Effects of Different Storage Temperatures on Shelf Life and Quality of Strawberry Fruit after Hot Water Treatment

2019-12-17

College of Life Science, Cangzhou Normal University, Cangzhou 061001, China

Abstract Taking the strawberry fruit from an agro-ecological park in Cangzhou as the experimental material, the effects of different storage temperatures on the shelf life and quality of strawberry fruit were studied. After being treated with hot water at 42℃, the strawberry fruit was stored at (20-25)℃ and (4±1)℃, respectively. It was found that the weight loss, cell membrane permeability, titratable acid content and soluble solids content differed between different storage temperatures. At low temperature, the quality of the strawberry fruit was better, and their decay was delayed by 12 d, that is, their shelf life was extended from 2 to 14 d. After hot water treatment, the permeability of the cell membrane and the contents of titratable acid and soluble solids in the strawberry fruit increased. In summary, low temperature can better maintain the quality of strawberry fruit.

Key words Strawberry, Shelf life, Quality, Cell membrane permeability

1 Introduction

China’s wild strawberry species are very rich. More than 101 strawberry germplasms have been collected in the world, with 11 germplasms distributed in China[1]. Strawberry is a plant of the family Rosaceae. It is a perennial evergreen grass plant with bright color and delicious taste. It is also soft and juicy, with abundant nutrients[2]. The maturity of strawberry is relatively early. It is a good nourishing product and is very popular among consumers. It can also be processed into sauces, wines, fruit tea, drinks and quick-frozen foods,etc., and has a very broad market.

Strawberry fruit has a high water content and a soft tissue. Due to the failure to better solve its storage and preservation problems, it is very susceptible to mechanical damage and microbial infiltration. Under normal temperature, it will change color and mold after 2 d and begin to decay after a long time[3]. Decay of strawberry fruit is mainly caused by gray mold and soft rot caused byBotrytiscinereaandRhizopusoryzae[4-5], which makes the value of strawberry fruit decline rapidly and is also not conducive to the development of strawberry production. This is also a difficult problem to be solved in fruit storage.

At present, the preservation of fruits and vegetables mainly starts from three stages of early, middle and late stages[6]to improve their storability, thus extending their shelf life. Among them, post-harvest preservation has always been a key issue in the preservation of fruits and vegetables[7]. China has a large amount of strawberries, and the industry has developed rapidly. Strawberry fruit is an important fruit in China. In recent years, the fruit varieties represented by strawberry have developed rapidly. People have a new understanding of the nutritional value of strawberry fruit, making the demand for strawberry fruit increase in domestic and foreign markets. The application of heat treatment technology in the preservation of fruits and vegetables has been continuously developed. Heat treatment, as a physical preservation method, is very outstanding in preservation effect. The heat treatment technology has been applied in the storage of fruits and vegetables such as apples[8], bananas[9], and tomatoes[10]. It meets food safety requirements, and is recognized and accepted by more and more people. To this end, taking strawberry fruit as a test material, the effects of different storage temperatures on the cell membrane permeability, weight loss, decay rate, fruit firmness, titratable acid content and soluble solids content of the strawberry fruit during storage were studied, so as to provide new techniques and methods for the storage and preservation of fruits such as strawberry and provide a theoretical basis for extending the shelf life of strawberry fruit.

2 Materials and methods

2.1 Test materialThe fruit of Hongyan (a strawberry cultivar) that is free of pests, diseases and mechanical damage and consistent in size and maturity was collected from an agro-ecological park in Cangzhou City. It was transported to the laboratory within 2 h after harvest.

2.2 Test methods

2.2.1Treatment and storage of test material. On the day of picking, the strawberry fruit was subjected to heat treatment at 42℃ for 15 min, ventilated forcedly for 4 h, air-dried, cooled to room temperature, placed in 20 pieces of 0.04-mm-thick plain plastic bags (550 mm × 600 mm, unsealed) with 200 g per bag, and stored at (4±1)℃ and (20-25)℃ respectively. The strawberry fruit that had not undergone heat treatment was taken as the control. The decay rate of each treatment was counted every 2 d. Sapling was carried out according to the specified time during the storage period for the observation of morphological indices and determination of quality indices. Three replicates were arranged for the determination of each index.

The strawberry fruit that had undergone hot water treatment was cooled and then stored at room temperature and low temperature, respectively. The storage period was 6 d, and sampling was conducted once every 2 d. The firmness, decay rate, weight loss, soluble solids content, titratable acid content and cell membrane permeability were determined.

