Effect of 37Cl enrichment on neutrons in a molten chloride salt fast reactor

2020-03-19LiaoYuanHeGuangChaoLiShaoPengXiaJinGenChenYangZouGuiMinLiu

Liao-Yuan He· Guang-Chao Li· Shao-Peng Xia· Jin-Gen Chen·Yang Zou· Gui-Min Liu

Abstract A molten chloride salt fast reactor (MCFR) is well suited to fuel breeding and the transmutation of transuranium (TRU) elements owing to its advantageous features of fast neutron spectrum and high TRU solubility.However, the neutron absorption cross section of 35Cl is approximately 1000 times greater than for 37Cl, which has a significant impact on the neutron physical characteristics of a MCFR. Based on an automatic online refueling and reprocessing procedure, the influences of 37Cl enrichment on neutron economy, breeding performance, and the production of harmful nuclides were analyzed. Results show that 37Cl enrichment strongly influences the neutron properties of a MCFR.With natural chlorine, 233U breeding cannot be achieved and the yields of S and 36Cl are very high. Increasing the 37Cl enrichment to 97% brings a clear improvement in its neutronics property, making it almost equal to that corresponding to 100% enrichment. Moreover, when 37Cl is enriched to 99%, its neutronics parameters are almost the same as for 100% enrichment.Considering the enrichment cost and the neutron properties,a 37Cl enrichment of 97%is recommended.Achieving an optimal neutronics performance requires 99% 37Cl enrichment.

Keywords Molten salt reactor · Molten chlorine salt fast reactor · 37Cl enrichment · Th–U fuel breeding

1 Introduction

The molten salt reactor (MSR) was selected as one of the six candidate reactors by the Generation-IV International Forum (GIF) for its outstanding features in terms of inherent safety, economics, reliability, and proliferation resistance [1]. It is the only liquid fuel reactor in which molten salt serves as both the fuel and the coolant,implying that no fuel fabrication is needed and online fuel reprocessing can be implemented without stopping the reactor [2]. Furthermore, based on the thorium–uranium fuel cycle, fuel breeding is achievable in both thermal and fast MSRs, which can improve the utilization of nuclear fuel while lowering the production of long-lived radioactive transuranic elements, compared to the uranium–plutonium fuel cycle [3].

An MSR can use fluoride salt or chloride salt as a fuel carrier, depending on which of the two reactor types is considered, i.e., a molten fluoride salt reactor or a molten chloride salt fast reactor (MCFR). Owing to the high corrosiveness of the chloride salt, however, most pioneering studies have focused on molten fluoride salt reactors, such as the advanced high-temperature reactor (AHTR) in the USA [4], the molten salt actinide recycler and the transforming system (MOSART) in Russia [5], the FUJI series reactors in Japan [6], and the molten salt fast reactor(MSFR) in France [7]. However, several advantages are still worthy of consideration in assessing the MCFR concept [8]. First, the slowing down of neutrons in chloride salt is not as severe as in fluoride salt, which makes the energy spectrum much harder in a MCFR than in a fluoride salt reactor. This is significantly advantageous for the breeding performance of fissionable nuclides and the transmutation of transuranium elements in a chloride salt fast reactor. In addition, the extraction period of fission products (FPs) can be prolonged because of the small neutron absorption cross section under the fast spectrum in an MCFR. More importantly, the actinides are highly soluble in chloride salt.A large amount of heavy nuclides can therefore be loaded into the chloride salt, which further contributes to the breeding performance and transmutation capacity of an MCFR.

Research into chloride salt reactors began in the 1950s at the Oak Ridge National Laboratory(ORNL).The MCFR concept was then proposed, involving NaCl+MgCl2+PuCl3+UCl3as the fissile fuel salt and UO2+Na as the solid breeding layer [8]. The breeding ratio (BR) was evaluated as 1.09, which served as a preliminary proof of the feasibility of fuel breeding using chloride salt in fast reactors.In the 1960s,the British Atomic Energy Authority also carried out research into MCFRs [9],in which NaCl+UCl3+PuCl3was used as the fuel salt and NaCl+UCl3as the breeding salt.The evaluated BR attained 1.53,which further proved the aptitude of MCFR for fuel breeding.Chloride salt fast reactors are presently receiving increasing attention worldwide. The Moltex [10] and DFR [11]conceptual designs have been proposed in Britain and Germany, respectively. TerraPower in the USA is also involved in the design of a simple and safe chloride salt fast reactor [12].

