Streamwise vortex generation by the rod

2019-09-28RyszardSZWABAPawelFLASZYNSKIPiotrDOERFFER

Ryszard SZWABA, Pawel FLASZYNSKI, Piotr DOERFFER

Department of Experimental Aerodynamics,Institute of Fluid Flow Machinery,Polish Academy of Sciences,Gdansk 80-231,Poland

KEYWORDS

Abstract The technology development related to aerodynamics is leading to ever increasing loads of wings, airfoils and turbine and compressor blades. The increase in aerodynamic forces is often leading to flow separation and depreciation of the aerodynamic performance of flying objects or propulsion systems.Flow control methods are required to avoid these negative effects.In the recent two decades the flow control by means of air-jet vortex generators has been also intensively investigated.In this method a streamwise vortex is introduced by an oblique jet.The necessity to supply air by a pipe system may be considered a disadvantage.In order to eliminate this feature,it has been proposed to put out a rod instead of a jet.It has been shown that the application of a rod can introduce the same effect as a jet, as long as the streamwise vortex generation is concerned and appropriate dimensions are used.The present paper focuses on the influence of rod vortex generators on a flow pattern downstream.The results presented here concern experimental and numerical investigations and provide guidelines for the design of a new flow control method dedicated mainly to external flows.

1. Introduction

The technology development related to aerodynamics is leading to ever increasing loads on wings, airfoils or turbine and compressor blades.The increase of aerodynamic forces is often related to the formation of shock waves,to the flow separation leading to the reduction of the aerodynamic performance of flying objects or propulsion systems. Flow control methods therefore are required to alleviate these negative effects. In many research centers a lot of effort has been undertaken to find a simple and effective flow control method to counteract separation. In recent decades several methods of flow control have been investigated.The research has concerned on plasma actuators,1synthetic jets,2solid(vane3or wedge type4) Vortex Generators (VG), inducing streamwise vortices which effectively counteract separation. Another way of flow control is the introduction of transpiration methods through a wall by suction and blowing depending on the application. Most known application of this type of flow control is the passive control of shock wave boundary layer interaction. In this method the shock pressure jump along the wall is driving a transpiration flow through perforated wall into the underlying cavity. This leads to the blowing upstream of the shock wave and suction downstream. A lot of attention for this type of flow control was paid in the European Project Euroshock II.5The details of flow modelling through perforated walls were presented in Ref.6.

Very often flow control methods rely on the energizing of the Boundary Layer (BL) upstream of the critical place (e.g.shock wave, separation, etc.), making it more resistant to the adverse pressure gradient and less likely to separate. One of the first investigations concerning the flow control issue were carried out by Wallis7and Pearcey.8They presented a very wide range of investigations concerning the flow control by streamwise vortices.The streamwise vortices were created basically by the means of solid vortex generators (vane types).Already then the Air-Jet Vortex Generators (AJVG) were mentioned as well. Flow control by means of solid VGs was also carried out in the other research centers over many following years.9In Ref.10the vane type VGs were used to enhance the lift over the wing at low speed,then in Ref.11the VGs were applied to reduce separation size in the rectangular S-duct diffuser.Vane type VGs have won their important position in the aviation technology and are broadly used.The main drawback of this technology is the additional drag which they induce during nominal conditions,when they are not needed.Following this,sub-layer VGs were developed4and investigated.They have not established market position however,due to their fragility, causing maintenance problems.

Equivalent method of streamwise vortices generation is by ejection of an oblique jet.This‘‘air jet vortex generators”have been intensively investigated over last two decades. Appropriate configuration of AJVG allows obtaining streamwise vortex of the similar intensity as in the case of traditional vane type VG. An advantage of AJVG is the possibility to switch the jet on and off, when needed, excluding an additional drag in cruise flight conditions. The streamwise vortices created in the flow entrain higher momentum fluid towards the wall and on the other hand push up the low momentum fluid against the main stream above the boundary layer. This organized mixing process appeared to be very effective in separation alleviation or elimination. Nowadays the continuous increase of the aircraft loading requires new development and innovative solutions.The idea of streamwise vortex generation by oblique air jet needs further development. Specific knowledge is needed to design the effective flow control device of this type. Therefore the research was also dedicated to the parametric study of AJVGs.12,13The research was mostly performed by means of numerical simulations14allowing for optimization studies. Only selected cases were also investigated experimentally.Combination of CFD with experiments allows looking deeply into the flow physics,accompanying the vortex generation by air-jet.

