Performance evaluation and optimization design of photoelectric pyrometer detection optical system

2020-05-23XueyanHanKeweiHuanShanjuSheng

Xue-yan Han, Ke-wei Huan, Shan-ju Sheng

School of Science, Changchun University of Science and Technology, Changchun 130022, China

Keywords:Photoelectric pyrometer Detection optical system ZEMAX MTF Spot diagram

ABSTRACT The measurement and control of high temperature play very important roles in national defense, military,scientific experiments,industrial and agricultural production.Photoelectric pyrometer is one of the important radiation thermometers for non-contact temperature measurement. It has an important application in the field of high temperature measurement, and its performance directly affects the accuracy of temperature measurement. By improving the design of the detection optical system of the photoelectric pyrometer, the imaging performance of the photoelectric pyrometer can be improved effectively,and the temperature measurement accuracy can be improved.In this paper,the temperature measurement principle of photoelectric pyrometer,the working principle of the detection optical system and the composition of the system are introduced.The optical components that affect the imaging of the optical system of the photoelectric pyrometer are analyzed. The optical pyrometer detection optical system is simulated by ZEMAX software,based on the analysis results,the Modulation Transfer Function(MTF) and the spot Diagram are used as the main evaluation criteria to optimize the design of the objective lens of the photoelectric pyrometer detection optical system. The imaging performance of the photoelectric pyrometer detection optical system and the accuracy of temperature measurement of the photoelectric pyrometer are improved by optimization design of the detection optical system.

1. Introduction

Temperature is one of the seven basic quantities in the International System of Units. Its measurement and control play very important roles in national defense, military, scientific experiments, industrial and agricultural production. With the advancement of science and technology, various types of radiation thermometers have been widely used in the fields of national defense, construction, electric power, electronics and metallurgy.Radiation measuring instruments promote the progress of scientific research and industry, and the urgent need for radiation thermometers is also driving the research of radiation thermometers[1,2]. High temperature measurement plays an important role in the industrial defense field of materials, energy, aerospace, metallurgy,machinery manufacturing,etc.[3].With the development of technology, the accuracy of radiation thermometer [4-6] is continuously improved, and the temperature measurement method is divided into contact temperature measurement and non-contact temperature measurement [7]. The radiation thermometer has a wide measuring range and can respond quickly without touching the object to be measured [8]. There are many types of radiation thermometers,such as photoelectric pyrometers,optical pyrometers, total radiation thermometers, colorimetric thermometers, fiber optic thermometers, infrared radiation thermometers,etc.[9].Photoelectric pyrometer is one of the important radiation thermometers for non-contact temperature measurement. It can be used as standard instrument in the high temperature range of 900-2500°C [10] Based on the temperature measurement principle of the photoelectric pyrometer, the working principle of the optical system and the current structure of the photoelectric pyrometer, the influence of lens and other optical elements on the performance of the detection optical system was analyzed,and ZEMAX software was used to simulate and optimize the design of the optical system of the photoelectric pyrometer.The MTF function and the Spot Diagram are used as the main evaluation parameters to analyze the imaging performance of some components of the detection optical system.By changing the structure of the objective lens to improve the design of the optical system of the photoelectric pyrometer. Finally, the temperature measurement accuracy of photoelectric pyrometer is improved.

2. The working principle of photoelectric pyrometer temperature measurement and detection optical system

2.1. The principle of temperature measurement

Photoelectric pyrometer is part of the brightness thermometer in the radiation thermometer.The brightness thermometer is based on Planck's law to determine the brightness of the object at a certain wavelength, brightness temperature is obtained by the brightness, and calculates the true temperature using a specific formula [5].

Planck's law of blackbody radiation describes the relationship between the spectral radiance L of a blackbody and the temperature T and wavelength as in Eq. (1):

where:L(λ,T) is the spectral radiance of the black body;

c1,c2are the first and second radiation constants;

λ is the wavelength in vacuum;

Tis the temperature of the measured black body.

