新疆棉田残膜回收方式及资源化再利用现状问题与对策

2019-10-10梁荣庆陈学庚张炳成蒙贺伟彭祥彬李卫敏

梁荣庆,陈学庚,张炳成,蒙贺伟,姜 鹏,彭祥彬,坎 杂,李卫敏

新疆棉田残膜回收方式及资源化再利用现状问题与对策

梁荣庆,陈学庚,张炳成,蒙贺伟,姜 鹏,彭祥彬,坎 杂※,李卫敏

(1. 石河子大学机械电气工程学院,石河子 832000;2. 农业部西北农业装备重点实验室,石河子 832000)

地膜覆盖栽培技术在促进农作物增产增收的同时,地膜残留问题也给农业生产环境及生态环境带来了诸多危害,地膜使用与农业生态环境保护及农业绿色可持续发展之间的矛盾日益突出。新疆作为中国棉花主产区,受种植面积增长、长年连作、地膜强度差及回收力度不够等多重因素影响,棉田残膜污染问题尤为严重。该文在实地调研的基础上,分析归纳当前新疆棉田地膜使用基本状况及残留污染情况,以当前新疆棉田残膜回收方式及资源化利用情况为主要研究内容,对采用不同回收方式回收的棉田残膜特点进行分析。通过实地调查当前新疆残膜初清理方式、再加工处理工艺流程及利用途径等基本情况,分析了各生产环节配套设备及工作过程,结果表明:先进适用的农田残膜回收机械缺乏、机收棉田残膜含杂量较高、残膜初清理及再加工设备缺乏且技术不成熟、残膜初清理及再加工企业较少等是阻碍新疆农田残膜资源化利用进程的主要影响因素,建议通过加快耐候性及高强度地膜推广与示范,提升农田残膜机械化回收技术水平,合理布局残膜初清理及再加工企业等多种途径,实现地膜生产、使用、回收及资源化利用各环节协同推进,形成全产业链闭环残膜污染治理模式,全方位及多层次解决新疆农田残膜污染问题,为新疆乃至全国农田残膜污染治理及资源化利用提供一定借鉴与参考。

地膜;回收;棉花;污染治理;初清理;资源化利用

0 引 言

地膜覆盖栽培技术具有改善农作物生长环境及调节农作物生长周期等功能[1-6],被广泛应用于国内外农业生产中[7],推动了农业生产力及农业产业发展[8-11],也促进了农作物增产增收[12],该技术自20世纪70年代引入以来,在中国大部分地区取得了迅速推广与应用,尤其在北方干旱、半干旱及高山冷凉地区使用最为普遍[13-18],目前农用地膜已成为中国农业四大生产资料(种子、地膜、农药及化肥)之一[19]。截止到2017年底,中国当年农作物地膜覆盖面积及总使用量已达到了1 865.7万hm2及143.7万t[20],年需求量增长趋势明显。随着地膜覆盖面积及使用量的增加,农田地膜残留给农业生产环境及生态环境带来了诸多问题,目前中国农田地膜残留量约占总使用量的1/4~1/3[8]。

新疆作为中国棉花主产区,地膜覆盖面积及使用量均居全国首位,残膜污染问题尤为严重[21-25],影响了棉花发育生长及产量[26-28],降低了农机作业质量[29-30]及造成了棉纺织品异性纤维含量超标[31-33],还产生了“视觉污染”[34]及“白色污染”[35],诸多问题表明地膜使用与农业生态环境保护及农业绿色可持续发展之间的矛盾日益突出。为解决农田残膜污染问题,多年来各级政府相继出台了相关政策、法律及法规[36-41],各高校、科研院所及企业也针对以棉田残膜为主要对象的机械化回收方式与方法开展了大量及深入研究[42-55],农田残膜污染治理工作已取得了初步成效,但农田残膜污染治理属于系统工程,收而不用又会造成二次环境污染及有效资源浪费。

因此,本文在前期研究及实地调研的基础上,以新疆棉田残膜初清理及资源化利用现状为主要研究对象,通过归纳当前新疆棉田地膜使用的基本状况及残留污染程度,对比分析采用不同回收方式回收的棉田残膜的初清理及资源化再加工利用难易程度,实地调查了当前新疆棉田残膜初清理方式、再加工处理工艺及利用途径等情况,对各生产环节配套设备及工作过程进行概述。目前新疆由于受先进适用的棉田残膜回收机械缺乏,机收棉田残膜含杂量高,残膜初清理及再加工企业较少等多重因素影响,回收后的棉田残膜并未进行及时有效处理和资源化利用,残膜回收和资源化利用需并举并重,才能有效解决残膜污染问题。为此,提出了加快耐候性及高强度地膜推广与示范,提升机械化农田残膜回收技术水平,开发合适的农田残膜初清理及再利用技术,合理布局残膜初清理及再加工企业等应对措施,实现地膜生产、使用、回收及资源化利用各环节协同推进,形成全产业链闭环残膜污染治理模式,多层次及全方位解决新疆棉田残膜污染治理问题,推动新疆乃至全国农田残膜污染治理及资源化利用进程。

1 新疆棉田残膜使用及污染情况分析

1.1 新疆棉田地膜使用情况分析

新疆地膜覆盖栽培技术从20世纪80年代在棉花种植中开始推广使用[56],现已扩展到了玉米、马铃薯、辣椒、加工番茄、花生、葫芦瓜及打瓜等农作物种植过程中,是促进新疆农业发展的重要手段之一。

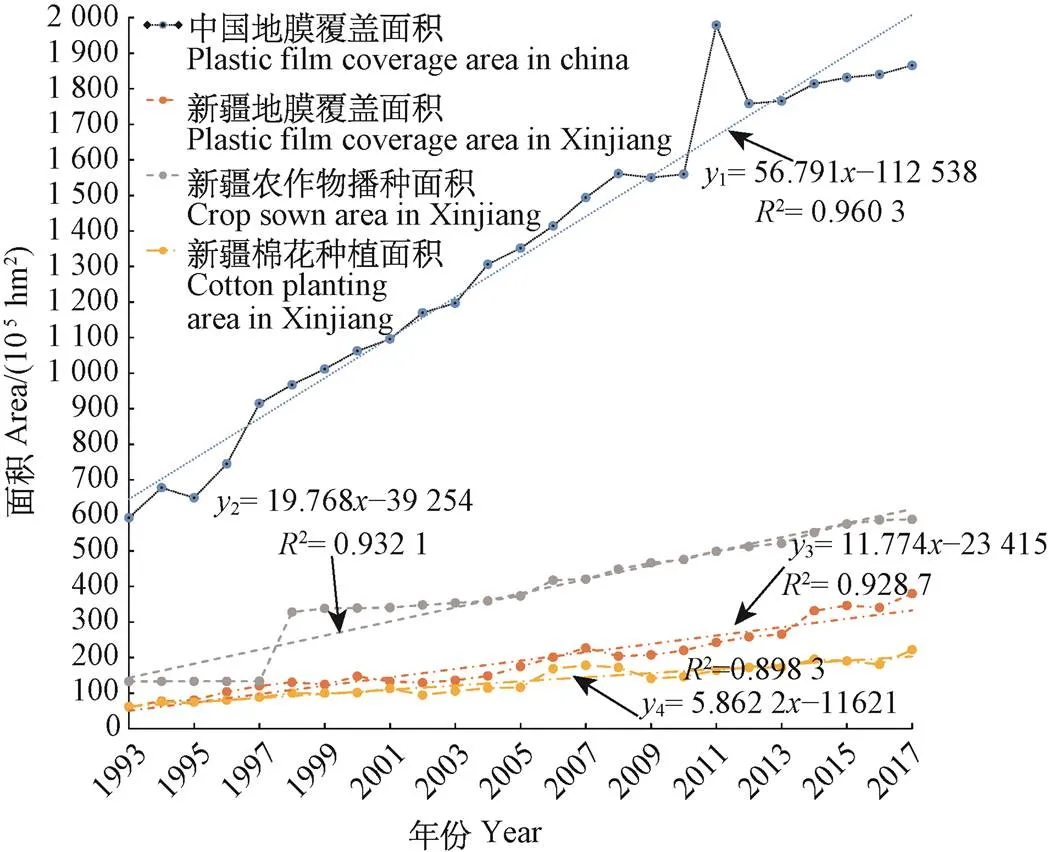

如图1,统计资料显示[57],1993年新疆农作物种植面积为132.9万hm2,其中棉花种植面积为60.64万hm2,新疆当年农田地膜覆盖面积为61.7万hm2,约占中国当年农田地膜总覆盖面积的10.4%,由于新疆棉花均采用覆膜种植,新疆棉田覆膜总面积也为60.64万hm2,约占新疆当年农田地膜总覆盖面积的98.3%。随着宽膜覆盖、膜下滴灌、精量播种等整套高效田间作业新工艺在新疆的率先提出与快速推广[58-60],该地区地膜覆盖栽培技术被提高到了新水平。

截止到2017年,中国及新疆当年农田地膜总覆盖面积分别为1 865.7万hm2及379.6万hm2,新疆当年农田地膜总覆盖面积约占中国当年农田地膜总覆盖面积的20.3%和新疆当年农作物总播种面积(588.7万hm2[19])的64.5%,而新疆当年棉花种植面积为221.75 万hm2,新疆棉花覆膜总面积也为221.75 万hm2,约占新疆当年农田地膜总覆盖面积的58.4%。

