Design of Tractor Traction Resistance Monitoring System for Potato Harvest Equipment

2019-12-26ZhaoLiYangShumingWangFuweiZhangQinwei

Zhao Li ,Yang Shuming ,Wang Fuwei ,Zhang Qinwei

(1.School of Electrical Information Engineering,Beifang University of Nationalities,Yinchuan,Ningxia 750021;2.School of Mechanical Engineering,Ningxia University,Yinchuan,Ningxia 750021;3.School of Mechatronic Engineering,Beifang University of Nationalities,Yinchuan,Ningxia 750021)

Abstract:Improper power matching of potato harvesting equipment leads to the prominent problem of discontinuity and instability of mining operations.In view of this problem,the research on traction resistance test technology of potato harvesting equipment tractor is carried out.The traditional mechanical tension meter has some problems,such as inaccurate test data and poor real-time performance.In this paper,single-chip microcomputer technology,sensor technology and wireless transmission technology are integrated to design the potato harvest equipment tractor traction resistance monitoring system.The sensor monitors the traction resistance in real time.The data is processed by the sub-controller and transmitted to the master controller in real time through the wireless transmission part.The master controller sends the data to the upper computer monitoring system.The test results show that the system can realize remote and real-time data acquisition and storage,which provides an important reference for optimizing the power matching of potato harvesting equipment tractor.

Key words:potato harvest equipment;tractor;power matching;traction resistance monitoring

More than 90% of the potatoes in Ningxia are concentrated in the mountainous areas of south central.Potato is a key characteristic industry in the southern mountainous region of Ningxia,among which the potato planting area in Guyuan is stable at 2 million mu,and a quarter of the per capita net income of farmers comes from potato,which is a strategic leading industry that plays an important role in promoting rural economic development and increasing farmers'income.The field investigation results of the harvester equipment show that the existing harvester and tools have the following problems.

(1)The insufficient height of the entrance of excavation leads to the prominent congestion of membrane,rice seedlings and soil.Every 20~30 meters of operating distance needs to clear the congestion.

(2)The problem of twining potato seedlings with power input axis is serious,every 20~30 meters of operating distance needs to clear the winding.

Figure 1 Potato Harvest Equipment Operation Site

The factors mentioned above,such as congestion,entanglement and high soil viscosity,lead to high traction resistance of potato harvesting equipment,and improper power matching leads to discontinuity and instability of mining operations,as shown in figure 1.

Too large selection of tractor power on potato harvest site leads to waste of power resources,and too small selection of power leads to insufficient power and discontinuous operation.In view of this problem,the research on the traction resistance test technology of potato harvest equipment tractor was carried out.Based on the analysis of excavation components and relevant theories of traction resistance,Li Xiang designed a potato excavation resistance testing device.Through field experiments,the influence of forward speed,shovel face angle and blade angle on traction resistance was analyzed,and parameters were optimized to reduce the traction resistance and power consumption of potato excavator[1];In order to detect the actual drag reduction effect of vibrating screen,Wu Haiping designed a dynamic testing device,and conducted traction resistance tests under several different operating conditions[2].Based on discrete dynamics,Gao Wenjie established the mathematical model of each module of the tractor set when working balance,and established the matching system of the tractor set for the secondary development of CATIA[3].In order to solve the problem of high traction resistance and power consumption in the working process of the potato harvard,Deng Weigang took the digging shovel as the research object,modified the traction force model in the time of tangent,and established the traction force model applicable to both tangent and slide cutting[4].

The traditional mechanical tension meter has some problems,such as inaccurate test data and poor real-time performance.In this paper,singlechip microcomputer technology,sensor technology and wireless transmission technology are integrated to design the potato harvest equipment tractor traction resistance monitoring system.The sensor monitors the traction resistance in real time.The data is processed by the sub-controller and transmitted to the master controller in real time through the wireless transmission module.The master controller sends the data to the upper computer monitoring system.The test results show that the system can realize remote and real-time data acquisition and storage,which provides an important reference for optimizing the power matching of potato harvesting equipment tractor.

