污泥厌氧消化过程的流变规律与脱水性能

2020-04-24曹秀芹王浩冉朱开金任晓莉

曹秀芹,王浩冉,江 坤,柳 婷,朱开金,任晓莉

污泥厌氧消化过程的流变规律与脱水性能

曹秀芹1,2,王浩冉2,江 坤3,柳 婷2,朱开金4,任晓莉4

(1. 北京建筑大学城市雨水系统与水环境省部共建教育部重点实验室,北京 100044;2. 北京建筑大学环境与能源工程学院,北京 100044;3. 中铁上海设计院集团有限公司,上海 200070;4. 太原工业学院,太原 030008)

为阐明厌氧消化过程中污泥流变学与污泥理化性能(脱水性能)之间的关联及低温水解预处理对污泥厌氧消化产气的影响,对常规污泥及低温热水解预处理污泥进行厌氧消化试验,结果表明试验结束时,低温热水解-厌氧消化的挥发性固体(volatile solids, VS)去除水平较常规厌氧消化污泥提高3.7个百分点,低温热水解预处理也使得消化污泥的脱水性提高1.59%;污泥屈服应力分别了降低了64.51%和71.47%;稠度系数分别减小了90.94%和92.83%,污泥流动性增强。整个消化过程VS/总固体(total solids, TS)和屈服应力随时间的变化均呈对数下降趋势;通过线性方程拟合和皮尔逊相关性分析表明,屈服应力与VS/TS、屈服应力变化与脱水性能改善两两间的拟合优度(R)均大于0.94,表明在厌氧消化过程中屈服应力、屈服应力变化与污泥VS/TS、脱水性能具有较好的线性关系。研究结果从流变学角度为厌氧消化过程中的监控和优化提供新思路和理论依据。

污泥;厌氧消化;低温热水解;屈服应力;脱水性能

0 引 言

统计表明,2017年中国城镇废水排放总量达到了6 996 609.97万t[1]。2020年污泥产量将达到6 000万t[2]。21世纪废水处理厂产生的污泥已使污泥的处理和处置成为关键的环境问题之一[3]。通常,厌氧消化(anaerobic digesters,AD)由于具有减少污泥的质量和体积,产生甲烷等能源气体,以及改善污泥的脱水性等优点[4-5],被广泛应用于污水污泥的处理。相关研究表明,由于厌氧消化受到有机物水解速率低的限制,为了增强污水污泥的溶解性进一步促进AD过程,多种预处理如:碱、热、超声波、臭氧、酶、电化学等被成功应用[6-7]。实践表明,污泥通过热水解预处理,可以提高消化效率,增加沼气产量,同时还可提高有机负荷率[8-9]。

消化池内物料的均质化和产气均依赖于污泥黏度和结构特征,污泥流变影响着厌氧降解的功能和产气效率[10],且消化过程中污泥的有效混合已被认为是实现最佳过程性能的关键物理操作[11]。同时,污泥处理高效设计和运行需要准确预测不同设备(如泵、换热器和混合系统)的流体动力学功能,而预测这些过程的正确流动行为需要对污泥流变学有准确的认识[12-15]。因此更好地了解厌氧消化过程中污泥的流变行为有助于改善其设计和运行。

近年来,相关研究者已开始尝试在厌氧消化、热水解预处理等技术中建立污泥流变参数与污泥理化参数之间的关系。曹秀芹等[16]通过低温热水解-厌氧消化工艺中污泥的流变特性分析表明,极限黏度与总固体含量(total solids, TS)之间呈指数关系;Kevin等[17]报道了污泥随着热水解温度的升高,储存模量(storage moduli,′)和损失模量(loss moduli,″)逐渐升高,并对含固率(7%~13%)的污泥,建立不同热水解条件下污泥含固率与极限黏度、流变特性指数,稠度系数的预测方程;Zhang等[18]发现厌氧消化过程中,储存模量′与有机物浓度呈线性关系;Mori等[19]报道在厌氧消化后,表观黏度和屈服应力随着有机物含量的减少而降低。Pevere等[20]和Dai等[21]建议流变学表征可用过程控制方法来监测反应器中消化进行时污泥的变化,但并未给出特定的流变参数。然而对于污泥厌氧消化过程中有机物可降解性、污泥理化特性和流变性能之间的相互关系缺乏全面的研究,缺少流变性参数是否能够描述厌氧消化性能的进一步探究。

本文将常规厌氧消化污泥和低温热水解-厌氧消化污泥进行厌氧消化试验,检测厌氧消化过程中污泥的理化特性如:挥发性脂肪酸(volatile fatty acids, VFAs)、pH值、VS/TS(volatile solids, VS; total solids, TS)等、流变特性和脱水特性,建立污泥厌氧消化期间流变特征与表征过程性能(效率)的特征理化参数间的关系,以期为评价和监测AD进程(性能)提供流变学的控制指标。同时考虑污泥脱水的巨大成本,研究消化过程中污泥流变与脱水之间的关系,提高对污泥流变性和脱水性之间关系的认识与理解,为进一步探索如何控制优化污泥脱水提供理论基础。

1 材料与方法

1.1 样品来源及预处理

接种污泥取自北京某污水厂中试厌氧消化反应罐,原污泥取自污水厂脱水污泥。首先预培养种泥除去其残留可生物降解有机物,预培养在35 ℃水浴中进行2 d。接种污泥的基本理化指标如表1所示。

1.2 试验设计与方法

为了比较不同基质对厌氧消化中流变和理化性质改变的影响,本研究共设置2个处理,分别以原污泥和低温热水解污泥作为基质(称常规厌氧消化和低温热水解-厌氧消化)。污泥低温热水解条件:在实验室可智能控温的小型试热反应釜中进行污泥的热水解试验,工作时维持反应釜内搅拌转速为36 r/min,温度为90 ℃,热解时长48 h。基质与种泥的混合比例为2∶1 (质量比)[6],试验设置3个平行组,每组包括8个平行反应器以定期地评估理化性质(如VFAs、pH值、VS/TS等)和流变特性。本试验厌氧消化反应器为实验室小试反应器,反应器体积为500 mL,试验前充入氮气,保持反应器内良好的厌氧环境,反应器内温度为(37±1)℃,整个消化试验运行20 d。厌氧消化前基质的基本理化性质如表1所示。

