孵化场微酸性电解水冲洗消毒效果试验研究

2019-07-23魏永祥李宗刚李保明郑炜超

魏永祥,李宗刚,李保明,3,涂 江,郑炜超,3

孵化场微酸性电解水冲洗消毒效果试验研究

魏永祥1,2,李宗刚1,2,李保明1,2,3,涂 江1,2,郑炜超1,2,3※

(1. 中国农业大学水利与土木工程学院,北京 100083;2. 农业农村部设施农业工程重点实验室,北京 100083;3. 北京市畜禽健康养殖环境工程技术研究中心,北京 100083)

孵化场出雏器和出雏筐的冲洗消毒是孵化生产的重要环节,该文针对孵化场使用化学消毒剂会导致化学残留、消毒效果低和病菌微生物耐药性增加等问题,将有效氯质量浓度为60~100 mg/L微酸性电解水应用于出雏器内壁、地面和出雏筐的冲洗消毒,并与常规化学消毒剂(50 mg/L聚维酮碘溶液和50 mg/L苯扎溴铵溶液)进行冲洗消毒效果对比研究。结果表明,有效氯质量浓度为60~100 mg/L的微酸性电解水冲洗消毒可以有效杀灭出雏器内壁、地面和出雏筐表面的总菌(需氧菌总数)、大肠杆菌和金黄色葡萄球菌,且杀菌效果随有效氯质量浓度和冲洗消毒时间的增加而提高。有效氯质量浓度为100 mg/L的微酸性电解水冲洗消毒3 min对出雏器内壁和地面总菌的杀菌率分别为93.9%和85.6%,且显著高于50 mg/L的聚维酮碘溶液的杀菌率(73.1%和69.6%)和50 mg/L的苯扎溴铵溶液的杀菌率(76.6%和74.5%)(< 0.05);对出雏筐表面冲洗消毒40 s,杀菌率为79.6%。较常规化学消毒剂,微酸性电解水冲洗消毒可显著提高对出雏器和出雏筐的消毒效果,同时还具有广谱、无残留等优点,是孵化场出雏器和出雏筐表面消毒的良好替代消毒剂。

消毒;清洗;杀菌;孵化场;微酸性电解水;出雏设备;有效氯

0 引 言

孵化是蛋鸡生产的重要环节,是实现蛋鸡行业良种化、专业化和市场化的重要保证。孵化过程的卫生状况会影响种蛋的孵化率和出雏率[1]。孵化厅及出雏设备的冲洗消毒,有助于减少微生物数量,保持良好的卫生状况,是孵化场稳定、高效生产的重要前提。

目前,孵化场多采用常规化学消毒剂进行消毒,如苯扎溴铵溶液、癸甲溴氨溶液、过氧乙酸溶液等[2-3]。常规化学消毒剂杀菌消毒,不仅会刺激养殖动物的呼吸道,引起应激反应,影响畜禽产品品质,还会对从业人员的身体健康造成危害[4-5]。常规化学消毒剂滥用会造成严重的环境问题,部分常规化学消毒剂的化学毒性可以持续数月,造成更为严重的环境污染[6]。此外,随着常规化学消毒剂的长期使用,微生物的抗药性问题也愈发严重,沙门氏菌的多重耐药性从20世纪90年代的20%~30%增加至21世纪初的70%,且其耐药谱仍在不断拓宽[6-7]。

电解水(electrolyzed water, EW)是一种广谱、高效、无残留的环境友好型消毒剂,通过电解稀盐酸溶液或氯化钠溶液制备。其中,pH值为5.0 ~ 6.5的电解水被称为微酸性电解水(slightly acidic electrolyzed water, SAEW),具有杀菌效果强,对人体、皮肤、有机材料等无腐蚀性,对铁块、碳钢等金属腐蚀性小[8-10],制备简单快捷,电解过程无需隔膜,生产成本低[11-12],使用后无化学残留,对环境和人畜危害小等优点[13-16]。近年来,微酸性电解水被广泛应用于畜禽场杀菌消毒,且取得了良好的应用效果[17-25]。Hao等[17]的研究表明,微酸性电解水对蛋鸡舍设备表面细菌具有显著的杀灭作用;郑炜超等[18]的研究表明,微酸性电解水喷雾对蛋鸡舍内空气及进场车辆表面微生物的消毒效果高于常规化学消毒剂。与蛋鸡舍主要针对鸡蛋生产相比,孵化场主要满足种蛋孵化需求,其装备、操作及管理有显著差别。而现有研究主要集中在蛋鸡舍环境消毒方向,关于微酸性电解水用于孵化场冲洗消毒的杀菌效果研究尚未报道。微酸性电解水用于孵化场冲洗消毒的效果如何,使用规程如何制定等问题尚不明确,亟需开展相关试验研究。本试验通过研究微酸性电解水对孵化场出雏设备表面微生物的冲洗消毒效果,并与孵化场现有2种常规化学消毒剂(聚维酮碘溶液和苯扎溴铵溶液)进行对比,探究微酸性电解水替代常规化学消毒剂对孵化场出雏设备冲洗消毒的可行性,以期为微酸性电解水在孵化场出雏设备日常冲洗消毒的应用提供理论依据。