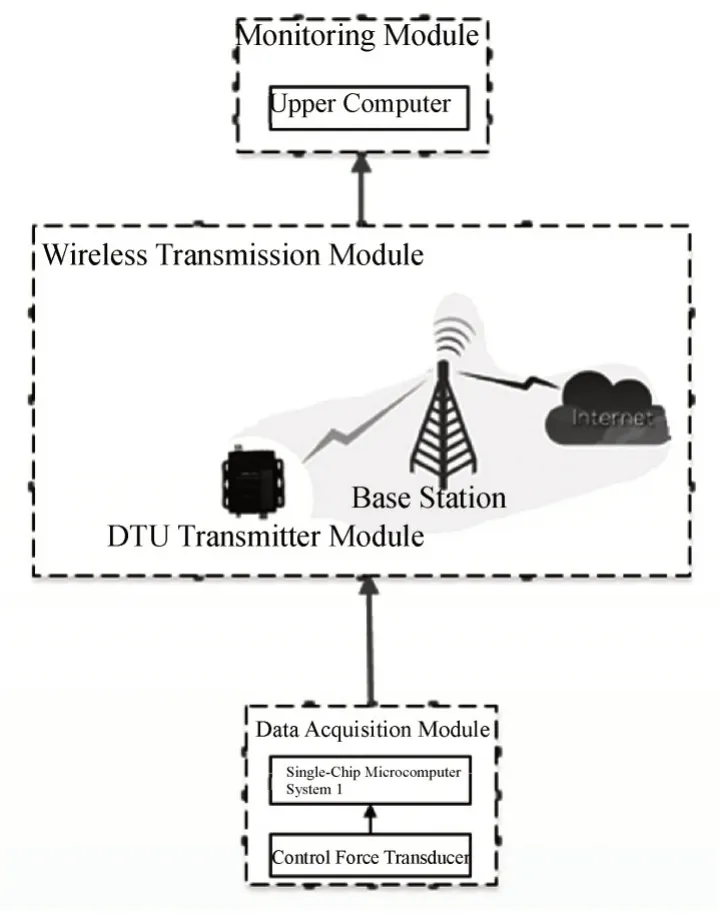

I.Overall Scheme Design of the System

Potato harvest equipment tractor traction resistance wireless monitoring system is mainly composed of data acquisition part,wireless transmission part and monitoring part.During the traction resistance test,the data collection part is installed between the tractor under load and the harvesting equipment.The real-time tension is collected and the data is sent to the wireless transmission part.The wireless transmission part transmits the data to the monitoring part,and the monitoring part completes the processing,analysis and storage of the data.The overall design scheme of the system is shown in figure 2.

Figure 2 Overall Design of Tractor Traction Resistance Wireless Monitoring System

II.Data Acquisition Module Design

(i)Design Scheme of Data Acquisition Module

The pull sensor connects the tractor to the potato harvesting device via a pull hook.The tension signal collected by the sensor is transmitted to the single-chip microcomputer system,which processes the analog signal data,continuously collects and filters the mean value for several times,the tension value after filtering is sent to the wireless transmission module through the single-chip microcomputer serial port.The design scheme of the data acquisition module is shown in figure 3.

Figure 3 Design Scheme of Data Acquisition Module

(ii)Hardware Design

(1)Sensor Selection

Tension sensor selects S beam structure sensor-QLLY,as shown in figure 4,technical parameters are shown in table 1.

Figure 4 Drawing of Tension Sensor

Table 1 Technical Parameters of Tension Sensor

(2)Acquisition Module Structure Design

The 3D structure design of the data acquisition module is carried out based on SolidWorks,and the design results are shown in figure 5 and figure 6.