1.2.1 常规理化指标的分析方法

总氨氮(total ammonia nitrogen content, TAN)由2种主要形式组成,即自由氨(free ammonia nitrogen content, FAN)和铵根离子(NH4+),其各自的相对含量与温度、pH值有关[22]。基于温度和pH值,FAN浓度可以通过式(1)计算获得[23]:

式中FAN为自由氨的质量浓度,mg/L;TAN是总氨质量浓度,mg/L;(K)表示开尔文温度,K。

基于VS去除水平(removal level based on VS, VSr)通过式(2)计算[24],假设不可降解物质(无机部分)的质量是恒定的。

式中VSt表示消化第d污泥中的VS/TS值,VS0表示厌氧消化启动时污泥中的VS/TS值。

1.2.2 污泥脱水指标的分析方法

试验引入离心脱水方法,这种方法作为可滤性测量的可靠替代被广泛接受[25-26]。使用污泥离心过滤后所得泥饼的含固率TSt(TSt:表示厌氧消化第天,污泥离心脱水泥饼的固体含量)来判断污泥的脱水性。本研究中,选择离心转速为10 000 r/min,离心时间20 min,将离心后的污泥通过0.45m孔径的微孔纤维滤膜以得到离心脱水过滤泥饼[6]。

1.2.3 污泥流变指标的分析方法

使用HAAKE Viscotester 550旋转黏度计(德国Haake 公司)测定污泥流变特性,由于实际测量过程中样品温度难以维持在(37±1) ℃,测量选用比较常用且经典的(20±0.1) ℃[27]。所有样品在测试前均先使用0.6 mm的筛子进行过滤[28],减小污泥由大颗粒导致的试验误差。对于每组流变试验,将50 mL污泥样品引入杯形为圆柱形几何形状(内径29 mm,外径32 mm,长度44 mm),流变仪剪切速率设定为在180 s内由0增大到1 000 s-1,由剪切速率扫描试验获得污泥流动曲线。由于Herschel-Bulkley (H-B) 模型涵盖了假塑性、剪切稀化和屈服应力这些特性,且能够较好描述静止和流动条件下污泥的流变行为[29],其模型表达式如式(3)所示。使用H-B模型对不同厌氧发酵时间污泥获得的污泥流动曲线进行拟合。

式中表示剪切应力,Pa;0表示屈服应力,Pa;称为流体稠度系数(fluid consistency index),反映材料黏性的大小,Pa·sn;表示剪切速率,s-1;表示流动指数。

1.3 测定指标及方法

污泥pH值采用Mettler-Toledo-210型pH计测定。TS,VS根据质量法测定,为避免吸水,将残留物立即置于干燥器中以达到室温(25±1) ℃。然后将干燥的样品在马弗炉中550 ℃下燃烧2 h,其后质量的减轻用于计算VS/TS。在测量溶解性有机物之前,先将污泥样品在10 000 r/min下离心处理20 min,然后将上清液通过孔径为0.45m的微纤维滤膜以收获滤液,所得滤液用于后续溶解性有机物含量的测定。挥发性脂肪酸(VFAs)含量通过配备火焰离子化检测器(FID)和毛细管柱(Rtx-WAX,0.25 mm×30 m)的日本岛津GC-2010 Plus气相色谱仪测量,N2用作载气,流量为30 mL/min,滤液预先用甲酸酸化将pH值调节至2.0。进样口和检测器的工作温度分别为210 ℃和250 ℃,柱温为100 ℃(保持1 min),并在10 min增加至210 ℃(保持1 min)。氨氮含量(TAN)通过纳氏试剂测定,以上所有指标测定每次共需要抽取污泥样品50 mL。

1.4 数据处理方法

试验前期每隔2 d取样一次,随着系统逐渐稳定每隔3 d取样一次,最后一次取样在第20天,第21天结束厌氧消化试验。

2 结果与分析

2.1 污泥厌氧消化性能

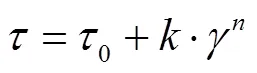

随着厌氧消化过程的进行,反应器中各项理化指标随消化时间改变如图1所示。

图1 厌氧消化过程中pH值,FAN,VFAs和VSr随消化时间的变化

对产酸微生物和产甲烷菌而言,其最适pH值分别在5~8.5和6.5~7.8范围之间[30-31]。图1显示出厌氧消化过程中pH值的变化,在整个厌氧消化过程中,pH值均维持在6.8~7.9之间,虽在厌氧消化进行到18 d时,常规厌氧消化的pH值超过7.8,但国内相关研究表明,厌氧消化过程中大多数细菌可以在pH值为5~8.5的范围内生长良好[32]。试验中pH值波动在厌氧消化允许的范围之内。

厌氧消化过程易受某些累积化学物质(如钠、钾、铵盐等)抑制,这些盐类会引起毒性效应从而对微生物起到抑制作用,其中FAN被认为是最主要的抑制剂[33]。随着消化时间的延长,由于含氮有机物质如蛋白质等的降解,FAN浓度先上升然后逐渐达到稳定,之后维持在某一范围内上下浮动。同时,由图1可知,低温热水解污泥中的FAN浓度只是比常规厌氧消化污泥稍有增加,说明90 ℃低温热水解有改善蛋白质由颗粒状向溶解态的水解作用,蛋白质大部分被溶解而不是降解[34]试验中FAN的浓度位于10~130 mg/L之间,低于Mccarty等[35]所报道的抑制水平150 mg/L。

VFAs在厌氧消化过程中变化如图1所示,常规厌氧消化和低温热水解厌氧消化在0~5 d和0~3 d内VFAs浓度显著增加,这一阶段VFAs的积累也导致了厌氧消化前期pH值的下降。低温热水解污泥先于常规厌氧消化污泥2 d达到VFAs的最大值,原因是低温热水解加速了水解这一限速步骤,缩短了厌氧消化的运行时间[36]。之后随着消化过程的继续进行,VFAs被不断转化为CO2和CH4,其浓度随之下降,最后达到一个较低的水平。在厌氧消化之前。低温热水解污泥中的VFAs含量比常规厌氧消化污泥中的要高,原因可能是由于脂质的降解所引起的[37],由于热处理的作用,长链脂肪酸可能被还原成较低分子量的脂肪酸,而它们本身可以在低链脂肪酸中被降解[9]。VFAs的产生也可能源于少量蛋白质降解[38]。

