秸秆坯块成型工艺参数及保水性试验研究

2019-08-19宫元娟刘德军白雪卫

宫元娟,邓 楠,刘德军,白雪卫,邱 硕

秸秆坯块成型工艺参数及保水性试验研究

宫元娟,邓 楠,刘德军,白雪卫,邱 硕※

(沈阳农业大学工程学院,沈阳 110161)

为探究玉米秸秆、豆粕和聚丙烯酸钠混合制备农用保水剂的生产工艺,以最大压缩力、混料水分、压缩速度、豆粕质量分数和聚丙烯酸钠质量分数为试验因素,以成型坯块的松弛密度为评价指标进行二次回归旋转组合试验,优化工艺参数组合并试验验证,在松弛密度的最优范围内分析其对坯块保水性能的影响。试验结果表明:坯块的松弛密度为460~540 kg/m3的条件下,得出最大压缩力为16~20.59 kN,混料水分为8.84%~12.96%,压缩速度为95.56~155.51 mm/min,豆粕质量分数为16.08%~24.02%,聚丙烯酸钠质量分数为4.91%~7.15%的最佳成型工艺参数;坯块的保水效果随松弛密度的增大而逐渐增强,有砂土时释水量随时间变化符合对数模型,无砂土时则符合线性模型,拟合方程的回归系数均大于0.9,成型坯块保水性的分析可靠,可为复合型农用保水剂的应用提供参考。

秸秆;优化;模型;坯块;成型工艺;松弛密度;保水性

0 引 言

辽西北干旱与半干旱地区土壤沙化严重、养分含量少,耕地利用率低,不利于农作物生长[1],亟需改良沙化土壤保水性和养分结构的新技术[2-3]。传统农用保水剂可分为树脂类、淀粉类和纤维素类3种,改善土壤水分状况的效果良好[4-5]。其中秸秆为原料的纤维素类保水剂,既可显著抑制水分流失,又兼具原料来源广、制备成本低、降解性好的优势,已成为近年研究的热点[6-8]。

秸秆是重要的生物质资源,但质地分散、能量密度低、储存与运输困难等特点制约其规模化、高值化利用[9],因此压缩成型势在必行[10-15]。生物质成型产品的物理特性受混料状况(如组成与配比、水分等)、成型工艺(如温度、压力等)和粘结剂种类等因素影响[16-20]。李伟振等[21]将玉米秸秆、木屑与木钠热压成型,发现温度和混料水分、混料水分和压力对松弛密度起显著交互作用。Muazu等[22]将淀粉作为粘结剂加入稻壳和玉米棒混料中,可强迫颗粒膨胀,成型砖的松弛密度降低。Jackson等[23]将盲草、柳枝稷、玉米秸秆与小麦秸秆压缩成型,发现混料水分对成型颗粒耐久性影响较大。冷压成型技术不破坏生物质内部结构,已用于生产高密度、低能耗的成型颗粒[24]。秸秆类纤维素保水剂的开发,需实现干旱环境下对沙化土壤释水与释肥的双重功效,秸秆单原料成型已无法满足需求,基于外源添加物的秸秆坯块研究仍需深入。本文在玉米秸秆中添加豆粕和聚丙烯酸钠作为营养物质与粘结剂,研究冷压方式下三者混合成型的最优工艺参数组合;模拟辽西北地区的土壤状况与气候条件,分析成型坯块松弛密度对其保水性能的影响规律,为丰富秸秆资源的利用途径、旱地农业区保水技术的发展提供参考依据。

1 材料与方法

1.1 试验材料与设备

玉米秸秆采自沈阳农业大学试验基地,2018年10月收获后粉碎至粒度小于4 mm,自然晾干后平均水分小于4%。黄色豆粕粉中蛋白质的质量分数为40%~48%,可提高作物品质,熟化土壤、杀灭或抑制土壤有害菌,实现均衡供肥[25-26]。粘结剂选用高吸水性的聚丙烯酸钠,白色固体粉末,可提高制品稳定性和耐老化性。三者按一定比例混配,定量喷壶均匀喷水调制不同水分的样本后,恒温箱内21 ℃密封储存24 h。参考文献[27]选择砂土粒径小于2 mm,细度模数为3.7~1.6。