1 材料与方法

1.1 试验出雏厅

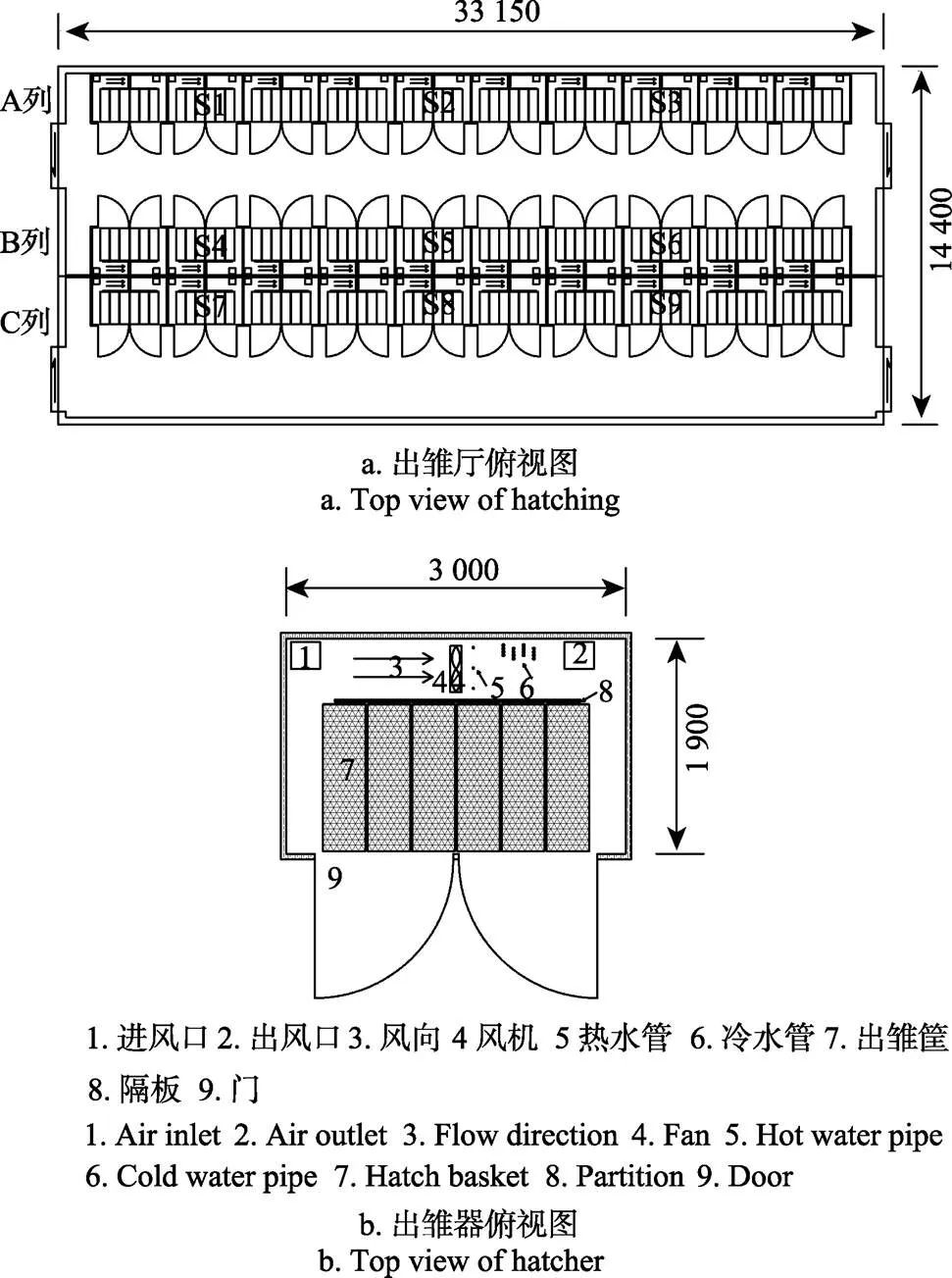

试验出雏厅位于北京市平谷区华都峪口禽业有限责任公司蛋鸡孵化场,试验时间为2017年11月~2018年1月,试验期间出雏厅内温度为19~21℃,相对湿度为20%~30%。如图1a所示,出雏厅尺寸为33.15 m×14.40 m×4.50 m(长×宽×高),水磨石地面,试验出雏厅内共30台出雏器(EICXDH-15120,青岛兴仪电子设备有限责任公司,中国),分3列,每列10台布置。如图1b所示,出雏器尺寸为3.0 m×1.9 m×2.0 m(长×宽×高),出雏器内壁箱板采用44 mm玻璃钢白泡板,出雏器地面为地板砖,其内可放置6列,每列16层的聚乙烯(PE,polyethylene)塑料出雏筐;出雏筐尺寸为130 cm×30 cm×12 cm(长×宽×高),单个出雏筐可放置168枚胚蛋。种蛋孵化过程包括1)孵化,种蛋处于孵化器内,19 d;2)出雏器,种蛋处于出雏器内,2 d。其中试验出雏厅生产操作流程为:1)第一天A列上午出雏,下午冲洗消毒;2)第二天上午A列进蛋和B列出雏,下午B列消毒;3)第三天上午B列进蛋和C列出雏,下午C列消毒,以3 d为一个循环周期。出雏厅消毒流程为:1)自来水高压水枪冲洗出雏器内壁,地面和出雏筐;2)消毒剂高压水枪冲洗消毒出雏器内壁,地面和出雏筐。

注:S1~S9表示9台出雏器。单位:mm。

1.2 试验消毒剂

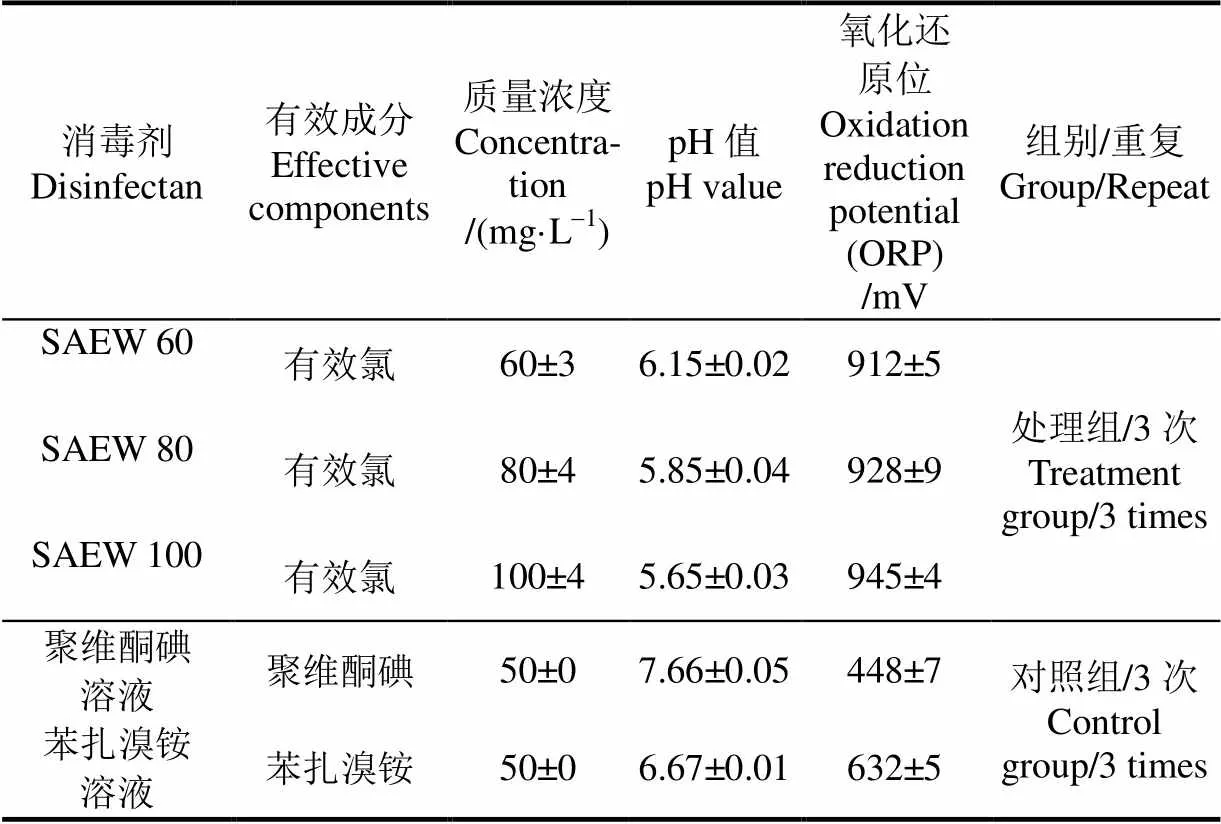

如表1所示,试验过程采用的消毒剂包括:微酸性电解水(60,80,100 mg/L)(大量现有研究[21, 26]建议微酸性电解水在畜牧领域(有机质较多)的使用浓度大于60 mg/L,因此本试验选用了60 mg/L及高于该浓度的两种微酸性电解水浓度)、聚维酮碘溶液(50 mg/L)和苯扎溴铵溶液(50 mg/L)(孵化场日常消毒所用浓度),其中微酸性电解水为试验替代消毒剂,聚维酮碘溶液(50 mg/L)和苯扎溴铵溶液(50 mg/L)为试验孵化场出雏厅生产实际所用消毒剂。