图1 1993—2017年农作物播种面积、地膜覆盖面积及棉花种植面积

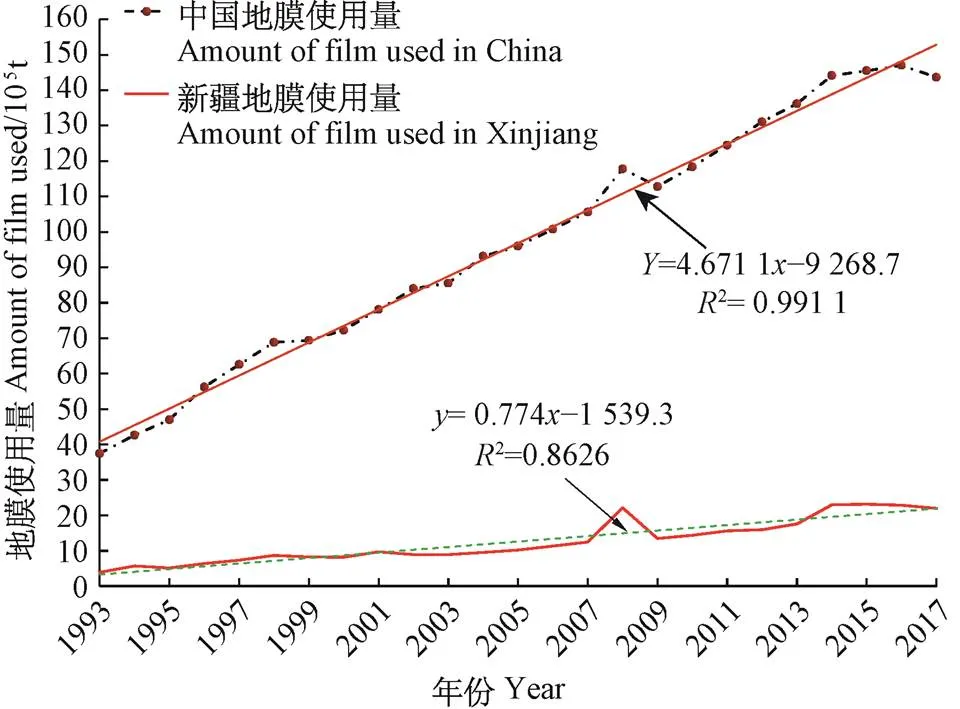

由图2可知,1993年中国及新疆当年农田地膜总使用量分别为37.5及3.9万t,新疆当年农田地膜总使用量约占中国当年农田地膜总使用量的10.4%,由于新疆当年棉花覆膜面积约占新疆当年农田地膜总覆盖面积的98.3%,则新疆当年棉花农田地膜使用总量约为3.83万t。截止到2017年,中国及新疆当年农田地膜总使用量分别为143.7及21.9万t,新疆当年农田地膜总使用量约占中国农田地膜总使用量的15.3%,按新疆当年棉花覆膜总面积约占新疆当年农作物覆膜总面积的58.4%推算,2017年新疆当年棉花农田地膜使用总量为12.8万t。

近年来,随着中国农业产业结构调整、基本国情发展现状、农作物种植区域变化及种植规模扩大等诸多因素影响,以高分子聚合物材料为主要成分的农田地膜在一段时间内仍会继续被广泛使用[13],给新疆乃至中国农田残膜污染治理增加了一定的难度。

图2 1993—2017年中国及新疆农田地膜总使用量

1.2 新疆棉田残膜污染情况分析

农田地膜主要成分为高分子聚合物,性能极为稳定,自然降解时间为200~400 a[61]。随着农田地膜使用量和使用年限不断增加[62],农田残膜在土壤中大量聚集,当前全国耕地农田地膜平均残留量约为60 kg/hm2,最高已达到了165 kg/hm2[63-64],给农业生产、农作物生长和生态环境保护等带来了诸多问题。

2018年全国棉花种植面积为335.2万hm2,新疆作为中国棉花主产区,2018年棉花种植面积为249.2万hm2,约占全国总量的74.3%[65]。随着新疆棉花种植面积逐年扩大及长年覆膜连作,30多年来棉田积累的残膜污染问题尤为突出。土壤耕层中残膜碎片增多主要是由于农田地膜材料厚度、覆膜强度及回收力度不够等影响因素所造成的[66],文献[67-72]显示,新疆长期覆膜棉田耕层地膜残留量为42~540 kg/hm2,平均残留量在260 kg/hm2以上,是全国农田地膜平均残留量的4倍多,且该指标随种植年限增加而不断增加,地膜覆盖连续20年种植棉花-加工番茄土壤耕层中地膜残留量甚至高达358 kg/hm2。另外,新疆棉田地膜在耕层中的残留量分布较为集中,据调查统计在0~300 mm耕层土壤中的残膜量约占地膜总残留量的85%以上,且以碎片居多,极易形成残膜障碍层,与表层残膜相比其回收及初清理更困难。

2 新疆棉田残膜回收现状

由于棉花为新疆地区主要农作物,为了解及掌握当前新疆残膜回收及资源化利用现状,该文主要以新疆棉田残膜为主要研究对象,对其回收方式及回收后状态等进行了实地调研,目前新疆棉田残膜回收方式以人工和机械回收为主。

2.1 人工收膜作业

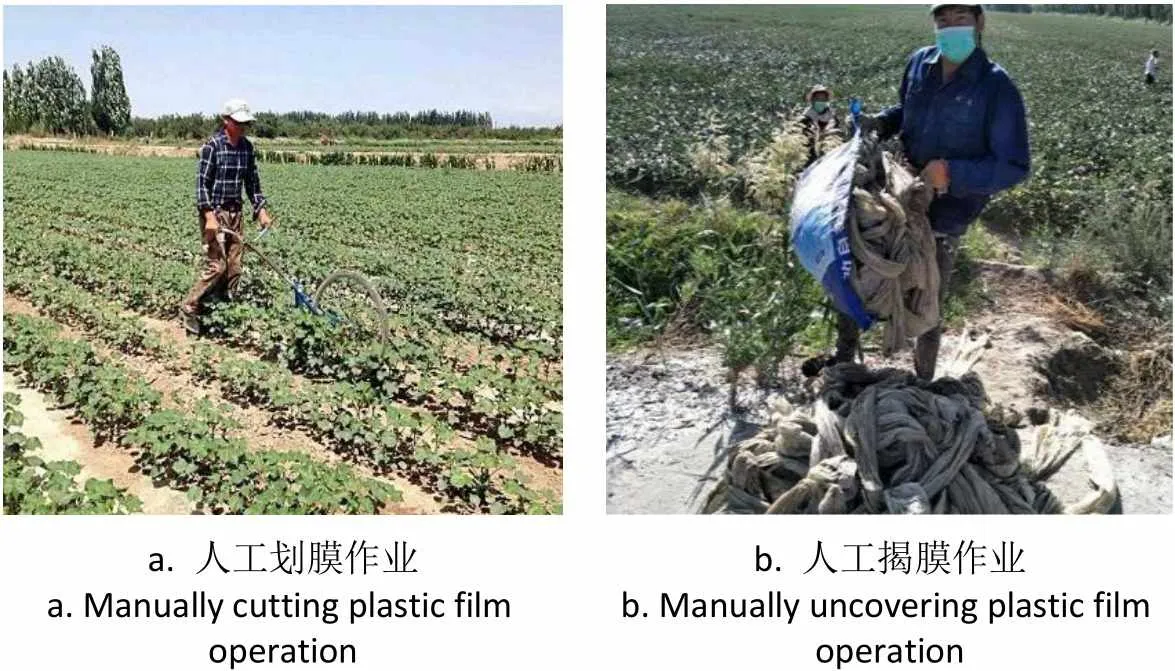

2018年对新疆阿拉尔市、石河子市、双河市及玛纳斯县等地棉田残膜回收情况调研过程中发现,调研结果显示:南疆部分地区棉田残膜回收采用人工揭边膜、划中膜及揭膜作业方式,人工揭边膜及划中膜作业(图3a)主要在每年5月下旬至6月中旬首次灌溉前进行,以铁锹辅助作业或直接拖拽为主,无相应机械配套;划中膜作业则利用简单圆盘式划膜片或铁钩完成,人工揭边膜及划膜作业成本为150~200元/(人·d),作业效率约为2.67 hm2/(人·d)。

a. 人工划膜作业a. Manually cutting plastic film operationb. 人工揭膜作业b. Manually uncovering plastic film operation

人工揭膜作业(图3b)主要集中每年8月中旬灌溉前或11月中旬采棉结束后且棉秆粉碎还田作业前后进行,8月中旬灌溉前揭膜作业时棉田残膜强度及完整性较好,且人工揭取的残膜较为完整,其残留量及含杂量较少,有利于资源化利用,但该时期棉花正处于发育生长期,棉株高且棉铃多,为避免伤铃,该环节均采用人工揭膜,并无相应配套或辅助机械;另外也有部分农户选择在11月中旬棉花收获结束后且棉秆粉碎还田作业前后进行揭膜作业,该阶段棉田残膜强度及完整性与8月中旬相比较差,揭膜完整性较低,回收的残膜含有一定量棉秆,不利于后期残膜初清理及资源化利用。调研显示,人工揭膜作业效率约为0.67 hm2/(人·d),农闲时期人工作业成本最高为150元/(人·d),近年来由于新疆劳动力短缺,农忙时节人工成本较昂贵,约为200元/(人·d),而且雇佣困难,成本高、工作效率低、用工量及劳动强度大等问题,不适合大面积连续作业。

新疆伊犁、阿拉尔及奎屯小部分降水量及水资源丰富地区也存在苗期人工揭膜作业,并不适合大范围推广,此外在棉花生长期进行人工破膜或揭膜不能够完全发挥地膜保湿保墒、增温抑草等功能,易造成棉花单株成铃数减少,降低单铃质量,从而导致减产[73-75]。

2.2 机械收膜作业

为实现新疆棉田残膜机械化回收,20世纪80年代新疆部分单位开始对残膜回收机进行研制[76],30多年来新疆各科研院所、高校及企业对以棉田残膜回收机为主进行了大量研究。棉花残膜回收机械根据不同作业时间主要分为播前残膜回收机械、苗期揭膜回收机械和秋后残膜回收机械[77],其中秋后残膜回收机械应用最为广泛。

1)播前残膜回收机械

播前残膜回收机械主要是在棉花播种前对耕层内前季及多年残膜碎片进行回收的作业机械,包括搂耙式、链筛式、钉齿式、弹齿式、联合整地式及深翻筛土式等类型[78-83]。以搂耙式、弹齿式及钉齿式等结构为主的播前残膜回收机械作业深度一般为50 mm,该类型机具回收的棉田残膜以短条或碎片为主,含杂量少,有利于棉田残膜初清理及资源化利用。

深翻筛土式播前残膜回收机又称为耕层残膜回收机,作业深度可达200 mm以下。在作业过程中,主要采用旋耕装置将土壤打散,利用链筛式等分离装置将土壤与残膜进行筛分,继而实现残膜的有效回收,该类作业机具回收的残膜以碎片为主且含杂量较高,若处理不及时或不合理极易造成二次环境污染。另外,由于机收残膜中夹杂大量往季或当季还田的棉秆,对秸秆还田实际效果也会产生一定影响。

2)苗期揭膜回收机械

苗期揭膜作业主要是在棉花首次灌溉前进行揭膜,由于此时农田地膜铺设时间较短,强度较好,易于进行整膜回收。根据回收方式不同苗期揭膜回收机主要分为卷模式、齿链式等类型,由于回收的棉田残膜完整性好,残膜收净率较高且含杂率较少[13,84-85],有利于后续的初清理及资源化利用。但苗期揭膜致使农田地膜起不到保温、保湿及抑草等作用,不仅会导致棉花灌溉次数及灌水量增加,还会造成棉田杂草疯长及棉花减产,该方法极不适用于以膜下滴灌技术为主的新疆等干旱地区,因此目前新疆大部分地区均未采用该作业方式,只在降水量充沛及水资源丰富的小部分地区进行了推广示范。