2.2.2Determination of decay rate. After treated with hot water at 42℃ for 15 min (covered with plastic wrap to avoid water loss), the strawberry fruit was ventilated forcedly for 4 h, cooled and stored at (20-25)℃ and (4±1)℃, respectively. The strawberry fruit that had not undergone hot water treatment was taken as the control. There were three replicates in each treatment group. The decay rate of the fruit was counted every 2 d.

Decay rate(%)=Number of decayed fruit/Total number of fruit

2.2.3Determination of cell membrane permeability. The skin of the strawberry fruit was cut into 10-mm rounds using a stainless steel punch[11]. A certain amount (1.00 g) of the rounds was placed into a 50-mL beaker, added with 20 mL of distilled water, stirred slowly at 20℃ for 15 min, measured (C1) by a conductivity meter (DDS-IIC), boiled for 20 min, cooled, added with 30 mL of distilled water, stirred evenly and measured (C2) by the conductivity meter (DDS-IIC) again. Three strawberries were selected for each group for each time of measurement, and the measurement was repeated three times.

Relative conductivity (%) = (C1/C2) × 100%.

2.2.4Determination of weight loss. Weight loss was determined using the weighing method. The strawberry fruit of each group was weighed just before the beginning of the storage and then weighed again just after the ending of the storage. Two strawberries were selected for each group.

Fruit weight loss (%) = [Mass of fruit before storage-Mass of fruit after storage for a certain period of time]×100%.

2.2.5Determination of fruit firmness[12]. The strawberry fruit of the treatment and control groups were taken out, cooled, dried and storage at (4±1)℃ and (20-25)℃, respectively. The firmness of the strawberry fruit at each temperature was measured. Two points were assigned randomly on the equator of each strawberry, and the firmness of the strawberry was measured by pressing the head of the durometer (GY-4) into the strawberry. The diameter of the probe was 5 mm, with a test distance of 6 mm and speed of 3 mm/s. Each strawberry was measured twice. The resistance (Unit: N) encountered at the time when the probe entered the most into the strawberry was regarded as the firmness of the strawberry. Three strawberries were used for each group.

2.2.6Determination of titratable acid content. Referring to the method of Ru Xuejuan[10], titratable acid content was determined using the acid-base titration method. Five strawberries were selected randomly from each group. After abandoning the non-edible portion, 50 g of the pulp was weighed, added with 50 mL of distilled water and homogenized with a homogenizer. Then, 20 g of the homogenate was weighed, diluted with water to 100 mL, bathed in hot water (75℃) for 30 min (shaken more than once during the time), cooled, diluted with water to 100 mL again, and filtered in success. A certain volume (20 mL) of the filtrate was added with two drops of phenolphthalein indicator (1%, 1 g of phenolphthalein dissolved in 100 mL of 80%-90% ethanol), titrated with sodium hydroxide standard solution (0.1 mol/L) until the solution turned reddish and the red color did not fade in 30 s. Malic acid was used as the conversion coefficient.

Titratable acid content [mmoL/100g(mL)] =[(c×V1×k)/V0]×[250/m(V)]×100%.

wherecis molar concentration of sodium hydroxide standard solution;V1is the volume of sodium hydroxide standard solution consumed by the titration (mL);V0is the volume of the sample liquid sucked for titration (mL); m(V) is sample mass (g or mL); 250 is the volume of the sample after leaching (mL); andkis the grams of malic acid corresponding to 1 mmol of sodium hydroxide standard solution (0.067).

2.2.7Determination of soluble solids content. Determination of soluble solids content was conducted according to the method of Chang Wenjun[7]. A total of two strawberries were randomly selected from each group. They flesh of the strawberries from each group was taken out with a knife, put into a mortar, mashed, wrapped with gauze and squeezed to obtain the juice, which was then measured using a digital Abbe refractometer (WAY-2S). The refractive index was recorded and converted to soluble solids content. In each group, the juice preparation and measurement was repeated three times.