Temperature of the ITS-90 international temperature scale to the temperature range above 961.78°C:

It can be seen from Eq. (2), wavelength is an important factor affecting the temperature scale recurrence, minor deviations can also have a large impact on the calculation of spectral responsivity measurements. Therefore, in order to measure the spectral responsivity of the photoelectric pyrometer more accurately and reduce the uncertainty of the effective wavelength in the transmission of high temperature quantity, it is necessary to accurately calibrate the wavelength of the grating monochromator before the spectral responsivity test.

Fig.1. Schematic diagram of radiant temperature meter optical system.

Fig. 2. Objective MTF curve.

2.2. The working principle and composition of photoelectric pyrometer detection optical system

Optical imaging systems,monochromators,photodetectors,and current amplifiers are the basic components of standard radiation thermometers. The optical system diagram is shown in Fig.1. The working principle can be simply summarized as follows: the measured object is imaged by the movable objective lens in the field of view,the center of the field diaphragm is a circular hole,and the surrounding is a mirror for aiming. The measured object is imaged on the circular hole, and then the measured object is divided into measuring light path and aiming light path.Detection optical system: The target radiation converges on the photodetectors passes through the center hole of the field diaphragm, the aperture stop, the condenser lens, and the interference filter.Aiming optical system: The image of the measured object is reflected by the field of view and the mirror, and it imaged in the observer's eye through objective lens and the eyepiece [11].

3. Structural design and performance analysis of photoelectric pyrometer detection optical system

The detection optical system is a key component of the pyrometer to achieve precise temperature measurement[12-14].The optical system directly determines the measurement accuracy of the photoelectric thermometer.The spectral responsivity is mainly related to the filter and the detector.The size effect of the radiation source is mainly caused by the reflection between optoelectronic pyrometer lenses,the phase difference and diffraction of the optical system, the dust in the optical component and the optical system,etc. [15-17]. The distance effect of the photoelectric pyrometer is mainly related to the energy distribution on the detector. The influence of spectral responsivity and radiation source size on the performance evaluation parameters of photoelectric pyrometer is related to the structure of detecting optical system. The detection optical system of the pyrometer consists of an objective lens,a field diaphragm, a converging lens, a filter and a detector. Thephotoelectric pyrometer detection optical system is designed by ZEMAX software, and the imaging performance of each part is analyzed, which is an important basis for the design and improvement of the pyrometer optical system.

Table 1 Objective optical component parameters.

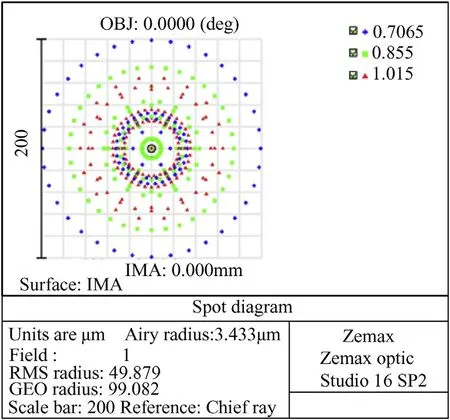

Fig. 3. Objective lens imaging.

Fig. 4. Objective image point spread function.

3.1. Objective lens simulation analysis

The radiation thermometer objective lens adopts double adhesive lens, whose performance parameters are as follows (see Table 1):

Fig. 5. MTF curve of 700 mm field of view pupil.

(1) The wavelength segment: 0.7066-1.016 μm, the center wavelength: 0.855 μm;

(2) Image distance: Infinity;

(3) Field of view: 0°;

(4) Focal length: 151.42 mm;

(5) Entry diameter:φ45.75 mm.

According to the selected the parameters of double cemented lens, the MTF and the diffuse radius were analyzed by ZEMAX software to evaluate the imaging performance of the objective lens.

The MTF curve of the objective lens imaging is shown in Fig. 2.As can be seen from Fig.2,the imaging of the objective lens on the on-axis field of view (0°) is very poor. When the system field of view is increased,the off-axis field of view aberration increases and the optical system imaging performance become worse.