3)秋后残膜回收机械

秋后残膜回收机械目前在新疆推广应用最为广泛,该类型机械作业时间主要集中在棉花收获结束后,其根据作业功能可分为单功能作业机具和联合作业机具。

单功能作业机具只能进行残膜回收作业,主要包括立杆式、滚筒式、滚刀式及夹指链式等类型[86-90],其中以立杆式残膜回收机应用作为广泛。该类型机具在棉秆粉碎还田前进行作业时,棉花根部及压入土壤中的地膜回收困难,且残膜易被棉秆缠绕,降低了残膜回收率;当该类型机具在棉秆粉碎还田后进行作业时,虽可避免棉秆缠绕问题,但还田棉秆也被同时回收,造成残膜含杂量高,不利于后续初清理及资源化利用。

秋后残膜回收联合作业机具主要包括弹齿式、夹指链式、链耙式、随动式及二次分离式等类型[91-97]。该类机具在作业过程中,利用棉花秸秆粉碎装置将棉秆粉碎,采用绞龙、输送带或气吹等多种方式将粉碎的棉秆抛至机具后侧或侧面,与此同时机具中的残膜回收装置对残膜进行有效回收,并将其送至集膜箱、卷膜辊或压膜打包辊等残膜收集装置中,一次性完成棉秆还田和残膜回收联合作业。由于部分秋后残膜回收联合作业机具回收的棉田残膜含杂量高,极不利于初清理及资源化利用。另外,该类型机具多采用侧置式抛秆,粉碎的棉秆被集条堆放在一行内,不易腐烂分解,在土壤耕层中易形成隔离层,影响棉花播种,降低棉种发芽率及成活率,致使棉花减产。

以陈学庚院士为主的研究团队研制的随动式及二次捡拾式秋后棉田残膜回收联合作业机,在作业过程中可将棉田残膜整片卷起,残膜杂质含量少,运输方便,有利于棉田残膜初清理及资源化利用,该机型目前仍处于试验验证阶段,还未进行市场推广[91]。

受残膜机类型、地区及作业工况条件等因素影响,当前新疆棉田残膜机械回收作业成本为150~525元/hm2,立杆式搂膜机作业费用最低,为150元/hm2,但回收后的残膜含杂量较高,需人工挑膜、捡膜;秋后残膜回收联合作业机具可一次性完成棉杆粉碎及残膜回收作业,作业成本较高,为525元/hm2,该机具回收后的残膜虽比立杆式搂膜机含杂量低,但其回收后的物料仍需人工捡膜,增加了残膜回收再利用成本;另外,若再对残膜运输、装卸成本进行核算,则回收与运输总成本又会增加,成本过高必然会降低农民回收残膜的积极性,从而会在一定程度上影响农田残膜回收及再利用,若政府出台相关补贴政策支持,农户回收农田残膜的积极性会提高。

3 新疆棉田残膜初清理及资源化利用现状

近年来,随着政府对残膜污染治理投入及宣传力度加大,新疆大部分地区均进行了残膜回收作业,残膜污染治理工作取得了初步成效,但回收后的残膜并未被有效与及时处理,而是多被堆弃、填埋或焚烧,从而造成了二次环境污染及资源浪费,由于农田残膜污染治理属于系统工程,残膜回收和资源化利用应并举并重,才能有效的解决残膜污染问题。

国内学者针对废旧农膜(主要是农业大棚覆盖用膜)的加工再利用工艺、方法及设备进行了大量研究[98-103],并取得了一定的成果,但其所处理物料杂质含量均较少,易于处理,而新疆机收棉田残膜中棉秆、土壤等杂质含量较高,且膜-土-秆分布无序、膜-土粘附较强及膜-秆相互缠绕复杂,传统的大棚膜、包装膜及其他废旧塑料加工再利用工艺流程及配套机械难以对其进行有效处理。针对新疆棉田机收残膜初清理问题,部分学者也进行了相关研究[104-105],但目前仍处于试验阶段。为了解新疆棉田残膜初清理、再生处理及资源化利用状况,2018年10月至12月对新疆阿拉尔市、石河子市、奎屯市及昌吉州玛纳斯县、吉木萨尔县等地区残膜初清理及资源化利用加工企业进行了实地调查。

3.1 棉田残膜初清理方式

目前新疆大部分地区棉田残膜初清理主要为水洗,主要包括滴灌带初清理和塑料水洗初清理2种。

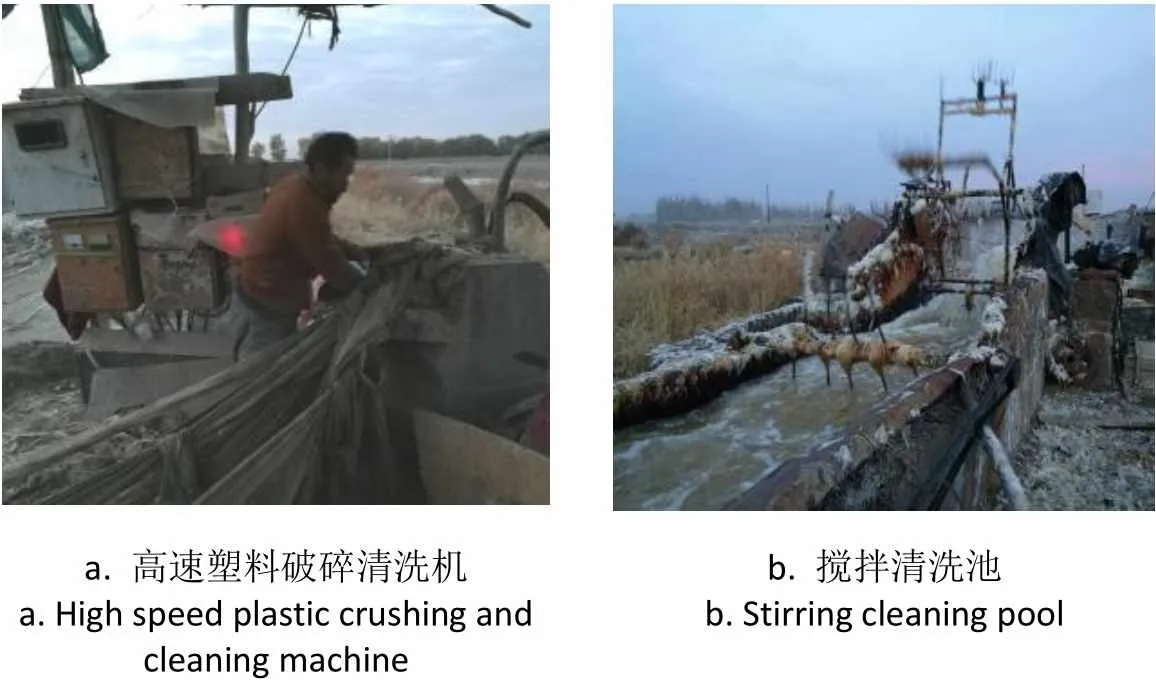

滴灌带初清理成套设备主要由高速塑料破碎清洗机、横向输送滚筒、搅拌清洗池及输送装置等组成,可一次性完成棉田残膜的破碎、清洗及输送等,如图4所示。该设备生产规模较小,制造或购买成本较低,在市场上占有一定比例。该类设备工艺流程为:破碎→漂洗→输送堆积,处理过程为:团状或条状无棉秆残膜被工程抓机夹至高速塑料破碎清洗机前并采用人工将其喂入,物料被高速旋转的滚刀式破碎辊破碎,与此同时破碎后的物料被破碎机上方注入的高速水流送至横向输送滚筒,经清洗搅拌池反复搅拌清洗后,再被抛至输送装置进行集中堆放,可一次性完成棉田残膜的初清理。

a. 高速塑料破碎清洗机a. High speed plastic crushing and cleaning machineb. 搅拌清洗池b. Stirring cleaning pool

塑料水洗初清理设备主要由输送带、破碎机(撕碎机)、搓洗机、清洗槽等立式脱水机等组成。该类成套设备配套功率均在150 kW以上,加工能力为1 500 t/a左右,整体售价均在100万元以上。该类设备工艺流程为:撕碎(破碎)→高速搓洗→漂洗→脱水,主要工作过程为:利用单轴破碎机(撕碎机)对无棉秆的长条状或团状残膜进行破碎,破碎后的棉田残膜则被送至高速螺旋搓洗机中进行反复搓洗,尽可能去除棉田残膜碎片表面粘附土壤,搓洗后的棉田残膜碎片再被送至搅拌清洗水槽中进行反复搅拌清洗,清洗干净后的棉田残膜碎片则被搅拌清洗槽中的捡拾抛送机构抛送至立式脱水机中进行脱水,完成棉田残膜的初清理。为使棉田残膜清理干净,该成套设备配置的搅拌清洗槽较长,最长可达24 m,沉淀循环水池为3 000 m3左右,在水洗过程中虽可加滤网对较大尺寸残膜碎片进行过滤,但在沉淀水池中仍有较小的残膜碎片存在。

滴灌带初清理设备与塑料水洗初清理设备虽在工作性能、成本造价、安全性、可靠性及功耗等方面差异较大,但两者对物料含杂率要求、设备性能及工艺流程基本相同。另外,以水洗为主的成套设备对棉田残膜含杂量及含杂类型要求较高,含杂量应<5%;为保证初清理生产线正常运转,需人工进行膜杂分离,费用约为120~150元/(人·d),人工成本超过150元/(人·d)时,企业就不再组织生产。