压缩设备选用济南试金集团有限公司出品的WDW-200电子式万能试验机,最大压缩力为200 kN,压缩速度范围为1~500 mm/min,成型通用模具内径为50 mm,高度为80 mm,底板可承受的最大压力为25 kN,试验设备示意图见图1。测定混料水分设备采用北京市永光明医疗仪器有限公司的101型电热鼓风干燥箱,以及深圳市冠亚电子科技有限公司的SFY-60远红外快速水分测定仪。

1.试验机开关 2.机架 3.横梁 4.夹头 5.顶杆 6.套筒 7.底座

1.Test equipment switch 2.Frame 3.Beam 4.Chuck 5.Ejector pin 6.Sleeve 7.Base

注:图中5、6、7构成压缩模具。

Note: 5,6 and 7 constitute compression mold in this picture.

图1 压缩试验设备示意图

Fig.1 Schematic diagram of compression test equipment

1.2 试验设计

1.2.1 坯块成型

将混料装入压缩模具,设定试验机的最大压缩力及压缩速度,压成坯块后从模具中挤出,室温保存,待松弛48 h后测量其质量、直径及高度、以松弛密度[28]作为成型效果的评价指标,可体现成型坯块松弛后的稳定性,计算公式如式(1)所示。

式中RDS为坯块的松弛密度(kg/m3);,,分别为坯块的质量(kg)、直径(m)和高度(m)。

以最大压缩力、混料水分、压缩速度、豆粕质量分数和聚丙烯酸钠质量分数为试验因素,采用五元二次回归正交旋转组合设计,根据单因素试验结果,将各因素按其水平及取值范围进行编码,因素水平编码表见表1。

表1 因素水平编码表

注:坯块中包含玉米秸秆、豆粕和聚丙烯酸钠。

Note: The block includes corn straw, soybean meal and sodium polyacrylate.

1.2.2 坯块保水性能试验

保水性微观上可表征物质内亲水分子与水分子之间的相互作用强度,宏观上可反映物料在外界环境(如温度、介质)变化时保持水分的能力[29]。为探究成型坯块在干旱区的保水效果,通过干燥箱模拟干旱环境,以箱内温度(20、50 ℃)模拟土壤释水的常温和极高温条件。试验采用坯块在有无砂土介质的2种释水情况来评价其保水性[30],记录数据并进行回归分析。为避免砂土样本间差异影响试验结果,各样本均过标准土筛并风干,保证初始质量与水分的差异可忽略,每组试验重复3次,释水量取平均值。

有砂土释水:室温下特定密度坯块在盛水烧杯中吸水至饱和后,置于盛砂土的有机玻璃盒(100 mm ×100 mm×80 mm)内。记录坯块-砂土的初始质量1,再将其移入预设温度的干燥箱,每隔1 h取出称质量W1,释水量1按公式(2)计算。

式中1为坯块-砂土的释水量,g;1为坯块-砂土初始质量,g;W1为第(+1)次取样时坯块-砂土的质量,g;1,2,…,10。

无砂土释水:室温下特定密度坯块在盛水烧杯中吸水至饱和,记录初始质量2,再将其放入预设温度的干燥箱,每隔1 h取出称质量W1,释水量2按公式(3)计算。

式中2为坯块的释水量,g;2为坯块初始质量,g;W1为第(+1)次取样时坯块的质量,g;1,2,…,10。

1.3 试验数据分析

采用Excel 2010对单因素试验数据进行方差分析,利用Design Expert 8.0和Excel 2010处理二次回归正交旋转组合试验及成型坯块的保水性试验数据。

2 结果与分析

2.1 回归模型的建立与分析

根据设计方案进行试验,结果见表2。各成型坯块稳定后的质量为19.24~22.08 g,高度为1.7~2.7 cm,直径变化小于0.02%忽略不计,取5 cm,松弛密度为395.76~586.06 kg/m3。图2为各因素变化影响坯块品质的部分试验样品,豆粕质量分数与压缩速度对坯块表面形态影响显著,其中图2a坯块的豆粕质量分数较大,表面较图 2b更光滑;图2d坯块压缩速度较大,表面较图2c更粗糙。对松弛密度进行回归分析,建立回归模型,结果见表3。

