Recent studies on potential accident-tolerant fuel-cladding systems in light water reactors

2020-03-19ShengLiChenXiuJieHeCenXiYuan

Sheng-Li Chen· Xiu-Jie He · Cen-Xi Yuan

Abstract Accident-tolerant fuel (ATF) has attracted considerable research attention since the 2011 Fukushima nuclear disaster. To improve the accident tolerance of the fuel-cladding systems in the current light-water reactors,it is proposed to develop and deploy (1) an enhanced Zrbased alloy or coated zircaloy for the fuel cladding, (2)alternative cladding materials with better accident tolerance, and (3) alternative fuels with enhanced accident tolerance and/or a higher U density. This review presents the features of the current UO2–zircaloy system. Different techniques and characters to develop coating materials and enhanced Zr-based alloys are summarized. The features of several selected alternative fuels and cladding materials are reviewed and discussed. The neutronic evaluations of alternative fuel-cladding systems are analyzed. It is expected that one or more types of ATF-cladding systems discussed in the present review will be implemented in commercial reactors.

Keywords Accident-tolerant fuel · Accident-tolerant cladding · Light-water reactor · Neutronic evaluation

1 Introduction

Because it is reliable, stable, and environmentally sustainable,nuclear power is one of the most important forms of clean energy for reducing CO2emissions. Figure 1 shows the percentages of different sources of world electricity production in 2017 (25,721 TWh) [1]. Currently,nuclear power accounts for approximately 10%of the total world electricity production. Nuclear energy is one of the most important energy resources for development.

The current nuclear fuel is based on the UO2–zircaloy system. The technology of the UO2–zircaloy system is mature because of the development and operation experience gained over the past half-century. The operational record of the UO2–zircaloy fuel rod was excellent under different conditions until the 2011 Fukushima Daiichi nuclear accident. The Fukushima accident indicated that the production of H2by the chemical reaction between Zr and water steam is drastic for the zircaloy cladding. It is widely recognized that the development of accident-tolerant fuel (ATF) is of great importance for increasing the accident tolerance for Gen-II and Gen-III light-water reactors (LWRs) under design-basis accident (DBA) and beyond-DBA (BDBA) conditions.

To improve the fuel performance under DBA and BDBA conditions, it is necessary to improve the accident tolerance of the fuel and cladding.The improvement of the cladding mainly involves the reduction of oxidation,which generates H2and produces heat through chemical reactions. The following methods have been proposed [2].

(1) Using a Zr-based cladding with better oxidation resistance and mechanical strength, i.e., improve the Zr-based materials and coating-layer design.

(2) Using alternative cladding materials with a high oxidation resistance and strength.

(3) Using an alternative fuel with a high thermal conductivity and/or high U density.

The improved oxidation-resistant Zr-based alloy has similar neutronic characteristics to the current zircaloy and can be deployed in a relatively short time owing to the limited changes in the present design basis and the corresponding regulations. The highly oxidation-resistant coating can protect the zircaloy cladding from a chemical reaction with high-temperature water, which was the primary source of the H2explosion in the Fukushima accident. Alternative cladding materials provide diversity for the development of an accident-tolerant cladding. The two approaches for improving the performance of the cladding are similar. Approach (1) can be deployed in a relatively short time,while approach(2)can potentially provide more significant improvements. Notably, increasing the specific heats of both the fuel and the cladding is helpful for delaying the melting of the cladding under DBA and BDBA conditions.

Compared with the currently used ceramic UO2fuel,improved accident-tolerant alternative fuels have one or more additional features, e.g., improved fission production retention, a higher thermal conductivity, a higher specific heat capacity, and a higher U (or actinide) density. Alternative fuels provide diversity for developing an ATF.However, because their fuel performance differs significantly from that of the currently used UO2fuel,a relatively long time is needed to change the design basis and the corresponding regulations for deploying alternative fuels.Some nuclear fuels and cladding materials of Gen-IV or fusion reactors are considered and investigated as candidate accident-tolerant fuels and claddings.

The remainder of this paper is organized as follows.We introduce the characteristics of the currently used UO2–zircaloy system in Sect. 2. Different technologies for approach (1) are reviewed in Sect. 3. In the light of the various possibilities for alternative cladding materials and alternative fuels, Sects. 4.1 and 4.2 briefly discuss the properties of some selected alternative fuels and claddings,respectively. Neutronic studies on ATF fuel-cladding systems are described in Sect. 5. Section 6 summarizes this review.

2 Current UO2–Zr alloy system

UO2fuel is widely used in LWRs because of its high melting point, compatibility with water (coolant), and stability under irradiation [3]. The well-known disadvantage of UO2fuel is its low thermal conductivity, which results in a large temperature gradient from the surface to the center of the fuel pellet. Owing to the extensive use of UO2over the past decades,its properties have been widely studied. One of the most commonly used formulae for the thermal conductivity of UO2, i.e., λUO2, was proposed by Fink [4]:

where λUO2has units of W/(K m), and t=T/1000 (with the temperature T given in K). This empirical formula is valid from room temperature to approximately the melting point of UO2. The isotopic components of the fuel vary with burnup owing to a considerable number of nuclear reactions, particularly nuclear fission from U. The relationship between the burnup and the thermal conductivity of UO2is described in Ref. [5].

Notably,the isotopic components of nuclear fuel depend on not only the burnup but also the operating history.In the experimental data of Fig. 2[4],discrepancies are observed among different measurements.Thus,all the semiempirical formulae for describing the thermophysical properties of UO2fuel are reasonable approaches, with certain deviations.

The design of dual-cooled annular fuel rod is considered to increase the safety margin for the melting of UO2fuel.Table 1 presents a comparison of the average and peak temperatures of UO2fuel with the typical cylindrical and dual-cooled annular designs [6, 7]. As shown, the annular design can reduce the average and peak fuel temperatures by approximately 100 and 300 K, respectively.

From a neutronic view point, the use of uranium oxide UOxcan optimize the utilization of neutrons in the fuel pellet and increase the efficiency of the chain reaction in the reactor. Figure 3 illustrates the total neutron reaction cross sections of235U,238U, and16O according to data from the Joint Evaluated Fission and Fusion (JEFF)-3.1.1 nuclear data library [8].The JEFF-3.1.1 data are presented herein because they well reproduce the measurements performed in a CEA integral benchmark experiment(PERLE) [9–13]. In nature, 99.8% of O isotopes are16O,which is a double-magic nucleus. Therefore, the neutron reactions with O in UOxare generally negligible compared with the reactions with U.

In nature, 0.005%, 0.72%, and 99.274% of U isotopes are234U,235U, and238U, respectively. However, as indicated by the neutron fission cross sections in Fig. 4, the fission cross section of the major isotope238U is smaller than that of235U.Therefore,to increase the fission reaction rate in UO2fuel,the amount of the fissile isotope235U must be increased.The235U enrichment in current LWRs ranges from 3.5 to 5%. Because235U and238U have identical chemical properties,the separation of these two U isotopes should be based on their different masses.

As shown in Fig. 4, the fission cross section of235U in the thermal energy region is significantly higher than that in the fast energy region. Consequently, in the current design of LWRs, the fission neutrons are thermalized to increase the fission reaction rate. Figure 5 shows the typical neutron flux spectra for the current UO2–Zr system at the beginning of life(BOL)and the end of life(EOL).The peaks of the thermal neutrons in the current LWRs design are optimized for the efficient use of neutrons for235U fission.

Zr-based materials are selected as the fuel-cladding materials because of the small neutron absorption cross section of Zr.Figure 6 shows the neutron-radiative capture cross sections of Zr isotopes in comparison with that of56Fe. Table 2 presents the total and radiative capture cross sections of Zr isotopes in comparison with those of56Fe at the thermal energy based on JEFF-3.1.1 [8], the latest European release JEFF-3.3 [15], and the latest American release ENDF/B-VIII.0[16].Figure 6 and Table 2 indicate that the neutron capture cross sections of Zr isotopes with even neutron numbers are >10 times smaller than that of56Fe,which is the most abundant isotope in natural Fe.Thesecond-to-last column in Table 2 presents the cross sections of natural Zr, which is denoted asnatZr. The cross sections of the natural Zr are only presented for comparison; the natural elements should not be used in the depletion calculation, because different isotopes have different cross sections.