3.2 棉田残膜资源化利用情况

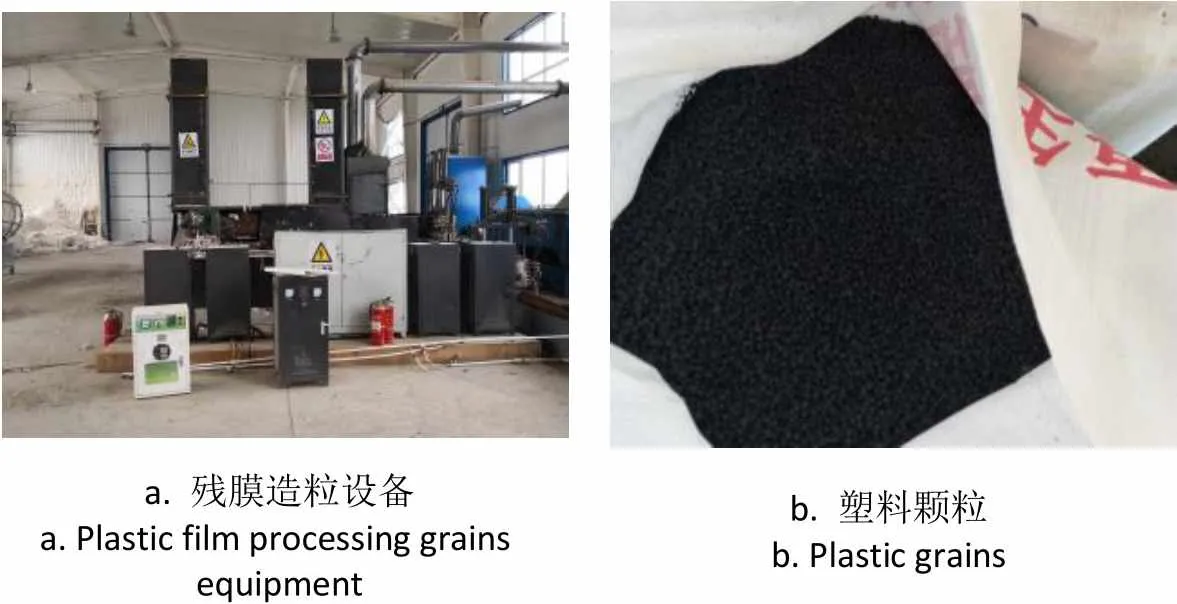

目前新疆初清理后的棉田残膜再生加工方法主要以再生造粒为主,该方式所配套的设备主要包括输送装置、熔融装置、挤出机及切粒机等,如图5所示。

a. 残膜造粒设备a. Plastic film processing grains equipmentb. 塑料颗粒b. Plastic grains

以水洗造粒为主的棉田残膜再生加工设备所生产的再生塑料颗粒最优可达二级标准,市场售价最高可达7 000元/t(原生新料价格为9 000元/t),该再生塑料颗粒可与新塑料颗粒按一定比例混合后用于滴灌带、周转箱及包装膜等塑料产品的生产制造。

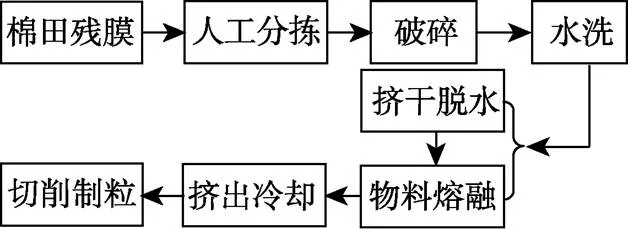

综上所述,新疆棉田残膜初清理及再利用总体加工工艺流程如图6所示。

图6 残膜初清理及再生加工工艺流程

4 棉田残膜资源化利用问题及策略

4.1 棉田残膜资源化利用存在的主要问题

1)先进适用的棉田残膜回收机械较为缺乏

30多年来各高校、科研院所及企业开发的棉田残膜回收机械种类虽然较多,而核心部件(起膜挑膜机构、输膜脱膜机构等)可靠性差、膜杂分离不彻底、边膜及根膜未能有效回收及耕层残膜回收难等是残膜回收中存在的主要瓶颈问题,先进适用的棉田残膜回收机械较为缺乏,受地膜厚度、强度及作业环境等多重因素影响,各类机型均存在可靠性差、回收效率低、回收的棉田残膜含杂量高等问题,造成大量棉田残膜难以及时有效回收或回收后无法进行资源化利用,进而造成残膜初清理及资源化再生加工企业生产原料不足,影响残膜初清理及再利用成套设备的正常运转,这不仅在一定程度上制约了棉田残膜资源化资利用进程,也严重阻碍了棉田残膜污染治理问题。

2)机收棉田残膜含杂量较高

机收播前及秋后棉田残膜含杂量较高,膜-土-秆分布无序、膜-土粘附较强及膜-秆相互缠绕复杂,造成棉田残膜初清理加工繁琐,为保证棉田残膜初清理工艺生产线正常运行,棉田残膜加工前需膜杂分离,该环节均采用人工分拣,劳动强度大、成本高、效率低且与实际生产加工需求极不匹配,增加了企业负担及运营成本,在一定程度上降低了企业对棉田残膜回收处理积极性。部分残膜回收加工企业虽要求农户按等级交收棉田残膜,但棉田残膜中仍带有或多或少的棉秆,仍需人工后续除杂作业。另外,现有膜杂分离设备多以滚筒筛为主,虽可去除一定土壤,但不能有效清理棉秆,且分离效率低,除杂后的棉田残膜仍裹卷大量土壤颗粒,不利于后续清洗,在一定程度上影响了棉田残膜回收再利用进程。

3)残膜初清理及再加工设备缺乏且技术不成熟

新疆残膜初清理及再加工专用设备较为缺乏且技术不成熟,现有残膜初清理及再加工成套设备多由滴灌带或废旧塑料成套处理设备及再加工改进而成,对物料含杂量、含杂种类等要求较高,由于滴灌带、废旧塑料与及棉田残膜之间物料特性、形态特征等差异性较大,该类成套设备并不完全适用于棉田残膜的初清理及再加工利用;而且现有残膜成套处理设备均以水洗为主,棉田残膜清洗过程中需大量水体进行循环,清洗次数减少或清洗线缩短虽可节水,但其表面粘附土壤颗粒清除不净会造成再生颗粒灰分增加,降低再生颗粒等级;若增加水洗次数或加长清洗线,虽可减少土壤含量,但又会在一定程度上增加运行成本。另外,由于新疆属于西北干旱地区,水资源弥足珍贵,以水洗造粒为主的残膜初清理及再加工与新疆自然资源可利用度不符。

4)残膜资源化利用加工方式及制品单一

受现有残膜再生加工工艺及配置设备限制,当前新疆棉田残膜资源化利用加工方式及制品单一,初清理后的棉田残膜多以生产再生塑料颗粒为主,由于地膜前期使用环境较为恶劣及后续初清理程度不一,再生塑料颗粒表面光洁度、力学特性及强度等均已发生变化,其应用范围会受到限制,该类塑料颗粒只能与新塑料颗粒按一定比例混合后用于滴灌带、周转箱及包装膜等塑料制品的生产制造,若再生塑料颗粒性能品质较差只能用于低端产品的生产制造或直接淘汰,但再生造粒生产工艺过程较为复杂,利润空间有限,不利于棉田残膜资源化利用产业的健康发展。

5)残膜初清理及再加工企业较少

目前新疆棉田地膜使用总用量均在20万t以上,总体投入较大,棉田残膜回收再利用前景较为广阔,但每单位面积农田残膜回收量小且分散。近年来农户对土壤污染危害认识及土地保护意识虽有所提高,但环境保护意识仍较差,由于残膜初清理及再加工企业较少,覆盖范围扩大及运输距离增加,增加了农户或企业运输成本,降低了农户或企业回收残膜的积极性,致使回收成本与残膜资源化利用之间的矛盾日益突出,虽有相关政策及奖惩机制对残膜回收处理方式进行限制,回收后的棉田残膜仍多被丢弃、填埋或焚烧,致使棉田残膜实际回收量较少,造成企业生产原料不足,难以维系企业实际加工需求。另外,由于棉田残膜较为松散,未打包或打捆时长途露天运输极易造成二次环境污染。

6)残膜资源化利用市场推动较为困难

当前新疆农田残膜采用多种方式及方法进行回收,棉田残膜回收工作进展也较为顺利,为棉田残膜再利用提供了前提条件;此外塑料回收再利用技术(再生造粒、木塑造粒、固体燃料制造等)较为成熟或趋于成熟,给棉田残膜再利用提供了后续保障;再者,以再生塑料颗粒、木塑颗粒为主原料的再生产品市场需求较大且利润较高,给棉田残膜回收再利用提供了良好的市场保障,棉田残膜回收再利用具有一定市场竞争力及较好市场效益,前景广阔。但由于残膜初清理技术匮乏及不成熟,造成残膜初清理及再利用成本较高,给企业运行带来一定的阻力和压力,致使棉田残膜从回收、初清理、再利用及市场销售产业链不健全,残膜资源化利用市场推动及运行较为困难。

4.2 策略及建议

1)加快耐候性及高强度地膜推广与示范

目前普通地膜厚度虽达到了GB 13735-2017《聚乙烯吹塑农用地面覆盖薄膜》的规定要求,但其强度未必能达到相应标准,由于新疆棉田地膜覆盖时间需100 d以上,该类地膜在回收时若强度不够也难以收集,且回收的棉田残膜碎片化较为严重及含杂量较高,因此在要求地膜厚度的同时,也需对其强度进行规定。与此同时应加快耐候性、高强度及可降解地膜的推广力度及速度,从根本上解决棉田残膜回收困难、含杂量高且杂质难以清理的问题,以便于初清理及资源化利用。

2)提升棉田残膜机械化回收技术水平

针对现有的棉田残膜回收机械存在的诸多问题,应加大科研投入,以农机与农艺融合为出发点,以提升机械化棉田残膜回收技术水平为总体目标,研究开发高效、高可靠性、适应性强且适用于普通标准地膜(厚度为0.01 mm)的棉田残膜回收机械,突破技术难点及攻克技术瓶颈,解决棉田边膜、根膜及耕层残膜回收难、残膜含杂量高等问题[54],重点攻克膜杂分离技术、边膜收获技术、起膜挑膜技术、输膜脱膜技术及耕层残膜回收技术等,并且能够满足整机价格低廉、操作简单及轻简化等要求,有效降低棉田残膜回收及资源化利用成本,增加企业受益及提高积极性。另外,还应对棉田残膜专用的装卸、打捆及转运机械进行开发,解决棉田残膜长距离转运问题。

3)开发合适的棉田残膜初清理及再加工技术

以水洗为主的棉田残膜初清理生产线及以再生造粒为主的棉田残膜再加工生产线与新疆自然条件及实际情况极为不符。因此,应针对目前新疆棉田残膜机械化回收的具体情况对棉田残膜初清理及资源化利用技术进行深入研究,研究开发适合新疆棉田残膜初清理及资源化利用的成套设备,合理布置加工工艺流程,尽量采用干式分离法或在膜杂不分离的情况下就可对其进行有效利用,从而降低企业运行成本及设备要求,在一定程度上减少二次环境污染。

4)拓展棉田残膜资源化利用路径

在开发合适的棉田残膜初清理及再加工技术基础上,多方面拓展棉田残膜资源化利用路径及使用范围,改变现有的再生塑料颗粒生产及利用模式,综合新疆丰富的农作物秸秆资源,通过发展木塑制粒,经后续加工将木塑颗粒转化为木塑制品用于室内装修、景区建设、环保物品制作及物流包装等,减少木材的使用及消耗;发展催化热解及生物质发电等资源化利用技术,将其转化为燃料或电能,实现棉田残膜及秸秆等废弃物的资源化综合利用,促进节能减排及绿色可持续发展。