回归方程模型=14.78>0.01(20,38)=2.37,<0.000 1,回归模型极显著;此模型的回归系数2为0.886 1,失拟=1.29<0.05(22,16)=2.26,=0.301 5>0.05,表明目标函数与各因素之间相关性良好,模型预测松弛密度的效果较好。因素1245对松弛密度的影响显著,影响顺序为:最大压缩力(1)>混料水分(2)>聚丙烯酸钠质量分数(5)>豆粕质量分数(4)。交互项121314152334对松弛密度的影响均显著,足够支撑5个响应变量,模型的预测和优化合理。剔除不显著项后的模型回归方程为

表2 成型坯块松弛密度的试验设计及结果

图2 部分成型坯块的试验样品图

Fig.2 Test sample pictures of several formed blocks

表3 松弛密度的回归方差分析

2.2 试验因素的交互作用分析

松弛密度越大,成型坯块越稳定;松弛密度越小,成型坯块会出现裂痕且易松散,需借助抗破坏试验和吸水试验确定松弛密度的优化区间。

首先进行抗破坏试验,将成型坯块侧放在WDW-200电子万能试验机平台上,悬梁夹紧压头等速向下运动。松弛密度大于540 kg/m3时,坯块抗破坏强度已达1 000 N,能耗较大;松弛密度小于460 kg/m3时,坯块松软易变形,故松弛密度在460~540 kg/m3时,坯块的抗破坏强度在600~1 000 N,抗破坏能力较好。其次进行吸水试验,发现上述所选密度范围的坯块吸水迅速且不松散。因此,坯块松弛密度的优化范围可设为460~540 kg/m3。