In our research group a lot of research was devoted to AJVG15,16which focused on the passive application where stagnation parameters of the air jet are equal to the far field stagnation parameters. In such approach jet stream may be tapped from any stagnation point, avoiding any additional energy to be supplied to drive the jets. The large experience in AJVG implementation17,18drove our group to the new idea of introducing a rod instead of a jet. Advantage of this new idea is that a rod can be easily operated by a MEMS(Micro-Electro-Mechanical Systems) actuator, allowing for electrical operation of this device. In many applications a rod may be superior to an air supply system. It is not so obvious that a rod may act in a similar manner as air jet.The effectiveness of Rod as Vortex Generator (RVG) has been investigated therefore and the results are presented here. It is shown that RVG may produce streamwise vortices of the same intensity as those induced by AJVG.The results presented here concern experimental and numerical investigations and provide guidelines for the design of a new flow control method dedicated mainly to external flows.

The topic of air-jet vortex generators was extensively investigated in the transonic wind tunnel of IMP PAN. Basing on this research,the main mechanisms driving the streamwise vortex formation have been identified. The main components of the flow structure are shown schematically in Fig.1.The main stream along the wall is deflected in the normal and transverse direction.This is a result of jet outflow from the hole,which is oblique and skewed with respect to the main flow direction.In the consequence, a large streamwise vortex is created ‘‘main vortex”.Together with this one,an additional‘‘lateral vortex”is induced of the opposite sense of rotation but much weaker.The main vortex(blue)is formed from the flow deflected in the normal direction and from the flow deflected on the obtuse angle side of the jet. The deflected stream flows into the low pressure zone,which is formed downstream of the jet,starting in this way a rotational motion. Then, the vortex is carried downstream keeping close to the wall. It contains also a part of the mass stream from the jet. The second, so-called lateral vortex (green), is created from the stream deflected on the acute side of the jet. Further downstream the main vortex is dominating the flow, and the ‘‘lateral vortex” is practically unnoticeable.

Fig. 1 Scheme of streamwise vortex creation.

While analyzing this vortex formation mechanism, one has to realize that the oblique jet in the flow acts like an obstacle,deflecting the incoming flow in an asymmetric way, leading to streamwise vortex formation. Being treated like an obstacle,the jet can be replaced by a rod.19Our investigations have shown that the equivalent flow structure, as in the case of AJVG,can be obtained downstream of the rod.To obtain this effect, a special optimized rod geometry must be applied.Retractable rods can be built in the MEMS technology allowing easy activation of an RVG.The potential application concerns external flows (e.g. wings, streamwise corners, engines intakes) where installation of an additional air supply system for an AJVG is difficult. Some examples for RVG application for subsonic and transonic flow are already presented. It was shown by means of numerical simulations that RVG can be applied on wind turbine blade20and helicopter rotor blade.21Experimental investigations of RVG effectiveness in separation reduction as the effect of the shock wave boundary layer interaction is presented in Ref.22. In Fig. 2, reduction of the separation zone is shown by the oil visualization. This is a view on the lower wall through a side wall window. The flow direction is from left to right and the shock wave location is marked by the dashed line.In this figure one can notice significant reduction of the separation size if the RVGs are applied.The separation length, measured by the distance from the shock to the reattachment line in the middle of the channel,is about 60% lower in comparison to the configuration without RVGs.

Fig. 2 Oil visualization in curved nozzle.