5)合理布局残膜初清理及再加工企业

在现有残膜资源化利用加工工艺及处理能力的基础上,对处理能力、运营成本及产出效益进行分析,核算残膜回收、运输、初清理及资源化利用各环节投入成本,在合适及合理范围建立残膜回收点,并对残膜初清理及再加工企业进行规划与合理布局,解决残膜回收、运输及装卸等环节的高成本问题;根据各级政府出台的残膜污染治理法律法规,各团场或乡镇应以户为单位落实任务并建立奖惩制度,通过建立回收登记表、交纳保证金、回收检查卡及收后补贴的方式推动残膜回收,在该过程中明确农田地膜生产者、销售者及使用者在农田残膜污染治理过程中的责任,建立有效奖惩机制,明确地膜使用者及加工企业相互之间责任与利益关系,确保农户及企业对农田残膜回收及再加工利用的积极性;在现有残膜污染治理法律及法规下,严格把控与积极引导,对农户及企业补贴金额、补贴方式及流程进行规范,探索农田残膜回收再利用长效运营机制,保证在无政府补贴时也可正常及长期运营;与此同时,积极宣传残膜危害及回收利用价值,在水源丰沛及气候条件适宜地区积极推动地膜减量化应用,从源头上解决残膜回收问题。

6)利用经济杠杆撬动残膜资源化利用产业发展

农田残膜污染治理是一个系统工程,在解决农田残膜机械化回收的同时,还应从全产业链薄弱环节入手,以政府相关部门为主导,联合各高校、科研院所及企业,通过各种渠道吸纳资金投入对残膜初清理关键技术进行研究开发,并加快和加大科技成果转化速度及力度,实现产品的市场布局与推广,打通地膜生产、使用、残膜回收、运输、初清理及资源化利用的各个环节,形成全产业链闭环处理模式;此外,政府还应加大招商引资力度,吸引个人资金及企业资金进入,多途径及多路径解决残膜资源化利用产业发展资金问题,利用经济杠杆撬动残膜资源化利用产业可持续发展。

5 结 论

1)截止到2017年,新疆当年农田地膜总使用量为21.9万t,新疆当年农田地膜总使用量约占全国农田地膜总使用量的15.3%,若按新疆当年棉花覆膜总面积约占新疆当年农作物覆膜总面积的58.4%推算,则2017年新疆当年棉花农田地膜使用总量为12.8万t。随着地膜使用量的增加及覆盖面积的扩大,残膜污染问题也日益凸显,新疆长期覆膜棉田耕层地膜残留量为42~540 kg/hm2,平均残留量在260 kg/hm2以上,是全国农田地膜平均残留量的4倍多,对生态环境及农业生产环境造成了重大影响,地膜使用与农业生态环境保护及农业绿色可持续发展之间的矛盾日益突出,残膜机械化回收虽在一定程度上解决了残膜污染问题,收而不用又会造成二次环境污染及有效资源浪费,残膜回收和资源化利用应并举并重,才能在根本上解决残膜污染问题。

2)专用的残膜初清理及资源化利用加工成套处理设备较为缺乏且技术不成熟,难以直接处理含杂量较高的机收棉田残膜,且该类成套设备多以水洗造粒主,由于新疆属于干旱地区,水资源较为匮乏,以水洗造粒为主的残膜初清理及再生加工生产线与实际情况不适应,在一定程度上阻碍了新疆棉田残膜资源化利用进程。因此,亟待研究与开发适合于新疆机收棉田残膜初清理、资源化利用加工工艺及技术装备。

3)新疆棉田残膜资源化利用面临的问题及困难较多,在开发合适的残膜初清理及再利用技术、设备的同时,还应打通地膜生产、使用、残膜回收、运输、初清理及资源化利用的各个环节,形成全产业链闭环处理模式;整合现有资源,合理布局加工企业,明确各环节责任,探索残膜回收再利用长效运营机制,多层次及全产业链融合发展,解决新疆棉田残膜污染问题。

[1] Anikwe M A N, Mbah C N, Ezeaku P I, et al. Tillage and plastic mulch effects on soil properties and growth and yield of cocoyam () on an ultisol in southeastern Nigeria[J]. Soil & Tillage Research, 2007, 93(02): 264-272.

[2] 严昌荣,何文清,薛颖昊,等. 生物降解地膜应用与地膜残留污染防控[J]. 生物工程学报,2016,32(6):748-760. Yan Changrong, He Wenqing, Xue Yinghao, et al. Application of biodegradable plastic film to reduce plastic film residual pollution in Chinese agriculture[J]. Chinese journal of biotechnology, 2016, 32(6): 748-760. (in Chinese with English abstract)

[3] 李昊,李世平,南灵,等. 中国棉花地膜覆盖产量效应的Meta分析[J]. 农业机械学报,2017,48(7):228-235. Li Hao, Li Shiping, Nan Ling, et al. Meta-analysis of effect of plastic film mulching on cotton yield in China[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(7): 228-235. (in Chinese with English abstract)

[4] Zhao H, Xiong Y, Li F, et al. Plastic film mulch for half growing-season maximized WUE and yield of potato via moisture-temperature improvement in a semi-arid agroecosystem[J]. Agricultural Water Management, 2012, 104 (2): 68-78.

[5] Hou X, Wang F, Han J, et al. Duration of plastic mulch for potato growth under drip irrigation in an arid region of Northwest China[J]. Agricultural and Forest Meteorology, 2010, 150(1): 0-121.

[6] 张俊鹏,曹彩云,冯棣,等. 微咸水造墒条件下植棉方式对产量与土壤水盐的影响[J]. 农业机械学报,2013,44(2):97-102. Zhang Junpeng, Cao Caiyun, Feng Di, et al. Effects of different planting patterns on cotton yield and soil water-salt under brackish water irrigation before sowing[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(2): 97-102. (in Chinese with English abstract)

[7] 张佳喜,谢建华,薛党勤,等. 国内外地膜应用及回收装备的发展现状[J]. 农机化研究,2013,35(12):237-240. Zhang Jiaxi, Xie Jianhua, Xue Dangqin, et al. Development status of applying plastic film and the residue mulching film collecting machine at domestic and overseas[J]. Journal of Agricultural Mechanization Research, 2013, 35(12): 237-240. (in Chinese with English abstract)

[8] 严昌荣,梅旭荣,何文清,等. 农用地膜残留污染的现状与防治[J]. 农业工程学报,2006,22(11):269-272.Yan Changrong, Mei Xurong, He Wenqing. et al. Present situation of residue pollution of mulching plastic film and controlling measures[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2006, 22(11): 269-272. (in Chinese with English abstract)

[9] 陈奇恩. 中国塑料薄膜覆盖农业[J]. 中国工程科学,2002(4):12-15,21.Chen Qien. Mulching agriculture using thin plastic film in China[J]. Engineering and Science, 2002(4): 12-15, 21. (in Chinese with English abstract)

[10] 张东兴. 农用残膜的回收问题[J]. 中国农业大学学报,1998,3(6):103-106. Zhang Dongxing. Study on collection of used plastic film in fields[J]. Journal of China Agricultural University, 1998, 3(6): 103-106. (in Chinese with English abstract)

[11] 王志超,李仙岳,史海滨,等. 农膜残留对土壤水动力参数及土壤结构的影响[J]. 农业机械学报,2015,46(5):101-106,140. Wang Zhichao, Li Xianyue, Shi Haibin, et al. Effects of residual plastic film on soil hydrodynamic parameters and soil structure[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(5): 101-106,140. (in Chinese with English abstract)

[12] Liu Enke, He Wenqing, Yan Changrong. ‘White revolution’ to ‘white pollution’-agricultural plastic film mulch in China[J]. Environmental Research Letters, 2014, 9(9): 091001.

[13] 赵岩,陈学庚,温浩军,等. 农田残膜污染治理技术研究现状与展望[J]. 农业机械学报,2017,48(6):1-14. Zhao Yan, Chen Xuegeng, Wen Haojun, et al. Research status and prospect of control technology for residual plastic film pollution in farmland[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(6): 1-14. (in Chinese with English abstract)

[14] Liu C A, Jin S L, Zhou L M, et al. Effects of plastic film mulch and tillage on maize productivity and soil parameters[J]. European Journal of Agronomy, 2009, 31(4): 241-249.

[15] Xie Z K, Wang Y J, Li F M. Effect of plastic mulching on soil water use and spring wheat yield in arid region of northwest China[J]. Agricultural Water Management, 2005, 75(1): 71-83.

[16] Zhou L M, Li F M, Jin S L, et al. How two ridges and the furrow mulched with plastic film affect soil water, soil temperature and yield of maize on the semiarid Loess Plateau of China[J]. Field Crops Research, 2009, 113(1): 41-47.

[17] 王琦,张恩和,李凤民,等. 半干旱地区沟垄微型集雨种植马铃薯最优沟垄比的确定[J]. 农业工程学报, 2005,21(2):38-41. Wang Qi, Zhang Enhe, Li Fengmin, et al. Optimum ratio of ridge to furrow for planting potato in micro-water harvesting system in semiarid areas[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2005, 21(2): 38-41. (in Chinese with English abstract)

[18] Wang X L, Li F M, Jia Y, et al. Increasing potato yields with additional water and increased soil temperature[J]. Agricultural Water Management, 2005, 78(3): 181-194.

[19] 叶永成,白福臣,于恺. 我国农膜技术的发展方向[J]. 塑料工业,2002,30(6):1-3. Ye Yongcheng, Bai Fuchen, Yu Kai. Developing trends of technique for agricultural films in China[J]. China Plastics Industry, 2002, 30(6): 1-3. (in Chinese with English abstract)

[20] 国家统计局. 中国统计年鉴[M]. 北京:中国统计出版社. 2018.

[21] 王志超. 农膜残留对土壤水分运移的影响及模拟研究[D]. 呼和浩特:内蒙古农业大学,2017. Wang Zhichao. Effect and Simulation of Soil Moisture Migration with Residual Plastic Film[D]. Huhhot: Inner Mongolia Agricultural University, 2017.

[22] 李元桥,何文清,严昌荣,等. 点源供水条件下残膜对土壤水分运移的影响[J]. 农业工程学报,2015,31(6):145-149. Li Yuanqiao, He Wenqing, Yan Changrong, et al. Effect of residual film on soil infiltration under drip irrigation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(6): 145-149. (in Chinese with English abstract)

[23] 王学农,史建新,郭俊先,等. 悬挂式棉秆粉碎还田搂膜机搂膜机构的设计与试验研究[J]. 农业工程学报,2008,24(1):135-140. Wang Xuenong, Shi Jianxin, Guo Junxian, et al. Experimental study and design on film raking mechanism of hanging film raker with cotton-stalk crushing and returning to field[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(1): 135-140. (in Chinese with English abstract)

[24] 邬强,王振华,郑旭荣,等. PBAT生物降解膜覆盖对绿洲滴灌棉花土壤水热及产量的影响[J]. 农业工程学报,2017,33(16):135-143. Wu Qiang, Wang Zhenhua, Zheng Xurong, et al. Effects of biodegradation film mulching on soil temperature, moisture and yield of cotton under drip irrigation in typical oasis area[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(16): 135-143. (in Chinese with English abstract)

[25] 董合干,刘彤,李勇冠,等. 新疆棉田地膜残留对棉花产量及土壤理化性质的影响[J]. 农业工程学报,2013,29(8):91-99. Dong Hegan, Liu Tong, Li Yongguan, et al. Effects of plastic film residue on cotton yield and soil physical and chemical properties in Xinjiang[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(8): 91-99. (in Chinese with English abstract)

[26] 牛瑞坤. 新疆阿克苏地区棉田残膜污染区域分布现状调查与分析[D]. 阿拉尔:塔里木大学,2016. Niu Ruikun. Investigation and Analysis of the Current Status on Regional Distribution of Plastic Film Residue Pollution of Cotton Field in Xinjiang Aksu Area[D]. Alar: Tarim University, 2016.

