Local scour by multiple slit-type energy dissipaters *

2020-04-02LiYaoJianhuaWu

Li Yao, Jian-hua Wu

1. College of Water Conservancy and Ecological Engineering, Nanchang Institute of Technology, Nanchang 330099, China

2. College of Water Conservancy and Hydropower Engineering, Hohai University, Nanjing 210098, China

Abstract: Energy dissipation and scour control are all the key issues for the design of hydraulic structures. On the basis of the high energy dissipation for the multiple slit-type energy dissipaters (M-STED) developed by the authors, in this work, the characteristics of the scour hole for the M-STED were experimentally investigated through three sets of those physical models with five cases and a scour hole form index was proposed. The results show that, the M-STED results in not only the high energy dissipation but also the mild upstream slope of the scour hole thanks to the scour hole form index of larger than 0.5, which is in favor of the safety of the release works.

Key words: Energy dissipation, scour, scour hole form index, multiple slit-type energy dissipater

In order to carry out the high energy dissipation and effective scour control, many kinds of flip buckets of the outlets for the release works have been designed and used in the high dam projects. Where the change of the outlet width was concerned, all those flip buckets could be divided into three types, i.e.,constant width type, expansion or contraction type[1].The slot-type flip bucket[1-2]or partial-flip bucket[3-4]is just the new development of the constant width type ones, which produce significant extension of the flow in the direction of the flow through the buckets. The deflector[5-6], the flaring pier[7], the slit-type[8], or the beveled edge of the outlet[9], in the way of contraction or expansion of the flip buckets, aim at the increasing of the dimension of the flow, either in the flow section or in the flow direction. Thus, the energy of the flow is greatly dissipated due to the decrease of the average velocity of the flow section.

For the various flip buckets mentioned-above,many works have been conducted about the flow regime, the energy dissipation, and the jet trajectory etc.. The geometries of the flip buckets have been developed and improved in order to increase the energy dissipation. It is well known that, the local scour control of the river bed downstream of the release works is a serious concern when the energy of the flow is dissipated effectively[10]. The energy dissipation and scour control are the two different aspects of the design of hydraulic structures.

Slit-type energy dissipater (STED) has been widely used in many high dam projects thanks to the high energy dissipation and simple geometry[11]. On the basis of the hydraulic characteristics of the STED,a kind of the multiple slit-type energy dissipater(M-STED) was proposed[12]. The findings showed that the energy dissipation of the M-STED increased 5%than that of the STED under the same approach flow Froude number.

The objectives of the present work are: for the M-STED, (1) to experimentally investigate the local scour characteristics of the river bed downstream of the M-STED, (2) to present a scour hole form index according to the different scour hole form of the M-STED, and analyze the effects of the geometry of the M-STED and the flow conditions through the M-STED on the local scour by means of this index.

The scour tests were conducted in High-speed Flow Laboratory, Hohai University (Nanjing, China).Figure 1 is the definition sketch of the experimental setup and the geometry of the M-STED. Figure 2 give the photo of the experimental setup and the flow. The experimental setup consisted of a pump, an approach conduit, a large feeding basin, a test model, and a flow return system. The feeding basin issued an approaching (subscript o) flow of depth hoand average velocity Vo, resulting in the approach flow Froude number Fro= Vo/(gho)0.5. The discharges Q were measured with discharge measurement weir instruments. The maximum pump capacity was 400 L⋅s-1, and the working head Howas 1.50 m.

Fig. 1 Definition sketch of experimental setup, flow through M-STED and geometry of M-STED

Fig. 2 Experimental set-up

The test model, made of perspex, is an outlet with short pressure, included three parts with pressure flow section, free-surface flow section and outlet section with the energy dissipater (Fig. 1). It is 0.15 m wide and 1.13 m long with the horizontal bottom. The channel width of B = 0.15 m was reduced to b = 0.08 m in the edge of the outlet. c1= c2= hST/n, is the layer height of the slit, where hST= DOUT= 18.75×10-2m, is the total height for the M-STED and also the height of the pressure outlet, n is the number of layers with the height c1and c2, a2= (B - b)/2, and a1is the slit sizes,respectively. The tailwater channel was designed in 1.00 m wide and 7.30 m long.

The river bed was laid by the gravels of the median size d50= 0.03 m and the depth DRB= 0.50 m.The initial tailwater level hTW= 1.50×10-2m was kept by means of the tailgate placed in the tailwater channel. The local scour tests were conducted with test durations up to 2 h, or it is sufficient to reach an equilibrium bed condition depending on the single test[13].

The origin of the coordinate system (xoz) is at the tailwater channel bottom below the M-STED end (Fig.1(a)). The maximum (subscript m) depth Zmof the scour hole and its position xmwere measured with a point gauge. The test program included three sets of physical models with five cases, see Table 1.