Presented here paper concerns RVG and investigations of its optimal configuration. It will be shown that the same flow structure can be produced downstream of a rod as well as downstream of a jet. It is expected that the RVG and AJVG configuration will be different due to the different behavior of a stiff rod and a soft jet.

At the beginning, the so-called standard configuration was used, treated as a validation case. This standard setting was investigated experimentally to have a validation base for numerical simulations (e.g. numerical scheme, turbulence model). Finally, an modified configuration was determined by numerical simulations. The new configuration was investigated experimentally and validated against CFD. With the obtained results the RVG effectiveness was confirmed.

2. Experimental setup

The experimental investigations were carried out in a test section which is shown in Fig.3.The nozzle is designed in such a way as to obtain a constant flow velocity downstream of the vortex generator, i.e. Ma=0.3. The lower and upper walls of the nozzle are rectilinear. The upper wall has an adjustable inclination angle. This allows compensating the cannel cross section defect due to the boundary layers at nozzle walls.The Reynolds number of the flow was Re=6.6×105.

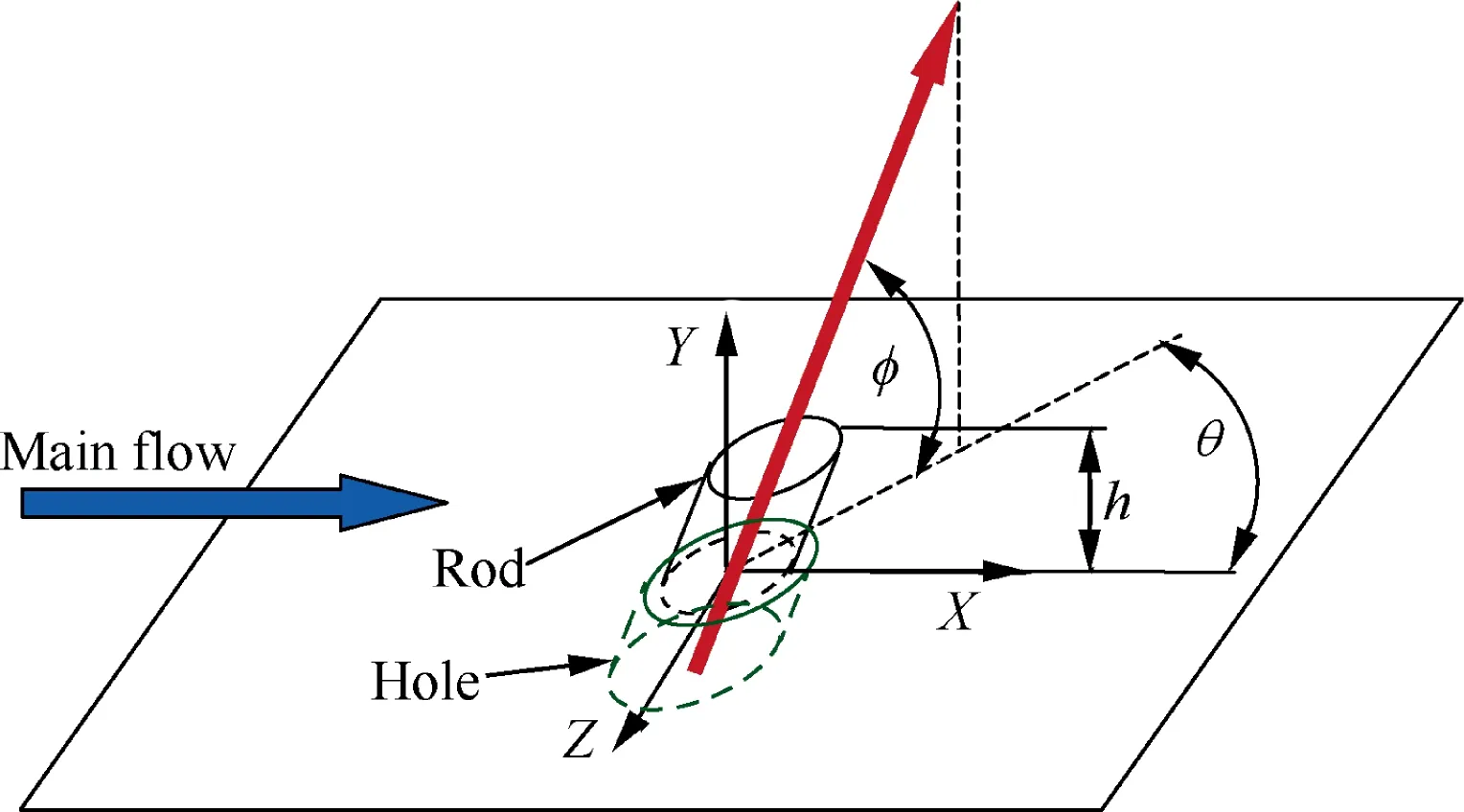

A more detailed view of the measurement region is shown in Fig. 4. The VG is placed on a measurement plate and the coordinate X=0 mm means the location of the rod. The rod has to be inclined at appropriate angles in relation to the main stream. The rod angles are defined in Fig. 5. There were two rod configurations in the flow, a standard one and modified one. The standard VG configuration was treated as a reference case with the pitch angle(plane OYZ,inclination to the wall) of φ=45° and the skew angle (plane OXZ, inclination to flow direction) θ=90°.

Fig. 3 General view of test section.

Fig. 4 View of measurement plate.

The pressure measurement taps were located downstream of the RVG (Fig. 4). The taps were located both along the channel and also in the spanwise direction. These taps were arranged in 5 rows and 8 columns. There are two traversing planes above the 4th and 8th row, downstream of the RVG(Fig. 4, OZY planes, X =54 mm and X=114 mm)in which the stagnation pressure was measured.The stagnation pressure measurement was taken by a Pitot probe, 0.5 mm in external diameter.