In 2011, the Strategic Project ‘‘Future Advanced Nuclear Energy–Thorium-based Molten Salt Reactor System (TMSR)’’ was launched by the Chinese Academy of Sciences (CAS). Its aim was to address the key technical issues of TMSRs and realize the efficient utilization of thorium [13]. Studies were carried out to assess the approaches to thorium fuel utilization for various MSRs,including fuel breeding in a FLiNaK MSFR [14], in an improved MSFR (IMSFR) [15], in a single-fluid doublezone thorium molten salt reactor(SD-TMSR) [16],and in a MCFR [17]. The MCFR results show that the molten chloride salt contributes to the fuel breeding performance and that NaCl is a more suitable carrier salt than other chloride salts because of its high TRU solubility.However,some problems remain to be addressed in MCFR design [18]. One of these relates to the high corrosiveness of chloride salt, which implies the need for the development and testing of structural materials suitable for providing reliable MCFR components such as the core vessel,pipes,pumps,and heat exchangers.Another issue concerns the35Cl atomic-number ratio in chloride. The neutron capture cross section is much greater for35Cl than for37Cl,implying a deterioration of the breeding performance and of the neutron economy of the MCFR. Furthermore,35Cl reacts by (n,γ) to form36Cl, which has a long half-life of 301,000 years and is easily soluble in water. Fuel salt leaking is consequently a significant human-health and environmental hazard.35Cl can also absorb a neutron to form sulfur [19], which can penetrate the alloy surface,thereby causing sulfur brittleness and hence affecting the mechanical properties of the structural materials. The influences of37Cl enrichment on the operation of MCFR must therefore be investigated.

In this study, different levels of37Cl enrichments,varying from 24.23 to 100%, were analyzed based on the MCFR. A general description of the MCFR and the calculation tools are provided in Sect. 2. In Sect. 3, the influences of37Cl enrichment are discussed from the viewpoint of the breeding performance at startup and of depletion over up to 100 years. The results, including the BR, the net production of233U, the doubling time (DT),and the production of36Cl and S are exhibited.In addition,two safety parameters for all the cases,i.e.,the temperature coefficient of reactivity (TCR) and the decayed neutron fraction (βeff) are also discussed. Finally, conclusions are given in Sect. 4.

2 General description of the MCFR and analysis methodology

2.1 General description of the MCFR

The MCFR model used in this paper is a non-moderate d chloride molten salt reactor, which is obtained by modifying the MSFR conceptual design [7, 20]. As shown in Fig. 1, there are two molten salt zones in the MCFR,namely the fuel zone and the fertile zone. The fuel zone(the red area in Fig. 1) consists of the active core, the surrounding primary circuit pipe, the heat exchangers, etc.The active core is a compact cylinder with equal diameter and height.The liquid fuel salt is pumped through the core from the bottom to the top and then to the heat exchangers.During this flow, the nuclear heat is transferred from the active core to the heat exchangers and then to the secondary loop. The fertile zone surrounds the active core in both the radial and axial directions and has a thickness of 70 cm(the blue area in Fig. 1).The fuel salt and the fertile salt are separated by a Ti-based alloy of thickness 2 cm.The activation products of the alloy in a fluoride-saltcooled high-temperature reactor (FHR) have been studied [21], but further study is still needed in a MCFR to confirm its stability and safety. The graphite reflector surrounding the fertile salt (the yellow area in Fig. 1) is adopted for fertile fuel saving [22]. Outside the graphite reflector,a 10-cm-thick B4C layer(the green area in Fig. 1)is arranged for the purpose of absorbing small amounts of neutrons leaking from the reactor. The outermost layer is also made of Ti-based alloy and serves as a supporting structure.