表1 消毒剂的理化性质

微酸性电解水由无隔膜次氯酸水发生器(水神BD-600L,上海富强旺卫生用品有限公司,中国),通过电解9%的稀盐酸溶液和自来水制备,制取的微酸性电解水有效氯质量浓度范围为10~100 mg/L。出雏厅常规消毒剂(50 mg/L的聚维酮碘溶液和50 mg/L苯扎溴铵溶液)分别由5%的聚维酮碘溶液和5%的苯扎溴铵溶液以 1﹕1 000倍数稀释制备。微酸性电解水有效氯质量浓度采用有效氯测试仪(RC-3F,日本笠原理化工业株式会社,日本)进行测量,测量范围为0~320 mg/L,精度为±1 mg/L;消毒剂酸碱度采用pH计(pH-8414,杭州盈傲仪器有限公司,中国)进行测量,测量范围为0~14.00,精度为± 0.01;消毒剂氧化还原电位采用氧化还原电位计(ORP-2626,杭州盈傲仪器有限公司,中国)进行测量,测量范围为0~999 mV,精度为± 1 mV。

1.3 细菌采样

如图1a所示,试验出雏器共9台(S1~S9)。采用表面擦拭法,分别对试验出雏器内壁、地面及出雏筐进行细菌采样。采样时间介于出雏器雏鸡运出后和下一次出雏种蛋运入前,分别于自来水及消毒剂高压水枪冲洗消毒前后进行采样。每台出雏器冲洗消毒前后分别选取3个内壁采样点和2个地面采样点,采样面积为5×5 cm2。出雏筐为网状结构,选择相邻的10个网格进行采样,每次采集3处不同的10个网格。

表面擦拭法操作步骤为,将浸润过灭菌缓冲蛋白胨水的无菌医用棉签,在采样点来回擦拭约20次,擦拭过程保持棉签转动,擦拭完成后,剪去棉签棒,将棉花头放入装有10 mL灭菌缓冲蛋白胨水的无菌离心管保存。

将装有棉花头和10 mL灭菌缓冲蛋白胨水的离心管进行振荡,分别对振荡后的样本液进行10倍梯度稀释,每个梯度取0.1 mL样本稀释液,分别均匀涂布于营养琼脂培养基、麦康凯琼脂培养基和甘露醇高盐琼脂培养基平板表面,在37℃条件下培养24~48 h后,对菌落数在30~300的平板进行菌落计数。表面细菌浓度通过公式(1)计算:

其中为表面细菌浓度,CFU/cm2;为平板上菌落的平均值,CFU;为样本原液体积,mL;为样本原液10倍稀释梯度数;为平板涂布液体体积,mL;为采样面积,cm2。

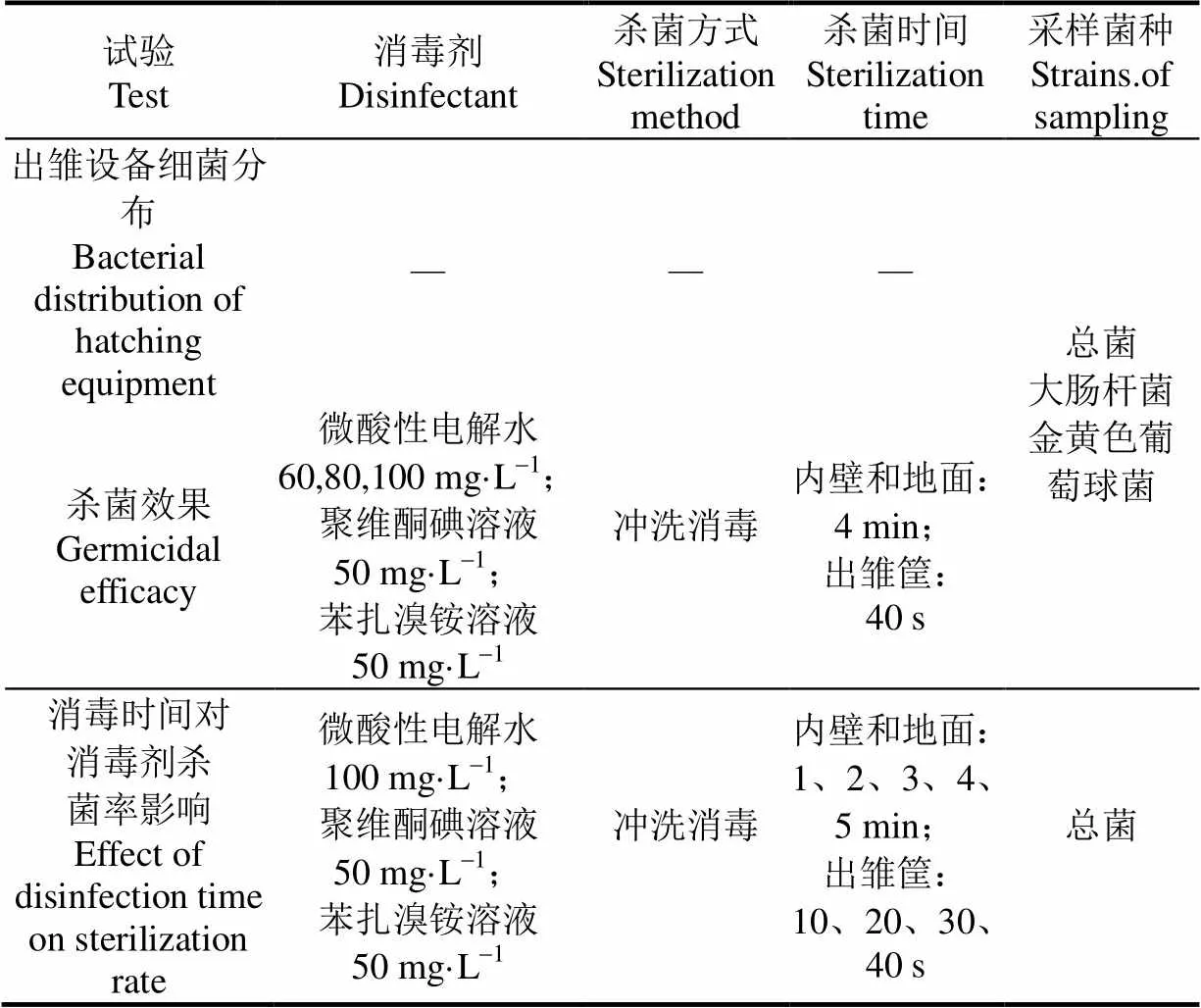

1.4 试验设计

如表2所示,试验分为出雏设备细菌分布研究、消毒剂杀菌效果研究和消毒时间对杀菌效果影响研究,采用单因素试验方法。其中,消毒剂杀菌效果研究试验中,按照孵化场现有消毒程序,采用高压水枪(压力:3.5 MPa;喷头孔径:2.2 mm)进行冲洗消毒(冲洗时间:出雏器和地面4 min,出雏筐40 s);消毒时间对杀菌效果影响研究试验中,采用高压水枪(压力:3.5 MPa;喷头孔径:2.2 mm)进行冲洗消毒。试验出雏器共9台(S1~S9),进行3次重复。