[27] 程桂荪,刘小秧,刘渊君,等. 农田地膜残片允许值的研究[J]. 土壤肥料,1991(5):27-30.

[28] 解红娥,李永山,杨淑巧,等. 农田残膜对土壤环境及作物生长发育的影响研究[J]. 农业环境科学学报,2007,26(S1):153-156. Xie Honge, Li Yongshan, Yang Shuqiao, et al. Influence of residual plastic film on soil structure crop growth and development in fields[J]. Journal of Agro-Environment Science, 2007, 26(S1): 153-156. (in Chinese with English abstract)

[29] 孙志洁. 棉田残膜污染调查及其危害[J]. 河南农业科学,2006(4):61-62.

[30] 刘艳霞. 中国农村地膜残留污染现状及治理对策思考[D]. 杨凌:西北农林科技大学,2014. Liu Yanxia. Reflections on the Pollution Status and Control Countermeasures of Plastic Film Residuals in Chinese Rural Areas[D]. Yangling: Northwest A&FUniversity, 2014.

[31] 张若宇,丁竹青,李晓良,等. 基于虚拟仪器的籽棉残膜分离装置测试系统[J]. 农业机械学报,2014,45(10):97-102. Zhang Ruoyu, Ding Zhuqing, Li Xiaoliang, et al. Automatic monitor system for mesh roller type unginned cotton and film remnant separator based on virtual instrument[J]. Transactions of the Chinese Society of Agricultural Machinery, 2014, 45(10): 97-102. (in Chinese with English abstract)

[32] 郭淑霞,坎杂,张若宇,等. 机采籽棉残膜静电分离装置分离试验[J]. 农业工程学报,2011,27(增刊2):6-10. Guo Shuxia, Kan Za, Zhang Ruoyu, et al. Separation test of electrostatic separating device for machine-harvested seed cotton and plastic film residue[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE) 2011, 27(Supp.2): 6-10. (in Chinese with English abstract)

[33] 郭文松,坎杂,张若宇,等. 网状滚筒式籽棉残膜分离机物料特性分析[J]. 农业工程学报,2011,27(增刊2):1-5. Guo Wensong, Kan Za, Zhang Ruoyu, et al. Analysis of material character based on mesh roller-type cotton and film remnant separator[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(Supp.2): 1-5. (in Chinese with English abstract)

[34] 马辉,梅旭荣,严昌荣,等. 华北典型农区棉田土壤中地膜残留特点研究[J]. 农业环境科学学报,2008,27(2):570-573. Ma Hui, Mei Xurong, Yan Changrong, et al. The residue of mulching plastic film of cotton field in North China[J]. Journal of Agro-Environment Science, 2008, 27(2): 570-573. (in Chinese with English abstract)

[35] 吾甫尔江·托乎提,艾海提·牙生,巴雅尔. 论地膜污染与防治对策[J]. 新疆环境保护,2000,22(3):176-178. Wupuerjiang Tuohuti, Aihaiti Yasheng, Bayaer. Discussion about mulch film pollution and countermeasure of prevention and control[J]. Environmental Protection of Xinjiang, 2000, 22(3): 176-178. (in Chinese with English abstract)

[36] 翁云宣. 2016生物基材料专刊序言[J]. 生物工程学报,2016,32(6):711-714. Weng Yunxuan. Preface for special issue on bio-based materials (2016)[J]. Chinese Journal of Biotechnology, 2016, 32(6): 711-714. (in Chinese with English abstract)

[37] 魏佳容. 减量化与资源化:农业废弃物法律调整路径研究[J]. 华中农业大学学报:社会科学版,2019,139(1):116-122,168. Wei Jiarong. Reduction and recycling: A study on the legal adjustment path of agricultural waste[J]. Journal of Huazhong Agricultural University: Social Sciences Edition, 2019, 139(1): 116-122,168. (in Chinese with English abstract)

[38] 杨育红. 我国应对农业面源污染的立法和政策研究[J]. 昆明理工大学学报:社会科学版,2018,18(6):18-26. Yang Yuhong. Legislation and policies for prevention and control of agricultural nonpoint sources pollution in China[J]. Journal of Kunming University of Science and Technology: Social Science, 2018, 18(6):18-26. (in Chinese with English abstract)

[39] 王蕾. 我国农业废弃物资源化法律制度研究[D]. 兰州:甘肃政法学院,2018. Wang Lei. Research on the Legal System of Agriculture Waste Resources in China[D]. Lanzhou: Gansu University of Political Science and Law, 2018.

[40] 王盛毅. 我国农用地污染防治立法研究[D]. 杭州:浙江农林大学,2013. Wang Shengyi. Research on Agricultural Land Pollution Prevention Legislation[D]. Hangzhou: Zhejiang A&F University, 2013.

[41] 魏欣. 中国农业面源污染管控研究[D]. 杨凌:西北农林科技大学,2014. Wei Xin. A Novel Framework for Agricultural Non-Point Source Pollution Management and Control in China[D]. Yangling: Northwest A&F University, 2014.

[42] 靳伟,张学军,鄢金山,等. 曲轴式棉田地表残膜回收机捡膜特性分析及工作参数优化[J]. 农业工程学报,2018,34(16):10-18. Jin Wei, Zhang Xuejun, Yan Jinshan, et al. Characteristic analysis and working parameter optimization of crankshaft type cotton field surface residual film collecting machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(16): 10-18. (in Chinese with English abstract)

[43] 罗凯,袁盼盼,靳伟,等. 链筛式耕层残膜回收机设计与工作参数优化试验[J]. 农业工程学报,2018,34(19):19-27. Luo Kai, Yuan Panpan, Jin Wei, et al. Design of chain-sieve type residual film recovery machine in plough layer and optimization of its working parameters[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(19):19-27. (in Chinese with English abstract)

[44] 康建明,彭强吉,王士国,等. 弹齿式残膜回收机捡拾装置改进设计与试验[J]. 农业机械学报,2018,49(S1):295-303. Kang Jianming, Peng Qiangji, Wang Shiguo, et al. Improved design and experiment on pickup unit of spring-tooth residual plastic Film collector[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(S1):295-303. (in Chinese with English abstract)

[45] 辛尚龙,赵武云,戴飞,等. 玉米全膜双垄沟残膜回收机改进设计与试验[J]. 农业机械学报,2018,49(S1):311-319. Xin Shanglong, Zhao Wuyun, Dai Fei, et al. Improved design and experiment of collector for corn whole plastic film mulching on double ridges[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(S1): 311-319. (in Chinese with English abstract)

[46] 施丽莉,胡志超,顾峰玮,等. 耙齿式残膜回收机自动脱膜机构设计[J]. 农业工程学报,2017,33(18):11-18. Shi Lili, Hu Zhichao, Gu Fengwei, et al. Design on automatic unloading mechanism for teeth type residue plastic film collector[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(18): 11-18. (in Chinese with English abstract)

[47] 王旭峰,胡灿,鲁兵,等. 抛膜链齿输送式残膜回收机设计与试验[J]. 农业机械学报,2018,49(3):122-129. Wang Xufeng, Hu Can, Lu Bing, et al. Design and experiment of sprocket conveying residual film recycling machine of casting film[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(3): 122-129. (in Chinese with English abstract)

[48] 徐弘博,胡志超,吴峰,等. 网链式花生地残膜回收机设计与试验[J]. 农业工程学报,2017,33(17):1-9. Xu Hongbo, Hu Zhichao, Wu Feng, et al. Design and experiment of network chain type residual plastic film collector for peanut field[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(17): 1-9. (in Chinese with English abstract)

[49] 罗威,王吉奎,罗新豫,等. 夹指链式残膜回收装置仿形及收膜机构的改进设计与试验[J]. 农业工程学报,2017,33(22):27-35. Luo Wei, Wang Jikui, Luo Xinyu, et al. Improved design and experiment of profiling and recycling plastic filmmechanism for clamping finger-chain type device of recycling residual plastic film[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(22): 27-35. (in Chinese with English abstract)

[50] 戴飞,郭笑欢,赵武云,等. 帆布带式马铃薯挖掘-残膜回收联合作业机设计与试验[J]. 农业机械学报,2018,49(3):104-113. Dai Fei, Guo Xiaohuan, Zhao Wuyun, et al. Design and experiment of canvas belt combined operation machine for potato digging and plastic film collecting[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(3): 104-113. (in Chinese with English abstract)

[51] 谢建华,陈学庚,孙超伟. 杆齿式残膜回收机卸膜过程分析及高速摄像试验[J]. 农业工程学报,2017,33(10):17-24. Xie Jianhua, Chen Xuegeng, Sun Chaowei. Unloading film process analysis and high-speed photography experiment of pole-tooth residual plastic film collector[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(10): 17-24. (in Chinese with English abstract)

[52] 牛琪,纪超,赵岩,等. 集条残膜打包机捡拾清理装置设计与试验[J]. 农业机械学报,2017,48(5):101-107. Niu Qi, Ji Chao, Zhao Yan, et al. Design and experiment on collecting and separating device for strip plastic film baler[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(5): 101-107. (in Chinese with English abstract)

[53] 戴飞,赵武云,孙伟,等. 马铃薯收获与气力辅助残膜回收联合作业机设计与试验[J]. 农业机械学报,2017,48(1):64-72. Dai Fei, Zhao Wuyun, Sun Wei, et al. Design and experiment of combined operation machine for potato harvesting and plastic film pneumatic auxiliary collecting[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(1): 64-72. (in Chinese with English abstract)

[54] 赵岩,郑炫,陈学庚,等. CMJY-1500型农田残膜捡拾打包联合作业机设计与试验[J]. 农业工程学报,2017,33(5):1-9. Zhao Yan, Zheng Xuan, Chen Xuegeng, et al. Design and test of CMJY-1500 type plastic film residue collecting and balling machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(5): 1-9. (in Chinese with English abstract)

[55] 严伟,胡志超,吴努,等. 铲筛式残膜回收机输膜机构参数优化与试验[J]. 农业工程学报,2017,33(1):17-24. Yan Wei, Hu Zhichao, Wu Nu, et al. Parameter optimization and experiment for plastic film transport mechanism of shovel screen type plastic film residue collector[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(1): 17-24. (in Chinese with English abstract)

[56] 周明冬,侯洪,董合干,等. 新疆农用地膜应用与残留污染现状分析[J]. 浙江农业科学,2015,56(12):2058-2061.