The imaging diffuse spot distribution at the focal plane after the objective lens converge the light is shown in Fig. 3. It can be seen that the radius of the Airy image of the objective lens is 3.433 μm,and the root mean square radius of the speckle after the objective imaging is 49.879 μm, which is much larger than Airy spot radius value.

The point diffusion function of the objective lens is shown in Fig.4.The relative irradiance peak of point diffusion function is only 0.05.

Table 2 Objective optical component parameters.

Fig. 6. Object distance 700 mm field of view pupil point map.

3.2. The design of detection optical system

The optical system of photoelectric pyrometer consists of objective lens, field diaphragm, aperture diaphragm, measuring concentrator lens, filter and detector. The optical system of photoelectric pyrometer is designed,and the parameters and positions of each optical element are determined.The imaging performance of the optical element (measuring convergent lens) without definite parameters and the imaging performance of energy detection optical path are analyzed.

3.2.1. The parameters of detecting optical system performance

According to the working principle and imaging process of the radiation thermometer,the energy detection optical path needs to satisfy the following imaging performance:

(1) Spectral segment: center wavelength: 0.855 μm, imaging bandwidth:30 nm (determined by filter performance);

(2) Working distance: 500-1000 mm;

(3) Inlet diameter:φ46 mm;

(4) Imaging range:always fill the center of the field diaphragm.

Fig. 7. Point-to-point map of 700 mm detector.

Fig. 8. Optical system design.

3.2.2. The structural parameters of detection optical system

The energy detection optical path design object distance range is 500-1000 mm.By adjusting the position of objective lens along the direction of optical axis, the measured target is always filled with the field of view pupil.The component parameters are shown in Table 2. If the working state of the object distance 700 mm is used as the reference position of the detection optical system, the objective lens needs more adjustment amount if the object distance becomes shorter than when the object distance becomes longer.

3.2.3. Imaging performance analysis of detection optical system

According to the working principle of the photoelectric pyrometer,field diaphragm should be placed at the focal plane of the objective lens in theory.It is necessary to analyze the image quality of the objective at the actual field stop position,which is currently measured.

3.2.3.1. Analysis of imaging performance at thefield diaphragm

(1). MTF

When the object distance is 700 mm, the modulation transfer function (MTF) can reflect the comprehensive imaging performance of the optical lens.The MTF curve of the objective lens at the field stop position is shown in Fig.5.It can be seen that the image quality at the field stop is poor.

(2). Diffuse spot

When the object distance is 700 mm, the distribution of the imaged diffuse spot at the optical field of the objective lens is as shown in Fig.6.As shown in the figure,the radius of the Airy image of the objective lens is 4.55 μm, and the square root radius of the speckle at the field diaphragm is more than 72 μm,which is much larger than the Airy disk radius.

3.2.3.2. Imaging performance analysis at the detector

(1). Diffuse spot

At the detector, the distribution of the diffuse spot in the different imaging fields of the detection optical system is shown in Fig. 7. The radius of the Airy disk is 5.193 μm. As can be seen from the figure below,the radius of the root mean square of the field of view of the detector is about 277.3 μm, much larger than the Airy disk radius value.

Fig. 9. Optimized objective lens structure.

Fig.10. Objective lens collimator MTF curve.

(2). The light distribution of the detector

When the working object distance is 700 mm, the area where the detector can receive energy is about 0.66 mm×0.997 mm.

4. Improved design of optical path for optical pyrometer detection optical system

Through the above analysis, the objective lens is a key part affecting the imaging quality of the entire optical system. The imaging quality of the optical path can be improved by optimizing the structure of the objective lens and adding the collimating lens and focusing lens.The optimized design of the photoelectric pyrometer detecting optical path system is shown in Fig.8.The objective lens(1) converges the radiant energy at the field stop (2), and the radiating energy through the field diaphragm is emitted by collimating mirror(3),the pupil(4)of the collimating mirror is placed at the exit position of the mirror(3),and finally the radiant energy is concentrated by the focusing mirror (5) to the detector (6).

The objective lens is in the form of two sets of double cemented lenses as shown in Fig.9.The working distance of the objective lens is 700-1500 mm, the focal length is about 147.6 mm, and the aperture is φ51 mm.The image quality of the objective lens can be clearly identified at different working distances.