Fig. 5 Definition of vortex generator angles.

The following measurements were carried out to investigate the effects of the RVG on the flow: (A) inlet flow conditions;(B) static pressure distribution on the wall downstream of the rod; (C) stagnation pressure planes in the boundary layer downstream of the rod; (D) oil visualization on the test wall surface.

3. Experimental results of standard RVG configuration

As mentioned before, the standard configuration of the rod consisted of the pitch angle φ=45° and the skew angle θ=90°. The diameter of the standard rod was d=2.0 mm.The measurements were carried out for two rod heights, e.g.h=1.8 mm and h=3.6 mm.The undisturbed boundary layer thickness downstream of the vortex generator at X=54 mm was approximate δ=10 mm. Thus the d/δ ratio was equal to 0.2 and the h/δ ratio was 0.18 and 0.36 respectively.

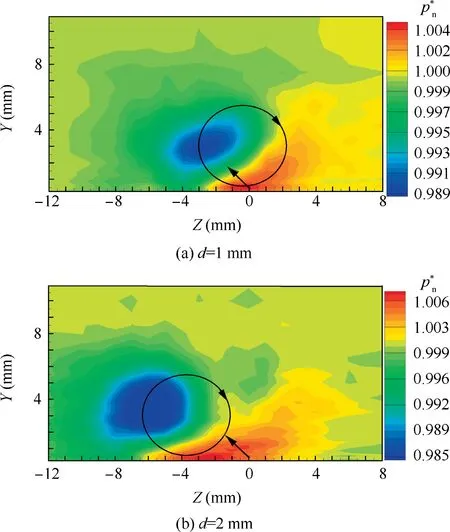

The measurement traverses were located at X=54 mm(5δ) and X=114 mm (11δ) behind the generator, what is shown in Fig. 4. The position of the generator rod was at X=0 mm. Coordinate Z is determined along the channel width.Z=0 mm is located at the channel center line.The axis of the rod is located at Z=0 mm at the test wall surface.The width of the measurement traverses was approximate 26 mm and it was in the range from Z= -16 mm to Z=10 mm.Coordinate Y represents the distance above the wall.The influence of streamwise vortices is shown in the boundary layer as stagnation pressure distribution. The results of stagnation pressure measurements as non-dimensional values, measured downstream of the rod at the plane X=54 mm for two RVG heights are shown in Fig. 6. These figures show maps of normalized stagnation pressure p*n, created in relation to the reference boundary layer stagnation pressure profile. This reference boundary layer profile is located at Z= -16 mm,outside the zone of the streamwise vortex influence. Eq. (1)shows the relation which describes how the normalized stagnation pressure maps were created.