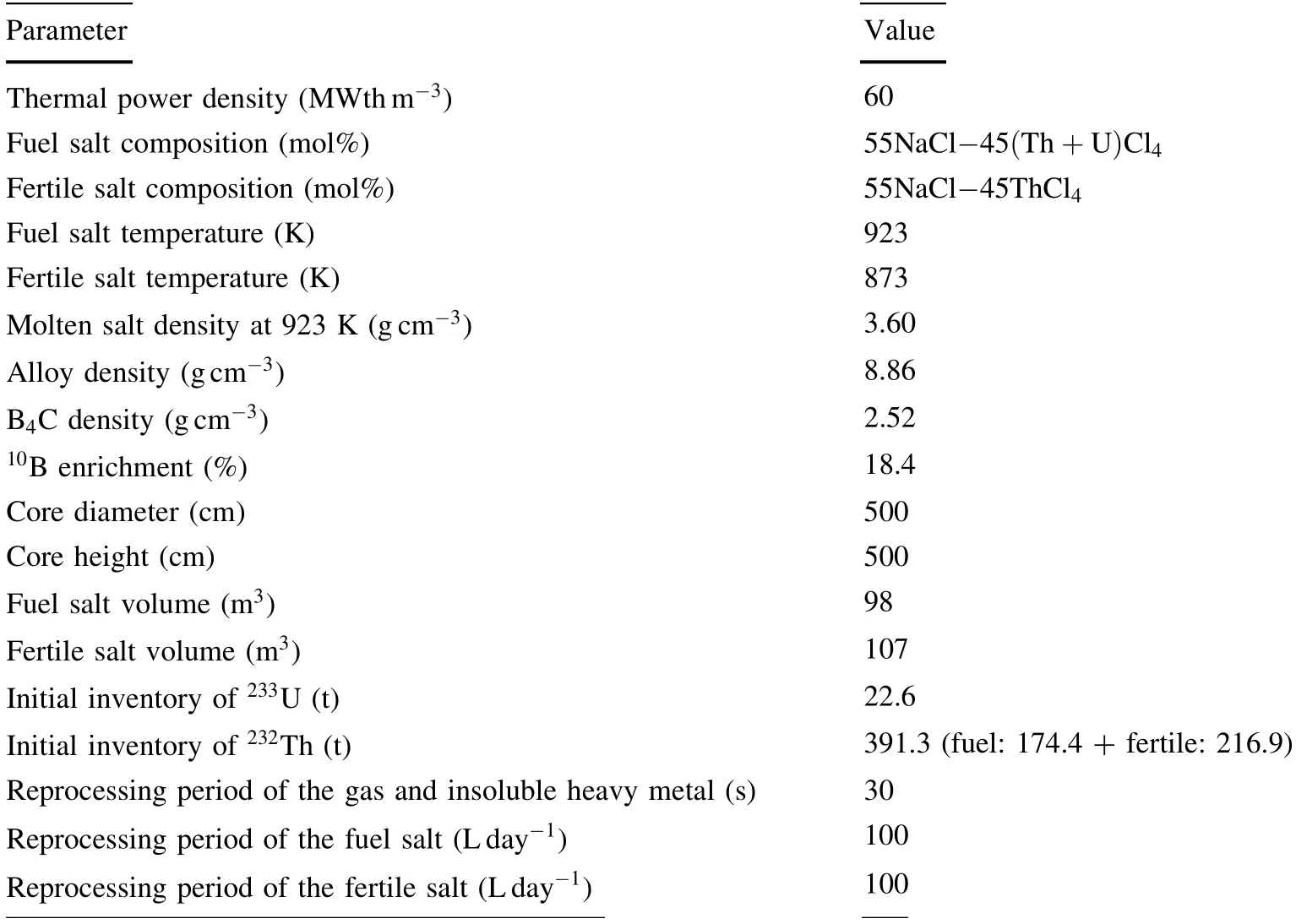

The MCFR operates with a thermal power density of 60 MWth m-3and the mean fuel temperature is 923 K. The main parameters are listed in Table 1. The fuel salt is 55NaCl-45(Th+U)Cl4in mol%, while the fertile salt is 55NaCl-45ThCl4. The Th and U in the fuel salt are232Th and233U, respectively, and their ratio is adjusted so as to maintain the reactor criticality. Because of the small difference in atomic mass between232Th and233U, the fuel salt and the fertile salt have the same density 3.6 g cm-3.There are two noteworthy and important differences between a MCFR and the MSFR. Firstly, the carrier salt changes from LiF for a MSFR to NaCl for a MCFR. The second difference relates to the proportion of heavy metal in the molten salt. (Th+U)Cl4can dissolve to a concentration of 45 mol% in chloride salt, while (Th+U)F4attains only 22.5 mol% in LiF, owing to the higher solubility of actinides in the chloride salt than in the fluorine salt.

2.2 Reprocessing scheme

Online reprocessing and refueling are two outstanding features for MSRs compared with traditional solid-fuel reactors. FP extraction constitutes a significant advantage to the neutron economy and to Th–U fuel breeding, while233U fuel could be added into the core without stopping the reactor,which would be beneficial for decreasing the initial excess reactivity and the initial loading of nuclear fuel. In addition,fertile232Th is added online to maintain the heavy metals at a constant level, and233Pa is also extracted to reduce its neutron absorption. Both of these actions are beneficial to the Th–U breeding performance.

The reprocessing diagram shown in Fig. 2 refers to a MSFR [20, 23]. There are two key processes in the extracting system. The first is the He gaseous bubbling system, which extracts FPs and non-dissolved metals (H,He,N,O,Ne,Ar,Kr,Xe,Rn,Zr,Ga,Ge,As,Nb,Mo,Tc,Ru, Rh, Pd, Ag, Cd, In, Sn, and Sb) mechanically. The removal period is set to 30 s in the calculation.The second is online pyrochemical reprocessing,which extracts soluble FPs from the bypass circuit. UCl3and PuCl3are first oxidized to UCl6and PuCl6, respectively, which can be removed in gas form from the liquid salt by distillation;they are reinjected into the core after distillation. Then,most actinides, including