Table 1 Case name and outlet geometry

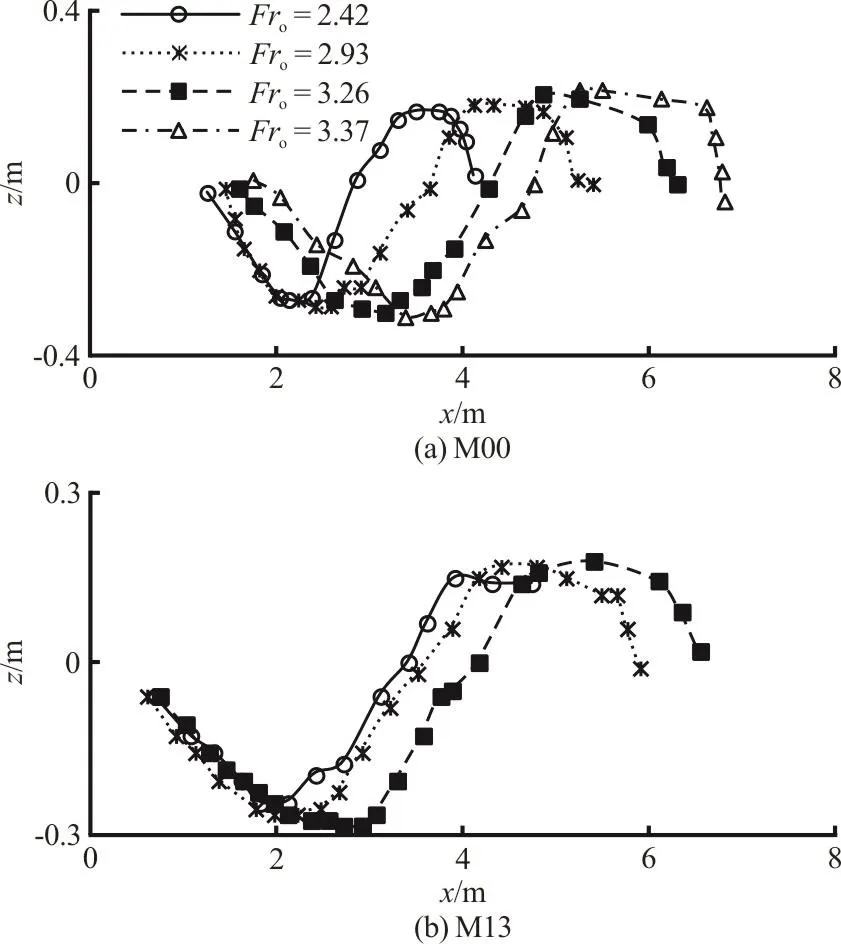

It could be seen that, the scour hole forms are closely related to the approach flow conditions and the geometric parameters of the outlets. Figure 3 show the effects of the approach flow Froude number Froon the scour hole forms for the two cases of the different outlet geometries, i.e., a1= 3.50×10-2m and n = 1 for M00 (Fig. 3(a)), and a1= 0 m and n = 12 for M13 (Fig.3(b)). Clearly, the maximum depth Zmand the position x1for their scour holes increase with the increase of the approach flow Froude number Frofor either M13 or M00. Those results should be dominated by the inertia force of the approach flow. The maximum depth Zmand the position xmbecome larger when the approach flow Froude number Froincreases, and then the inertia force of the approach flow increases.

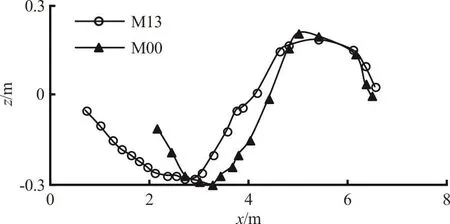

Meanwhile, some novel phenomena could be seen. Let us draw Fig. 4, which is the comparisons of the scour hole forms for the two different cases at Fro= 3.26, and its data derived from Fig. 3. Firstly, the maximum depth Zmand the position xmof the scour holes for M00 are larger than those for M13 at the same approach flow Froude number Fro. It means that the nappe from the flip bucket with single slit or called STED (i.e., M00) is of larger energy than that with multiple slits or called M-STED (such as M13).In other words, the flip bucket of the latter has much better effects of energy dissipation than that of former[12].

Secondly, it could be easily discovered that,where the position xm(Fig. 1(a)) was concerned, in the direction of the flow, the upstream and downstream slopes of the scour hole are of significant asymmetry for M-STED. The upper slope is mild, while lower one is relative steep. Those characteristics of the scour hole form with mild upper slopes support the base stability and then the safety of the release works.While the scour hole form is approximately symmetric for the structures of STED, i.e., single slit outlet, like M00. Clearly, there are the much more significant advantages for the M-STED than the STED.