In this way the local deficit and surplus of stagnation pressure in relation to the flow without a rod can be visualized.Such presentation of the stagnation pressure values localizes the streamwise vortex influence,its position and sense of rotation very well. Undoubtedly, a very important advantage of such visualization of the results is that one can see the places where the vortex transports the momentum towards and away from the wall. The maps in Fig. 6 show a downstream view onto the traversing plane. The rod location (54 mm upstream of the measurement plane) in the spanwise direction is indicated by an arrow.

Fig. 6 Normalized stagnation pressure of standard RVG.

In Fig. 6 one can see the local minima and maxima of the normalized stagnation pressure. One minimum (blue area)and one maximum (red area) correspond to a single streamwise vortex generated by a rod. On one side the vortex lifts the low momentum fluid(blue)and on the other side it pushes the high momentum fluid down towards the wall (red). The core of the vortex is located between the minimum and maximum of the stagnation pressure change. The sense of rotation of the vortex is indicated by arrows.The color scale is identical for all plots and shows the normalized pressure (p*n) distribution in the area of streamwise vortex. The strongest vortex intensity is generated by a VG which has the largest difference between the red and blue areas, in other words, where the difference between the minimum and the maximum in the stagnation pressure is the highest.

Putting a rod of a standard configuration one can see that two vortices have been created. One maximum and two local minima are formed.The main streamwise vortex has been created on the left side and a secondary, slightly weaker one on the right side. The vortex intensity increases in proportion to the VG height. The generator of the 3.6 mm height shows a slightly larger difference between the minimum and the maximum (approximate 3%) in relation to the smaller generator.For the 3.6 mm rod height the secondary vortex is weaker in relation to the main vortex than in the case of the smaller generator. For the smaller generator the secondary vortex is almost as strong as the main one,because the RVG configuration is beyond the optimum. Fig. 6 also show that the main vortex is located to the left of the vortex generator position.This means that the vortex core downstream of the rod is shifting in a direction determined by the rod.

Fig. 7 shows map of the normalized stagnation pressure measured in further traverse downstream of the rod at X=114 mm. As one can see, the flow pattern does not change,there is still the arrangement of two vortices.The vortices become weaker,nevertheless the vortex dissipation rate is small.

As it has been mentioned before,the desirable flow pattern is to obtain one strong vortex downstream of the vortex generator. The secondary, small vortex should be very weak and it should not be visible in the pressure field in distance of 5δ downstream of the VG.12Here one has obtained two vortices of comparable intensity what means that standard RVG configuration (φ=45°, θ=90°) is far from the optimal one.

Fig. 7 Normalized stagnation pressure of standard RVG(h=3.6 mm, X =114 mm).

In Fig.9 the surface oil visualization of the flow on the nozzle lower wall is shown. In this figure trace of vortices downstream of the rod is visible which is adequate to the flow structure shown in the stagnation pressure results. Streamwise accumulation of oil indicates separatrices located outside of the arrangement of two vortices. Accumulation of oil in the longitudinal direction, which is characteristic of the flow with vortices occurs at the point where the air lifts up(black dashed lines) away from the wall. In the case of counter-rotating vortices with the sense of rotation shown in Fig. 9, longitudinal accumulation of oil appears at their outer side. The flow between adjacent vortices is transported down to the wall and a reattachment is formed, marked by a white dashed line.In this region the surface friction coefficient increases and the oil film thinning occurs. For the higher generator (Fig. 9(b)),the vortex effect in the spanwise direction is wider, what also can be seen in the stagnation pressure results (see Fig. 6).