如图1所示,随着消化时间的不断延长,VS去除水平逐渐升高,并最终趋于平衡,表示随消化过程进行,有机物逐渐被微生物分解后趋于稳定化。研究表明,在污泥厌氧消化期间,VS减少量在30%~45%的范围内[39],本试验中常规厌氧消化的最终VS去除率为44.6%。低温热水解-厌氧消化的最终VS去除水平达到48.3%,较常规厌氧消化污泥高3.7个百分点。厌氧消化产生的气体体积与VS降解呈正相关[40],预示着低温热水解预处理后,污泥具有更高的沼气产量。

2.2 厌氧消化过程中污泥脱水性能

对于不包含预处理过程的常规厌氧消化单元而言,消化产物的脱水性随着消化过程的继续而不断恶化[41],也有报道脱水性得到了改善[42]。其他研究人员发现了厌氧消化期间污泥的脱水性不稳定:出现一开始有所改善随后恶化[4],一开始恶化随后改善[43],或保持大致不变等情况[44]。但是,当超声波或低温热水解等预处理应用于厌氧消化时,普遍认为消化物的脱水性可以得到改善[6]。

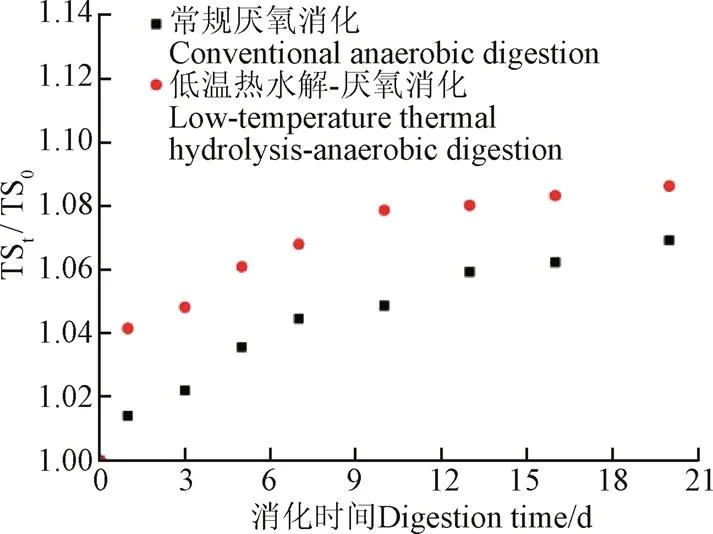

试验采用离心脱水的方法来评价厌氧消化对污泥脱水性的作用。随着消化过程的进行,消化污泥的脱水性随时间的改变如图2所示。

注:TS0是厌氧消化启动时,污泥离心脱水泥饼的固体含量;TSt是厌氧消化第t天,污泥离心脱水泥饼的固体含量。

由图2可知,消化污泥的脱水能力均随着消化持续时间的延伸而得到改善,这表明厌氧消化增强了污泥的脱水性。消化污泥中挥发性有机固体主要成分是多糖和蛋白质等物质,能够显著影响污泥网络强度和结合水含量[45],由于消化过程使得VS不断被溶解或去除,导致结合水得到释放,污泥结构变得更为松散流动性能加强,引起脱水能力的提升。Dai等[21]使用热重分析仪(纯氮气载气系统)测量了厌氧消化前后污泥中的水分分布情况,发现经过厌氧处理后污泥中的结合水和表面水的含量减少,而自由水和间隙水所占的比例增加,有利于脱水的进行。本试验在整个消化过程中,低温热水解-厌氧消化中TSt/TS0的值均高于常规厌氧消化,污泥低温热水解预处理厌氧消化后,较常规厌氧消化污泥的脱水性提高1.59%。

2.3 厌氧消化过程中污泥流变特性的改变

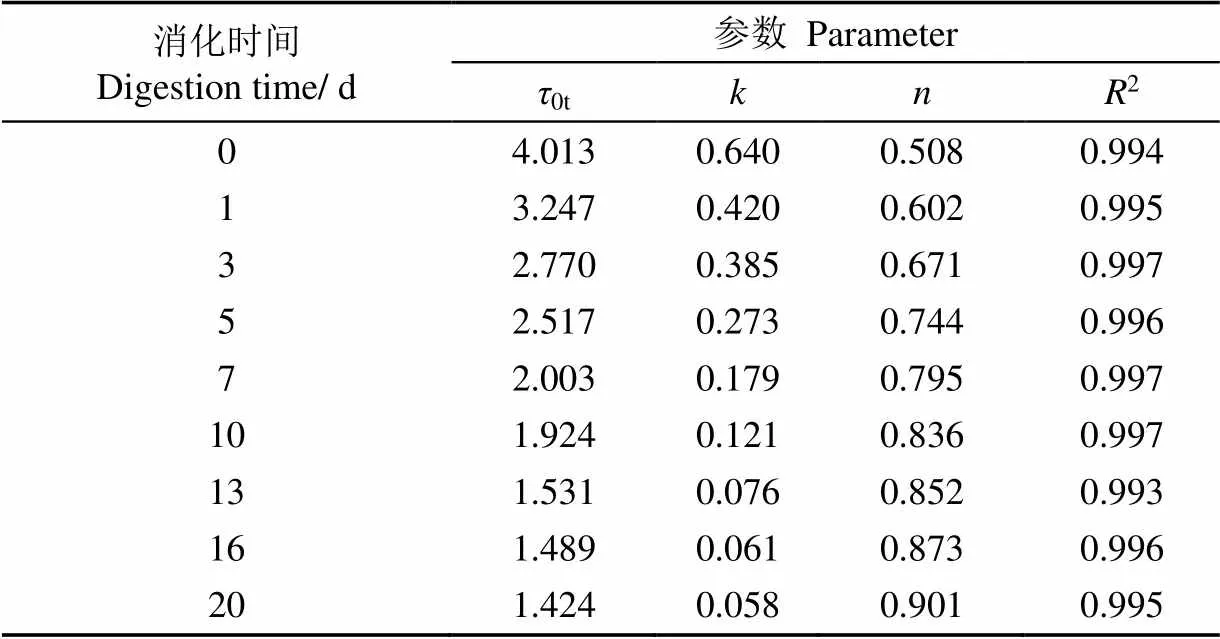

根据旋转粘度计法,获得在不同厌氧消化时间内污泥流动曲线图,使用 Herschel-Bulkley模型对污泥流动曲线进行拟合,拟合情况如表2和表3所示。

表2 常规厌氧消化污泥流动曲线H-B模型拟合

注:0t为厌氧消化第天污泥屈服应力,Pa;为流体稠度系数;为流动指数;2为拟合优度,下同。

Note:0tis the yield stress of sludge when anaerobic digestion in thedays, Pa;is dimensionless consistency coefficient;is consistency index;2is goodness of fit, the same below.