[57] 中华人民共和国农业农村部. 中国农业统计年鉴[M]. 北京:中国农业出版社, 1993-2017.

[58] 陈学庚,李亚雄,贺志新,等. 棉花铺膜播种机技术改造应注意的几个问题[J]. 新疆农垦科技,1996(6):20-21.

[59] 温浩军,陈学庚,李亚雄. 新疆生产建设兵团棉花精量播种现状及发展趋势[J]. 中国农机化,2005(5):32-33.

[60] 陈学庚,赵岩. 棉花双膜覆盖精量播种机的研制[J]. 农业工程学报,2010,26(4):106-112. Chen Xuegeng, Zhao Yan. Development of double-film mulch precision planter for cotton seeding[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(4): 106-112. (in Chinese with English abstract)

[61] 王频. 残膜污染治理的对策和措施[J]. 农业工程学报,1998,14(3):190-193. Wang Pin. Measures to reduce the pollution of residual of mulching plastic film in farmland[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 1998, 14(3): 190-193. (in Chinese with English abstract)

[62] 张雨蒙,申丽霞. 农田土壤残膜的污染现状及应对措施[J]. 天津农业科学,2018,24(2):86-90. Zhang Yumeng, Shen Lixia. Pollution of residual film in farmland soil and countermeasures[J]. Tianjin Agricultural Sciences, 2018, 24(2): 86-90. (in Chinese with English abstract)

[63] 汪军,杨杉,陈刚才,等. 我国设施农业农膜使用的环境问题刍议[J]. 土壤,2016,48(5):863-867. Wang Jun, Yang Shan, Chen Gangcai, et al. Environmental problems and countermeasures of mulch film application in intensive agriculture system in China[J]. Soils, 2016, 48(5): 863-867. (in Chinese with English abstract)

[64] 肖军,赵景波. 农田塑料地膜污染及防治[J]. 四川环境,2005,24(1):102-105. Xiao Jun, Zhao Jingbo. Farmland plastic film pollution and its countermeasures[J]. Sichuan Environment, 2005, 24(1): 102-105. (in Chinese with English abstract)

[65] 国家统计局. 2018年全国棉花生产继续较快增长[EB/OL]. 2018-12-29[2019-05-18]. http://www.stats.gov.cn/tjsj/sjjd/201812/ t20181229_1642168.html.

[66] 祖米来提·吐尔干,林涛,严昌荣,等. 地膜覆盖时间对新疆棉田水热及棉花耗水和产量的影响[J]. 农业工程学报,2018,34(11):113-120. Zumilaiti Tuergan, Lin Tao, Yan Changrong, et al. Effect of plastic film mulching duration on soil temperature and moisture in field and cotton water comsumption and yield in Xinjiang[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34 (11): 113-120. (in Chinese with English abstract)

[67] 严昌荣,王序俭,何文清,等. 新疆石河子地区棉田土壤中地膜残留研究[J]. 生态学报,2008,28(7):3470-3474. Yan Changrong, Wang Xujian, He Wenqing, et al. The residue of plastic film in cotton fields in Shihezi, Xinjiang[J]. Acta Ecologica Sinica, 2008, 28(7): 3470-3474. (in Chinese with English abstract)

[68] 徐刚,杜晓明,曹云者,等. 典型地区农用地膜残留水平及其形态特征研究[J]. 农业环境科学学报,2005,24(1):79-83. Xu Gang, Du Xiaoming, Cao Yunzhe, et al. Residue levels and morphology of agricultural plastic film in representative areas of china[J]. Journal of Agro-Environment Science, 2005, 24(1): 79-83. (in Chinese with English abstract)

[69] 许咏梅,房世杰,马晓鹏,等. 农用地膜污染防治战略研究[J]. 中国工程科学,2018,20(5):96-102. Xu Yongmei, Fang Shijie, Ma Xiaopeng, et al. Prevention and control strategy for the pollution of agricultural plastic film[J]. Engineering Sciences, 2018, 20(5): 96-102. (in Chinese with English abstract)

[70] 刘建国,李彦斌,张伟,等. 绿洲棉田长期连作下残膜分布及对棉花生长的影响[J]. 农业环境科学学报,2010,29(2):246-250. Liu Jianguo, Li Yanbin, Zhang Wei, et al. The distributing of the residue film and influce on cotton growth under continuous cropping in oasis of Xinjiang[J]. Journal of Agro-Environment Science, 2010, 29(2): 246-250. (in Chinese with English abstract)

[71] 王振华,贺怀杰,郑旭荣,等. 新疆典型绿洲棉秆还田对覆膜滴灌棉田残膜分布的影响[J]. 农业工程学报,2018,34(21):120-127. Wang Zhenhua, He Huaijie, Zheng Xurong, et al. Effect of cotton stalk returning to fields on residual film distribution in cotton fields under mulched drip irrigation in typical oasis area in Xinjiang[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(21): 120-127. (in Chinese with English abstract)

[72] 王亮,林涛,严昌荣,等. 地膜残留量对新疆棉田蒸散及棵间蒸发的影响[J]. 农业工程学报,2016,32(14):120-128. Wang Liang, Lin Tao, Yan Changrong, et al. Effects of plastic film residue on evapotranspiration and soil evaporation in cotton field of Xinjiang[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(14): 120-128. (in Chinese with English abstract)

[73] 贺怀杰,王振华,郑旭荣,等. 长期膜下滴灌棉田残膜变化趋势研究[J]. 干旱区研究,2018,35(6):1487-1495. He Huaijie, Wang Zhenhua, Zheng Xurong, et al. Study on the change trend of the residual film in the cotton field under the long-term mulched drip irrigation[J]. Arid Zone Research, 2018, 35(6): 1487-1495. (in Chinese with English abstract)

[74] 张占琴,魏建军,杨相昆,等. 揭膜对土壤温湿度及棉花根系发育的影响[J]. 干旱地区农业研究,2016,34(2):55-61. Zhang Zhanqin, Wei Jianjun, Yang Xiangkun, et al. Effects of plastic film uncovering on soil temperature,moisture level,and cotton root growth[J]. Agricultural Research in the Arid Areas, 2016, 34(2): 55-61. (in Chinese with English abstract)

[75] 牛生和,王华兵,朱环元. 克拉玛依生态农业区揭膜对棉花生长的影响[J]. 新疆农垦科技,2007(5):14-15.

[76] 叶良中. 新疆兵团研制成残膜回收机[J]. 农业机械,1992(7):14-15.

[77] 张学军,吴成武,王伟,等. 齿形刮板式残膜与残茬输送装置设计与试验[J]. 农业机械学报,2008,39(9):49-51. Zhang Xuejun, Wu Chengwu, Wang Wei. et al. Design and experiment on the zigzag scraper transportation device for remnant plastic film and stubble[J]. Transactions of the Chinese Society for Agricultural Machinery, 2008, 39(9): 49-51. (in Chinese with English abstract)

[78] 杨莹,白圣贺,赵守瑞,等. 耕层残膜回收机的研究[J]. 安徽农业科学,2017,45(7):184-186. Yang Ying, Bai Shenghe, Zhao Shourui, et al. Study on soil residual film recycling machine[J]. Journal of Anhui Agricultural Sciences, 2017, 45(7): 184-186. (in Chinese with English abstract)

[79] 马少辉,张学军. 1QZ-3900型耕层残膜收获机的研制[J]. 农机化研究,2011,33(7):93-96. Ma Shaohui, Zhang Xuejun. Development on 1QZ-3900 plastic film collector[J]. Journal of Agricultural Mechanization Research, 2011, 33(7): 93-96. (in Chinese with English abstract)

[80] 张攀峰,胡灿,王旭峰,等. 旋耕钉齿式耕层残膜回收机起膜部件动力学分析[J]. 农机化研究,2018,40(4):14-18,25. Zhang Panfeng, Hu Can, Wang Xufeng, et al. Kinetic analysis of rotary tillage nail tooth plastic film recycling machine hook film unit[J]. Journal of Agricultural Mechanization Research, 2018, 40(4): 14-18,25. (in Chinese with English abstract)

[81] 赵攸乐,张学军,靳伟,等. 链齿耙式耕层残膜回收机捡拾机构的设计[J]. 农机化研究,2019,41(2):119-122,127. Zhao Youle, Zhang Xuejun, Jin Wei, et al. Design of pick-up mechanism for the chain-teeth-rake topsoil incomplete plastic film recycling machine[J]. Journal of Agricultural Mechanization Research, 2019, 41(2): 119-122,127. (in Chinese with English abstract)

[82] 周智祥,杨志城,杨宛章,等. 气吹式春播前残膜回收机的研制[J]. 新疆农业大学学报,2005,28(1):61-65. Zhou Zhiyang, Yang Zhicheng, Yang Wanzhang, et al. Development of a type of air blast plastic film collector before spring sowing[J]. Journal of Xinjiang Agricultural University, 2005, 28(1): 61-65. (in Chinese with English abstract)

[83] 闫盼盼,曹肆林,罗昕,等. 弹齿链耙式播前残膜回收机的设计研究[J]. 农机化研究,2016,38(6):137-142. Yan Panpan, Cao Silin, Luo Xin, et al. Research on the spring-tooth-chain-rake incomplete plastic film recycling machine[J]. Journal of Agricultural Mechanization Research, 2016, 38(6): 137-142. (in Chinese with English abstract)

[84] 薛文瑾,王春耀,朱振中,等. 卷膜式棉花苗期残膜回收机的设计[J]. 农业机械学报,2005,36(3):148-149,147. Xue Wenjin, Wang Chunyao, Zhu Zhenzhong, et al. Design of rolling-film residue collector for cotton seeding[J]. Transactions of the Chinese Society for Agricultural Machinery, 2005, 36(3): 148-149, 147. (in Chinese with English abstract)

[85] 刘晨,薛文瑾,朱振中,等. MSM-3型苗期残膜回收机[J]. 新疆农机化,1999(4):13.