4. Numerical simulations for rod vortex generator

As shown above, streamwise vortices can be successfully generated by means of the RVG. However, based on the results of investigation for the jet vortex generators12or vane and other type of fixed vortex generators,23,24one can expect the influence of the RVG configuration on the streamwise vortex intensity. In this paper, the effect of the RVG skew angle θ on the streamwise vorticity is discussed.It has been found that the obtained streamwise vorticity increases with a decreased pitch angle. The applied minimum pitch angle is φ=30°due to the technological constraints. Therefore further research has been carried out at this φ value and the results are shown below.

Validation of the numerical model is carried out by means of comparison with experimental data for the reference configuration (pitch angle φ=45° and the skew angle θ=90°).Comparison with experimental data (presented above) allows for assessment of the flow structure prediction.Numerical simulations for the investigated cases were carried out by means of ANSYS Fluent and the unstructured hexahedral mesh was generated in Hexpress/NUMECA.

Fig. 9 Surface oil visualization downstream of rod.

The computational domain and mesh details close to the rod are shown in Fig. 10. The domain size in case of simulations for the standard configuration(investigated experimentally) is defined according to the test section dimensions.In case of simulations for different RVG skew angles, the domain size is decreased and the dimensions are presented in Fig. 10. Thus, the mesh size can be reduced by neglecting side and upper wall boundary layers, which has a negligible effect on the single vortex generator in the middle of the lower wall.The mesh consists of about 3×106hexahedra cells. In both cases, test section configuration and simplified one, the mesh is refined close to walls in order to keep about 40 cells in the boundary layer (y+≈1). The mesh is also refined in spanwise direction (Z direction) downstream of the rod to provide a high resolution in the vortex zone. At the location of 20 rod diameters(d)downstream,there are about 40 mesh cells within the zone of generated vortices. The simulations were done for k-ω SST (Shear Stress Transport).25Pressure based algorithm and MUSCL (Monotonic Upwind Scheme for Conservation Laws) scheme is applied. At the inlet, the total conditions are defined according to the measurements, so the total pressure in boundary layer profile is set upstream of the RVG.The boundary conditions for the turbulence model are applied based on the simulations for the flat plate and the same Mach number, but without RVG. Due to that, turbulent quantities in the boundary layer with the imposed total pressure distribution can be applied at the inlet. At the outlet, the static pressure was adjusted to obtain the required Mach number of 0.3.

Fig. 10 Computational domain and mesh details.

As mentioned above,numerical model is validated by comparison with experimental data for the standard configuration(pitch angle φ=45° and the skew angle θ=90°). Numerical results for diameter d=2 mm and height h=1.8 and h=3.6 mm are presented(Fig.11)as a normalized total pressure at the control plane downstream of RVG (X=54 mm).These results are compared with the measurements shown in Fig. 6. In case of both RVG heights, one can notice a lower range of total pressure non-uniformity in the pitch direction(Z direction) predicted numerically. Zones of low normalized pressure are closer to each other than shown by the measurements. It results from the lower diameter of the streamwise vortex predicted by numerical simulations. Direct comparison of the vortex size cannot be done due to the lack of measured velocity. Anyway, the minimum and maximum of the total pressure predicted by simulations are close to the measured values. The normalized total pressure distribution shown in Fig. 11 indicates the existence of the increased normalized pressure above the maximum located closer to the wall. The second maximum located further from the wall is an effect of the fluid transport from the outer zones of the boundary layer with a higher total pressure level. Such higher values are not noticed by Pitot probe measurements at a higher distance from the wall. In spite of such difference, one can conclude that the numerically predicted flow structure is similar,although the vortex size and intensity are different.

As mentioned above,vortex intensity cannot be determined directly by Pitot probe measurements, but it can be estimated by the normalized values and the minimum and maximum location. Numerical simulations provide an opportunity for a direct comparison of the proposed normalized pressure with the vorticity field, in particular by the streamwise component of vorticity vector ωx, defined as:

where uzand uyare the vector velocity components in Z and Y direction respectively.