表3 低温热水解-厌氧消化污泥流动曲线H-B模型拟合

从表2和表3中可以看出,伴随厌氧消化持续时间的不断增长,屈服应力(0t)和流体稠度系数()不断降低,而流动指数()值持续上升,说明污泥经过厌氧消化后流动性变好。低温热水解-厌氧消化污泥和常规厌氧消化污泥在第20 天的屈服应力较在初始时的屈服应力分别了降低了64.51%和71.47%。经20 d厌氧消化后,低温热水解预处理厌氧消化污泥τ0t值较常规厌氧消化污泥减少42.41%。低温热水解-厌氧消化污泥和常规厌氧消化污泥在第20天的稠度系数()较在初始时的稠度系数分别了降低了90.94%和92.83%。经20 d厌氧消化后,低温热水解预处理厌氧消化污泥值较常规厌氧消化污泥减少24.13%。且整个厌氧消化过程中,低温热水解预处理污泥较传统常规污泥的流动性增强,可能是低温热水解-厌氧消化污泥较常规厌氧消化污泥VS去除率较高的原因之一。

研究表明固体含量是影响污泥流变性的一个最主要的因素[14,46],这是因为固体含量的增加可以减少污泥颗粒之间的距离,增加他们之间的相互作用,并随后增强污泥在受到剪切时的流动阻力[47]。伴随厌氧消化的进行,VS不断被降解去除,导致固体含量持续减小,这可能是引起污泥流动性能改善的主要原因。Dai等[21]揭示了厌氧消化处理可以改变污泥中的水分分布,使结合水和表面水的含量减少,同时增加了自由水和间隙水的含量,这也是引起污泥流动性改善的原因之一。

2.4 厌氧消化过程中污泥流变特性与理化指标关系

本研究中选择屈服应力作为考察厌氧消化过程的特征流变参数。同时,有针对地选择VS/TS比值作为监测消化进程的特征理化参数,探究消化过程中污泥的特征流变和理化参数间的关系。