Table 1 Temperatures of cylindrical and annular UO2 fuel [6, 7]

Different Zr-based alloys have been developed in the past decades using different alloying elements to improve the performance, such as mechanical strength. Table 3 presents the components of different types of zircaloys.One of the most commonly used zircaloys in pressurized water reactors (PWRs) is zircaloy-4, which is hereinafter denoted as Zr-4. The thermal conductivity of Zr-4 is [17]

The second-order coefficient in the original expression is 7.25×10-7T2[17]. We changed the power from - 7 to- 6 according to the experimental data from Ref. [17].Additionally, because the experimental measurements are taken from room temperature to approximately 1000 K,this expression is valid below 1000 K. The International Atomic Energy Agency (IAEA) recommended the following thermal conductivity of zircaloy according to experimental data for zircaloy-2 and Zr-4 [18]:

This formula is valid, with an uncertainty of 4–7% for temperatures ranging from 300 K to approximately 1800 K.

Over the past approximately 60 years of development,zircaloy has been highly optimized through various experiments and industrial feedback.The critical problems with the mechanical behavior of UO2–zircaloy were presented by Wang et al.[20].A main drawback of zircaloy in LWRs is that Zr reacts with water steam at high temperatures:

This reaction produces H2, which increases the pressure in the reactor pressure vessel and the concrete containment.This was the primary source of H2exposure in the Fukushima Daiichi nuclear accident.Therefore,the idea of an ATF cladding is to add a coating to the zircaloy or replace the zircaloy with another cladding material to prevent or reduce the production of H2under accident conditions.The dynamic response of the Chinese CAP1000containment under steam explosion accidents can be simulated in detail using the models developed by Sun Yat-sen University and the China Nuclear Power Technology Research Institute [21].

Table 2 Thermal neutron total and radiative capture cross sections of Zr isotopes in comparison with 56Fe

Table 3 Compositions (in wt%) of main zircaloys other than Zr

3 Surface-modified Zr-based cladding

Because the aforementioned approach (1) for the ATF cladding can be deployed in a relatively short time,extensive studies have been performed on it in the past several years. This section reviews different coating materials and improved Zr-based alloys. The coating materials are presented in the following order: metallic coatings,nonmetallic coatings,ceramic coatings,and oxide dispersion-strengthened (ODS) coatings. Ion-implanted improved zircaloys are briefly reviewed at the end of this section.

3.1 Metallic coatings

3.1.1 Pure Sn

Thin and uniform Sn coatings were deposited on Zr-4 by evaporation under vacuum conditions (10-5Torr) [22].Because the Sn coating was between the alloy and the oxide as a liquid agent, the oxidation performance of Zr-4 was improved. After oxidization in 250-Torr O2at 500 °C and corrosion in high-pressure water at 349 °C and 176 atm, the rates of both reactions of the Sn-coated Zr-4 decreased with the increasing thickness of the Sn coating.

3.1.2 Y coating

Y is widely investigated because of its oxidation resistance. It is expected to form stable, protective yttrium oxide at high temperatures, potentially reducing the oxidation of zircaloy-2. After exposure to supercritical water at 400 °C for 168 h,for untreated zircaloy-2,the formation of a fully developed zirconia layer and a subsurface O diffusion zone occurs. For Y-coated zircaloy-2 after oxidation at a high temperature, the surface-generated Y2O3prevents the O from further diffusing into the interior[23].

3.1.3 Pure Cr

Cr is the most recognized ATF coating in the world because of its resistance to corrosion in the LWR coolant,its stability under neutron irradiation(260–400 °C),and its resistance to high-temperature steam oxidation [24].AREVA in France fabricated a physical vapor deposition prototype machine to prepare a Cr coating on a full-length zircaloy cladding [25]. At present, the main countries in which pure Cr coatings are studied are France (AREVA/CEA/EDF), South Korea (KAERI), the USA (UIUC,University of Wisconsin-Madison, and University of Michigan), and China (Sun Yat-sen University).

The performance of the Cr-coated zircaloy was investigated at CEA in the framework of the French Nuclear Institute, in partnership with AREVA and EDF [26–28].The results indicated that compared with the traditional uncoated zircaloy, the developed Cr coating significantly improved the high-temperature oxidation and mechanical properties (i.e., ductility and strength) of the zircaloy. In Park’s study,an arc ion plating technique was used to coat a Cr layer onto the surface of Zr-4 as an anti-oxidation coating. The pure Cr phase was identified by X-ray diffraction (XRD) analysis, and the Cr film was compact and uniform. A Cr film on Zr-4 successfully acted as a corrosion-protective layer even in a 1473-K high-temperature steam environment [29]. In Korea, Kim et al. investigated the effects on coating structures and properties of different parameters, i.e., the laser beam power, inert gas flow,cooling of Zr-based alloys,and Cr powder control,in the deposition of a Cr coating by three-dimensional laser coating technology [30, 31]. After a high-temperature oxidation test, the Cr coating successfully acted as a corrosion barrier layer. Additionally, after both ring-compression and tensile tests, the Cr coating did not peel off,indicating that the adhesion property of the coating was excellent. Cr coatings were also prepared on a Zr-4 alloy by multi-arc ion plating by our research team[32],and the effects of the bias and air pressure on the oxidation properties of the coatings were examined in detail. The results indicated that the bias potential and air pressure had significant effects on the oxidation performance and that the oxidation resistance of the Cr coating decreased when the bias pressure and air pressure were too high or low, as shown in Fig. 7. If the Cr coating is deposited directly on the surface of the Zr alloy, it causes mutual diffusion between the Zr and Cr. A large amount of Cr-rich precipitates can be observed in the Zr alloy substrate upon cooling [33].

In addition to the oxidation and mechanical properties,the irradiation effects were investigated in detail. Jiang et al. at the University of Michigan found that the irradiation effect of the Cr coating is related to not only the dose but also the coating thickness [34]. Owing to the smaller columnar grains and larger lattice distortion in thinner coatings,the evolution of the irradiation defects is delayed.

3.1.4 Cr-based binary alloys

At present, the main countries in which Cr-alloy coatings, e.g., CrAl coatings, are studied are South Korea(KAERI) and the USA (UIUC).

For the CrAl coating, the addition of Al can modify the structure of the coating and affect its oxidation performance[35].When the Al content is high,the coating forms cubic γ-Al2O3after high-temperature oxidation, and when the Al content is low, the coating produces Cr2O3and Al2O3simultaneously after high-temperature oxidation.The thickness of the CrAl coating deposited at KAERI in Korea ranged from 40 to 60 μm [36]. Because the CrAl binary alloy had higher strength than the Zr alloy, the mechanical properties of the modified surface, i.e., the creep and wear resistance, were improved.

3.1.5 Fe-based alloys

At present, the main countries in which Fe-based alloy coatings are studied are South Korea (KAERI) and the USA (UIUC).

For Fe-based alloys, such as FeCrAl, it is necessary to add a barrier layer at the coating/substrate interface to prevent the formation of Zr–Fe eutectic at high temperatures [7]. According to the UIUC research team, yttriastabilized zirconia(YSZ)and zirconia have the potential to act as a barrier layer [37]. In contrast, the KAERI team selected a barrier layer of Cr [36] or Mo [38]. The thickness of an FeCrAl coating deposited at KAERI in Korea ranged from 40 to 60 μm [36]. An oxidation experiment indicated that the FeCrAl had good performance as a coating material on the ATF cladding. In addition to the formation of a eutectic with Zr, the significant neutronic penalty is a disadvantage of FeCrAl as an ATF cladding coating [39].

3.1.6 High-entropy alloy

Since the high-entropy alloy was proposed by Yeh of National Tsinghua University (Taiwan, China) in 2004[40], it has rapidly attracted attention owing to its high strength/hardness, good oxidation resistance, outstanding wear resistance, and superior radiation resistance. Zhang et al. at Sichuan University, China, prepared a AlCr-MoNbZr high-entropy alloy coating for ATF [41]. A corrosion experiment was performed over 1 month in an autoclave at 360 °C and 18.7 MPa. The results indicated that no zircaloy substrate oxides were formed, indicating the excellent corrosion resistance of the high-entropy alloy coating. Zhang et al. also prepared AlCrMoNbZr/(AlCr-MoNbZr)N multilayer high-entropy alloy coatings used it for an ATF cladding [42]. Compared with the single-layer AlCrMoNbZr or (AlCrMoNbZr)N coating, the AlCr-MoNbZr/(AlCrMoNbZr)N multilayer coating can more effectively inhibit the diffusion of Al and the formation of the boehmite phase. A 50/50-nm AlCrMoNbZr/(AlCr-MoNbZr)N multilayer coating exhibited higher corrosion resistance than 5/5-nm and 10/10-nm multilayer coatings.