Such comparison at a control plane downstream of the RVG is shown in Fig. 12. In both figures, streamlines located in the range of streamwise vortices indicate the existence of two counter-rotating vortices. The vortex located on the left side is stronger than the one on the right side. This confirms that the main vortex is stronger than the secondary one. Such effect is also seen in Fig. 11(a) pressure plot, where the local minimum of the normalized total pressure is lower on the left side than on the right side.This effect is in agreement with the measurements shown in Figs. 6 and 7.

Fig. 11 Normalized numerical stagnation pressure of standard RVG with different heights (d=2 mm, X =54 mm).

According to the experience arising from the AJVG investigations, it is known that the vortex intensity (strength) can be increased by a modification of the skew and the pitch angles. In order to find the rod inclination to the wall and the main flow direction leading to the maximum vorticity, a parametric study was carried out. The streamwise vorticity ωxis defined as the objective function. The selected results for the two RVG diameters (d=1 mm and d=2 mm) and the height of 3.6 mm are shown in Fig. 13. In the plot(Fig. 13 (a)), the streamwise vorticity ωxis normalized by the vorticity generated with standard configuration (ωx-base),so the ratio indicates how stronger are generated vortices by modified configurations. As shown, the streamwise vorticity ωxis highly dependent on the skew angle θ (for the constant pitch angle φ=30°) and for higher RVG diameter the maximum is obtained at a lower θ value. Comparing both cases,one can state that the larger diameter at the same RGV height induces higher vorticity.

Fig. 12 Streamlines and normalized stagnation pressure or vorticity of standard RGV (d=2 mm, h=3.6 mm).

Any modification of the RVG skew angle θ has a strong effect on the local maximum and the vorticity distribution(Fig. 14). It is shown that one strong vortex is created instead of two vortices with a similar absolute vorticity value. In the vicinity of the main vortex,a counter rotating secondary weak vortex is also created. Although, the flow structure topology requires further investigation,the obtained results indicate significant influence of the skew angle on the generated vortex intensity and the RVG effectiveness.

5. Experimental results for modified RVG configuration

The modified RVG configuration, according to the numerical simulations, yielded the pitch angle φ=30° and the skew angle in the range of θ=40°-50°,depending on the rod diameter. For the experiment requirements the same skew angle θ=45° for both rod diameters was assumed. As it can be noticed in Fig. 13, that vorticity for this skew angle is located very near to the maximum. The modified RVG configuration is different to the one, considered as the reference one. The investigations were carried out in the same test section(Fig.3)as for a standard configuration and at the same Mach number for two different generator rod diameters, namely,d=1 mm and d=2 mm. The rod height for each diameter was the same and equaled to h=3.6 mm, hence the ratio h/δ=0.36, and the ratio d/δ=0.1 and 0.2.

Fig. 13 Streamwise vorticity of two RVG with different diameters (h=3.6 mm).

Fig. 15 show normalized stagnation pressure maps for two different rod diameters in the distance 5δ downstream of the vortex generator. In these figures one can see that a single streamwise vortex (one minimum and maximum of pressure area) was created in the flow behind the modified rod vortex generator. This is quite a different flow pattern than in the case of the standard configuration, where two streamwise counter-rotating vortices were formed downstream of the rod. A desirable flow pattern (one main vortex, see Fig. 1)downstream of the vortex generator is formed for the modified configuration.

Fig. 14 Streamwise vorticity of RVG (d=2 mm, h=3.6 mm).

Fig. 15 Normalized stagnation pressure of modified RVG(h=3.6 mm, X =51 mm (5δ)).

These results show the effectiveness of the performed parametric study, carried out by means of numerical simulations,which allowed the streamwise vorticity to be increased up to 4 times at the lower diameter/height ratio in comparison to the standard configuration. The increase in vorticity confirms the experimental results where a higher pressure difference between the high and low pressure zone (compare Figs. 6(b)and 15(b)) is observed. The relative difference between the modified and standard RVG in the normalized stagnation pressure is about 60%. Comparing the action of an optimized generator of different diameters one can see that in the case of a generator with a larger diameter d=2.0 mm, the difference between the minimum and the maximum pressure is higher compared to the generator of a smaller diameter,d=1.0 mm. Such a result shows that the vortex intensity increases with an increase in the vortex generator rod diameter.