Figure 5 3D Structure of Data Acquisition Module

Figure 6 Internal Structure of Data Acquisition Module

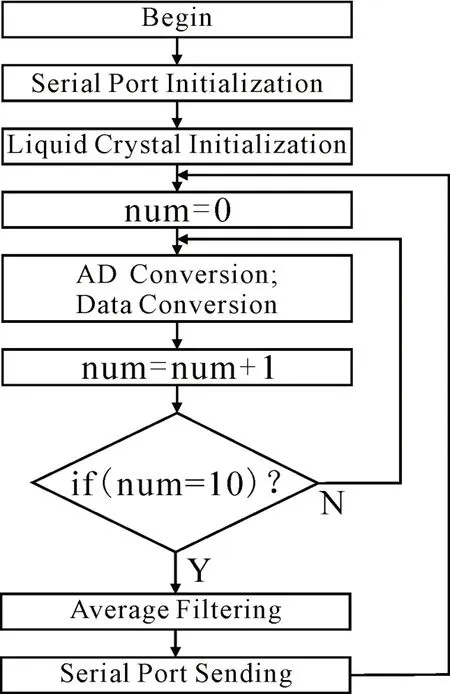

(iii)Software Design

KEIL was used to develop single-chip microcomputer software for data acquisition module,which mainly realized initialization,data acquisition of tension sensor,AD conversion,mean filtering,serial port transmission and other functions.The software workflow is shown in figure 7.

Figure 7 SCM System Software Flow Chart

III.Wireless Transmission Module Selection

The wireless transmission module is a wireless communication network composed of DTU,mobile base station and Internet,one is connected to the sub-controller system to complete data transmission,while the other is connected to the master controller to complete data reception.The DTU wireless transmission module is shown in figure 8.

Figure 8 DTU Wireless Transmission Module

IV.Design of Monitoring Module

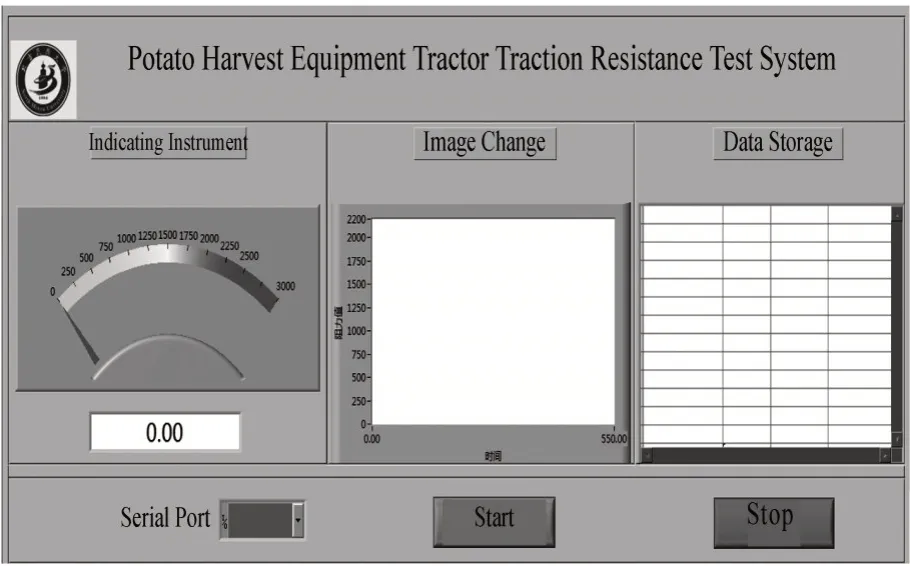

(i)Design of Upper Computer Monitoring Panel

Based on LabView software,the monitoring panel of potato harvest equipment tractor traction resistance test system is developed,which mainly consists of display instrument,image curve,data storage,test control and other modules.The monitoring panel is shown in figure 9.

Figure 9 Monitoring Panel

(ii)Design of Upper Computer Programming

The upper computer program includes serial port initialization,serial port buffering,data interception and saving,etc.The graphical program block diagram is shown in figure 10.

V.Conclusion

Figure 10 Upper Computer Program Block Diagram

According to the above design of potato harvest equipment tractor traction resistance monitoring system,the functional test is conducted,the results show that the system can collect traction resistance data stably,reliably and timely,it provides an important reference for optimizing the power matching of potato harvester tractor.

杂志排行

中阿科技论坛(中英文)的其它文章

- Study on the Casas-Alvero Conjecture of Univariate Polynomials

- Application of Computer Lingo Software in Production Efficiency

- Maple Demonstration Example of Spatial Graphic

- Study on Gemological Characteristics of Changbai Jade

- Innovation and Application of Key Technologies of Arc Spring Damping Flywheel Assembly

- Research on Medical Image Segmentation Based on Morphology