3 Results and analysis

3.1 Effects of different temperatures on the decay rate of strawberry fruit after hot water treatmentAfter treated with hot water (42℃) for 15 min, the strawberry fruit was stored at normal temperature and low temperature, respectively. The decay situation of the strawberry fruit is shown in Fig.1. When stored at normal temperature, the strawberry fruit of the control and hot water treatment groups began to decay 2 d later. As time proceeded, the decay rate of the hot water treatment group was lower than that of the control group. When stored at low temperature, the strawberry fruit of the control group began to decay 8 d later, and that of the hot water treatment group began to decay 14 d later; and the decay rate of the hot water treatment group was also lower than that of the control group. The result show that after hot water (42℃) treatment, the strawberry fruit stored at low temperature was better than that stored at normal temperature, and the decay of the strawberry fruit stored at low temperature was delayed by 12 d compared with that stored at normal temperature, that is, under the condition of low temperature, the shelf life of the strawberry fruit that had undergone heat treatment was extended from 2 to 14 d.

Fig.1 Effects of different storage temperatures on the decay rate of strawberry fruit after hot treatment

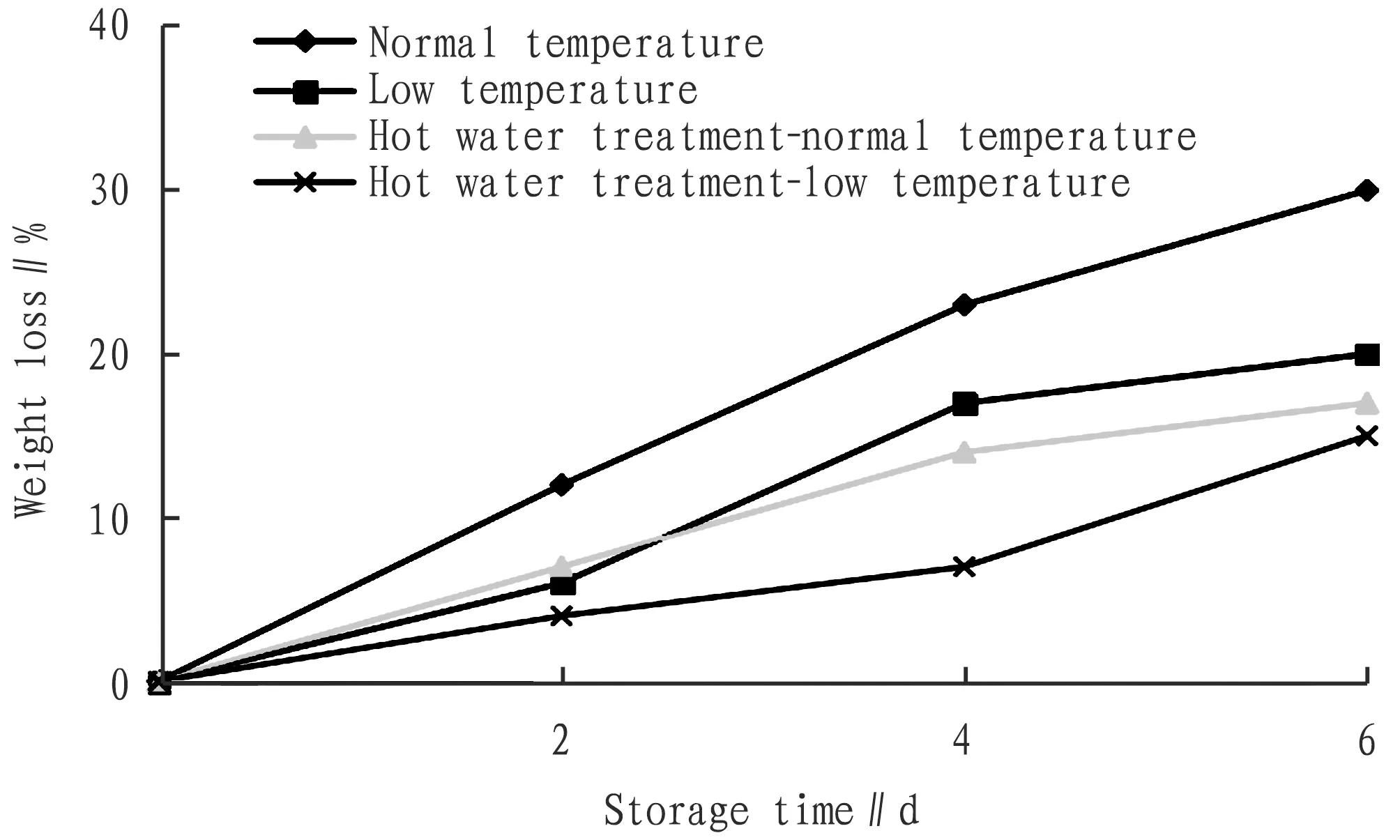

3.2 Effects of different temperatures on the weight loss of strawberry fruit after hot water treatmentAs shown in Fig.2, the weight loss of strawberry fruit increased with time. At normal temperature, the weight loss of strawberry fruit was generally smaller than that of the control. At the beginning, the weight loss of the strawberry fruit that had undergone low temperature and hot water treatment did not change much. As time went on, the weight loss of the strawberry fruit of the hot water treatment group stored at normal temperature was lower than that of the strawberry fruit of the control group stored at low temperature; and the weight loss of the strawberry fruit of the hot water treatment group stored at low temperature was lower than those of the strawberry fruit of the control group, especially lower than that of the strawberry fruit of the control group stored at normal temperature. It indicates that for strawberry fruit that has undergone hot water treatment, the more favorable storage temperature is low temperature, which is more conducive to the preservation of the strawberry fruit and the development of strawberry industry.