Th, Pa, and minor actinides(MA), are extracted by reductive extraction and stored in the stockpile for several months to allow233Pa to decay into233U.Finally,the carrier salt is recovered through lowpressure distillation technology, leaving the FPs for disposal. At this stage, some of the233U is refueled into the core to maintain criticality and any remainder constitutes the net233U production. The chemical reprocessing rate is set to 100 L day-1, which is much lower than the processing rate of 4600 L day-1in a TMSR with a thermal spectrum [23].Considering the fuel salt and the fertile salt volumes of 98m3and 107m3, the corresponding reprocessing periods are set to 980 days and 1070 days,respectively.

Table 1 Main parameters of the MCFR

2.3 Calculation tool

SCALE6.1 is a comprehensive code package developed by ORNL, which can be used to analyze criticality safety,burn-up, radiation shielding, radioactive source terms,sensitivity, and uncertainty [24]. In this study, the CSAS module was used for the criticality calculation, while TRITON served for the problem-dependent cross-section processing and the multi-group neutron transport calculation. KENO-VI was suitable for the transport calculation.Other modules, such as CENTRM/PMC and BONAMI,were also invoked as required when used to process the cross sections in the resolved and unresolved resonance energy regions, respectively. The ORIGEN-S module was used for the time-dependent depletion and decay calculations in SCALE 6.1. However, it was replaced with MODEC in this study, which can accurately track the evolution of nuclides inside and outside the core. The MODEC program, which includes a high-precision fuelconsumption solver based on the Chebyshev Rational Approximation Method (CRAM) and the improved Transmutation Trajectory Analysis (TTA), ensures the accuracy of the calculation [25]. It considers the unique fuel-consumption characteristics of a liquid MSR and introduces the pseudo-decay factors for online post-treatment. To deal with the non-homogeneous term for the continuous feeding characteristics of liquid MSR, the program adopted two optional methods of numerical integration and augmented matrix to extend the CRAM solver,and the TTA solver was extended by the pseudo-nuclear method to increase the calculation accuracy.

