occurs because the two ageing treatments have opposite effects on the adhesive. In fact, the adhesive did not complete cross-linking due to the cure at room temperature. Ageing in air completed the polymerization making the specimen more stable at high temperatures, while ageing in water tends to block the polymerization despite the ageing temperatures being higher than theTgof the adhesive. The test results at 120°C with the EA 9309NA lead to the same conclusion as those carried out with the AF 163-2K: the operating temperature, if much higher than theTgof the adhesive, is the only influence factor on the apparent shear strength of the bonded joints.

Declarations of interest

None.

Acknowledgement

This work was carried out with the funding of the Italian M.I.U.R.(Ministry of Instruction, University and Technological Research).

杂志排行

Defence Technology的其它文章

- A comparison of the ballistic behaviour of conventionally sintered and additively manufactured alumina

- Investigation on energy output structure of explosives near-ground explosion

- Characteristics structure analysis on debris cloud in the hypervelocity impact of disk projectile on thin plate

- A fast-running method for blast load prediction shielding by a protective barrier

- Coating processes towards selective laser sintering of energetic material composites

- Dynamic modeling and parameter identification of a gun saddle ring