3.2 Nonmetallic coatings

3.2.1 Pyrolytic C (PyC) coating

To mitigate the pellet cladding interaction–stress corrosion cracking problem and improve the accident tolerance, a PyC coating was deposited using a thermal cracking method on the inner surface of Zr-4 tubes[43, 44]. Although the authors did not perform high-temperature oxidation or corrosion experiments, they investigated factors affecting the coating process in detail, e.g.,the temperature, time, and flow rate.

3.2.2 Polycrystalline diamond (PCD) coating

A PCD coating with a thickness of 300 nm was used to protect the nuclear fuel cladding of a Zr alloy from undesirable oxidation while preserving its function, without the loss of chemical stability [45]. Experimental results indicated that the PCD coating had good radiation resistance and high-temperature steam oxidation resistance. The experimental results of Ashcheulov et al.indicated that the weight gain of a Zr alloy protected by a PCD coating grown using a microwave plasma-enhanced linear antenna chemical vapor deposition apparatus was 47% lower than that of the Zr alloy without PCD protection after oxidation at 950 °C [46].

3.2.3 Si or silicide coating

Si coatings were applied to the surface of a Zr-based alloy by the plasma spray (PS) and laser beam scanning(LBS)methods[47].In a high-temperature oxidation test at 1200 °C, there were problems with the PS coating technology, such as pore formation and interfacial oxidation caused by weak adhesion.To solve the problems of the PS coating method, LBS treatment was applied to the surface of the PS coating.The pure Si coating was transformed into a Si–Zr mixed layer, and the pores in the Si coating were successfully removed, as shown in Fig. 8. The interfacial oxidation was suppressed by the formation of diffusion bonds between the Zr-4 substrate and the Si–Zr mixed layer.

The air-oxidation behavior of Zr2Si, ZrSi, and ZrSi2coatings deposited on a Zr alloy substrate by magnetron splashing at a low temperature was investigated [48]. The Ar pressure had a significant effect on the microstructure of the coating, and a lower pressure was beneficial for the formation of a denser and more protective microstructure.According to the oxidation results, ZrSi2was better than the other coatings, possibly owing to the formation of a protective layer composed of nanocrystalline SiO2and ZrSiO4in the amorphous Zr–Si–O matrix. A research group in the USA deposited a ZrSi2coating by magnetron sputtering, which exhibited excellent oxidation resistance[49]. After a severe thermal shock test, i.e., water quenching from 700 to 85 °C in 20 s,this coating exhibited no surface degradation, e.g., spallation or cracking.

3.3 Ceramic coatings

3.3.1 Nitrides

At present, the main countries in which nitride coatings are studied are Norway(IFE),the USA(Pennsylvania State University), and China (Sun Yat-sen University and the University of South China).

The research team at Pennsylvania State University, in conjunction with Westinghouse Electric Co., performed a detailed study on the corrosion of TiAlN and TiN coatings[50, 51]. They found that the TiAlN coating underwent Al depletion in a high-temperature water environment, yielding a boehmite phase.A layer of CrN was deposited on the outside of the TiAlN coating to solve this problem. Additionally,they studied alternating TiN and TiAlN layers and found that 8-layer TiN/TiAlN had the best corrosion resistance. A TiAlCrN coating was prepared by multi-arc ion plating by our research group [52]. Under corrosion at 18.5 MPa and 360 °C,the coating did not crack or fall off,and the weight gain of the coating was reduced by an order of magnitude compared with that of the original Zr alloy.In Canada,Daub et al.from Canadian Nuclear Laboratories found that a CrN coating exhibited high corrosion resistance under PWR conditions, under CANDU conditions,and in a superheated steam environment[53].Furthermore,they found that CrN and TiAlN coatings can reduce the H2ingress into Zr-4. Our research group deposited a CrN coating by multi-arc ion plating, and an oxidation experiment was performed from 760 to 1160 °C in an air environment[54].Even after oxidation at 1160 °C,the coating remained intact and exhibited no sign of shedding or cracking. However, a typical feature of a nitride coating is that it decomposes at high temperatures. CrN and its decomposition products are also oxidized,and the possible chemical reactions involved are as follows:

In the most recent study conducted by our group,although the CrN coating was excellent without damage after being oxidized at 1160 °C for 1 h, after two thermal cycles, i.e., 1160 °C →room temperature →1160 °C →room temperature, the CrN coating began to fall off. This was due to the difference between the thermal expansion coefficients of the CrN ceramic coating and the Zr alloy. Therefore, our research group is currently studying the CrN gradient coating. As indicated by a mechanical analysis of a surface-coated zircaloy cladding,a spatial-gradient coating is more promising than a discrete coating [55]. Another research group in China performed a detailed analysis of the residual stress of a nitride coating deposited by magnetron sputtering[56].The results indicated that the coating underwent compressive stress, and the residual stress of the coating prepared at a low sputtering power was higher than that for a high sputtering power. The results of another study confirmed that if the coefficient of thermal expansion of a TiN coating is significant, the coating peels off after the thermal shock resistance test [57].

Mandapaka et al. at the University of Michigan deposited two types of coatings(4-bilayer TiAlN/TiN and a TiN monolithic coating) on ZIRLOTMusing cathodic arc physical vapor deposition [58]. The results of oxidation in supercritical water indicated that the zircaloy with the deposited coating was oxidized to a more degree than the original zircaloy, and a thick oxide layer was present between the coating and the substrate. This phenomenon was due to the penetration of the crack in the coating during the deposition process, which allowed O to contact the substrate through the coating.

3.3.2 Mn+1AXn(MAX) phases

At present, the main countries in which MAX phase coatings are studied are Germany (KIT), France (AREVA and CEA), and the USA.

In Mn+1AXnphases,M is an early transition metal,A is an A-group element(typically IIIA or IVA),and X is either C or N [59]. Owing to the good thermal stability of the MAX phase and the properties of both metals and ceramics, these materials have attracted increasing attention in recent years. Additionally, some phases, such as Ti2AlC,are stable under neutron-irradiation conditions and are therefore promising for high-temperature nuclear applications [60]. Maier et al. deposited a Ti2AlC coating on the surface of Zr-4 by the cold spray technique and performed oxidation experiments in an air environment at 700 °C and in water vapor at 1005 °C[61].The oxidation resistance of the Zr alloy with the coating was significantly better than that of the Zr alloy without the coating.Although the MAX phase has many advantages, its preparation is challenging,mainly because this ternary system is likely to form compounds with other atomic ratios.For example,Yeom’s Ti–Al–C coating obtained by magnetron sputtering was amorphous. However, a crystal structure of Ti2AlC can be obtained by keeping the coating temperature at 900 °C for 3 s in laser surface treatment [62]. In research performed for a Master’s thesis at the University of Tennessee,in situ high-temperature grazing incidence XRD results indicated that a Cr2AlC MAX phase was formed when the temperature was increased to 500 °C [63].

The oxidation and mechanical properties of the ceramic coating are good. However, the fuel cladding can undergo diametrical compression when the reactor is in service.Ensuring that the brittle ceramic coating does not crack or fall off is a challenging problem [2]. To verify the feasibility of the Ti3AlC2coating, Au ion irradiation and nanoindentation were performed to simulate the severe displacement damage and high pressure, respectively,applied to the cladding surface [64]. Even after irradiation to approximately 14 displacements per atom (DPA), no amorphization was observed in the coating. In a nanoindentation test, under a stress of 16.6 GPa, the coating was still not cracked. Another problem is that the A-group element, such as Al or Si, may diffuse out of the MAX phases and form intermetallics with the zircaloy [65]. For example, the amount of Al penetration into the zircaloy is roughly an order of magnitude larger than that of Si penetration. A research group at CEA in France verified that amorphous Cr–Al–C can be converted into Cr2AlC by annealing the as-deposited coatings at a temperature below that corresponding to the metallurgical degradation of the zircaloy [66].

3.3.3 SiC coating

In the field of ATFs,SiC is generally used to completely replace the Zr alloy in the body material. However, a research group in China deposited an SiC coating on Zr-4 by magnetron sputtering[67].The results indicated that the dense SiC coating had excellent mechanical properties,with high hardness (25.61 GPa), elastic modulus(214.9 GPa), and critical load (8.24 N) values. In the future,it is necessary to study the oxidation performance of the SiC coating in detail.