To simulate the special burn-up mode of a MSR(online reprocessing), the in-house program TMCBurnup was developed according to the flowchart in Fig. 3. First, the parameters of the molten salts and the core geometry are input for initialization. Second, the neutron transportation and depletion are calculated by the TRITON and MODEC modules, respectively, where Pa and FPs are extracted from both the fuel and fertile salts. Third, the233U and Th heavy metals are injected into the molten salt to keep the total inventory of actinides constant to maintain the stability of the molten salt, and the molar fraction ratio of233U and Th is adjusted to maintain the reactor’s criticality.In this study, the effective multiplication factor (keff) was set to 1.005±0.005 throughout the operation.The number of neutrons per keffcycle was 10,000. The first 15 keffcycles were skipped to allow the spatial fission source to settle to an equilibrium before obtaining the final keffestimate by averaging. In total, 285 keffcycles were executed in the criticality calculation,with an average error of approximately 25 pcm. To verify the TMCBurnup simulation of a fast MSR,we tested it on the basis of the MSFR concept and compared the neutronics parameters such as the evolution of nuclides and the BR in a MSFR using reference values [7].The comparisons,displayed in Figs. 4 and 5, show that the TMCBurnup results agree well with the reference values, which proves the reliability of TMCBurnup for calculations for a MSFR.

3 Results and discussion

This section investigates different37Cl enrichments,ranging from natural enrichment (24.23%) to 100%, based on the MCFR. The results corresponding to the range 95–100% (especially 97–100%) are very similar, as displayed by the near overlap of the data in the figure. For clarity,only seven representative lines are plotted.The calculation results corresponding to different37Cl enrichments are listed in Tables 2 and 3. First, the233U concentration and the BR at startup are given in Sect. 3.1, followed by the excess reactivity and the operation period without processing in Sect. 3.2. Then, the breeding performance with online reprocessing and the production of36Cl and S are given in Sects. 3.3 and 3.4,respectively.Finally,the safety parameters, including TCR and βeff, are presented in Sect. 3.5.

3.1 233U concentration and the BR at startup

Online refueling allows the critical state to be maintained by adjusting the molar concentration of233U.Therefore, the critical concentration of233U at startup was explored first for different core radii and37Cl enrichments.For Th–U fuel cycle starting with233U and232Th,the BR is defined as [26]:

where Raand Rcdenote the neutron capture and absorption rates, respectively. This equation is applied to the calculation for a total BR in core and blanket.At startup,the BR can be simplified as:

Table 2 Breeding parameters for different 37Cl enrichments

Table 3 Production of 36Cl and S for different 37Cl enrichment

It should be noted that the initial BR is oversimplified.However, for an MSR with a given reprocessing rate, a greater initial BR also implies a greater BR at equilibrium.Thus, Eq. (2) is still used in this subsection to predict a suitable geometry with a large BR, and the actual233U production is analyzed according to mass evolution in Sect. 3.3.

The initial233U concentration and the BR are plotted as functions of the core radius in Fig. 6a, b, respectively. For a certain37Cl enrichment, the233U concentration clearly decreases while BR increases with increasing core radius when the radius is less than 250 cm, resulting from the decrease in neutron leakage when the core increases. In other words, an increase in core radius contributes to a decrease in neutron leakage from the fuel salt, and therefore less233U is needed to maintain the reactor in a critical state.Simultaneously,more neutrons are absorbed by232Th for fuel breeding, while the neutron absorption of233U remains nearly constant because of the adjustments of the233U molar fraction to maintain criticality.Thus,according to Eq. (1), the BR increases with increasing core radius.

When the radius exceeds 250 cm, both the233U concentration and the BR remain nearly constant, signifying that the core is sufficiently large and neutron leakage from the fuel salt is sufficiently low. Furthermore, the dependences of the233U concentration and of the BR on the core radius show almost the same trends for other37Cl enrichments.Therefore, the following study was performed with a core radius of 250 cm.