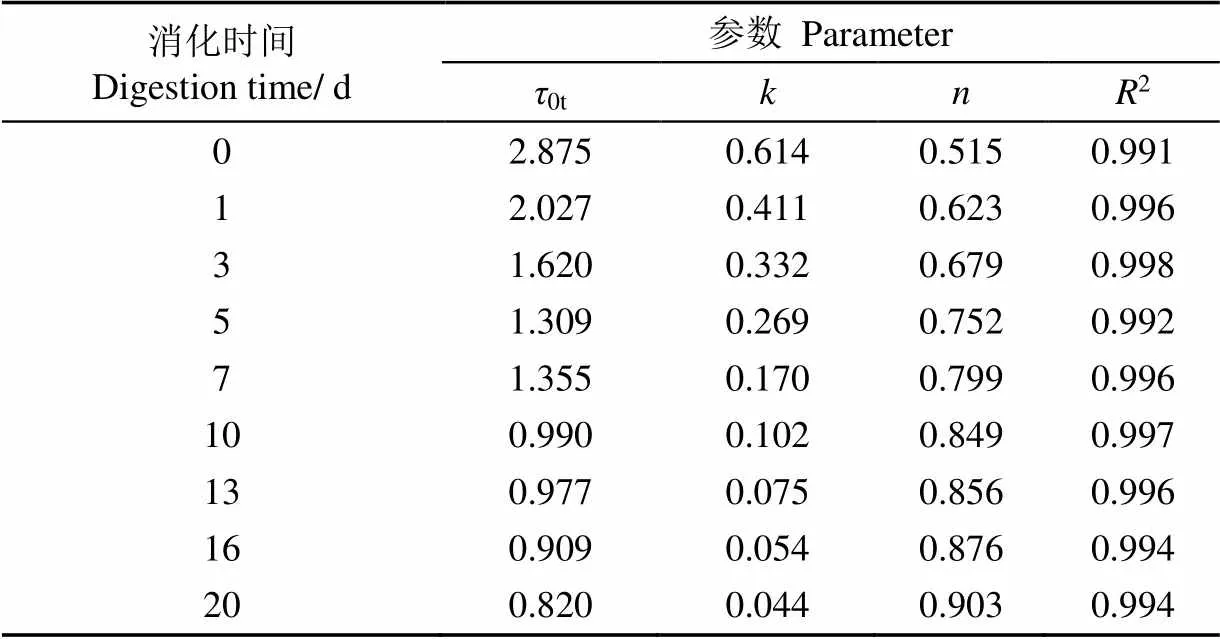

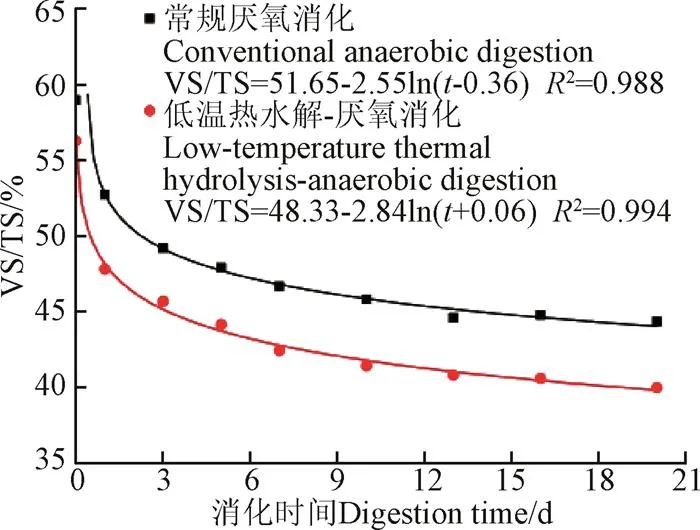

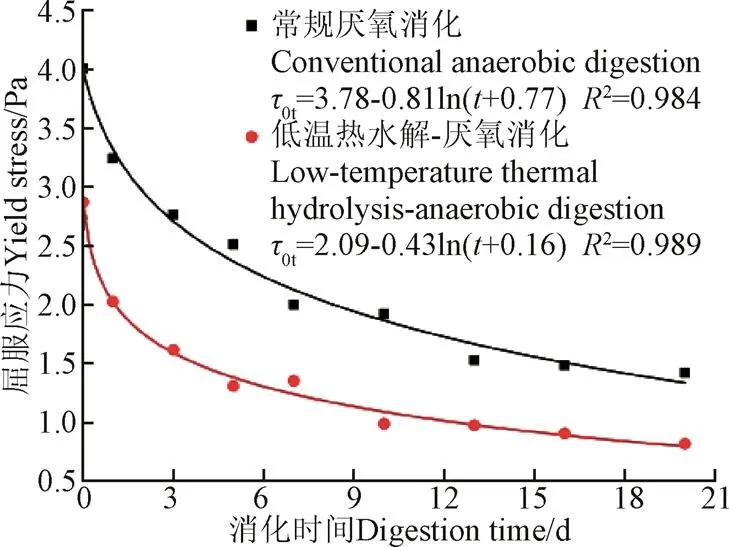

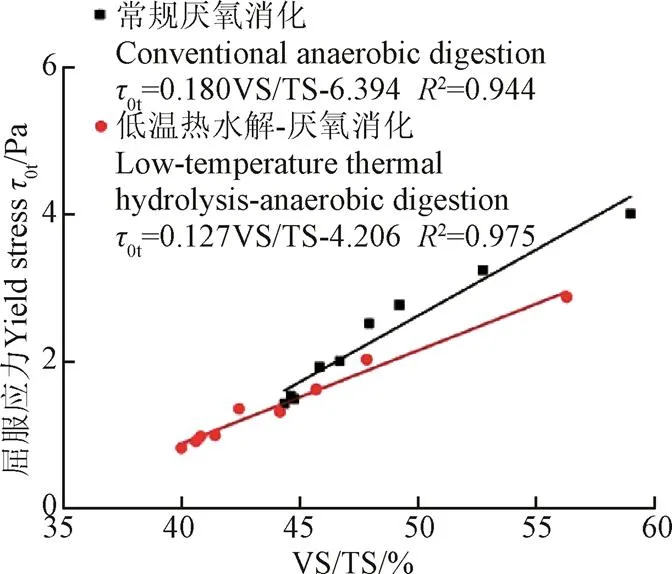

伴随消化过程的进行,污泥的VS/TS比值、0t(0t表示厌氧消化第天污泥屈服应力)随消化时间的改变分别如图3和图4所示。可以看出,在整个厌氧消化期间,VS/TS比值不断降低,同时屈服应力也不断减小。消化过程使VS不断被降解去除,造成系统内的TS含量的下降,而TS含量与屈服应力值呈正相关,从而引起消化过程屈服应力的降低。通过数据拟合,伴随消化过程中,污泥VS/TS比值与0t均大致遵循对数下降的趋势,拟合优度均达到0.98以上。对数方程拟合式如图3、图4所示。

图3 厌氧消化过程VS/TS的变化

图4 厌氧消化过程屈服应力的改变

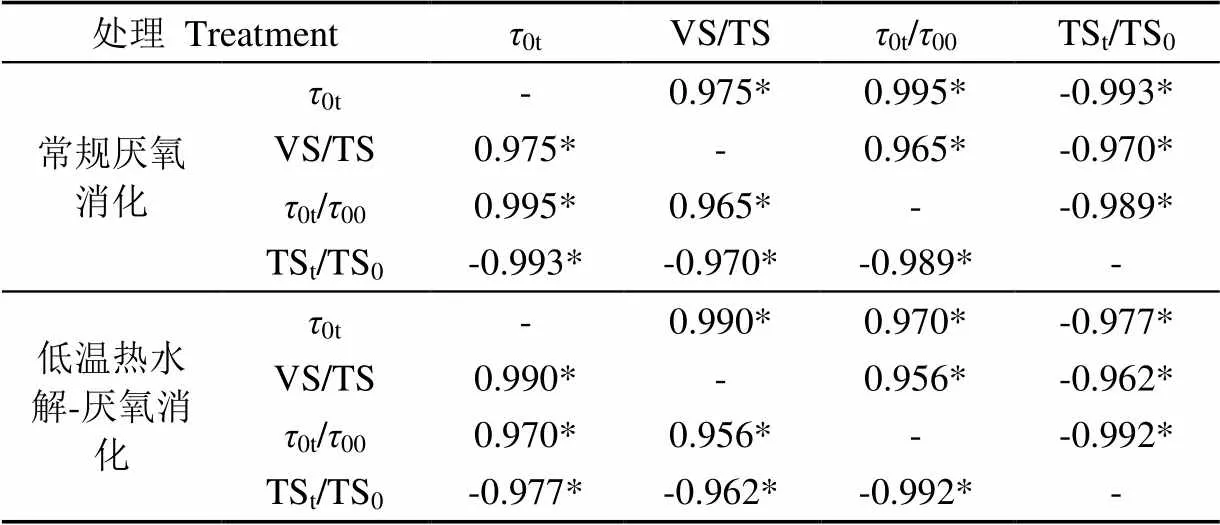

作对应不同消化时间的屈服应力(0t)和VS/TS比值的图,如图5所示。结果发现,0t和VS/TS之间存在着线性关系,拟合方程如图5所示,拟合优度2在0.94以上,表明污泥中的VS主要影响污泥0t,同时0t的改变也可以反映VS的变化。如图6所示,消化过程中污泥屈服应力变化(0t/00)和脱水性能(TSt/TS0)的改变存在线性关系,拟合方程如图6所示,拟合优度R2在0.97以上,表明0t/00与TSt/TS0具有很强的相关性。

图5 屈服应力τ0t和VS/TS关系

注:τ00为厌氧消化启动时污泥屈服应力,Pa。

为全面了解污泥流变性(0t、0t/00)和理化性质(VS/TS、TSt/TS0)之间的关系,使用Pearson相关性进行了总体交互作用的统计研究。统计概率是通过线性回归得到的,每个相关性的置信限度为95%。当值小于0.05时,验证各参数之间的相关性[48],结果如表4所示。

表4 不同污泥理化性质与流变性能皮尔逊相关性

注:*在0.01级别(双尾)相关性显著;(+):正相关;(-):负相关;

Note: *. Correlation is significant at the 0.01 level (2-tailed). (+) Positive correlation; (-) Negative correlation.