3.4 ODS layer

The ODS layer differs from the two aforementioned coatings. Under LBS, it does not remain on the surface of the Zr alloy but permeates into the Zr alloy. The surface modification of the Zr alloy by LBS can improve the properties of the Zr alloy, e.g., increasing the wear resistance, increasing the corrosion resistance, and improving the strength.A schematic of the ODS treatment is shown in Fig. 9. Kim et al. in Korea used the LBS method to inject 10-μm Y2O3particles into a 2-mm-thick Zr alloy to form an ODS structure [68, 69]. Y2O3particles were uniformly distributed in an ODS-alloyed layer using LBS technology,without voids or cracks. The average particle size of the dispersed particles in the ODS layer was 20 nm, and the thickness of the ODS layer was 0.4 mm, accounting for 20% of the total thickness of the Zr-4 alloy sheet. At 500 °C, the yield strength of the Zr alloy covered with the ODS layer was >65% higher than that of the initial Zr alloy. The increase in the strength was caused by the martensitic transformation of the Zr-4 alloy. Additionally,other coatings, such as Cr, Cr alloys, and FeCrAl/Cr, can be deposited on the ODS layer. The function of the ODS layer is to increase the high-temperature strength, and that of the surface coating is to increase the corrosion/oxidation resistance [70].

3.5 Modification by ion implantation

In 1987, ion-implantation experiments revealed the following: (1) The concentration and depth of the implanted ions can be effectively controlled, (2) ion implantation can improve the microhardness and wear properties of materials, and (3) ion implantation can significantly extend the lifetime of manufacturing tools in practical industrial applications[71].Oxidation of zircaloy-2 in the nonsurface-treated condition and after ion implantation with N and C was conducted after exposure to an environment of pressurized water at 25 MPa and a temperature of 300 °C [23]. N and C ion implantation resulted in a thinner oxidation layer compared with the pristine zircaloy-2. To investigate the effect of Al addition on the air-oxidation behavior of a zircaloy, Peng et al.performed a series of irradiation tests on a ZIRLO alloy with different doses of Al ions [72]. The effect of the Al injection on the weight gain of the ZIRLO alloy is shown in Fig. 10. The oxidation weight gain of the ZIRLO alloy increased with the oxidation time in all cases, and the oxidation weight gain rate decreased with an increase in the irradiation dose. When the irradiation dose of Al reached 1018ions/cm2, the oxidation weight gain of the ZIRLO alloy was only 30% of that of the original sample, indicating that the oxidation properties of the Zr alloy can be significantly improved by irradiation with Al ions.

4 Alternative fuel-cladding system

The various alternative fuels and cladding materials and their combinations provide diversity for obtaining commercial nuclear fuel with a high efficiency and safety level.In the past years, many alternative materials have been proposed and considered for the ATF and cladding, and they are briefly reviewed in this section.

4.1 Alternative fuels

As mentioned in Sect. 2, UO2fuel has a low thermal conductivity. Therefore, alternative fuels with a higher thermal conductivity have been considered. There are two strategies to enhance the thermal conductivity of the nuclear fuel:(1)incorporating metal or other materials into the UO2fuel and (2) completely replacing the UO2fuel.

The former strategy is based on the current UO2fuel and thus can be deployed in the short term. However, incorporating metal into ceramic UO2fuel may reduce the melting point, as indicated by the examples in Table 4.Therefore, the margin for fuel melting must be quantified for regulatory reasons. Incorporating other components into UO2fuel reduces the U density in the fuel.One should increase the235U content (or introduce fissile Pu isotopes having larger thermal neutron fission cross sections than235U [73]) into the fuel or reduce the amount of absorber materials to maintain the reactivity for operation and the cycle length.

The latter strategy requires more time for development and deployment but can significantly improve the fuel performance. It is possible to obtain a fuel with both a higher thermal conductivity and a higher U density than UO2fuel,such as U3Si2and UN fuels,which are discussed in the following subsections. Table 4 presents the percentages of U(and other included actinides in some cases)for different fuels.

4.1.1 UO2–BeO

The loading of BeO in the UO2ceramic fuel can significantly improve the thermal conductivity of the fuel because BeO has a higher thermal conductivity than the ceramic UO2material. As indicated by the experimental data for the thermal conductivity of BeO presented in Ref.[78] and their interpretation by Zhou [79], the thermal conductivity of BeO is 22 times higher than that of UO2at room temperature. At 1500 K, the ratio of the thermal conductivity of BeO to that of UO2is 3 and 7 according to the Fink model [4] and the Harding and Martin (HM)formula [80], respectively.

Figure 11 presents the thermal conductivity for UO2–BeO fuel with different volume fractions of BeO [81], in comparison with that of UO2fuel [4]. As shown, doping with BeO can significantly increase the thermal conductivity of the UO2fuel; 2.1% volumetric (= 0.6% by mass)loading of BeO can increase the thermal conductivity of UO2fuel by approximately 50%at 1800 K(and by>50%if the HM model [80] is used for UO2). According to Ref.[82],the thermal conductivity of UO2–(4.2 vol%)BeO fuel at 1100 K is higher than that of UO2fuel by 10% or 25%,depending on the incorporation method. Additionally, the thermal conductivity of UO2–BeO fuel was investigated by Li et al. using statistical continuum mechanics for BeO fractions ranging from 0 to 100% [83]. The thermal conductivity of UO2–BeO fuel versus the volumetric content of BeO at room temperature computed using the statistical continuum model is shown in [83].

Many studies have been performed on UO2–BeO fuels with different volume fractions of BeO. The irradiation behavior of 12%235U-enriched UO2–(30 vol%)BeO fuel was tested by Johnson and Mills in 1963 [84]. Ishimoto et al. performed an experiment in which the thermal conductivity of UO2fuel was significantly improved by adding 1.1, 2.1, 3.2, 4.2, and 36.4 vol% BeO [82]. Chandramouli and Revankar developed a thermal model of UO2–BeO fuel,which is used for analyzing the performance during aloss-of-coolant accident (LOCA) [85]. The neutronic properties of UO2–(5 vol%)BeO and UO2–(10 vol%)BeO fuels were examined by Smith [86]. McCoy and Mays reported that the incorporation of BeO (4 and 9.6 vol%)can reduce the internal rod pressures and the fission gas release [87]. Recently, Zhou and Zhou studied the thermophysical and mechanical properties of UO2–(36.4 vol%)BeO fuel with different claddings [79].

Table 4 Proportions of actinides and melting points for different U-based fuels

The doping of BeO requires an increase in235U enrichment for maintaining the cycle length. Because the cost of BeO is approximately five times higher than that of UO2fuel [88], the fabrication of UO2–BeO fuel is more expensive than that of the current UO2fuel.However,it is possible to compensate for the additional cost of the fuel fabrication by extending the fuel cycle length.

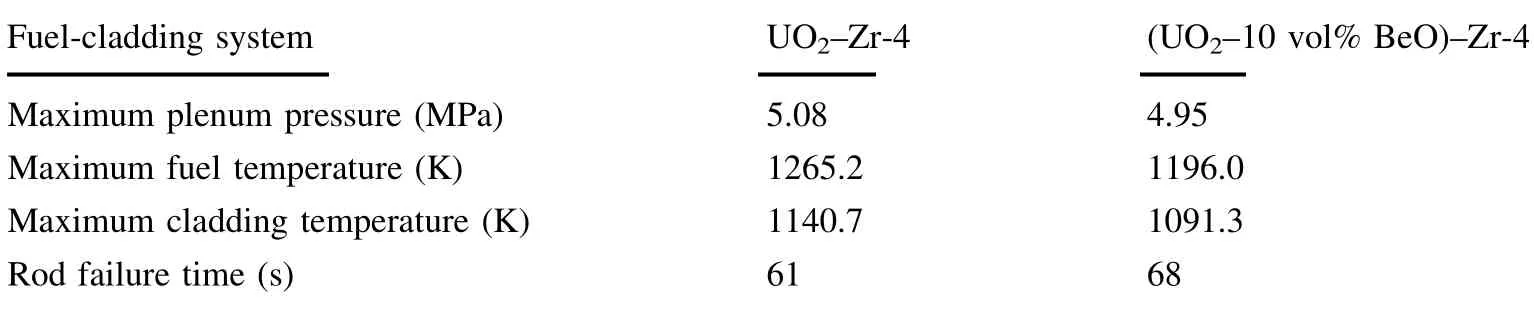

Table 5 presents a comparison of the behavior of UO2–Zr-4 and UO2–(10 vol%)BeO–Zr-4 fuel-cladding systems under the LOCA condition [7]. As shown, the BeO-doped fuel can reduce the maximum plenum pressure and maximum fuel and cladding temperature and delay the rod failure under the LOCA condition.