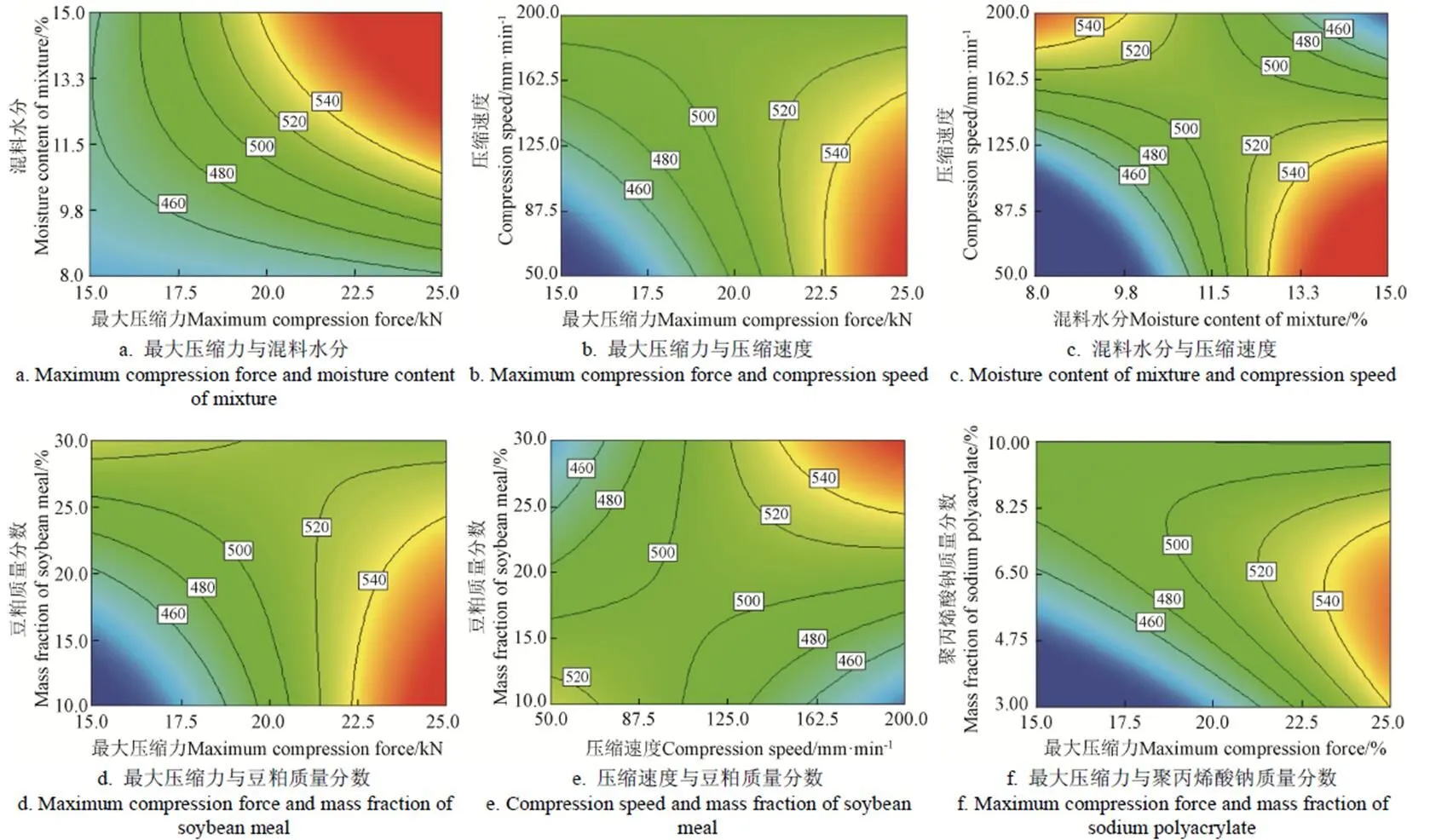

利用Design Expert 8.0绘制等高线图,对交叉项121314152334的交互作用予以分析,结果见图3。

注:图中等高线值为松弛密度,kg·m-3。

由图3a可知,当松弛密度一定时,混料水分随着最大压缩力增大而减少,说明压缩过程中适宜水分可增大分子间作用力,具有粘结与润滑作用,所以混料水分应相应的增加[21]。由图3b可知,当松弛密度在460~500 kg/m3之间且一定时,压缩速度随着最大压缩力的增大而减小;当松弛密度在520~540 kg/m3之间且一定时,压缩速度随着最大压缩力的增大而增大。由图3c可知,当松弛密度在460~500 kg/m3之间且一定时,压缩速度随着混料水分的增加而减小;当松弛密度在520~540 kg/m3之间且一定时,压缩速度随着混料水分的增加而增大。由图3d可知,当松弛密度在460~500 kg/m3之间且一定时,豆粕质量分数随着最大压缩力的增大而减小;当松弛密度在520~540 kg/m3之间且一定时,豆粕质量分数随着最大压缩力的增大而增大。由图3e可知,当松弛密度在460~500 kg/m3之间且一定时,豆粕质量分数随着压缩速度的增大而增大;当松弛密度在520~540 kg/m3之间且一定时,豆粕质量分数随压缩速度的增大而减小。由图3f可知,当松弛密度在460~480 kg/m3之间且一定时,聚丙烯酸钠质量分数随着最大压缩力的增大而减小;当松弛密度在500~540 kg/m3之间且一定时,随着聚丙烯酸钠质量分数的增大,最大压缩力先减小后增大。

2.3 成型参数优化

以松弛密度(460~540 kg/m3)为试验指标的优化区间,通过软件Design Expert 8.0对回归模型进行分析计算,得出最佳工艺参数为:最大压缩力为16~20.59 kN,混料水分为8.84%~12.96%,压缩速度为95.56~155.51 mm/min,豆粕质量分数为16.08%~24.02%,聚丙烯酸钠质量分数为4.91%~7.15%。

2.4 验证试验

为验证二次回归模型预测的准确性,随机选取一组优化组合(最大压缩力为16 kN,混料水分为11%,压缩速度为130 mm/min,豆粕质量分数为20%,聚丙烯酸钠质量分数为6%),设定10次重复试验取数据平均值,结果如表4所示。

在优化试验条件下,满足秸秆压缩坯块的松弛密度在460~540 kg/m3之间,试验值与预测值之间的相对误差为1.03%,吻合度良好,模型具有较好的可靠性,对秸秆冷压成型工艺具有参考意义。