表2 试验设计

1.5 数据处理

消毒剂杀菌率通过公式(2)计算:

其中为杀菌率,%;P为消毒前细菌浓度,CFU/cm2;P为消毒后细菌浓度,CFU/cm2。

本研究数据采用Microsoft Excel 2013软件进行数据处理和作图,采用SPSS 19.0软件进行单因素方差分析,< 0.05表示差异显著,> 0.05表示差异不显著。试验数据均以“平均值±标准差”表示。

2 结果与分析

2.1 出雏设备细菌分布

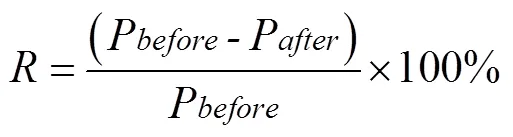

出雏器内壁、地面及出雏筐表面细菌分布如图2所示,总菌(需氧菌总数)、大肠杆菌和金黄色葡萄球菌在试验出雏器内壁、地面和出雏筐表面的浓度均呈现为:地面≥内壁>出雏筐。出雏器内壁和地面表面3种细菌浓度均显著高于出雏筐表面(> 0.05)。出雏前,出雏器内壁、地面和出雏筐均进行严格的消毒,出雏过程中,细菌从外部向内部感染可能性较大,且出雏过程中的温度和湿度均有利于微生物滋生,进而造成相对暴露的地面和内壁相较于出雏筐更容易被感染。

注:同种细菌不同字母表示两者间差异显著(P < 0.05),下同。

2.2 微酸性电解水对出雏器内壁的杀菌效果

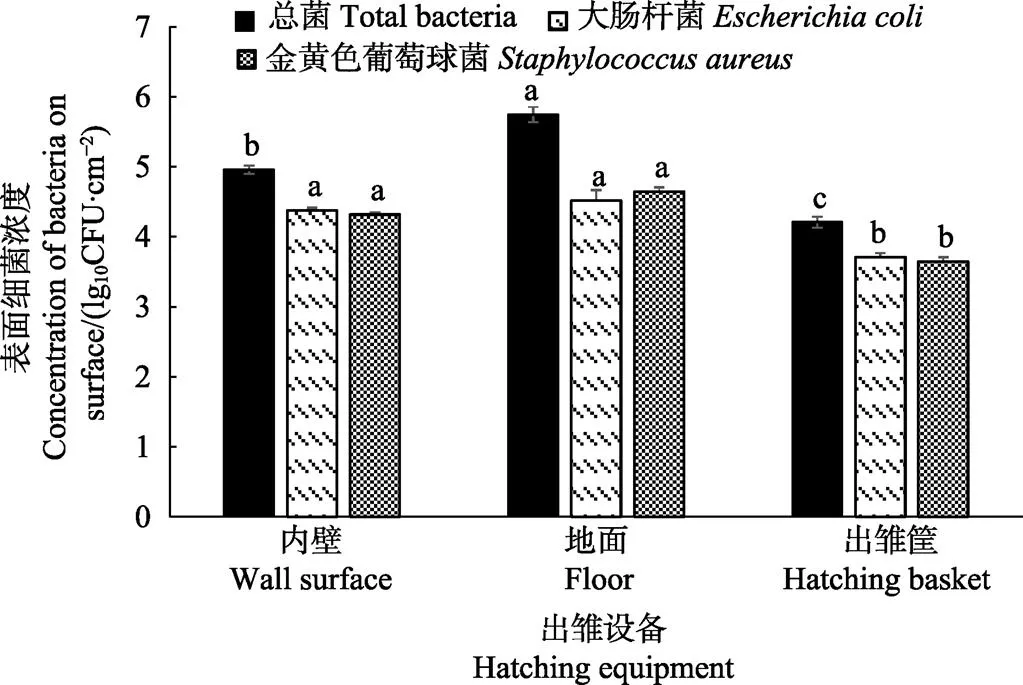

如图3所示,微酸性电解水冲洗消毒对出雏器内壁表面总菌的杀菌率为80.1%~93.9%;对大肠杆菌的杀菌率为78.1%~89.1%;对金黄色葡萄球菌的杀菌率为72.5%~91.2%,且对3种细菌的杀菌率随微酸性电解水有效氯质量浓度增加而升高。2种常规消毒剂(50 mg/L聚维酮碘溶液和50 mg/L苯扎溴铵溶液)对出雏器内壁表面总菌、大肠杆菌和金黄色葡萄球菌的杀菌率无显著差异(> 0.05),且对总菌和大肠杆菌的杀菌率均低于有效氯质量浓度为60 mg/L的微酸性电解水,对金黄色葡萄球菌的杀菌率与有效氯质量浓度为60 mg/L的微酸性电解水对其的杀菌率无显著差异(> 0.05)。Nan等[27]进行的悬液杀菌研究结果表明,大肠杆菌对SAEW的敏感性显著高于金黄色葡萄球菌,且SAEW对大肠杆菌细胞损伤明显大于金黄色葡萄球菌细胞。唐晨晨等[28]研究了不同碘伏制品的杀菌效果,结果证明了同种碘伏制品对金黄色葡萄球菌的杀菌对数值小于其对大肠杆菌的杀菌对数值。吕桂芬等[29]开展的微酸性电解水对奶牛乳房炎致病菌体外抑菌效果表明,60 mg/L的微酸性电解水和聚维酮碘溶液对金黄色葡萄球菌的杀菌效率无显著性差异,上述研究结果与本研究结果一致。

微酸性电解水对出雏器内壁表面3种细菌的杀菌率随有效氯质量浓度增加而升高,该试验结果与Tagawa和张秋婷等[30-31]的结果一致。有效氯质量浓度为80 mg/L和100 mg/L的微酸性电解水对出雏器表面3种细菌的杀菌率均显著高于2种常规消毒剂(< 0.05)。郑炜超等[19]研究证明了中性电解水的杀菌效果高于聚维酮碘溶液,而相同浓度条件下微酸性电解水的杀菌能力显著高于中性电解水[20],该结果与本试验微酸性电解水的杀菌效果高于聚维酮碘溶液杀菌效果的结论一致。因此,采用有效氯质量浓度大于60 mg/L的微酸性电解水对出雏器内壁表面细菌进行冲洗消毒能达到较好杀菌效果,优于2种常规消毒剂(50 mg/L聚维酮碘溶液及50 mg/L苯扎溴铵溶液)。

注:SAEW 60、80、100表示有效氯质量浓度为60、80、100 mg·L-1的微酸性电解水;聚维酮碘和苯扎溴铵的质量浓度为50 mg·L-1,下同;冲洗消毒时间:4 min.