An essential feature of9Be,which accounts for 100%of natural Be, is the relatively large (n, α) cross sections at a neutron energy of <3 MeV, as shown in Fig. 12. Additionally,the product of the9Be(n,α)reaction is6He,which decays to6Li with a half-life of 0.82 s. As shown in Fig. 12, the (n, t) cross section of6Li is large, while both the tritium and4He from the6Li (n, t) reaction are in gaseous states.The small(n,α)cross sections of fissile and fissionable heavy nuclei have been evaluated in recently released nuclear libraries,such as ENDF/B-VIII.0[16]and JEFF-3.3 [15]. Regardless of the fission products, the primary production of the He gas should come from9Be.The gas released from the fuel pellet increases the pressure in the gap between the fuel rod and the cladding.This results in the swelling of the fuel rod and an increase in the pin pressure.

4.1.2 U–Mo

Similar to the incorporation with BeO, Mo is incorporated into the current UO2fuel for increasing the thermal conductivity of the fuel and the subsequent margin for fuel melting. Figure 13 [89] presents the thermal conductivity of U–10Mo at different burnup levels with respect to the temperature (left) and at different temperatures with respect to the burnup level(right).It is noteworthy that the burnup (denoted as BU in Fig. 13) used in Ref. [89] is the relative consummation of235U by nuclear reactions other than radiative capture:

where the index 0 corresponds to the initial concentrations.The thermal conductivity is significantly increased by doping 10 wt%Mo (compared with data shown in Fig. 2).

Table 5 Comparison between UO2–Zr-4 and UO2–(10 vol%)BeO–Zr-4 fuelcladding systems under LOCA conditions [7]

Figure 13 presents experimental measurements performed under different conditions. Figure 14 shows a plot of the model-based thermal conductivity of U–Mo [89].The decreasing tendency of the thermal conductivity with the increasing burnup in Fig. 14 agrees with the data shown in Fig. 13. Additionally, Fig. 14 shows a counterintuitive tendency for the incorporation of different amounts of Mo:The 13.3 wt% Mo-doped fuel has slightly lower thermal conductivity than the 10 wt% Mo-doped fuel.

Notably,Mo can participate in a chemical reaction with water above 1000 °C [90]:

H2is a primary source of reactor containment explosion accidents, such as the Fukushima accident. Even if the cladding encloses the Mo in the fuel under normal conditions, the process of H2production under accident conditions should be considered.

According to the neutron economy, Mo doping requires more235U in the fuel(greater enrichment or higher density)to achieve the same cycle length as the current fuel.Among the different Mo isotopes,95Mo has the largest neutron capture cross section in the thermal region. Table 6 presents the corresponding thermal neutron capture cross sections of JEFF-3.1.1 [8] and the isotopic abundanceweighted value. It can be concluded that95Mo contributes 85% of the thermal neutron capture reaction among all the isotopes that occur in nature. Therefore, a reduction of the95Mo content in the Mo material can significantly enhance the neutron economy of U–Mo fuel. For industrial applications,the optimization of Mo for incorporation into UO2fuel should consider the trade-off between the cost of reducing the content of95Mo and the enhancement in the neutron economy.

4.1.3 U3Si2

The U-Si binary is considered for ATF because of its thermodynamic stability [91]. Among the different U-Si binaries, U3Si has the largest proportion of U. However,experiments indicated that the U3Si fuel swellsconsiderably under irradiation [92–94]. Moreover, it is dissociated into solid U and U3Si2above 900 °C [74].Among the U-Si binaries USi2, U3Si5, USi, U3Si2, and U3Si, U3Si2has the second-highest U content (after U3Si).Additionally, U3Si2fuel has good performance under irradiation [92, 94] and several advantageous properties compared with UO2fuel[74].Furthermore,tests involving burnup of up to 20 MWd/kgU indicated that U3Si2fuel swells less than UO2and U3Si2has less fission gas release than UO2[7].

Table 6 Thermal neutronradiative capture cross sections(unit: barn) of Mo isotopes of JEFF-3.1.1 [8]

Compared with the UO2fuel, the U3Si2fuel has a significantly higher thermal conductivity. A semiempirical formula for conservatively describing the thermal conductivity of U3Si2fuel is given as follows [95]:

where T represents the temperature (in K). According to Ref. [95], this empirical formula is valid from room temperature to 1473 K. However, Shimizu reported that this linear expression corresponded to experimental data measured from 470 to 1150 K and overestimated the thermal conductivity below 200 °C [96]. Figure 15 shows the thermal conductivities of UO2[4] and U3Si2[95] for temperatures ranging from 470 to 1150 K. The thermal conductivity of U3Si2is higher than that of UO2. With the increasing temperature, the thermal conductivity of U3Si2increases, whereas that of UO2decreases. The increase in the thermal conductivity may be considered as an inherent safety characteristic of the U3Si2fuel for releasing heat from the fuel. Moreover, the higher thermal conductivity allows more accident-tolerant claddings whose thermal performance is not as good as that of a zircaloy, such as SiC.

A drawback of the U-Si binary is its low oxidation resistance. As shown in Fig. 16 [91], the U3Si2and U3Si5fuels begin oxidizing at 270 °C, whereas the oxidation of the current UO2fuel begins at 390 °C.Additionally,for the U3Si2fuel, the oxidation rate quickly increases with the temperature compared with U3Si5.

4.1.4 UN

Among the alternative fuel candidates, UN fuel has the highest U content.The thermal conductivity of UN fuel can be empirically calculated as follows [97]:

where T represents the temperature (in K), and λUNhas units of W/(K m). This empirical formula is valid for temperatures below approximately 2000 K. The thermal conductivity of UN fuel based on this analytical formula is plotted as a function of the temperature in Fig. 15 in comparison with that of UO2fuel.Similar to the U3Si2fuel,the thermal conductivity of the UN fuel increases with the temperature. As explained for the U3Si2fuel, this may be considered as an inherent safety feature of the UN fuel.Additionally, the thermal conductivity of the UN fuel is significantly higher than that of the UO2fuel, while its melting point (2630 °C) [77] is comparable to that of the UO2fuel(2847 °C)[74].Consequently,the use of UN fuel as an ATF can significantly increase the margin for fuel melting and allow the use of advanced claddings. Other physical properties, such as the lattice parameter, density,and thermal expansion coefficient,were correlated with the temperature by Hayes [98]. It is also noteworthy that the discrepancy of the experimental measurements for the thermal conductivity of the UN fuel (shown in Fig. 17[99]) is greater than that in Fig. 2 for the UO2fuel.

The neutronic drawback of UnatN is a large reactivity penalty due to14N,which accounts for 99.6%of natural N.As shown in Fig. 18, the cross section of15N is smaller than that of14N below 0.1 MeV owing to the even neutron number of15N. Therefore, U15N was considered as a potential ATF [93]. The use of15N rather than natural N can prevent the production of long-life radiotoxic14C by the(n,p)reaction of14N,whose cross section is also shown in Fig. 18. Moreover, as shown in Fig. 18, the (n, α) cross section of15N is significantly smaller than that of14N.This indicates that replacing natural N with15N can reduce the production of He gas, which accelerates the fuel swelling and increases the pin pressure. Remarkably, the nuclear reactions of14N account for approximately 16%of the gas release (He and H2) [7].

The enrichment of15N can significantly increase the performance of UN fuel. However, the cost of enrichment must be considered for deployment and industrial applications. At present, the most competitive enrichment processes cost approximately 30 Euros (approximately 235 yuan)per gram of15N[7].As the cost of the fabrication of the current UO2fuel is approximately a few tens of yuan per gram, the cost of15N enrichment is an essential issue for U15N fuel.One possible method for reducing the cost of15N enrichment is the recycling of15N.

Another well-known disadvantage associated with UN fuel is its chemical reaction with water [100]. Above 250 °C, the following two reactions have been observed[7].