For a certain core radius, the233U concentration is also seen to decrease and the BR to increase with increasing37Cl enrichment. The reason is that the neutron absorption rate of35Cl decreases with increasing37Cl enrichment (as shown in Fig. 7)and more neutrons are absorbed by232Th and233U. This is helpful for fissile fuel saving with the increase of37Cl enrichment in the carrier salt. When the37Cl enrichment is greater than 97%, the neutron absorption of35Cl is very small, which has little impact on neutron economy and the breeding performance.

3.2 Excess reactivity and operation period without processing

As mentioned above, for a given core radius, different37Cl enrichments correspond to different233U concentrations. To explore the neutron characteristics without postprocessing, the233U concentration was fixed to 5.0 mol%,the critical value for chloride salt with natural enrichment.Then,the effect of37Cl enrichment on the initial reactivity and full-power operation period was analyzed (as reported in this subsection). The result with online processing is given in the next subsections.

The initial excess reactivity is plotted as a function of37Cl enrichment in Fig. 8. When the37Cl enrichment is 24.23% (natural chloride), the initial excess reactivity is 122 pcm, and it increases to approximately 15,823 pcm when the37Cl enrichment is 97%. The reason is that the neutron absorption cross section of35Cl is very large.With increasing37Cl enrichment, the35Cl content and hence its neutron absorption rate decrease. Thus, the neutron utilization efficiency improves, which in turn results in an improvement of the excess reactivity. When the37Cl enrichment increases to 100%, the initial excess reactivity equals 15,858 pcm. This value is almost equal to that corresponding to 97% enrichment, since the35Cl content and its corresponding neutron absorption rate are very low and the excess reactivity is less affected by increasing37Cl enrichment. Besides, the keffevolution under full-power operation without post-processing is shown in Fig. 9. The operation period is only 175 days when the37Cl enrichment is 24.23%, and it increases to 2245 days when the enrichment is 97%, which is almost the same as for 100%enrichment.The trend followed by the full-power operation period with respect to increasing37Cl enrichment is very similar to that of the initial excess reactivity. This is also because a decrease in35Cl leads to a decrease in its neutron absorption, which further improves the neutron utilization efficiency in the active core and then extends the fullpower operation period.When the37Cl enrichment exceeds 97%,the operation period remains almost constant because the neutron absorption of35Cl is sufficiently low.

3.3 Breeding performance with online reprocessing

This subsection explores depletion with online reprocessing from the perspective of the BR, the net production of233U, and the doubling time (DT), three important parameters for evaluating the fuel breeding performance in a MSR. As explained in Sect. 2.2, with online reprocessing,233U can be added into the core to maintain criticality without stopping the reactor, such that keffcan be maintained between 1.000 and 1.005 throughout the operating time.The parameters that reflect the breeding capability of a MCFR include M0, the DT, and the average annual production of233U for different37Cl enrichments, and are listed in Table 2.

Under this condition, the BR is obtained using Eq. (1),as displayed in Fig. 10.37Cl enrichment clearly plays an important role in the evolution of the BR.Figure 10 shows that,for a given37Cl enrichment,the BR increases slightly over time, in contrast to a thermal reactor like a MSBR.This is due to the accumulation of234U, which has a large neutron fission cross section under a fast spectrum and provides additional neutrons for nuclear fuel breeding. In addition, the FPs produced during the operation have a much smaller absorption cross section in a MCFR than in a thermal reactor, which implies little impact on the MCFR breeding capability. Besides, when chloride with a natural enrichment level is adopted, the BR is even less than 1.0,meaning that more fissile fuel is consumed than produced,and fuel breeding cannot be realized. Increasing37Cl enrichment can improve its BR significantly. When37Cl enrichment increases to 97%, the BR can be improved to 1.299, which is only 0.6% lower than for 100%37Cl enrichment.