The type of collimating lens depends on the aberration requirements,and can be used with a simple monolithic lens,such as a Plano-convex or lenticular lens. These lenses allow for a larger relative aperture. Double-glued lenses can also be used, and the relative aperture is also appropriately reduced. The MTF curve of the objective lens collimator at different working distances is shown in Fig.10.It can be seen that the resolution is very high,and the MTF curve almost coincides with the diffraction limit, and the image quality is good.

The structure of objective lens, collimating mirror,and focusing mirror in the detection optical system is shown in Fig. 11. The focusing mirror in the optical system improves the ability of the edge beam to be incident on the detector.In the same main optical system,the additional field lens will reduce the area of the detector,if the same detector area is used,the field of view can be enlarged and the incident flux can be increased, the non-uniform illumination on the photosensitive surface of the detector is homogenized.When the focal length of the focusing lens is 72 mm and the working distance is 700 mm, the total length between the front surface of the objective lens and the focal plane of the focusing mirror is 385.2 mm.

The MTF curves of the objective lens,the collimating mirror and the focusing mirror at different working distances are shown in Fig.12. It can be seen that when the energy detecting optical path uses this design scheme,the imaging effect is better than before the improvement.

The point map of the energy detecting optical path at different object distances is shown in Fig.13.It can be seen that the imaging diffused spots of different fields of view of the system are close to the Airy disk of the system.

Fig.11. Objective lens, collimating mirror, focusing mirror light path diagram.

Fig.12. Objective lens, collimating mirror, focusing mirror MTF curve.

Fig.13. Energy detection optical path at different point distances.

In summary, using two sets of double-glued lenses to optimize the detection optical system of photoelectric pyrometers after design, the MTF function is close to the diffraction limit, and the diffuse spot is close to the system's Airy plaque, which is well imaged and meets the design requirements.

5. Conclusion

The imaging performance of photoelectric pyrometer detecting optical system is an important factor affecting the temperature measurement of photoelectric pyrometer.Based on the structure of the optical system of the radiation thermometer and the parameters of the optical elements,this paper analyzes the main problems existing in the optical system of the photoelectric pyrometer, and optimizes the design and evaluation of the objective lens of the optical system of the photoelectric pyrometer. When the object distance of the original photoelectric pyrometer is 700 mm, at the detector, the Airy radius is 5.193 μm, and the RMS radius of each field of view is about 277 μm, which is much larger than the Airy radius. After the optical system of the photoelectric pyrometer is improved,when the object distance of the detecting optical system is 700 mm,the Airy radius of the objective lens imaging is 10.35 μm,and the RMS radius of each field of view is between 7.12 and 8.242 μm;When the object distance of the detecting optical system is 1100 mm, the Airy radius of the objective lens imaging is 9.585 μm, and the RMS radius of each field of view is between 8.8912 and 11.195 μm; When the object distance of the detecting optical system is 1500 mm, the Airy radius of the objective lens imaging is 9.262 μm, and the RMS radius of each field of view is between 11.345 and 13.974 μm.After the detection optical system is improved,the RMS radius of each of each field of view are close to the Airy radius of the system. The MTF function of the improved objective lens is close to the diffraction limit at different distances,and the area between the curve and the coordinate axis increases significantly. The data show that after improving the detection optical system, the imaging quality of the system is significantly improved, which improves the imaging performance of the photoelectric pyrometer, and improves the design level and detection quality of the independently developed photoelectric pyrometer.

Foundation item

Jilin Province Science and Technology Development Plan Project(20190701024GH).

杂志排行

Defence Technology的其它文章

- A comparison of the ballistic behaviour of conventionally sintered and additively manufactured alumina

- Effect of operating temperature on aged single lap bonded joints

- Investigation on energy output structure of explosives near-ground explosion

- Characteristics structure analysis on debris cloud in the hypervelocity impact of disk projectile on thin plate

- A fast-running method for blast load prediction shielding by a protective barrier

- Coating processes towards selective laser sintering of energetic material composites