Fig.2 Effect of different storage temperatures on the weight loss of strawberry fruit after hot water treatment

3.3 Effects of different temperatures on the cell membrane permeability of strawberry fruit after hot water treatmentAs shown in Fig.3, the relative conductivity of the strawberry fruit on the day of purchase reached 76%. The possible reason was that the skin of the strawberry fruit was thinner, and the rate of change of substances inside the strawberry cells was relatively fast. At the temperature of (20-25)℃, as the storage time extended, the relative conductivity of cell membrane of the strawberry peel increased in the control group and the treatment group. At low temperature of (4±1)℃, the relative conductivity of strawberry peel also increased. On the 6th d, at normal temperature, the relative conductivity of cell membrane of the strawberry peel in the treatment group was lower than that in the control group, and the relative conductivity of cell membrane of the strawberry peel in the control group reached 89%. At low temperature, the relatively conductivity of cell membrane of the strawberry peel in the treatment group was also lower than that of the control group. The results show that the relative cell membrane conductivity of peel of the strawberry fruit that had undergone hot water treatment and was stored at different temperatures was both smaller than that of the control group.

Fig.3 Effects of different storage temperatures on the cell membrane permeability of strawberry fruit after hot water treatment

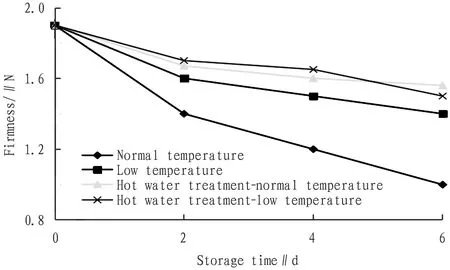

Fig.4 Effects of different storage temperatures on the firmness of strawberry fruit after hot water treatment

3.4 Effects of different temperatures on the firmness of strawberry fruit after hot water treatmentAs the storage period was extended, the firmness of the strawberry fruit gradually reduced ( Fig.4). Regardless of the storage temperature, the firmness of the strawberry fruit of the hot water treatment group was greater than that of the control group. That is, hot water treatment is more favorable to the maintaining of the firmness of strawberry fruit, so that the strawberry fruit can be better preserved.