The net annual production of233U was then explored since it is the dominant fissile material in the Th–U fuel cycle. Because of the online reprocessing,233Pa could be extracted from the active core and from the fertile salt to decay into233U.The233U obtained from the decay of233Pa in the fertile salt was also extracted. The extracted233U was partially refueled into the active core to ensure criticality. Thus, the annual net production of233U can be expressed as [26]:where the subscripts ex and re denote extraction and refueling, respectively.

The annual net production of233U is plotted in Fig. 11,and shows that37Cl enrichment also has a significant impact. When the chloride at the natural enrichment level is adopted, the net production of233U is negative, signifying that fuel breeding cannot be realized without enriching37Cl.When37Cl enrichment increases from 96 to 97%,the annual net233U production increases by 7 kg,the same result as by increasing37Cl enrichment from 97 to 100%. In addition, the annual net233U production of the 99%37Cl enrichment is 283 kg·a-1, which is almost the same as for 100% enrichment.

When the net production of233U (M) equals the initial inventory of233U (M0), the fissile fuel doubles. This is sufficient for starting a new MCFR, and the corresponding time is the doubling time.Table 2 shows that the DT of the MCFR is much longer than that of the MSFR (48 years),owing to its larger core volume and the larger initial inventory of233U. When the37Cl enrichment increases from 96 to 97%, the DT decreases by 2.05 a, which is slightly greater than the decrease in DT resulting from increased37Cl enrichment from 97 to 100%.When the37Cl enrichment increases to 99%,the DT is shortened to 62.93 a, which is only 0.3% longer than the DT for 100%37Cl enrichment.

In summary,the results for the BR,the net production of233U, and the DT all display very similar trends. When using natural chloride salt,233U breeding cannot be realized owing to the high neutron absorption rate of35Cl.When the37Cl enrichment is increased, its breeding performance displays a clearer improvement. When the enrichment increases to 97%, its breeding performance is very close to 100%. When it is enriched to 99%, its breeding capability is almost the same as for 100%.

3.4 Production of 36Cl and S

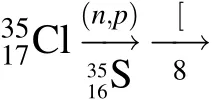

Because of the neutron absorption of35Cl, S and36Cl are generated through the reactions of (n,γ), (n, p) and(n,α) [19], as shown in Fig. 12. Element S can cause‘‘sulfur cracks’’that corrode the structural material.36Cl is a long-lived radionuclide that is easily soluble in water [8]and a leak would be toxic to human health and the environment. Thus, it is necessary to reduce the production of these two elements.

The impact of37Cl enrichment on the production of S and36Cl was determined, giving the results shown in Fig. 13. The S and37Cl contents after 100 years are listed in Table 3.It appears that the buildup of S and36Cl is much faster when natural chloride salt is used. After 100 years,the S and36Cl contents reach approximately 802 and 948 ppm, respectively, but only approximately 30 and 36 ppm in the case of 97%37Cl enrichment. When the37Cl enrichment increases to 99%, the S and36Cl contents are 12 and 13 ppm, respectively, nearly equal to the values corresponding to 100%enrichment,namely 9 and 11 ppm.From the perspective of reducing the production of harmful isotopes and ensuring the normal operation of the reactor,37Cl also needs to be enriched. When the enrichment of37Cl increases from 96 to 97%, the S and36Cl contents after 100 years decrease by 30 and 26 ppm, which is slightly more than the decrease caused by an increased37Cl enrichment from 97 to 100%. When the37Cl enrichment increases to 99%, the production of harmful isotopes is almost the same as for 100% enrichment.

3.5 Safety parameters

This subsection investigates two safety parameters,namely the temperature coefficient of reactivity(TCR)and the delayed neutron fraction (βeff).

For safety reasons, the TCR must be kept negative during the reactor’s operation. For an MSR, it is a comprehensive effect containing the fuel temperature coefficient (FTC) and the moderator temperature coefficient(MTC), while the FTC consists of the fuel density coefficient and the fuel Doppler coefficient.Given the absence of a moderator in a MCFR, the TCR is defined as:

where K and T represent the effective multiplication factor and the fuel salt temperature, respectively.