[86] 罗威,王吉奎,牛海龙,等. 夹指链式残膜回收机清杂装置的设计与试验[J]. 农机化研究,2018,40(2):75-79. Luo Wei, Wang Jikui, Niu Hailong, et al. Design and test on debris clean-up device of clamping finger-chain type device for recycling agricultural plastic film[J]. Journal of Agricultural Mechanization Research, 2018, 40(2): 75-79. (in Chinese with English abstract)

[87] 张佳喜,杨程,郭俊先,等. 滚刀式青贮玉米起茬及残膜回收联合作业机的设计与试验[J]. 农业工程学报,2018,34(6):25-34. Zhang Jiaxi, Yang Cheng, Guo Junxian, et al. Design and experiment of hob-type joint operation machine for silage corn root stubble plucking and residual plastic film collecting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(6): 25-34. (in Chinese with English abstract)

[88] 刘旋峰,石鑫,郭兆峰,等. 滚筒式残膜回收机的性能试验研究[J]. 农业工程学报,2017,33(16):26-31. Liu Xuanfeng, Shi Xin, Guo Zhaofeng, et al. Performance test on roller type residual film recycling machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(16): 26-31. (in Chinese with English abstract)

[89] 赵英杰,陈永,周鹏,等. 弹齿轨道式残膜回收机参数优化及试验[J]. 农机化研究,2018,40(5):127-131. Zhao Yingjie, Chen Yong, Zhou Peng, et al. Parameter optimization and test on elastic tooth track type machine for residual film recycling[J]. Journal of Agricultural Mechanization Research, 2018, 40(5): 127-131. (in Chinese with English abstract)

[90] 王科杰,胡斌,罗昕,等. 残膜回收机单组仿形搂膜机构的设计与试验[J]. 农业工程学报,2017,33(8):12-20. Wang Kejie, Hu Bin, Luo Xin, et al. Design and experiment of monomer profiling raking-film mechanism of residue plastic film collector[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(8): 12-20. (in Chinese with English abstract)

[91] 杨松梅,颜利民,莫毅松,等. 随动式残膜回收机捡拾装置设计与试验[J]. 农业机械学报,2018,49(12):109-115,164. Yang Songmei, Yan Limin, Mo Yisong, et al. Design and experiment on collecting device for profile modeling residual plastic film collector[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(12): 109-115,164. (in Chinese with English abstract)

[92] 于云海,陈学庚,温浩军. 秸秆粉碎与残膜集条联合作业机的研制与试验[J]. 农业工程学报,2016,32(24):1-8. Yu Yunhai, Chen Xuegeng, Wen Haojun. Developmentand experiment of straw chopping and plastic film strip-collection combined machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(24): 1-8. (in Chinese with English abstract)

[93] 何义川,王序俭,王吉亮,等. 棉花秋后残膜回收与茎秆粉碎联合作业机设计[J]. 西北农业学报,2013,22(8):199-204. He Yichuan, Wang Xujian, Wang Jiliang, et al. Research and design of cotton plastic film collector & field straw chopper combined machine after autumn[J]. Acta Agriculturae Boreali-Occidentalis Sinica, 2013, 22(8): 199-204. (in Chinese with English abstract)

[94] 蒋永新,陈发,王学农,等. 棉秸秆还田及残膜回收机改进设计研究[J]. 新疆农业科学,2008(S2):159-161.

[95] 由佳翰,陈学庚,张本华,等. 4JSM-2000型棉秆粉碎与残膜回收联合作业机的设计与试验[J]. 农业工程学报,2017,33(10):10-16. You Jiahan, Chen Xuegeng, Zhang Benhua, et al. Design and experiment of 4JSM-2000 type combined operation machine for cotton stalk chopping and residual plastic film collecting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(10): 10-16. (in Chinese with English abstract)

[96] 王学农,冯斌,陈发,等. 棉秸秆切碎及残膜回收联合作业关键技术研究[J]. 新疆农业大学学报,2005,28(3):52-55. Wang Xuenong, Feng Bin, Chen Fa, et al. Research on key technic of cotton stalk shredding and used polythene film collecting combined machine[J]. Journal of Xinjiang Agricultural University, 2005, 28(3): 52-55. (in Chinese with English abstract)

[97] 王吉奎,付威,王卫兵,等. SMS-1500型秸秆粉碎与残膜回收机的设计[J]. 农业工程学报,2011,27(7):168-172. Wang Jikui, Fu Wei, Wang Weibing, et al. Design of SMS-1500 type straw chopping and plastic film residue collecting machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(7): 168-172. (in Chinese with English abstract)

[98] 马莉. 废旧农膜干法造粒工艺研究及应用性分析[D]. 上海:同济大学,2006. Ma Li. Study of Waste Agriculture Film Dry Process Granulitization and Utility Analysis[D]. Shanghai: Tongji University, 2006.

[99] 王志芸,和丽萍. 废旧农用塑料薄膜再生利用技术研究[J]. 云南环境科学,2006,25(4):38-40. Wang Zhiyun, He Liping. Study on regeneration technology of waste and old agriplast[J]. Yunnan Environmental Science, 2006, 25(4): 38-40. (in Chinese with English abstract)

[100] 柴希娟. 造纸废渣、废地膜再生处理制备聚合物基废弃物复合材料研究[D]. 昆明:昆明理工大学,2007.

[101] 李诗龙. 废旧农膜的回收再生利用技术[J]. 再生资源研究,2005(1):9-12. Li Shilong. Recycling agricultural plastic films[J]. Recycling Research, 2005(1): 9-12. (in Chinese with English abstract)

[102] 朱梦诗,刘从九. 浅谈我国废旧农膜回收利用现状[J]. 长沙大学学报,2015,29(2):101-104. Zhu Mengshi, Liu Congjiu. On the recycle status of agricultural plastic films in China[J]. Journal of Changsha University, 2015, 29(2): 101-104. (in Chinese with English abstract)

[103] 李梅,周恭明,陈德珍. 中国废旧农用塑料薄膜的回收与利用[J]. 再生资源研究,2004(6):18-21. Li Mei, Zhou Gongming, Chen Dezhen. Waste agricultural plastic film recycling technology in China[J]. Recycling Research, 2004(6): 18-21. (in Chinese with English abstract)

[104] 李俊虹,罗昕,胡斌,等. 机收残膜混合物水洗清选装置的研究与试验[J]. 农机化研究,2019,41(5):152-156. Li Junhong, Luo Xin, Hu Bin, et al. Research and experiment of the water-separating device for residual film mixture[J]. Journal of Agricultural Mechanization Research, 2019, 41(5): 152-156. (in Chinese with English abstract)

[105] 石鑫,牛长河,王学农,等. 滚筒筛式废旧地膜与杂质风选装置设计[J]. 农业工程学报,2017,33(18):19-26. Shi Xin, Niu Changhe, Wang Xuenong, et al. Design of roller sieve waste plastic film and trash winnowing machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(18): 19-26. (in Chinese with English abstract)

Problems and countermeasures of recycling methods and resource reuse of residual film in cotton fields of Xinjiang

Liang Rongqing, Chen Xuegeng, Zhang Bingcheng, Meng Hewei, Jiang Peng, Peng Xiangbin, Kan Za※, Li Weimin

(1.,,832000,; 2.,832000,)

Plastic film mulching cultivation technology has functions such as improving crop growth environment and regulating crop growth cycle, and it has been widely used in agricultural production processes at home and abroad, and it has promoted agricultural productivity and agricultural industry development. But the problem of mulch film residue has brought many harms to the agricultural production environment and the ecological environment. The contradiction between the use of mulch film and the ecological environment protection of agriculture and the sustainable development of agriculture has become increasingly prominent. Xinjiang is the major cotton producing area in China, and the area covered by plastic film and the amount of its use rank first in the country, and the problem of residual film pollution in cotton fields in Xinjiang is particularly serious, which is affected by multiple factors such as growing planting area, continuous cropping, poor film strength and insufficient recycling. The problem of residual film pollution in cotton fields affects the growth and yield of cotton, and the quality of agricultural machinery operations has been reduced and the content of heterogeneous fibers in cotton textiles has exceeded the standard. In recent years, through the formulation and implementation of laws and regulations and the research and development of cotton film residual membrane mechanized recycling technology, the residual film pollution control work has achieved initial results, but residual film pollution control is a system engineering, and the problem of recycling but not using will cause secondary environmental pollution and effective use of resources. Based on the analysis and induction of the current basic use conditions and residual pollution situation of farmland mulch in Xinjiang, the paper took the current recycling method, the residual film preliminary cleaning method and resource re-utilization situation of cotton fields in Xinjiang as the main research content, and the characteristics of the residual film in cotton fields recycled by different methods were analyzed, the difficulty of initial cleaning and recycling of cotton film residues recovered by different methods was compared and analyzed. Through field investigations on the current basic conditions of the residual film preliminary cleaning method, reprocessing process flow and utilization methods in Xinjiang, the supporting equipment and working process of each production link were analyzed. The results showed that the main influencing factors that hindered the resource reusing process of residual film in cotton fields in Xinjiang were the lack of the advanced and applicable cotton fields residual film recycling machinery, higher residual film impurity in the cotton field harvested by machine, the lack of equipment and immature technology of the residual film preliminary cleaning and reprocessing method, the single cotton fields residual film recycling and reprocessing methods and products, and less residual film preliminary cleaning and reprocessing enterprises. Residual film recycling and resource re-utilization should be carried out in order to effectively solve the residual film pollution problem. Based on this, the coping strategies were proposed. It was recommended to accelerate the production and use of film by improving the weathering and high-strength film promotion and demonstration, improving the mechanized recycling technology of cotton fields residual film, developing suitable residual film preliminary cleaning and reprocessing technology, and rationally arranging the preliminary cleaning and reprocessing enterprises, recycling and reuse of all links to form a closed-loop residual film pollution control model for the entire industrial chain, comprehensive and multi-level solution to the problem of residual film pollution in cotton fields in Xinjiang, which were conducive to energy saving and emission reduction and sustainable development of agriculture and could provide some reference for farmland residual film pollution control and resource reuse in Xinjiang and even the whole country.

films; recycling; cotton; pollution control;preliminary cleaning;resource utilization

2019-05-08

2019-06-14

兵团重大科技项目(2018AA001/04);国家自然科学基金资助项目(51605312)

梁荣庆,博士生,主要从事现代农业装备研究。Email:liangrongqing2008@163.com

坎 杂,教授,博士生导师,主要从事现代农业装备研究。Email:kz-shz@163.com

10.11975/j.issn.1002-6819.2019.16.001

X705

A

1002-6819(2019)-16-0001-13

梁荣庆,陈学庚,张炳成,蒙贺伟,姜 鹏,彭祥彬,坎 杂,李卫敏. 新疆棉田残膜回收方式及资源化再利用现状问题与对策[J]. 农业工程学报,2019,35(16):1-13. doi:10.11975/j.issn.1002-6819.2019.16.001 http://www.tcsae.org

Liang Rongqing, Chen Xuegeng, Zhang Bingcheng, Meng Hewei, Jiang Peng, Peng Xiangbin, Kan Za, Li Weimin. Problems and countermeasures of recycling methods and resource reuse of residual film in cotton fields of Xinjiang[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(16): 1-13. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2019.16.001 http://www.tcsae.org