表4 试验验证结果

2.5 保水性能分析

分别制备松弛密度为460、480、500、520、540 kg/m3的成型坯块,有砂土和无砂土2种试验条件下坯块释水量变化见图4。

由图4可知,在同一温度下,释水量随烘干时间增加而增大,但随松弛密度增大而减小,是因为松弛密度增大的同时孔隙度减小,坯块对水分有更大的束缚力,所以大密度坯块的保水效果整体好于小密度坯块。利用Excel软件分析,坯块-砂土的释水量(1)变化规律可近似用烘干时间的对数函数拟合,如图4a所示,在填充的砂土与秸秆坯块双重作用下,整体孔隙度减小,释水量缓慢降低趋于平衡,所以拟合的对数关系更明显。在坯块的释水量(2)与烘干时间的方程拟合中,线性拟合的回归系数(2>0.98)均大于对数拟合的回归系数(2>0.96),所以线性关系更明显,如图4b所示,松弛密度越大,拟合直线斜率越小,说明释水越慢,保水能力越强。二者拟合方程和回归系数见表5,各回归系数2均大于0.9,拟合程度较好。

综上所述,成型坯块的保水性能与其松弛密度关系密切,同一温度下有砂土介质时释水较无砂土介质时释水缓慢,且释水量小于后者,成型坯块用于砂土中的保水效果较好。

a. 坯块-砂土a. Block-sandb. 坯块b. Block

表5 释水量拟合方程

3 结 论

1)成型坯块的最佳工艺参数组合为:最大压缩力为16~20.59 kN,混料水分为8.84%~12.96%,压缩速度为95.56~155.51 mm/min,豆粕质量分数为16.08%~24.02%,聚丙烯酸钠质量分数为4.91%~7.15%。

2)在成型坯块的松弛密度为460~540 kg/m3的条件下得出最优工艺参数范围,满足实际生产中低能耗与高标准的要求。回归模型的试验值与预测值间的相对误差为1.03%,模型可靠,对冷压成型工艺具有参考意义。

3)随松弛密度的增大,成型坯块的保水效果逐渐增强。有砂土时释水量与烘干时间近似呈对数关系,无砂土时释水量与烘干时间近似呈线性关系。各拟合方程的回归系数2均大于0.9,数据可靠,为成型坯块的保水利用提供参考。

[1] 苗恒录,李泽坤,徐冰,等. 保水剂在干旱沙区作物应用中的研究进展[J]. 北方农业学报,2018,46(1):85-89. Miao Henglu, Li Zekun, Xu Bing, et al. Research progress on the application of super absorbent polymer in crops in arid sandy area[J]. Journal of Northern Agriculture, 2018, 46(1): 85-89. (in Chinese with English abstract)

[2] 李宝新. 辽西北半干旱地区农作物节水灌溉主要技术[J]. 现代农村科技,2014(9):43-44.

[3] 李晨,苏晓蕾,张妍,等. 干旱半干旱地区城市节水景观营造策略[J]. 中国城市林业,2016,14(5):64-67. Li Chen, Su Xiaolei, Zhang Yan, et al. Strategies for water-saving landscape establishments in cities at arid and semi-arid area[J]. Journal of Chinese Urban Forestry, 2016, 14(5): 43-44. (in Chinese with English abstract)

[4] 黄占斌,张国桢,李秧秧,等. 保水剂特性测定及其在农业中的应用[J]. 农业工程学报,2002,18(1):22-26. Huang Zhanbin, Zhang Guozhen, Li Yangyang, et al. Characteristics of aquasorb and its application in crop production[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2002, 18(1): 22-26. (in Chinese with English abstract)

[5] 庄文化,冯浩,吴普特. 高分子保水剂农业应用研究进展[J]. 农业工程学报,2007,23(6):265-270. Zhuang Wenhua, Feng Hao, Wu Pute. Development of super absorbent polymer and its application in agriculture[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2007, 23(6): 265-270. (in Chinese with English abstract)

[6] Krul L P, Nareiko E I, Matusevich Y I, et al. Water super absorbents based on copolymers of acrylamide with sodium acrylate[J]. Polymer Bulletin, 2000, 45(2): 159-165.