由表4可知,在常规厌氧消化污泥反应过程中,屈服应力与VS/TS(=0.975,<0.01)、0t/00与TSt/TS0(=−0.989,<0.01)两者之间有较强的相关性;在低温热水解-厌氧消化污泥反应过程中,0t与VS/TS(=0.990,<0.01)、0t/00与TSt/TS0(=−0.992,<0.01)两者之间有较强的相关性。表明在厌氧消化过程中屈服应力、屈服应力变化与污泥VS/TS、脱水性能具有较好的线性关系,建议实际工程中通过改变搅拌(包括机械搅拌、气体搅拌等)的速率,可控制反应器内部剪切应力;改善污泥厌氧消化性能;提高污泥脱水性能的效果。本文从流变学角度为厌氧消化过程中的监控和优化提供新思路和理论依据。

3 结 论

1)常规厌氧消化的最终VSr为44.6%,低温热水解-厌氧消化的最终VSr为48.3%,较常规厌氧消化污泥高3.7个百分点;在整个厌氧消化过程中,低温热水解-厌氧消化中TSt/TS0的值均高于常规厌氧消化,低温热水解预处理使得消化物的脱水性提高1.59%。表明低温热水解预处理有助于厌氧消化产气效率及污泥脱水性能的提高。

2)经低温热水解处理污泥,在整个厌氧消化过程中,污泥的0t值均小于常规厌氧消化污泥,表明低温热水解-消化污泥在厌氧消化过程中的流动性能优于常规厌氧消化污泥;常规厌氧消化和低温热水解-厌氧消化污泥结束后,其τ分别了降低了64.47%和71.51%;值分别减小了90.94%和92.83%,污泥流动性增强。

3)在整个消化过程中,VS/TS(volatile solids/total solids)和屈服应力随时间的变化均呈对数下降趋势;通过线性方程拟合和皮尔逊相关性统计研究表明,厌氧消化过程中,0t与VS/TS、0t/00与TSt/TS0两者间的拟合优度2均大于0.94,皮尔逊相关性分析表明在厌氧消化过程中屈服应力、屈服应力变化与污泥VS/TS值、脱水性能具有较好的线性关系。由于厌氧消化的复杂性,后续试验将采用相关试验和方法验证流变学指标作为监控优化指标的可行性;并进一步探究厌氧消化过程中污泥不同形态水分的变化规律与污泥流变学之间的关系,阐明厌氧消化过程中污泥流变学与脱水性能变化机理。

[1] 国家统计局,国家环境保护总局. 中国环境统计年鉴2017[M]. 北京:中国统计出版社,2017.

[2] 戴晓虎. 我国城镇污泥处理处置现状及思考[J]. 给水排水,2012,38(2):1-5.

[3] Chen S, Li N, Dong B, et al. New insights into the enhanced performance of high solid anaerobic digestion with dewatered sludge by thermal hydrolysis: Organic matter degradation and methanogenic pathways[J]. J Hazard Mater, 2018, 342(15): 1-9.

[4] Kopp J, Miiller J, Dichtl N, et al. Anaerobic digestion and dewatering characteristics of mechanically disintegrated excess sludge [J]. Water Science & Technology, 1997, 36(11): 129-136.

[5] 曹秀芹,袁海光,赵振东,等. 黄原胶溶液模拟消化污泥流动性能分析[J]. 农业工程学报,2017,33(15):260-265.

Cao Xiuqin, Yuan Haiguang, Zhao Zhendong, et al. Analysis on xanthan gum solution to simulate flow performance of digestion sludge[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(15): 26-265. (in Chinese with English abstract)

[6] Zhang J, Li N, Dai X, et al. Enhanced dewaterability of sludge during anaerobic digestion with thermal hydrolysis pretreatment: New insights through structure evolution[J]. Water Research, 2017, 131(15): 177-185.

[7] 陈文宾,胡庆昊,徐国想,等. 微氧预处理对有机废水厌氧消化产甲烷的影响[J]. 农业工程学报,2010,26(11):256-259.

Chen Wenbin, Hu Qinghao, Xu Guoxiang, et al. Effect of micro-aerobic pretreatment on anaerobic digestion of organic wastewaters for methane production[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(11): 256-259. (in Chinese with English abstract)

[8] Morgan-Sagastume F, Pratt S, Karlsson A, et al. Production of volatile fatty acids by fermentation of waste activated sludge pre-treated in full-scale thermal hydrolysis plants[J]. Bioresource Technology, 2011, 102(3): 3089-3097.

[9] Appels L, Degrève J, Bruggen B V D, et al. Influence of low temperature thermal pre-treatment on sludge solubilisation, heavy metal release and anaerobic digestion[J]. Bioresource Technology, 2010, 101(15): 5743-5748.

[10] Dieudé-Fauvel E, Héritier P, Chanet M, et al. Modelling the rheological properties of sludge during anaerobic digestion in a batch reactor by using electrical measurements[J]. Water Research, 2014, 51(15): 104-112.

[11] Wu B X. Computational fluid dynamics investigation of turbulence models for non-newtonian fluid flow in anaerobic digesters[J]. Environmental Science & Technology, 2010, 44(23): 8989-8995.

[12] Farno E, Baudez J C, Parthasarathy R, et al. Rheological characterisation of thermally-treated anaerobic digested sludge: Impact of temperature and thermal history[J]. Water Res, 2014, 56(2): 156-161.

[13] Nicky E, Flora M, Dong Y S, et al. Rheological characterisation of municipal sludge: A review[J]. Water Res, 2013, 47(15): 5493-5510.

[14] Urrea J L, Collado S, Laca A, et al. Rheological behaviour of activated sludge treated by thermal hydrolysis[J]. Journal of Water Process Engineering, 2014, 5: 153-159.

[15] Nicky E, Flora M, Paul S. The laminar/turbulent transition in a sludge pipeline[J]. Water Science & Technology A Journal of the International Association on Water Pollution Research, 2012, 65(4): 697-702.

[16] 曹秀芹,王鑫,蒋竹荷,等. 高含固污泥在热水解-厌氧消化工艺中的流变特性分析[J]. 环境工程学报,2017,11(4):2493-2498.