The evolution of the TCR over time under different37Cl enrichments is plotted in Fig. 15. For a given depletion time,the absolute value of the TCR for natural chloride salt is much smaller than that for 100%37Cl enrichment owing to the large neutron absorption cross section of35Cl.When the37Cl enrichment exceeds 70%, the temperature coefficient is negative and varies within a small range.

Additionally, Fig. 15 shows that, for a given37Cl enrichment,the TCR increases during the first 20 years as a result of the accumulation of FPs,which causes an adverse effect on the negative feedback of the temperature. Then,the amount of FPs remains constant because of the online reprocessing, so that the TCR also remains nearly unchanged over the subsequent 80 years. However,regardless of the changes in enrichment, the TCR can remain sufficiently negative over 100 years of operation,thereby ensuring the safe operation of the MCFR.

Another important parameter for ensuring the reactor’s safety is βeff, which is mainly driven by the delayed neutron fraction of fissile nuclides. It is defined as:

The evolution of βeffover time,given in Fig. 16,shows that,for a given depletion time,βefffor natural chloride salt is less than for 100%37Cl enrichment. This phenomenon originates from the differences in the fission fraction of fissile nuclides under different37Cl enrichments. This is further studied and exhibited as follows.

For simplicity,only two cases are shown.The solid lines in Fig. 17 represent the fission rate fraction of fissile nuclides for a 24.23%37Cl enrichment, while the dashed lines represent that for 97%37Cl enrichment. The fissile nuclides, including233U,235U,241Pu,239Pu, and234U, are all considered for their high content and large fission cross section under the fast spectrum [27]. The single delayed neutron fractions of233U,234U,235U,241Pu, and239Pu in the MCFR spectrum are 291, 531, 668, 543, and 219 pcm,respectively. The fission rate fraction of233U decreases while that of the other fissile nuclides especially234U and235U increases during operation. Thus, their total βeffincreases during operation.

For a given time of depletion, βeffis greatest when the37Cl enrichment is 100%,owing to the smallest fission rate fraction of233U. But βefffor different37Cl enrichments increases less than 5 pcm over 100 years of operation,because233U has a dominant fission fraction during 100 years of operation. Thus, no significant problem would be posed to the reactor’s safety with regard to the delayed neutron fraction.

4 Summary

This study discussed the influences of37Cl enrichment in a MCFR from the perspectives of neutron economy, the breeding performance, the production of harmful nuclides,and safety parameters. The results show that37Cl enrichment significantly influences the neutronics properties of a MCFR. With natural chloride,233U breeding cannot be achieved, and the yields of S and36Cl reach 802 and 948 ppm in 100 years of operation. This is clearly unfavorable for the normal operation of a MCFR. Therefore, it is necessary to enrich37Cl. Increasing the37Cl enrichment to 97%yields a clear improvement in its neutronics properties owing to the large decrease in the absorption rate of35Cl,and its neutronics performance is similar to that corresponding to 100%37Cl enrichment.Besides,when the37Cl enrichment increases to 99%, the values of its neutronics performance are almost identical as for 100% enrichment.Considering the enrichment cost and the neutronics properties, a37Cl enrichment of 97% is recommended. However, achieving optimal neutronics performance requires a37Cl enrichment of 99%. In addition, during 100 years of operation, the TCR can remain sufficiently negative, and βeffchanges only slightly, regardless of the level of37Cl enrichment. Both of these effects satisfy the reactor’s safety requirement.

杂志排行

Nuclear Science and Techniques的其它文章

- Spin coating of TPB film on acrylic substrate and measurement of its wavelength shifting efficiency

- Optimization of the S-band side-coupled cavities for proton acceleration

- Multi-frequency point supported LLRF front-end for CiADS wide-bandwidth application

- Recent studies on potential accident-tolerant fuel-cladding systems in light water reactors

- Complex structure of human Hsp90N and a novel small inhibitor FS5

- Mo¨ssbauer spectroscopy studies on the particle size distribution effect of Fe–B–P amorphous alloy on the microwave absorption properties