2.3 微酸性电解水对出雏器地面的杀菌效果

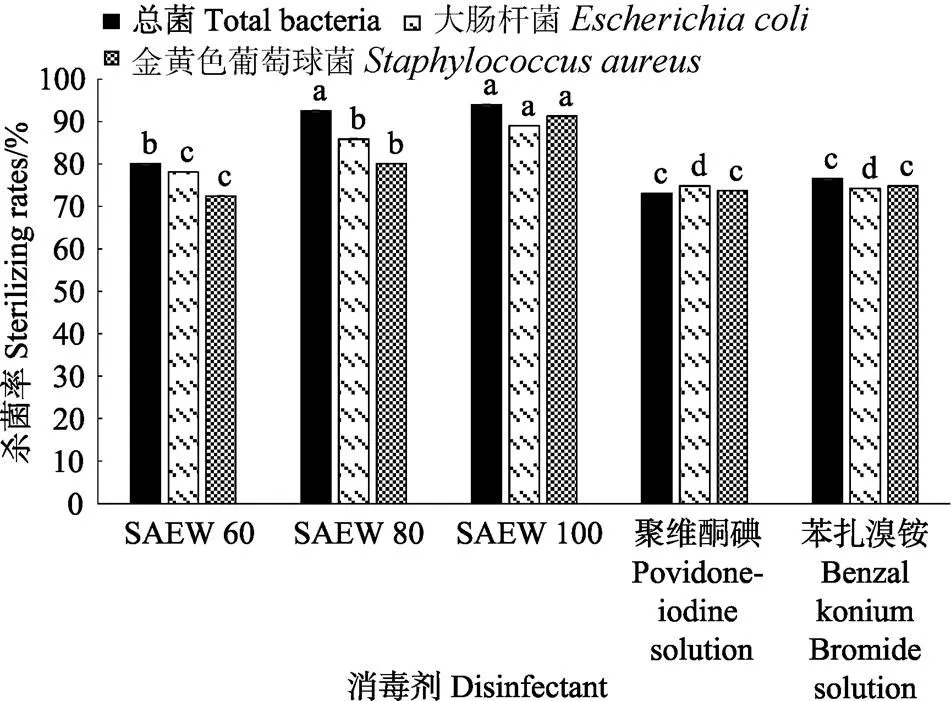

如图4所示,微酸性电解水冲洗消毒对出雏器地面总菌的杀菌率为65.3%~80.1%;对大肠杆菌的杀菌率为57.3%~74.9%;对金黄色葡萄球菌的杀菌率为62.0%~74.3%,且对3种细菌的杀菌率随微酸性电解水有效氯质量浓度增加而升高。2种常规消毒剂(50 mg/L聚维酮碘溶液和50 mg/L苯扎溴铵溶液)对出雏器地面总菌、大肠杆菌和金黄色葡萄球菌的杀菌率无显著性差异(> 0.05),有效氯质量浓度为100 mg/L的微酸性电解水对出雏器地面3种细菌的杀菌率均显著高于2种常规消毒剂的杀菌率。因此,采用有效氯质量浓度为100 mg/L的微酸性电解水对出雏器地面进行冲洗消毒能达到较好杀菌效果,优于2种常规消毒剂(50 mg/L聚维酮碘溶液及50 mg/L苯扎溴铵溶液)。

2.4 微酸性电解水对出雏筐表面的杀菌效果

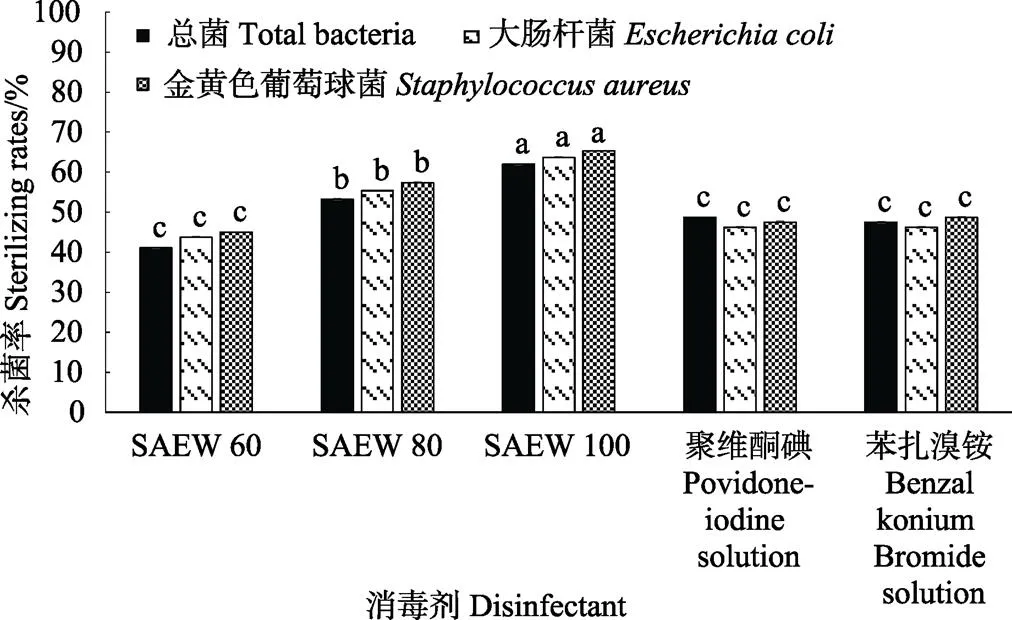

如图5所示,微酸性电解水冲洗消毒对出雏筐表面总菌的杀菌率为41.1%~62.0%;对大肠杆菌的杀菌率为43.8%~63.7%;对金黄色葡萄球菌的杀菌率为45.1%~65.3%,且对3种细菌的杀菌率随微酸性电解水有效氯质量浓度增加而升高。2种常规消毒剂(50 mg/L聚维酮碘溶液和50 mg/L苯扎溴铵溶液)对出雏筐表面总菌、大肠杆菌和金黄色葡萄球菌的杀菌率无显著差异(> 0.05)。有效氯质量浓度为60 mg/L的微酸性电解水对3种细菌的杀菌率同2种常规消毒剂对3种细菌的杀菌率无显著差异(> 0.05)。因此,采用有效氯质量浓度大于60 mg/L的微酸性电解水对出雏筐表面进行冲洗消毒能达到较好杀菌效果,优于2种常规消毒剂(50 mg/L聚维酮碘溶液及50 mg/L苯扎溴铵溶液)。

注:冲洗消毒时间为4 min.