Cao Xiuqin, Wang Xin, Jiang Zhuhe, et, al. Analysis on rheological characterization of high solid sludge in process of thermal hydrolysis-anaerobic digestion[J]. Chinese Journal of Environmental Engineering, 2017, 11(4): 2493-2498. (in Chinese with English abstract).

[17] Kevin H, Ehsan F, Saeid B, et al. Rheological characterization of thermal hydrolysed waste activated sludge[J]. Water Res, 2019, 156: 445-455.

[18] Zhang J, Haward S J, Wu Z, et al. Evolution of rheological characteristics of high-solid municipal sludge during anaerobic digestion[J]. Applied Rheology, 2016, 26(3): 32937.

[19] Mori M, Isaac J, Seyssiecq I, et al. Effect of measuring geometries and of exocellular polymeric substances on the rheological behaviour of sewage sludge[J]. Chemical Engineering Research & Design, 2008, 86(6): 554-559.

[20] Pevere A, Guibaud G, Hullebusch E V, et al. Viscosity evolution of anaerobic granular sludge[J]. Biochemical Engineering Journal, 2006, 27(3): 315-322.

[21] Dai X, Gai X, Dong B. Rheology evolution of sludge through high-solid anaerobic digestion[J]. Bioresource Technology, 2014, 174: 6-10.

[22] Siles J A, Brekelmans J, Martín M A, et al. Impact of ammonia and sulphate concentration on thermophilic anaerobic digestion[J]. Bioresour Technol, 2010, 101(23): 9040-9048.

[23] 段妮娜,董滨,李江华,等. 污泥和餐厨垃圾联合干法中温厌氧消化性能研究[J]. 环境科学,2013,34(1):321-327.

Duan Nina, Dong Bin, Li Jianghua, et, al. High-solids anaerobic co-digestion of sludge and kitchen garbage under mesophilic conditions[J]. Environmental Science, 2013, 34(1): 321-327. (in Chinese with English abstract).

[24] Konrad K, Marc W, Manfred L, et al. Mono fermentation of grass silage by means of loop reactors[J]. Bioresource Technology, 2009, 100(23): 5934-5940.

[25] Hidaka T, Arai S, Okamoto S, et al. Anaerobic co-digestion of sewage sludge with shredded grass from public green spaces[J]. Bioresource Technology, 2013, 130(1): 667-672.

[26] Feng Guohong, Guo Yabing, Tan Wei. Effects of thermal hydrolysis temperature on physical characteristics of municipal sludge[J]. Water Science & Technology: A Journal of the International Association on Water Pollution Research, 2015, 72(11): 2018-2026.

[27] 陆军,陈洁,盛奎川,等. 超高压处理玉米醇溶蛋白的流变性和热特性分析[J]. 农业工程学报,2013,29(5):259-265.

Lu Jun, Chen Jie, Sheng Kuichuan, et, al. Rheological properties and calorimetric analysis on zein under high pressure treatment[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(5): 259-265. (in Chinese with English abstract)

[28] Feng G, Liu L, Wei T. Effect of thermal hydrolysis on rheological behavior of municipal sludge[J]. Industrial & Engineering Chemistry Research, 2014, 53(27): 11185-11192.

[29] Hong E, Yeneneh A M, Sen T K, et al. A comprehensive review on rheological studies of sludge from various sections of municipal wastewater treatment plants for enhancement of process performance[J]. Advances in Colloid & Interface Science, 2018, 257: 19-23.

[30] Fang W, Zhang P, Zhang G, et al. Effect of alkaline addition on anaerobic sludge digestion with combined pretreatment of alkaline and high pressure homogenization[J]. Bioresour Technol, 2014, 168: 167-172.

[31] Luo Qingming, Li Xiujin, Zhu Baoning, et, al. Anaerobic biogasification of NaOH-treated corn stalk[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2005, 21(2): 111-115.

罗庆明,李秀金,朱保宁,等. NaOH处理玉米秸秆厌氧生物气化试验研究(英文)[J]. 农业工程学报,2005,21(2):111-115. (in English with Chinese abstract)

[32] 韩玉伟. 北京城市污泥热水解:厌氧消化组合工艺效能研究[D]. 北京:北京工业大学,2016.

Han Yuwei. Efficicencies of Thermal Hydrolysis-Anaerobic Digestion of Municipal Sludge in Beijing[D]. Beijing: Beijing University of Technology, 2016. (in Chinese with English abstract)

[33] Jin R, Huang G, Ma C, et al. Ammonia inhibition of anaerobic digestion[J]. Industrial Water Treatment, 2010, 30(4): 9-12.

[34] 曹秀芹,柳婷,江坤,等. 低温热水解处理对污泥流变特性的影响[J]. 环境工程,2019,37(12):104-108.

Cao Xiuqin, Liu Ting, Jiang Kun, et al. Effect of low-temperaturethermal hydrolysis process on sludge rheology[J]. Environmental Engineering, 2019, 37(12): 104-108. (in Chinese with English abstract)

[35] Mccarty R L, Mckinney R E. Salt Toxicity in Anaerobic Digestion [J]. Water Pollution Control Federation, 1961, 33(4): 399-415.

[36] Lise Appels, Jan Degrève, Bart Van der Bruggen, et al. Influence of low temperature thermal pre-treatment on sludge solubilisation, heavy metal release and anaerobic digestion[J]. Bioresource Technology, 2010, 101(15): 5743-5748.

[37] Shanableh A, Jomaa S. Production and transformation of volatile fatty acids from sludge subjected to hydrothermal treatment[J]. Water Science & Technology, 2001, 44(10): 129-135.

[38] Bougrier C, Delgenès J P, Carrère H. Effects of thermal treatments on five different waste activated sludge samples solubilisation, physical properties and anaerobic digestion[J]. Chemical Engineering Journal, 2008, 139(2): 236-244.

[39] Habiba L, Hassib B, Moktar H. Improvement of activated sludge stabilisation and filterability during anaerobic digestion by fruit and vegetable waste addition[J]. Bioresource Technology, 2009, 100(4): 1555-1560.

[40] Xue Y, Liu H, Chen S, et al. Effects of thermal hydrolysis on organic matter solubilization and anaerobic digestion of high solid sludge[J]. Chemical Engineering Journal, 2015, 264: 174-180.

[41] Houghton J I, Quarmby J, Stephenson T. The impact of digestion on sludge dewaterability[J]. Process Safety & Environmental Protection, 2000, 78(2): 153-159.