The production of H2through these reactions can potentially cause a H explosion. Lopes et al. reported that minimizing the open porosity can improve the water resistance of nitride fuel [101]. To avoid the chemical reaction with water,researchers have proposed the addition of other fuels that insulate the UN fuel from the water in the case of cladding failure,including UN–UO2[102],UN–U3Si5[93],and UN–U3Si2fuels [103]. In our previous publication[14],we proposed that the fully ceramic microencapsulated(FCM) fuel design [104–106] may be another possible solution for avoiding the chemical reaction between the UN fuel and water.

In addition to the chemical reaction with water, irradiation-induced swelling is an issue associated with UN fuel.Figure 19 presents the irradiation-induced volumetric swelling for different fuels [99]. As shown, the volumetric swelling of the UN fuel is>3 times greater than that of the current UO2fuel and >2 times greater than that of the U3Si2fuel. Doping of the U3Si2and UO2fuels can reduce the irradiation swelling of the UN fuel,but swelling is still a significant challenge for UN-based fuels.

4.2 Alternative claddings

To improve the accident tolerance of the nuclear fuelcladding system, the use of alternative fuels and/or enhanced claddings is proposed. Two types of ATF claddings can be selected: a Zr-coated cladding or an alternative cladding. Zr-based claddings are discussed in Sect. 3.This subsection mainly focuses on the alternative claddings FeCrAl and SiC.

4.2.1 FeCrAl

Stainless steel (SS) has historically been used in LWRs[107–109]. Figure 20 shows the worldwide fuel failure rates from 1960 to 2010 [110]. Compared with a zircaloy cladding, an SS cladding leads to a higher likelihood of fuel failure in boiling water reactors (BWRs) but less failure in PWRs. Therefore, enhanced SSs are proposed as candidate materials for the ATF cladding. Among the different types of SSs,FeCrAl is considered as a candidate material for the ATF cladding.The addition of Cr and Al to SS can improve the oxidation resistance [111, 112]. Furthermore, the addition of Cr and Al can improve the neutron economy in LWRs owing to their smaller neutron capture cross sections compared with Fe (see Fig. 21).FeCrAl has better resistance to environmentally assisted cracking than modern-type 304SS [113]. Additionally, as indicated by the oxidation kinetics shown in Fig. 22[114],the oxidation rate of FeCrAl is more than two orders of magnitude lower than that of a zircaloy [110]. The irradiation-induced atomic displacement damage was recently investigated [115]. The FeCrAl cladding material is currently being tested in commercial nuclear reactors [116].The corresponding neutron-and photon-induced irradiation damage can be calculated using the methods presented in Refs. [117–121].

Commercial FeCrAl contains 20 wt%Cr and 5 wt%Al.Reducing the Cr content can improve the irradiation resistance by reducing the amount of Cr-rich α′precipitates[122, 123]. The high-temperature oxidation behaviors of different types of low-Cr FeCrAl alloys were investigated[124]. The melting points of different low-Cr FeCrAl alloys vary from 1525 to 1543 °C [125] and are slightly higher than that of the commercial FeCrAl (1500 °C) [7].However,as indicated by the effects of the Cr and Al alloy contents on the steam oxidation resistance at 1473 K shown in Fig. 23 [126], lower Cr and Al contents correspond to a lower oxidation resistance [111, 112].

The thermal conductivity of FeCrAl is not so different from the current zircaloy. Figure 24 presents the thermal conductivities of FeCrAl and Zr-4. The thermal conductivity of Zr-4 is based on Eq. (2),and that of the zircaloy is the value recommended by the IAEA. The systematics of the thermal conductivity as a function of the temperature T(in units of K) were presented by Qiu et al. [127] as

for the APMT FeCrAl manufactured by Kanthal[128]and the FeCrAl material studied by Ott et al. [114]. Notably,the thermal conductivity of AMPT given by Kanthal [128]can be described by the following second-order polynomial:

where T represents the temperature(in K).This polynomial fitting is represented by the green dashed curve in Fig. 24.

Figure 25 shows the peak cladding temperature (PCT)of UO2fuel combined with zircaloy and FeCrAl claddings under a large-break LOCA condition with low-pressure coolant injection(LPCI)starting 91 s after the break[114].The approximately 75-K difference in the maximum temperature between the two systems is mainly due to the higher specific heat of FeCrAl. Therefore, although the thermal conductivity of FeCrAl is close to that of the current zircaloy, the higher specific heat can increase the margin for cladding melting or delay the cladding melting.

In addition to a higher specific heat, FeCrAl has improved mechanical strength than the current zircaloy for temperatures up to 1300 °C [114]. Additionally, it has a better irradiation resistance than the zircaloy [114]. For example,the irradiation growth observed in Zr alloys[129]is not expected in austenitic steel [130, 131]. This is confirmed by Ref. [132]. Moreover, FeCrAl has excellent corrosion resistance in both PWR and BWR coolant environments [133].

Compared with the zircaloy, SSs (including FeCrAl)have a significantly larger thermal neutron absorption cross section, which reduces their neutron economy. To compensate for the negative reactivity of FeCrAl, higher U density fuels, such as UN and U3Si2, and/or higher235U enrichment fuels can be used together with FeCrAl.Another challenge of using FeCrAl is the release of tritium into the coolant, because it does not react with H2to form stable hydrides as in the case of the zircaloy[7].This issue may be resolved by the addition or formation of alumina on the inner or outer surface of the cladding [134]. It is also possible to use other tritium barriers that are developed for fusion reactors [135].

4.2.2 SiC and SiC/SiC

The SiC ceramic was initially proposed to be used in fusion reactors and is now also considered as an enhanced ATF-cladding material.SiC has excellent high-temperature properties,a high irradiation resistance,low activity,and a small thermal neutron absorption cross section. The main issue for the nuclear application of SiC is the ductile feature of the ceramic. To improve the properties of SiC for nuclear applications, the following four nuclear-grade SiC materials are proposed [136].

(1) Simple continuous SiC fiber-reinforced SiC matrix composites [137–140], which are denoted as SiCf/SiC or SiC/SiC: Two crucial issues associated with SiCf/SiC are hydrothermal corrosion and the low retention capacity of fission products [141, 142].

(2) Two-layered ceramic cylinders[143,144],as shown in Fig. 26a: The inner SiCf/SiC is designed to withstand the peak mechanical and swelling-induced tensile stresses, while the outer monolith layer protects against the reaction with steam.

(3) Duplex SiC cladding design [145, 146],as shown in Fig. 26b: The inner SiC is designed to enclose the radiative fission products, and the outer layer provides additional strength to the cladding.

(4) Triplex SiC cladding design [143, 145, 147], as shown in Fig. 26c: This is based on the duplex design, with an additional 50–150-μm-thick environmental barrier coating that provides additional protection from corrosion.The thermal conductivity of nonirradiated SiC depends on the fabrication process. Figure 27a summarizes the thermal conductivity of different types of SiC [148]. The analytical fitting shown in Fig. 27 is expressed as follows[148]:

where T represents the temperature (in K). Notably, the thermal conductivity of SiC is significantly reduced by neutron irradiation [149]. Figure 27b presents the thermal conductivity of SiC irradiated at different temperatures with respect to the fast neutron fluence [148].As shown,a higher irradiation temperature leads to a higher roomtemperature thermal conductivity of SiC. The changes in the thermal conductivity due to irradiation were studied in detail [150].

SiC can be oxidized by steam water by the following chemical reaction at a temperature higher than approximately 1100 °C:

Thus, the oxidation of SiC in steam produces both H2and CO. However, the oxidation rate of SiC is significantly lower than that of the zircaloy. As shown in Fig. 28, the parabolic oxidation rate constant of SiC is approximately three orders of magnitude smaller than that of the zircaloy.Comparing Figs. 21 and 28 reveals that the oxidation rate of SiC is lower than that of FeCrAl.Consequently,SiC has a better oxidation resistance under accident conditions than the zircaloy and FeCrAl.

Recently, a CEA team investigated the chemical compatibility of SiC with UO2+x[152]. It was found that rare chemical reaction occurs between SiC and UO2+xat temperatures up to 1514 K. Notably, CO gas was observed between 1450 and 1970 K. Additionally, a liquid phase formed between 1850 and 1950 K in the UO2+x/SiC system.

5 Neutronic studies on alternative fuel-cladding systems

The neutronic performance is a critical feature of nuclear reactors. Therefore, neutronic studies are of great importance for new fuel and cladding designs. The neutronic evaluations of different fuel-cladding systems are summarized in this section.