注:冲洗消毒时间为40 s

物体表面有机物含量显著影响微酸性电解水的消毒效果[26],在出雏过程完成时,出雏器表面的有机物含量观察结果呈现为:地面>内壁,因此造成了3种不同有效氯质量浓度的微酸性电解水对3种表面不同细菌的杀菌率均呈现为:内壁>地面。出雏筐冲洗消毒时间为40 s,低于日常地面和内壁冲洗消毒时间(4 min),造成其杀菌率低于出雏器内壁和地面的杀菌率。Zheng等[32]的研究结果表明消毒前的清洗能够提高消毒剂对物体表面细菌的杀菌效果,因此在冲洗消毒前使用自来水冲洗对出雏器和出雏筐进行有机物清理能够显著提高消毒剂的杀菌效果。另外不同消毒材料也是影响微酸性电解水杀菌效果的重要因素[33]。此外出雏筐在长期的使用过程中会出现磨损和划痕等情况,使得出雏筐表面更加容易沾染有机物和微生物而难以冲洗。

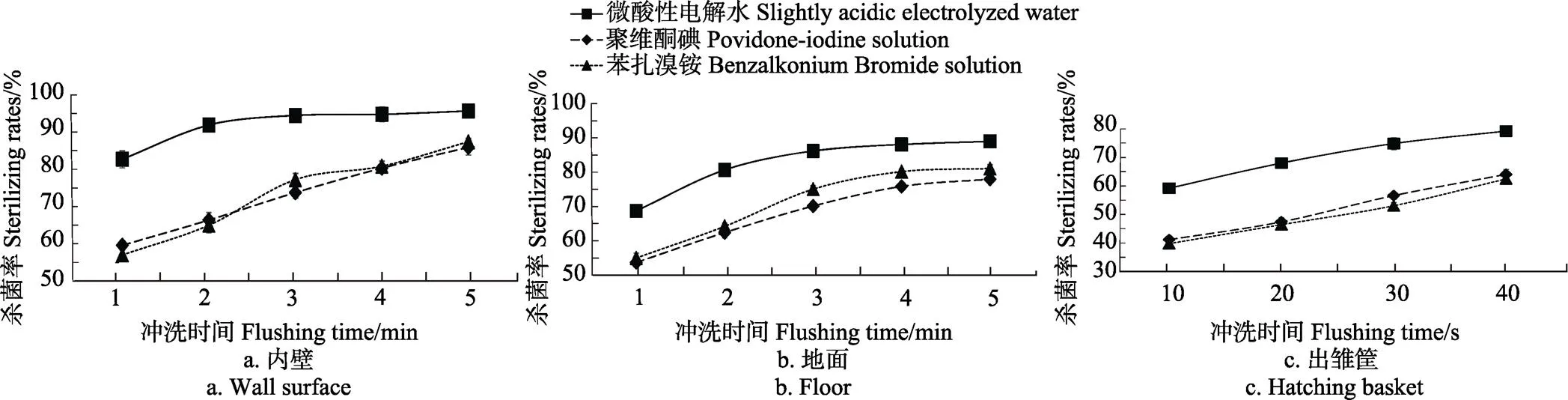

2.5 冲洗时间对出雏设备杀菌效果的影响

有效氯质量浓度为100 mg/L的微酸性电解水和2种常规消毒剂(50 mg/L聚维酮碘溶液和50 mg/L苯扎溴铵溶液)对出雏器内壁冲洗消毒的杀菌率如图6a所示。采用微酸性电解水对出雏器内壁冲洗消毒2 min,对出雏器内壁表面总菌杀菌率为91.3%;冲洗消毒3 min,杀菌率为93.9%,且显著高于50 mg/L的聚维酮碘溶液的杀菌率(73.1%)和 50 mg/L的苯扎溴铵溶液的杀菌率(76.6%)(< 0.05)。冲洗消毒时间延长至4 min或5 min,微酸性电解水对出雏器内壁表面总菌杀菌率无显著性增加(> 0.05);相同冲洗消毒时间下,100 mg/L微酸性电解水对出雏器内壁表面总菌的杀菌效果显著优于50 mg/L聚维酮碘溶液和50 mg/L苯扎溴铵溶液(< 0.05)。如图6b所示,延长冲洗消毒时间同样能够提高微酸性电解水对地面总菌的杀菌效果,冲洗消毒时间由1 min增加至3 min,有效氯质量浓度为100 mg/L的微酸性电解水对地面总菌的杀菌率从68.2%提高至85.6%,且显著高于3 min时,50 mg/L的聚维酮碘溶液的杀菌率(69.6%)和50 mg/L的苯扎溴铵溶液的杀菌率(74.5%)(< 0.05),继续延长冲洗消毒时间,其杀菌率无显著增加(> 0.05)。如图7c所示,100 mg/L微酸性电解水冲洗消毒10、20、30和40 s时对出雏筐表面的杀菌率分别为59.4%、68.3%、75.2%和79.6%,且杀菌效果显著优于50 mg/L聚维酮碘溶液和50 mg/L苯扎溴铵溶液(< 0.05)。微酸性电解水冲洗消毒时间越长,载体表面细菌杀菌效果越好。Issa-Zacharia等[34]研究表明,随着作用时间的增加,微酸性电解水对大肠杆菌及金黄色葡萄球菌的杀菌作用增强;Hao等[35]研究表明,微酸性电解水对伪狂犬病毒的杀灭效果随作用时间的增加而增强;倪莉[36]研究同样表明,随着作用时间的增加,微酸性电解水对沙门氏菌的作用效果增强。臧一天等[21]利用响应面优化方法对轮胎表面微酸性电解水冲洗消毒的研究结果表明,冲洗时间是影响微酸性电解水消毒效果的重要因素之一,且随着微酸性电解水冲洗消毒时间的延长,其消毒效果具有显著的提高。在采用有效氯质量浓度为100 mg/L的微酸性电解水对出雏器内壁、地面和出雏筐进行冲洗消毒时,建议冲洗消毒时间分别为3 min、3 min和40 s,且由图6c可以看出,100 mg/L的微酸性电解水对出雏筐表面总菌的杀菌率还处于上升趋势,所以可以通过延长消毒时间来提高微酸性电解水对出雏筐的杀菌效率。

注:微酸性电解水的有效氯质量浓度为100 mg·L-1;聚维酮碘和苯扎溴铵的质量浓度为50 mg·L-1。

3 结 论

有效氯质量浓度为60~100 mg/L的微酸性电解水冲洗消毒可以有效杀灭出雏器内壁、地面和出雏筐表面的细菌,且在一定范围内,杀菌效果随有效氯质量浓度和冲洗消毒时间的增加而提高。有效氯质量浓度为100 mg/L的微酸性电解水对出雏器内壁、地面和出雏筐表面的杀菌率显著高于2种常规消毒剂(50 mg/L聚维酮碘溶液和50 mg/L苯扎溴铵溶液)(< 0.05)。在实际消毒过程中,使用有效氯质量浓度为100 mg/L的微酸性电解水冲洗消毒3 min,对出雏器内壁和地面总菌的杀菌率分别为93.9%和85.6%,继续延长冲洗消毒时间,杀菌效果无明显提高(> 0.05);对出雏筐表面冲洗消毒40 s,对其表面总菌的杀菌率为79.6%。综上,微酸性电解水是孵化场出雏器和出雏筐表面消毒净化的良好替代消毒剂。

[1] Samberg Y, Meroz M. Application of disinfectants in poultry hatcheries[J]. Revue Scientifique Et Technique, 1995, 14(2):365-80.

[2] 王卫明,王虎林,张文平. 孵化场的卫生消毒[J]. 中国家禽,2010,32(10):49-49.