Fig. 3 Effects of Fro on scour hole forms

Fig. 4 Comparisons of scour hole forms for two different cases(Fro = 3.26)

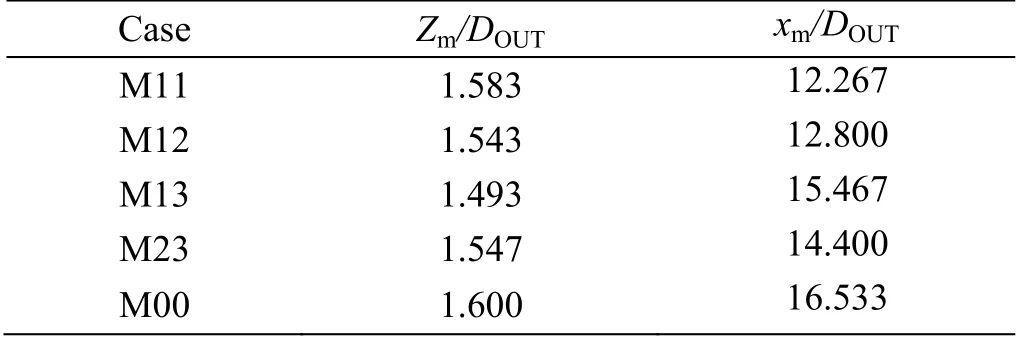

Table 2 gives the maximum depth Zmand the position xmof the scour holes at Fro= 3.26 for all the cases listed in Table 1, in which DOUT= 18.75×10-2m,is the outlet height of the pressure flow section for the physical test model. We can see that Zm/DOUTdecreases and xm/DOUTincreases when n increases or a1decreases. For the effects of n, considering cases M11-M13, the decrease of Zm/DOUTis dominated by the increase of the energy dissipation with the increase of n, while the increasing xm/DOUTmay be affected by the decreasing gravitational effect due to the increasing n, and then producing thinner nappe for each layer of the nappe.

Table 2 Scour hole characteristics (Fro = 3.26)

In particular, case M00, as a reference with the single slit or as a STED, has the largest Zmand xmin all the cases, in which the other cases are the outlet with the multiple slits or the M-STED. The results of case M00 means that, this case has the relative small energy dissipation comparing to the other cases, due to no multiple slits, and then no multiple layers of the nappe when n = 1. As a result, the relative large energy of the nappe produces large Zmand xmdue to the relative concentration of the flow and the weak air entrainment into the flow.

We have known that the scour hole form is of asymmetry of the upstream and downstream slopes for M-STED (see Fig. 4). In order to describe those kinds of the characteristics of the scour hole form for the outlet energy dissipaters with the different geometric parameters, a scour hole form index γ is constructed and can be defined as

where the parameter x1, xmand x2are the distances of the beginning, the maximum depth and the end of a scour hole in the direction of the flow, respectively(Fig. 1(a)), and γ = 0-1. Symmetric scour hole form appears when γ = 0.5, the upstream scour hole is mild slope if γ > 0.5, indicating that the release works are steady in this situation due to the mild upstream slope of the scour hole. While γ < 0.5 means that there is the steep upstream slope of the scour hole.

Figure 5 is the variation of γ with Frofor the two typical cases, i.e., M13 and M00, as the extreme structures at the aspects of both a1and n. Obviously, γ increases with the increase of Frofor either M13 or M00, however, γ of M13 due to its large slope increases much more rapidly than that of M00. It demonstrates clearly that the structure of the M-STED produces the milder upstream slope of the scour hole than that of the STED. Naturally, the value of γ, or the slope of the upstream slope, depends on the geometric parameters of the M-STED (or the STED), just like a1or n. Figure 6 is the variation of γ with a1(a) and n (b)at Fro= 3.26. γ decreases with the increase of a1at the same Fro(see Fig. 6(a)). In other words, γ gets to the maximum value when a1= 0, while γ tends to 0.5 when a1= a2, such as M00. Meanwhile, γ increases with the increase of n at the same Fro(see Fig. 6 (b)).Parameter n =1 is equal to a1= a2, in this situation,M-STED becomes back to STED.

Fig. 5 Variation of γ with Fro

Fig. 6 Variation of γ with (a): a1/Dout and (b): n at Fro = 3.26

In brief, the present work investigates experimentally the local scour hole forms and some characteristics of the M-STED, a kind of the outlet structure developed by the authors. Comparing with the outlet of the STED, the M-STED produces the weak local scour hole, and is of the large energy dissipation. Furthermore, the scour hole form index is proposed to describe the forms of the scour hole. As far as the M-STED, the scour form index of larger than 0.5 shows the mild upstream slope of the scour hole, which is in favor of the safety of the release works.

杂志排行

水动力学研究与进展 B辑的其它文章

- Liutex core line and POD analysis on hairpin vortex formation in natural flow transition *

- Numerical study on the bubble dynamics in a broken confined domain *

- Flow characteristics in open channels with aquatic rigid vegetation *

- A study of the evolution of nanoparticle dynamics in a homogeneous isotropic turbulence flow via a DNS-TEMOM method *

- Numerical investigation on the drag force of a single bubble and bubble swarm *

- Liutex-based vortex dynamics: A preliminary study *