[42] Li X Y, Yang S F. Influence of loosely bound extracellular polymeric substances (EPS) on the flocculation, sedimentation and dewaterability of activated sludge[J]. Water Res, 2007, 41(5): 1022-1030.

[43] Miron Y, Zeeman G, Lier J B V, et al. The role of sludge retention time in the hydrolysis and acidification of lipids, carbohydrates and proteins during digestion of primary sludge in CSTR systems[J]. Water Res, 2000, 34(5): 1705-1713.

[44] Jensen P D, Astals S, Lu Y, et al. Anaerobic codigestion of sewage sludge and glycerol, focusing on process kinetics, microbial dynamics and sludge dewaterability[J]. Water Res, 2014, 67: 355-366.

[45] Neyens E, Baeyens J. A review of thermal sludge pre-treatment processes to improve dewaterability[J]. J Hazard Mater, 2003, 98(1): 51-67.

[46] Cao X, Jiang K, Xin W, et al. Effect of total suspended solids and various treatment on rheological characteristics of municipal sludge[J]. Research on Chemical Intermediates, 2018, 44(6): 1-16.

[47] Tang B, Zhang Z. Essence of disposing the excess sludge and optimizing the operation of wastewater treatment: rheological behavior and microbial ecosystem[J]. Chemosphere, 2014, 105(4): 1-13.

[48] Miryahyaei S, Olinga K, Abdul Muthalib F A, et al. Impact of rheological properties of substrate on anaerobic digestion and digestate dewaterability: New insights through rheological and physico-chemical interaction[J]. Water Res, 2018, 150(1): 56-67.

Rheology and dewaterability of sludge during anaerobic digestion

Cao Xiuqin1,2, Wang Haoran2, Jiang Kun3, Liu Ting2, Zhu Kaijin4, Ren Xiaoli4

(1.100044;2.100044; 3.200070; 4.030008)

Biogas is one of the most hopeful renewable energy sources in the world. The anaerobic digestion (AD) process has been studied intensively over the last few decades, its application on biomass and solid waste digestion, as well as in wastewater treatment, agriculture. In order to gain a comprehensive insight, the interactive relationship between substrate rheology, physicochemical properties, and biogas production as well sludge dewaterability was investigated. Anaerobic digestion experiments were performed on conventional sludge and low temperature thermal hydrolysis pretreatment sludge. The experiment lasted for 20 days. Rheological indicators and physical and chemical indicators of conventional sludge and low temperature thermal sludge were determined by the rotational viscometer method and standard method during anaerobic digestion. The results showed that the pH value was maintained 6.8 to 7.9, which was within the allowable range of anaerobic digestion. The concentration of Free Ammonia (FAN) is between 10-130 mg/L, which was lower than the inhibition level of anaerobic digestion. The content of VFAs (Volatile Fatty Acid) in low temperature thermal hydrolysis sludge was higher than that in conventional anaerobic digestion sludge. The final Volatile solids removal level (VSr) of low temperature thermal hydrolysis-anaerobic digestion reached was 48.3%, and it was higher than conventional anaerobic digestion (44.6%). The dewaterability of sludge increased with the anaerobic time during the AD, andthe low temperature thermal pretreatment increased the dewaterability of digestion by 1.59%, which demonstrated the improved dewaterability of low temperature thermally hydrolysis treated sludge. After the conventional anaerobic digestion and the low temperature thermal digestion, the yield stress of the sludge decreased by 64.51% and 71.47%, respectively. The consistency coefficient decreased by 90.94% and 92.83%, respectively. It implied the sludge fluidity significantly enhanced.During the whole digestion process, the VS/ Total solids (TS) and yield stress (0t) showed a logarithmic downward trend with time. Using the linear equation fitting and Pearson correlation statistics analysis, the correlation between rheological (yield stress and yield stress change) and physicochemical parameters (VS/TS and dewaterability) were investigated. The results showed that all the goodness of fit (2) were greater than 0.94. During the whole conventional anaerobic digestion, the yield stress was positively and strongly correlated with VS/TS value (=0.975,<0.01), and the yield stress change was negatively and strongly correlated with dewaterability (=-0.989,<0.01). During low temperature thermal hydrolysis anaerobic digestion, the yield stress was positively and strongly correlated with VS/TS value (=0.990,<0.01), and the yield stress change was negatively and strongly correlated with dewaterability improved (=-0.992,<0.01). It is implied that there is a strong correlation between sludge yield stress and sludge VS/TS value. From the perspective of rheology, it provided the new ideas and theoretical basis for monitoring and optimization in the process of anaerobic digestion. In this study, the theoretical basis and feasibility of rheological control indicators for evaluating and monitoring low temperature thermal hydrolysis and anaerobic digestion processes (performance) were provided. Finally, the future work should focus on investigating the specific effects of specific ingredients (including polysaccharides, proteins, lipids, humic acids, glycoproteins, etc.) in EPS on sludge dehydration, and exploring the different forms of water in the sludge during anaerobic digestion, to reveal the relationship between the change law and sludge rheology, and clarifying the mechanism of sludge rheology and dehydration performance during anaerobic digestion. At the same time, the research on the influence of rheology on the level of chemistry and microorganism also needs to make progress.

sludge; anaerobic digestion; low temperature thermal hydrolysis; yield stress; dewaterability

2019-11-06

2020-02-20

北京建筑大学市属高校基本科研业务费专项资金资助(X18182),山西省重点研发计划项目(201803D31074)。

曹秀芹,教授,主要从事污泥及固体废弃物资源化利用、CFD 数值模拟等方面研究。Email:caoxiuqin@bucea.edu.cn

10.11975/j.issn.1002-6819.2020.05.027

X703

A

1002-6819(2020)-05-0233-08

曹秀芹,王浩冉,江 坤,柳 婷,朱开金,任晓莉. 污泥厌氧消化过程的流变规律与脱水性能[J]. 农业工程学报,2020,36(5):233-240. doi:10.11975/j.issn.1002-6819.2020.05.027 http://www.tcsae.org

Cao Xiuqin, Wang Haoran, Jiang Kun, Liu Ting, Zhu Kaijin, Ren Xiaoli. Rheology and dewaterability of sludge during anaerobic digestion[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(5): 233-240. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2020.05.027 http://www.tcsae.org