5.1 Current system using coated zircaloy cladding

In general,because the coating is thin compared with the 570-μm-thick zircaloy cladding,the neutronic behaviors of the zircaloy with a coating are similar to those of the current UO2–zircaloy system. Examples of the fuel temperature coefficient (FTC; also called the Doppler coefficient), the moderator temperature coefficient (MTC), and the void reactivity coefficient (VRC) with 5% (VRC05)and 90% (VRC90) coolant leakage for 50-μm-thick coatings at the BOL and EOL are presented in Table 7 [153].The quantitative data in Table 7 confirm that the neutronic behaviors of the coated zircaloy are similar to those of the current zircaloy cladding.

The main change in the neutronic characteristics of the coated zircaloy cladding is the reactivity loss due to the increase in neutron absorption caused by the coating materials. Figure 29 shows the additional235U enrichmentin the UO2fuel needed to compensate for the anti-reactivity induced by the coating materials by keeping the cycle length equal to that of the current UO2–Zr-4 system [153].The anti-reactivity induced by the additional coating depends on the materials and the thickness of the coating.However, because the coating materials typically have higher mechanical strength than the zircaloy, the addition of the coating may allow the thickness of the zircaloy to be reduced. Consequently, the necessary increase in235U enrichment should be smaller than that shown in Fig. 29.Moreover, if fuel with higher U density is used, the importance of the negative reactivity induced by the coating materials decreases.

Table 7 Reactivity coefficients for a PWR with 50-μm coatings,calculated by Younker and Fratoni [153]

5.2 UO2–BeO fuel and zircaloy cladding system

Compared with the current UO2–Zr-4 system, the doping of BeO into UO2fuel reduces the cycle length if the same235U enrichment is used. Smith reported that the cycle length was reduced by approximately 2 and 3 d with the addition of 5 and 10 vol% BeO, respectively, for an 18-month cycle length design [86]. The increases of the U enrichment for different amounts of BeO doping are presented in Ref. [154].

As an example at the BOL given in Fig. 30, Refs.[86, 155] show that the addition of BeO to the UO2fuel leads to the softening of the neutron flux spectrum. This is the main reason why the control rod worth is higher for the UO2–BeO fuel than that for the current UO2fuel.However,as shown in Fig. 31, Smith reported that a higher B concentration is required with BeO doping to maintain the core under the critical condition [86]. Notably, the critical B concentration depends on the U enrichment.

Figure 32 shows the4He production for the reference UO2–Zr-4 system and different UO2–BeO fuels with zircaloy, FeCrAl, and SiC claddings. As explained in Sect. 4.1.1, the incorporation of BeO leads to significant4He production. Nevertheless, as the concentrations of Kr and Xe shown in Fig. 33,the gas production of Kr and Xe is similar between the UO2and UO2–BeO fuels. Because the production of Xe is far more important than that of Kr and He,the contribution of BeO to the total gas production is limited. However, because the independent variable in Figs. 32 and 33 is the number of EFPDs, similar gas production on the same EFPD implies less gas production at the same burnup level for greater BeO doping (the same power with a smaller U mass).This conclusion agrees with Ref.[87],in which less fission gas release was observed in UO2–BeO fuel compared with UO2fuel at a given burnup level.

Figure 34 (upper panel) shows the radial power distribution for 10 and 36.4 vol% BeO at the BOL, middle of life (MOL), and EOL [154]. The radial power distribution is flatter with the incorporation of larger amounts of BeO.Because the thermal conductivity of UO2–BeO increases with the fraction of BeO and the radial power distribution is flatter for greater BeO doping,the radial fuel temperature is significantly flatter for UO2–BeO fuel doped with a larger amount of BeO. On the other hand, for the UO2–(36.4 vol%)BeO fuel, as shown in Fig. 34 (lower panel)[154], the radial power distribution is not sensitive to the cladding material.Thus,the radial temperature distribution is mainly determined by the cladding material, which affects the temperature at the surface of the fuel pellet.

5.3 UN fuels and zircaloy cladding system

Because UN fuel has a significantly higher U density than UO2fuel, the moderator-to-fuel ratio of UN-based fuel is lower than the typical value (~2) for the UO2–Zr system if the geometric design and the fuel assembly are not changed.Therefore,the MTC of UN-based fuel is more negative than that of the current UO2fuel. This was verified by Brown et al.,who calculated the MTCs of different UN-based fuels and UO2fuel, as shown in Fig. 35 [156].The enhanced moderator feedback can be considered as an improved inherent safety feature of UN-like high U density fuels.

Owing to the decrease in the moderator-to-fuel ratio compared with that for the UO2fuel, the neutron flux spectra for the UN-based fuel are hardened.The hardening of the neutron spectrum of the UN-based fuel is confirmed by Ref. [156] and is shown in Fig. 36. A direct consequence of the hardening of the neutron spectrum is a decrease in the B and control rod worth, as shown in Fig. 37 [156]. Therefore, the control system should be redesigned for UN-based fuel.

5.4 U3Si2–FeCrAl system

U3Si2–FeCrAl systems have a different neutronic performance from the current UO2–Zr-4 system because of the different moderator-to-U ratios and different thermal absorption cross sections of the claddings. Consequently,neutronic studies are important and fundamental for the U3Si2–FeCrAl system.

Figure 38 presents the infinite multiplication factor(kinf)for 4.9%-enriched U3Si2fuel with FeCrAl claddings of different thicknesses, as well as the current UO2–Zr-4 system (235U enrichment is 4.9% in the ‘‘Ref.’’ case) [14].At the BOL, the reactivity of the U3Si2–FeCrAl system is lower than that of the UO2–Zr-4 system because (1)FeCrAl has a larger thermal neutron absorption cross section than the zircaloy and(2)the higher U density in U3Si2(and larger volume of fuel for a cladding thickness of<571.5 μm) leads to a lower moderator-to-U ratio. The decrease in kinfwith the increasing EFPD is smaller for the U3Si2–FeCrAl systems because of(1)the larger amount of239Pu production [14] and (2) the lower burnup level (the same power production but more U).

Even if the kinfat the BOL is smaller for U3Si2–FeCrAl systems,this does not imply that a lower B concentration is needed to maintain the reactor core under the critical condition. In fact, similar to the hardening of the neutron spectrum (as shown in Fig. 39 [14]) due to the larger thermal neutron capture cross section of FeCrAl than that of zircaloy [14, 156–158], the B is less efficient for providing a negative reactivity.Salazar et al.reported that the critical B concentration of the U3Si2–FeCrAl system is higher than that of the UO2–Zr-4 system for an 18-month cycle length I2S-LWR design [159].

Because the U3Si2fuel has a higher U density than the UO2fuel, it can compensate for the negative reactivity induced by FeCrAl. The relationship between the235U enrichment(e,in%)and the FeCrAl thickness(t,in μm)is expressed as follows (for the same cycle length as the current Westinghouse 24-month cycle UO2–Zr-4 system)[14]:

Assuming that the thickness of the steel is 350 μm (this value has been historically used) [109], the critical235U enrichment is 4.58%. The gain of the fuel enrichment allows the U3Si2–FeCrAl system to transmute long-lived minor actinides [160]. If the 4.9% enrichment is used for the U3Si2–FeCrAl system,the critical cladding thickness is 450 μm. This combination was referred to as the ‘‘new fuel-cladding combination’’ in our previous work and is denoted as ‘‘new’’ in the figures.

For example, at 500 EFPDs, as shown in Fig. 40 [161],the radial power distributions in the fuel pellets of the current UO2–Zr-4 system and three U3Si2–FeCrAl combinations with critical235U enrichment determined by Eq. (21) are close to each other [161]. Moreover, with the same cycle length, the hybrid UO2/U3Si2fuel with the FeCrAl cladding has a similar radial power distribution to the four aforementioned scenarios, as a function of EFPD[161]. The following second-order polynomial can fit the radial power distribution as a function of the fuel exposure(s) [161]:

where x represents the normalized radial distribution, and the coefficients a, b, and c can be expressed in the following form [73]:

Here,A,B,C,D,and E are constants determined by fitting simulated data.