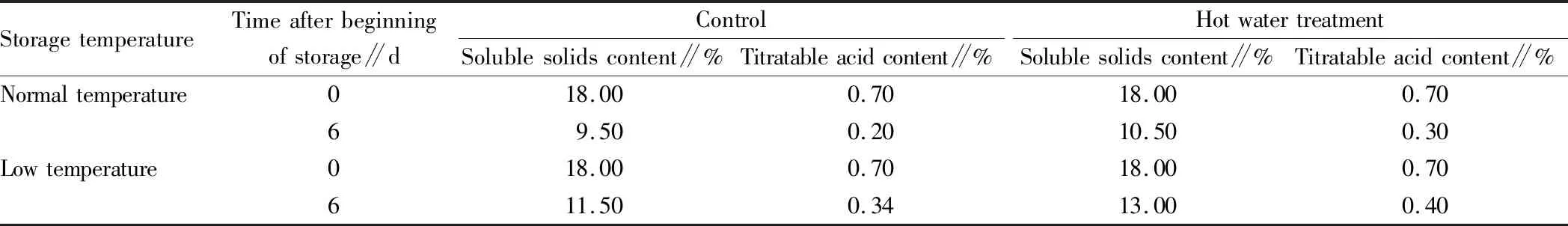

3.5 Effects of different temperatures on the soluble solids and titratable acid contents of strawberry fruit after hot water treatmentOn the 6th d of the storage, the strawberry fruit was sampled for the determination of soluble solids content and titratable acid content. As shown in Table 1, in both the treatment and control groups, the contents of soluble solids and titratable acid in the strawberry fruit stored at different temperatures reduced as the storage period was extended. At normal temperature, the contents of soluble solids in the strawberry fruit of the control and hot water treatment groups decreased by 8.5% and 7.5%, respectively, and the contents of titratable acid decreased by 5.0% and 4.0%, respectively. On the 6th d of the storage at low temperature, the content of soluble solids in the strawberry fruit of the treatment group was higher than that of the control group, and the content of titratable acid in the strawberry fruit of the treatment group was also higher than that of the control group. The results show that under the storage condition of low temperature, the decreases in the soluble solids content and titratable acid content in the strawberry fruit that had undergone hot water treatment were smaller than those in the strawberry fruit of the control group, indicating that hot water treatment is more favorable to the preservation of strawberry fruit.

Table 1 Effects of different storage temperatures on soluble solids and titratable acid contents of strawberry fruit after hot water treatment

StoragetemperatureTimeafterbeginningofstorage∥dControlSolublesolidscontent∥%Titratableacidcontent∥%HotwatertreatmentSolublesolidscontent∥%Titratableacidcontent∥%Normaltemperature018.000.7018.000.7069.500.2010.500.30Lowtemperature018.000.7018.000.70611.500.3413.000.40

4 Conclusions and discussion

The hot water treatment technology can inhibit rot and pathogens in fruits and vegetables during their storage and preservation to improve the shelf life. The results of this study show that hot water treatment and low-temperature storage can delay the decay and prolong the shelf life of strawberry fruit. When stored at normal temperature, the strawberry fruit began to decay 2 d later. After treated with hot water and stored at low temperature, the decay of the strawberry fruit was delayed by 14 d,i.e., the shelf life of the strawberry fruit was extended from 2 d to 16 d. Low-temperature storage after heat treatment significantly reduced the weight loss of strawberry fruit during storage, conducive to the preservation of strawberry fruit. At the storage temperature of (20-25)℃ and (4±1)℃, as the storage time increased, the relative conductivity of the strawberry fruit increased, which is consistent with the findings of Huang Xingbao[13]and Han Junqi[14]on chestnut and the finding of Ba Liangjie[15]on dragon fruit. Under the condition of low temperature, the growth and reproduction of microorganisms can be controlled, and the nutrients in strawberry fruit are not rapidly decomposed by microorganisms, thereby reducing the decrease in strawberry firmness. At the storage temperature of normal temperature, the soluble solids contents in the strawberry fruit of the treatment and control groups reduced by 8.5% and 7.5%, respectively, and the contents of titratable acid decreased by 5.0% and 4.0%, respectively. At the storage temperature of low temperature, the contents of soluble solids and titratable acid in the strawberry fruit of the hot water treatment group were both higher than those of the control group, indicating that heat treatment and low-temperature storage can better maintain the quality of strawberry fruit. In short, China’s strawberry industry has developed rapidly, bringing a lot of economic and social benefits to China[16]. Heat treatment can effectively reduce the decay of strawberry fruit without affecting the quality of the strawberry, and it will hopefully replace the chemical approach. Research on heat treatment, as a physical preservation method for fruits and vegetables without poisonous effect or pesticide residues, has become very active in some related fields. It has become one of the fruit and vegetable preservation methods that have received much attention in recent years. In particular, the method of heat treatment has been continuously improved and updated in recent years.

杂志排行

Asian Agricultural Research的其它文章

- Application Effects of Stabilized Fertilizer with Reduced Amount and Frequency on Rice

- Characteristics of Changes in Energy Consumption of Rural Residential Buildings from the Perspective of Province and Recommendations

- Contents of Heavy Metals in Typical Aquatic Products from a Market in Binzhou

- Analysis of the Land Use Structure in Alpine Valley Area of Jinsha River: Taking Xueshan Township, Luquan County, Yunnan Province as an Example

- Assessment on Ecological Capital of Small Towns: A Case Study of Baita Town, Weifang

- Yield Gap Analysis of Wheat in Rice-wheat Rotation Regions of Anhui Province, China