[3] 付阳,刘丰. 鸡孵化场和种蛋的消毒方法[J]. 现代畜牧科技,2010(4):39-39.

[4] 周小涛,樊莉蕊,唐非,等. 室内空气过氧乙酸消毒的健康影响[J]. 环境与健康杂志,2006,23(3):228-230.

Zhou Xiaotao, Fan Lirui, Tang Fei, et al. Experiment study of adverse effects of peracetic acid used as an air disinfectant on exposed people[J]. Journal of environment and health, 2006, 23(3): 228-230. (in Chinese with English abstract)

[5] 徐伟忠,朱丽霞,陈建华. 电功能水在农业上的应用[J]. 江西农业学报,2006,18(6):137-140.

Xu Weizhong,Zhu Lixia,Chen Jianhua. Application of electricity functional water in agriculture[J]. Acta Agriculturae Jiangxi, 2006, 18(6): 137-140. (in Chinese with English abstract)

[6] Sara G, Bengtsson B E. Chemicals and biological products used in south-east Asian shrimp farming, and their potential impact on the environment -A review[J]. Science of the Total Environment, 2001, 280(1): 93-131.

[7] Su L H, Chiu C H, Chu C, et al. Antimicrobial resistance in nontyphoid salmonella serotypes: a global challenge[J]. Clinical Infectious Diseases, 2004, 39(4): 546-551.

[8] Abadias M, Usall J, Oliveira M, et al. Efficacy of neutral electrolyzed water (NEW) for reducing microbial contamination on minimally-processed vegetables[J]. International Journal of Food Microbiology, 2008, 123(1): 151-158.

[9] Koide S, Takeda J I, Shi J, et al. Disinfection efficacy of slightly acidic electrolyzed water on fresh cut cabbage[J]. Food Control, 2009, 20(3): 294-297.

[10] Zang Y T, Li B M, Shi Z X, et al. Inactivation efficiency of slightly acidic electrolyzed water against microbes on facility surfaces in a disinfection channel[J]. Int J Agric & Biol Eng, 2017, 10(6): 23-30

[11] Bonde M R, Nester S E, Khayat A, et al. Comparison of effects of acidic electrolyzed water and NaOCl onteliospore germination[J]. Plant Disease, 1999, 83(7): 627-632.

[12] Krstajić N, Nakić V, Spasojević M. Hypochlorite production II. Direct electrolysis in a cell divided by an anionic membrane[J]. Journal of Applied Electrochemistry, 1991, 21(7): 637-641.

[13] 姬真真,石志芳,范佳英,等. 微酸性电解水消毒对肉鸡舍内微粒和微生物的影响[J]. 中国畜牧杂志,2017,53(3):96-99.

Ji Zhenzhen, Shi Zhifang, Fan Jiaying, et al. Effects of slightly acidic electrolyzed water on the disinfection of particulate and microbial in broiler house[J]. Chinese Journal of Animal Science, 2017, 53(3): 96-99. (in Chinese with English abstract)

[14] Bialka K L, Demirci A, Knabel S J, et al. Efficacy of electrolyzed oxidizing water for the microbial safety and quality of eggs[J]. Poultry science, 2004, 83(12): 2071-2078.

[15] Park H, Hung Y C, Chung D. Effects of chlorine and pH on efficacy of electrolyzed water for inactivatingO157:H7 and[J]. International Journal of Food Microbiology, 2004, 91(1): 13-18.

[16] Cui X, Shang Y, Shi Z, et al. Physicochemical properties and bactericidal efficiency of neutral and acidic electrolyzed water under different storage conditions[J]. Journal of Food Engineering, 2009, 91(4): 582-586.

[17] Hao X X, Li B M, Wang C Y, et al. Application of slightly acidic electrolyzed water for inactivating microbes in a layer breeding house[J]. Poultry Science, 2013, 92(10): 2560-2566.

[18] 郑炜超,李保明,倪莉,等. 微酸性电解水无害化消毒净化技术在蛋鸡场的应用研究[J]. 中国家禽,2014,36(5):2-5.

Zheng Weichao, Li Baoming, Ni Li, et al. Slightly acidic electrolyzed water of harmless disinfection and purification technology applied in poultry farm[J]. China Poultry, 2014, 36(5): 2-5. (in Chinese with English abstract)

[19] 郑炜超,李保明,尚宇超,等. 蛋种鸡场中性电解水带鸡喷雾消毒试验研究[J]. 农业工程学报,2010,26(9):270-273.

Zheng Weichao, Li Baoming, Shang Yuchao, et al. Experimental study on spraying disinfection with neutral electrolyzed water in a layer breeding farm[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(9): 270-273. (in Chinese with English abstract)

[20] Zheng W, Cao W, Li B M, et al. Bactericidal activity of slightly acidic electrolyzed water produced by different methods analyzed with ultraviolet spectrophotometric[J]. International Journal of Food Engineering, 2012, 8(3): 1-14.

[21] 臧一天,李星烁,李保明,等. 微酸性电解水对污染轮胎表面的模拟消毒优化[J]. 农业工程学报,2015,31(20):199-204.

Zang Yitian, Li Xingshuo, Li Baoming, et al. Simulation of disinfection optimization of vehicle tire surface using slightly acidic electrolyzed water[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(20): 199-204. (in Chinese with English abstract)

[22] Ni L, Cao W, Zheng W, et al. Efficacy of slightly acidic electrolyzed water for reduction of foodborne pathogens and natural microflora on shell eggs[J]. Food Science and Technology Research, 2014, 20(1): 93-100.

[23] Zheng W, Kang R M, Wang H N, et al. Airborne bacterial reduction by spraying slightly acidic electrolyzed water in a laying-hen house[J]. Journal of the Air & Waste Management Association, 2013, 63(10): 1205-1211.

[24] Fasenko G M, O'Dea Christopher E E, Mcmullen L M. Spraying hatching eggs with electrolyzed oxidizing water reduces eggshell microbial load without compromising broiler production parameters[J]. Poultry Science, 2009, 88(5): 1121-1127.

[25] 臧一天,李保明,郑炜超,等. 微酸性电解水雾滴沉积量及粒径对畜牧环境杀菌效果的影响[J]. 农业工程学报,2017,33(9):224-229.

Zang Yitian, Li Baoming, Zheng Weichao, et al. Influence of droplet size and deposition on slightly acidic electrolytic water spraying disinfection effect on livestock environment[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(9): 224-229. (in Chinese with English abstract)

[26] Oomori T, Oka T, Inuta T, et al. The efficiency of disinfection of acidic electrolyzed water in the presence of organic materials[J]. Analytical Sciences, 2000, 16(4): 365–369.

[27] Nan S J, Li Y Y, Li B M, et al. Effect of slightly acidic electrolyzed water for inactivatingO157:H7 andanalyzed by transmission electron microscopy[J]. Journal of Food Protection, 2010, 73(12): 2211-2216.

[28] 唐晨晨,孙巍,王玲,等. 常用碘伏制品的杀菌性能研究[J]. 江苏预防医学, 2019, 30(1):13-14,39.