The use of a nonuniform radial power distribution reduces the peak fuel temperature because of the relatively high thermal power density at the periphery of the fuel pellet. This is confirmed in Fig. 41 [161], in which the periphery phenomenon becomes more important from low burnup to high burnup and from a uniform power distribution to a realistic nonuniform radial power distribution.Additionally, because the thermal conductivity of U3Si2is higher than that of UO2(see Fig. 15), similar radial power distributions imply a flatter radial temperature distribution in the U3Si2fuel.

Even if the 571.5-μm-thick FeCrAl leads to an approximately 60 K higher temperature at the surface of the fuel pellet compared with the zircaloy cladding [162],the centerline temperature in the U3Si2fuel is approximately 200 K lower than that in the UO2fuel [161]. If a thinner FeCrAl cladding is used(e.g.,450 μm,as proposed in Ref. [14], or the historically used thickness of 350 μm[109]),the fuel temperature is lower for the U3Si2–FeCrAl combination.Moreover,our recent study indicated that the use of a dual-coolant annular fuel rod can significantly reduce the fuel temperature of U3Si2–FeCrAl systems[163].

Figure 42 shows the FTCs and MTCs of the current UO2–Zr-4 system and the new U3Si2–FeCrAl system [14].The FTCs and MTCs of the two systems are close at<200 EFPDs. In general, the absolute values of the FTC and MTC for the U3Si2–FeCrAl system are slightly smaller than those for the UO2–Zr-4 system at >200 EFPDs.Consequently, the U3Si2–FeCrAl system has slightly less inherent safety than the current UO2–Zr-4 system.

Reference[14]compares the VRC of the two systems in the cases of 5% and 50% void of the moderator. The behaviors of the VRC are similar to those of the MTC,because both the increase in the moderator temperature and the loss of coolant lead to the reduction of the amount of moderator. Therefore, the inherent safety of the U3Si2–FeCrAl system under the LOCA accident condition is slightly lower than that of the current UO2–Zr-4 system from the view point of reactivity feedback.

The control rod worths of the two systems are presented in Fig. 43 [14]. As shown, the control rod is less effective for U3Si2–FeCrAl owing to the hardening of the neutron spectrum. Consequently, a new control system design,including the control rods and B-concentration control, is required for the U3Si2–FeCrAl fuel-cladding system.

5.5 Comparison of alternative systems with current fuel-cladding system

This subsection briefly summarizes the neutronic features of different fuel-cladding systems compared with the current UO2–Zr-4 fuel-cladding system. Table 8 presents the hardening and the softening of the neutron flux spectrum, the efficiency of reactivity control, and the cycle length.

The hardening of the neutron spectrum for UO2fuel with the coated zircaloy cladding has not been studied in detail. However, because the coating materials have larger thermal neutron absorption cross sections than the zircaloy,slight hardening of the neutron spectrum is expected. The neutron spectra of the other three cases are already presented in the corresponding detailed analyses.For the same control materials, the efficiency of the reactivity control is mainly determined by the neutron flux spectrum. Therefore, the reactivity control is more efficient for a softer neutron spectrum.More efficient reactivity control does not necessarily imply a more accessible control system. For example,UO2–BeO fuel has a softer neutron spectrum than UO2fuel (as shown in Fig. 30), but the former requires ahigher B concentration to maintain the critical condition(as shown in Fig. 31) because of its higher reactivity.

Table 8 Neutronic features of different alternative fuel-cladding systems compared with the current fuel-cladding system

The cycle length is one of the most important characteristics affecting the neutron economy of a fuel-cladding system. It depends on the fuel enrichment, cladding thickness, operational history, etc. We compare the cycle lengths of different alternative fuel-cladding systems with that of the current UO2–Zr-4 fuel-cladding system,assuming the same fuel enrichment and cladding thickness and neglecting other factors, such as the operational history. A shorter cycle length is expected for UO2fuel with the coated zircaloy cladding, owing to the additional neutron absorption provided by the coating materials. This applies to both the UO2–BeO fuel and the zircaloy cladding system, because the doping of BeO leads to a smaller amount of U. In contrast, UN fuel with the zircaloy cladding has a longer cycle length than the current UO2–Zr-4 system, because of the higher U density in the fuel.

There is a compensation in the U3Si2fuel and FeCrAl cladding system, because the fuel has a higher U density and the cladding has a larger thermal neutron absorption cross section than the current system. Numerical results indicate that the U3Si2–FeCrAl combined system has a shorter cycle length than the UO2–Zr-4 system if the same fuel enrichment and cladding thickness are used.However,because of the better mechanical performance of FeCrAl compared with the zircaloy,a significantly thicker cladding is possible. If 350-μm-thick steel (historically used [109])is employed,the critical235U enrichment is 4.58%.If 4.9%enrichment(as for the reference UO2–Zr-4 system)is used,the critical cladding thickness is 450 μm for the U3Si2–FeCrAl system.

6 Summary

To improve the accident tolerance of the nuclear fuelcladding system in LWRs, extensive studies on the enhanced ATF have been performed after the Fukushima accident. In this review, we discussed the features of the current UO2–Zr system, including the optimized neutron economy,the thermal conductivity of the UO2fuel,and the main challenges for the zircaloy cladding. Then, we summarized different technologies that can improve the fuel performance under normal and accident conditions.

For protecting the cladding from the chemical reaction of Zr with water, a surface-modified Zr-based cladding is proposed for improving the oxidation resistance of the fuel cladding. We introduced different coating technologies,including metallic coatings, nonmetallic coatings, ceramic coatings, and the ODS coating. Numerous coating technologies have been developed by different laboratories. In addition to the coating technology, the implantation of several ions, such as Al, for increasing the oxidation resistance of the zircaloy is a feasible short-term solution to improve the accident tolerance of the fuel cladding.

Because the technology of the zircaloy has been well optimized in the past seven decades,it is difficult to obtain a significant improvement in Zr-based materials. The coating design can protect the cladding from oxidation.However, the main issue associated with the coating technology is the compatibility of the coating material with the zircaloy, including the matching of the thermal explosion coefficient, the diametrical compression, microstructure, and interdiffusion with Zr. Thus, alternative cladding materials have been proposed. Owing to the diversity of alternative materials,this review summarized the neutronic and thermophysical properties of FeCrAl- and SiC-based cladding materials.

The development of the ATF also allows the development and deployment of other fuels, including the advanced designs of the present UO2fuel (e.g., the FCM fuel design), the current UO2fuel doped with other materials to improve the thermal conductivity, and alternative fuels. The present review focused on BeO and Mo-doped UO2fuels, U3Si2fuel, and UN fuel. In addition to the enhanced thermal conductivity, U3Si2and UN have a higher U density than the current UO2fuel.

Because neutronic evaluation is fundamental for the application of enhanced ATF systems, we reviewed neutronic studies on different ATF systems. Regarding the coating technology, because the coating layer is significantly thinner than the cladding,the neutronic performance should be close to that of the current UO2–Zr system,with the exception of the neutron economy. The additional coating material in the cladding leads to greater neutron absorption by materials other than U, and the cycle length is reduced if the same type of fuel is used. Nevertheless,this issue can be easily resolved by slightly increasing the235U enrichment.

In the case of using alternative fuels or alternative cladding materials, the neutronic performance differs from that of the current UO2–Zr system, because of the changes in the neutron flux spectrum. The inherent safety level is also changed with the B coefficient and control rod worth,as well as the FTC, MTC, and VRC. Moreover, different power distributions lead to differences in the fuel temperature distribution and the subsequent thermomechanical performance of the fuel. Consequently, considerable modification of the reactor core design is needed to use the alternative fuel-cladding systems. This is why alternative fuels and cladding materials are difficult to deploy in the short term.

In summary, many types of potential accident-tolerant fuel-cladding systems were discussed in the present review.Although difficulties exist and further investigations should be performed, it is expected that one or more of the discussed systems will be implemented in commercial reactors.

Acknowledgements Computational resources were provided by Sun Yat-sen University and the National Supercomputer Center in Guangzhou.

杂志排行

Nuclear Science and Techniques的其它文章

- Effect of 37Cl enrichment on neutrons in a molten chloride salt fast reactor

- Spin coating of TPB film on acrylic substrate and measurement of its wavelength shifting efficiency

- Optimization of the S-band side-coupled cavities for proton acceleration

- Multi-frequency point supported LLRF front-end for CiADS wide-bandwidth application

- Complex structure of human Hsp90N and a novel small inhibitor FS5

- Mo¨ssbauer spectroscopy studies on the particle size distribution effect of Fe–B–P amorphous alloy on the microwave absorption properties