Fig. 16 Normalized stagnation pressure downstream of AJVG(d=1 mm, 5δ downstream of jet).

Fig.16 shows normalized stagnation pressure maps for single AJVG of 1 mm diameter in the distance 5δ downstream of the jet. This result was obtained also for the same flow configurations(test section and flow velocity:Ma=0.3)that in case of RVG experiments. The jet configuration angles were also optimized in terms of its intensity.12In Fig.16 one can see that a single streamwise vortex is observed in the flow in some distance behind the AJVG. Comparing the flow pattern downstream of the RVG and AJVG of similar diameter (see Figs. 15(a) and 16) one can say that in the case of RVG modified configuration one has obtained the same flow structure as in flow with AJVG, one minimum and one maximum correspond to a single streamwise vortex generated by a rod or a jet. In terms of vortex intensity one can conclude that vortex downstream of RVG is slightly stronger in relation to the AJVG one.The difference between the minimum and the maximum of pressure is slightly higher in case of RVG. The pressure maximum is on the same level,but the pressure minimum is a little bit lower in case of RVG regards to the AJVG flow case.

6. Conclusions

An experimental and numerical investigation has been carried out to study the mechanism of streamwise vortex generation by the new type of vortex generator, namely the rod vortex generator. The flow patterns developed downstream of the rod vortex generator of various configuration were compared with the air-jet vortex generator. The investigated RVGs were of different height and diameter. The results presented here provide guidelines for the design of a new flow control method dedicated mainly to external flows. The following more detailed conclusions can be also drawn from the presented experimental results:

(1) Downstream of the rod vortex generator of a standard configuration (pitch angle φ=45° and the skew angle θ=90°) in the flow the two counter-rotating vortices are created. The vortices intensity increases in proportion to the VG height.

(2) The numerically predicted flow structure is similar to the experimental one, however due to the complex dissipative processes in such flow the vortex size and intensity are different.

(3) A parametric study of RVG configuration made by means of CFD shows that changing the pitch and skew angle(to φ=30°and θ=40°-50°respectively)shows a significant increase of vortex intensity generated by the rod in relation to the reference configuration and also significant influence on flow structure topology downstream of the vortex generator,one strong vortex is created instead of two vortices with a similar absolute vorticity value.

(4) The experimental comparison of the flow pattern downstream of the rod and jet of similar diameter shows that in the case of RVG modified configuration one has obtained the same flow structure as in flow with AJVG. In terms of vortex intensity, the vortex downstream of RVG is slightly stronger in relation to the AJVG one.

The most important conclusion which can be drawn from the above described investigations is that a new method to generate streamwise vortices, using an appropriately inclined rod can replace the air-jet vortex. In many types of applications it can be easier to install rods, activated by MEMS actuators than air-jets with an air supply system.

One can also conclude that the flow structure downstream of the rod vortex generator is very similar to the air jet vortex generator.An optimized rod vortex generator delivers a single streamwise vortex of the similar intensity, potentially even higher, as an air-jet vortex generator.

Acknowledgement

The research was supported by a grant from the Polish Ministry of Science and Higher Education (No. N502209438).

杂志排行

CHINESE JOURNAL OF AERONAUTICS的其它文章

- Special Column of BWB Civil Aircraft Technology

- Assessment on critical technologies for conceptual design of blended-wing-body civil aircraft

- Exploration and implementation of commonality valuation method in commercial aircraft family design

- Effects of stability margin and thrust specific fuel consumption constrains on multi-disciplinary optimization for blended-wing-body design

- Nacelle-airframe integration design method for blended-wing-body transport with podded engines

- On developing data-driven turbulence model for DG solution of RANS