[29] 吕桂芬,乌云达来,李玉坤,等. 甘油混合条件下微酸性电解水对奶牛乳房炎致病菌体外抑菌效果评价[J]. 中国乳品工业,2018,46(11):4-6,10.

Lyu Guifen, Wuyun Dalai, Li Yukun, et al. Evaluation of glycerol added slightly acidic electrolyzed water (SAEW) teat dipping agent for dairy cow mastitis pathogens bacteriostatic efficacy in vitro[J]. China Dairy Industry, 2018, 46(11): 4-6, 10. (in Chinese with English abstract)

[30] Tagawa M, Yamaguchi T, Yokosuka O, et al. Inactivation of a hepadnavirus by electrolysed acid water[J]. Journal of Antimicrobial Chemotherapy, 2000, 46(3): 363-368.

[31] 张秋婷,林素丽,朱松明,等. 超高压与微酸性电解水结合对鲜切果蔬的杀菌效果研究[J]. 农业机械学报,2017, 48(3):343-349.

Zhang Qiuting, Lin Suli, Zhu Songming, et al. Combined effect of high pressure and slightly acidic electrolyzed water on sterilization of fresh-cut fruits and vegetables[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(3): 343-349. (in Chinese with English abstract)

[32] Zheng W, Ni L, Li B. Electrolyzed water and its application in animal houses[J]. Frontiers of Agricultural Science and Engineering, 2016, 3(3): 195-205.

[33] 南松剑. 微酸性电解水用于奶牛场消毒和奶牛乳房炎防控的研究[D]. 北京:中国农业大学,2011.

Nan Songjian. Disinfection Effect of Slightly Acidic Electrolyzed Water in the Dairy Farm and Application on the Control of Dairy Mastitis[D]. Beijing: China Agricultural University, 2016. (in Chinese with English abstract)

[34] Issa-Zacharia A, Kamitani Y, Morita K, et al. Sanitization potency of slightly acidic electrolyzed water against pure cultures ofcoli and, in comparison with that of other food sanitizers[J]. Food Control, 2010, 21(5): 740-745.

[35] Hao X X, Shen Z Q, Wang J L, et al. In vitro inactivation of porcine reproductive and respiratory syndrome virus and pseudorabies virus by slightly acidic electrolyzed water[J]. Veterinary Journal, 2013, 197(2): 297-301.

[36] 倪莉. 微酸性电解水对蛋鸡场沙门氏菌的杀菌规律研究[D]. 北京:中国农业大学,2016.

Ni Li. Bactericidal Efficiency of Slightly Acidic Electrolytic Water Against Salmonella in Laying Houses[D]. Beijing: China Agricultural University, 2016. (in Chinese with English abstract)

Experiment on flusher-disinfection effect by slightly acidic electrolyzed water in poultry hatcheries

Wei Yongxiang1,2, Li Zonggang1,2, Li Baoming1,2,3, Tu Jiang1,2, Zheng Weichao1,2,3※

(1.100083,; 2.100083,3.100083,)

Regular flusher-disinfection in hatcheries is an important measure to prevent epidemic diseases. However, traditional chemical disinfectants used in hatcheries can cause toxic residue, low disinfection effect and bacterial resistance. In practical production of hatchery, the traditional clean-in-place including three parts: 1) surface of the inside wall of the hatcher, 2) surface of the floor, 3) surface of the hatching basket. The flusher-disinfection durations were set 4 min for the surface of the inside wall of the hatcher and the floor and 40 s for the surface of the hatching basket with traditional chemical disinfectants (povidone-iodine solution or benzalkonium bromide solution) to reduce the number of bacterial microorganisms and maintain good hygiene condition. Slightly acidic electrolyzed water (SAEW, pH=5.0-6.5) is proved to be a broad-spectrum, high-efficiency, low corrosive, residue-free, and environment-friendly disinfectant, which could be a potential alternative disinfection of the traditional chemical disinfectants. Aiming at finding an optimal of using SAEW in cleaning hatcher and reducing cleaning costs, an experiment with three components: bacterial distribution on the surface of the hatching equipment, germicidal efficacy of various disinfectants, and the effect of disinfection time on the sterilizing rate were conducted. Surface swabbing was used to sample the total bacteria,, andon the surface of the inside wall, floor, and hatching basket of the hatching equipment. SAEW with the concentrations of 60, 80, and 100 mg/L, as alternative disinfections of flusher disinfection, were chosen to compare with two traditional chemical disinfectants (povidone-iodine solution and benzalkonium bromide solution) by single-factor test. In the study of the effect of disinfection time on the sterilizing rate, disinfection durations were set as 1, 2, 3, 4, 5 min for the surface of inside wall and floor, and 10, 20, 30, 40 s for the surface of hatching basket, respectively. high-pressure water jet with nozzle orifice diameter of 2.2 mm operated at 3.5 MPa was used in the whole cleaning process. The results showed that flusher-disinfection using 60-100 mg/L (available chlorine concentration, ACC) slightly acidic electrolytic water could effectively reduce the total bacteria (total aerobic bacteria),andon the surface of the inside wall and floor in hatcheries, and the surface of hatching basket. The bactericidal effect increased with the increase of ACC and treatment time. The total bacteria sterilization rates were 93.9% and 85.6% by flusher-disinfection using 100 mg/L SAEW at the duration of 3 min for the surface of the inside walls and floor of hatchers, respectively,which was significantly higher than using 50 mg/L povidone-iodine solution or 50 mg/Lbenzalkonium bromide solution (<0.05). Flusher-disinfection using 100 mg/L SAEW for 40 s on the hatching basket surfaces could reach a sterilization rate of 79.6%. The bactericidal effect of flusher-disinfection in hatches could be improved by using SAEW which is also a broad-spectrum and non-residual disinfectant, and flusher-disinfection using SAEW can be an alternative to traditional chemical disinfectants used for disinfection in hatcheries.

disinfection; cleaning; sterilization; hatcheries; slightly acidic electrolytic water; hatching equipment; available chlorine concentration

10.11975/j.issn.1002-6819.2019.10.020

S8

A

1002-6819(2019)-10-0157-07

2018-12-20

2019-04-18

国家现代农业(蛋鸡)产业技术体系项目(CARS-40)

魏永祥,博士生,研究方向为设施养殖过程控制与环境。Email:weiyongxiang@cau.edu.cn

郑炜超,副教授,主要从事畜禽设施养殖工艺与环境控制方面的研究。Email:weichaozheng@cau.edu.cn

魏永祥,李宗刚,李保明,涂江,郑炜超.孵化场微酸性电解水冲洗消毒效果试验研究[J]. 农业工程学报,2019,35(10):157-163. doi:10.11975/j.issn.1002-6819.2019.10.020 http://www.tcsae.org

Wei Yongxiang, Li Zonggang, Li Baoming, Tu Jiang, Zheng Weichao.Experiment on flusher-disinfection effect by slightly acidic electrolyzed water in poultry hatcheries [J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(10): 157-163. (in Chinese with English abstract) doi:10.11975/j.issn.1002- 6819.2019.10.020 http://www.tcsae.org