[7] 廖人宽,张志成,任树梅,等. 化学集成调控技术对土壤水氮与玉米产量的影响[J]. 农业机械学报,2014,45(6):166-171. Liao Renkuan, Zhang Zhicheng, Ren Shumei, et al. Effects of chemical integrated control technology on soil water, soil nitrogen and maize yield[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(6): 166-171. (in Chinese with English abstract)

[8] 张慧瑛,樊丹阳,卢妹妹,等. 利用小麦秸秆制备的保水剂性能研究[J]. 水土保持通报,2017,37(2):193-198. Zhang Huiying, Fan Danyang, Lu Meimei, et al. Synthesis and water-holding performance of water retaining agent made from wheat straw[J]. Bulletion of Soil and Water Conservation, 2017, 37(2): 193-198. (in Chinese with English abstract)

[9] 阮建雯,蔡宗寿,余继文,等. 国内外农作物秸秆固化成型技术研究[J]. 世界农业,2014(4):40-43.

[10] 薛冬梅,武佩,马彦华,等. 生物质致密成型技术研究进展[J]. 安徽农业科学,2018,46(1):32-36,70. Xue Dongmei, Wu Pei, Ma Yanhua, et al. Research progress on technologies of biomass densification[J]. Anhui Agricultural Science, 2018, 46(1): 32-36, 70. (in Chinese with English abstract)

[11] 夏先飞,肖宏儒,肖苏伟,等. 生物质致密成型原料预处理技术研究进展及试验初探[J]. 中国农机化学报,2018,39(2):61-66. Xia Xianfei, Xiao Hongru, Xiao Suwei, et al. Research on the raw materials pretreatment technology of biomass densification process[J]. Journal of Chinese Agricultural Mechanization, 2018, 39(2): 61-66. (in Chinese with English abstract)

[12] 白阳,闫文刚,刘志刚. 生物质燃料致密成型方式的发展现状与展望[J]. 林业机械与木工设备,2018,46(9):10-15. Bai Yang, Yan Wengang, Liu Zhigang. Development status and prospects of biomass briquette fuel dense molding method[J]. Forestry Machinery and Woodworking Equipment, 2018, 46(9): 10-15. (in Chinese with English abstract)

[13] 李海亮. 水稻秸秆营养穴盘气动成型机理及试验研究[D]. 大庆:黑龙江八一农垦大学,2018. Li Hailiang. Pneumatic Molding Mechanism and Experiment Research on Straw-based Nutrient Seedling-growing Bowl Tray[D]. Daqing: Heilongjiang Bayi Agricultural University, 2018. (in Chinese with English abstract)

[14] 鲜红. 我国生物质成型燃料的研究进展[J]. 林业建设,2017(5):33-36. Xian Hong. Research progress on biomass briquettes in China[J]. Forestry Construction, 2017(5): 33-36. (in Chinese with English abstract)

[15] 宗煜翔,万芳新,蒲军,等. 生物质制粒成型机理的研究现状[J]. 林业机械与木工设备,2016,44(7):4-6,11. Zong Yuxiang, Wan Fangxin, Pu Jun, et al. Research situation of biomass pellet forming mechanism[J]. Forestry Machinery and Woodworking Equipment, 2016, 44(7): 4-6, 11. (in Chinese with English abstract)

[16] Peng J H, Bi H T, Lim C J, et al. Study on density, hardness, and moisture uptake of torrefied wood pellets[J]. Energy Fuels, 2013, 27(2): 967-974.

[17] Mitchual S J, Frimpong K, Darkwa N A. Effect of species, particle size and compacting pressure on relaxed density and compressive strength of fuel briquettes[J]. International Journal of Energy and Environmental Engineering, 2013, 4(1): 30.

[18] 涂德浴,李安心,何贵生. 水稻秸秆与木屑混合原料热压成型试验[J]. 农业工程学报,2015,31(20):205-211. Tu Deyu, Li Anxin, He Guisheng. Hot pressing forming experiment of the rice straw and sawdust mixed material[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(20): 205-211. (in Chinese with English abstract)

[19] 涂德浴,李安心,何贵生. 水稻秸秆冷压成型工艺参数优化[J]. 中国农业科技导报,2015,17(3):56-62. Tu Deyu, Li Anxin, He Guisheng. Parameter optimization of rice straw cold press process[J]. Journal of Agricultural Science and Technology, 2015, 17(3): 56-62. (in Chinese with English abstract)

[20] 李荣丽,刘小勇,张占国,等. 玉米秸秆含水率与常温压缩成型压力之间关系的研究[J]. 工程与试验,2009,49(3):61-63. Li Rongli, Liu Xiaoyong, Zhang Zhanguo, et al. Study on the relation between percentage of moisture of chopped corn stalks and the force of room temperature compression[J]. Engineering and Test, 2009, 49(3): 61-63. (in Chinese with English abstract)

[21] 李伟振,姜洋,饶曙,等. 玉米秸秆和木屑及木钠混配成型工艺参数优化[J]. 农业工程学报,2018,34(1):198-203. Li Weizhen, Jiang Yang, Rao Shu, et al. Parameter optimization of corn stover blended with sawdust and sodium lignosulphonate compression experiments[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(1): 198-203. (in Chinese with English abstract)

[22] Muazu R I, Stegemann J A. Effects of operating variables on durability of fuel briquettes from rice husks and corn cobs[J]. Fuel Processing Technology, 2015, 133: 137-145.

[23] Jackson J, Turner A, Mark T, et al. Densification of biomass using a pilot scale flat ring roller pellet mill[J]. Fuel Processing Technology, 2016, 148: 43-49.

[24] 王瑞丽,魏楷峰,刘洋,等. 饲料用秸秆丝化多频快速压缩成型工艺参数优化[J]. 农业工程学报,2016,32(21):277-281. Wang Ruili, Wei Kaifeng, Liu Yang, et al. Optimization of process parameters for multi-frequency rapid compression molding of corn stalk silk used for forage[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(21): 277-281. (in Chinese with English abstract)

[25] 万述伟,张守才,赵明,等. 豆粕有机肥与化肥配施对大棚春黄瓜产量品质和土壤肥力的影响[J]. 中国农学通报,2013,29(31):188-193. Wan Shuwei, Zhang Shoucai, Zhao Ming, et al. Effect of soybean meal combined application of chemical fertilizer on greenhouse cucumber yield and quality and soil fertility[J]. China Agricultural Science Bulletin, 2013, 29(31): 188-193. (in Chinese with English abstract)

[26] 王海杰,李萌萌,关二旗,等. 微波处理对豆粕胶黏剂性能影响的研究[J]. 中国油脂,2019,44(3):102-106. Wang Haijie, Li Mengmeng, Guan Erqi, et al. Effect of microwave treatment on properties of soybean meal adhesive[J]. China Oils and Fats, 2019, 44(3): 102-106. (in Chinese with English abstract)

[27] 国家质量监督检验检疫总局. 建设用砂GB/T14684-2011[S]. 北京:中国标准出版社,2011.

[28] 王功亮,姜洋,李伟振,等. 基于响应面法的玉米秸秆成型工艺优化[J]. 农业工程学报,2016,32(13):223-227. Wang Gongliang, Jiang Yang, Li Weizhen, et al. Process optimization of corn stover compression molding experiments based on response surface method[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(13): 223-227. (in Chinese with English abstract)

[29] 王中华,刘咏梅,吴限彩,等. 聚丙烯酸高吸水树脂的合成及性能研究[J]. 天津化工,2018,32(5):12-14. Wang Zhonghua, Liu Yongmei, Wu Xiancai, et al. Study on the synthesis and properties of polyacrylic acid high absorbent resin[J]. Tianjin Chemical Industry, 2018, 32(5): 12-14. (in Chinese with English abstract)

[30] 孙宾宾,杨博. 高吸水树脂产品吸水保水性能测试方法综述[J]. 化学工程师,2013,27(10):30-33. Sun Binbin, Yang Bo. Review of measurement methods about water absorption and water retention properties of super-absorbent resin[J]. Chemical Engineer, 2013, 27(10): 30-33. (in Chinese with English abstract)

Optimization of forming process parameters and water retention performance of straw blocks

Gong Yuanjuan, Deng Nan, Liu Dejun, Bai Xuewei, Qiu Shuo※

(,,110161,)

The preparation of straw-based agricultural water-retaining agent is one of the effective ways to utilize crop resources. It can solve the problems of low soil nutrient content and low utilization rate of cultivated land in arid and semi-arid areas of Northwest Liaoning. However, the characteristics of straw such as dispersed texture, low bulk density, high cost in storage and transportation restrict its large-scale and value-added utilization. As a result, the biomass densification technique has attracted wide attention. To the best of our knowledge, the physical properties of the densified products are influenced by the mixing conditions of raw materials, pressing parameters and types of binders, and addition of high protein yellow soybean meal powder into soil can improve the quality of crops, ripen the soil, kill or inhibit soil harmful bacteria, and achieve the balance of fertilizer supply, while the white sodium polyacrylate as the binder can improve the stability and absorption of the products. Therefore, these two components were mixed with straw blocks proportionally to make samples with different water content in this study, then the mixture was loaded into a compression die (50 mm inner diameter and 80 mm height) that controlled by the WDW-200 electronic universal testing machine. The clamp of the testing machine held the die head and keeps the plumb state. After maximum compression force and compression speed were set by a computer, the machine started to move downward, and densified block was extruded from the die at a room temperature. The quality, diameter and height of the product were measured after a complete relaxation, and the relaxation density was calculated. To explore an optimal forming process of agricultural water-retaining agent, a quadratic general rotary combination design was adopted, with the maximum compression force, moisture content of mixture, compression speed, mass fraction of soybean meal and mass fraction of sodium polyacrylate were test factors. The softwares of Design-Expert 8.0.6 and Excel 2010 were applied for the variance analysis and response surface analysis of experimental results, with the aim to establish mathematical model between the index and each influencing factor, as well as optimize the combination of forming parameters. Furthermore, in the optimum range of relaxation density, the soil condition and climate conditions in Northwest Liaoning were simulated. The water retention capacity of formed blocks with or without the sandy soil medium were evaluated and compared by water release at intervals in a temperature controlled drying oven, and effect of relaxation density was analyzed as well. Results showed that the relaxation density was significantly affected by following four factors (< 0.000 1), and the degree of importance were maximum compressive force > moisture content of mixture > mass fraction of sodium polyacrylate > mass fraction of soybean meal. Under the condition of relaxation density of 460-540 kg/m3, the optimized combinations of cold forming parameters were maximum compression force of 16-20.59 kN, moisture content of mixture of 8.84%-12.96%, compression speed of 95.56-155.51 mm/min, mass fraction of soybean meal of 16.08%-24.02%, mass fraction of sodium polyacrylate of 4.91%-7.15%. The error was 1.03% in the test verification, which was reliable in prediction. The water-holding capacity of formed block was closely related to relaxation density, the water release increased with drying time, but decreased with the increase of relaxation density at the same temperature. Because the block with larger relaxation density had greater binding force on water, the water retention performance was better. By using the softwares of Excel 2010, it was calculated that the block-sand overall porosity decreased, water release decreased slowly and tended to balance with the double action of filling sand and straw block, so water release of block-sand and drying time conformed to the logarithmic model; while in the absence of sand, the regression coefficients of linear fitting (2> 0.98) were greater than those of logarithmic fitting (2> 0.96), so it followed the linear model obviously, the relaxation density was larger, the slope of straight line was smaller, the water retention performance was stronger. In summary, the regression coefficients of two fitting equations were all greater than 0.9, water release in the sandy soil medium was slower and smaller than that without the sandy soil medium, which indicated that water retention performance of block-sand was better, the analysis of water retention was reliable and provided a reference for the application of compound agricultural water retention agent.

straw; optimization; model; block; forming process; relaxation density; water retention performance

2019-04-19

2019-06-02

国家自然科学基金资助项目(51405311);农业部公益性行业科研专项(201503134);辽宁省教育厅重点项目(LSNZD201707)

宫元娟,博士,教授,博士生导师,主要从事秸秆利用技术与装备研究。Email:yuanjuangong@163.com

邱 硕,博士,实验师,主要从事秸秆利用技术与装备研究。Email:gcq4032018@163.com

10.11975/j.issn.1002-6819.2019.12.030

S216.2;S156.2

A

1002-6819(2019)-12-0248-08

宫元娟,邓 楠,刘德军,白雪卫,邱 硕. 秸秆坯块成型工艺参数及保水性试验研究[J]. 农业工程学报,2019,35(12):248-255. doi:10.11975/j.issn.1002-6819.2019.12.030 http://www.tcsae.org

Gong Yuanjuan, Deng Nan, Liu Dejun, Bai Xuewei, Qiu Shuo. Optimization of forming process parameters and water retention performance of straw blocks[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(12): 248-255. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2019.12.030 http://www.tcsae.org