碳纤维固定的高速分块SPMSM转子强度分析

2019-07-22陈亮亮祝长生乔晓利伍家驹

陈亮亮 祝长生 乔晓利 伍家驹

关键词:表贴式永磁同步电机;碳纤维护套;解析解;强度分析;应力函数法

DOI:10.15938/j.emc.2019.06.000

中图分类号文献标志码:A 文章编号:1007 -449X(2019)06 -0000 -00

Abstract:As for the problem of no analytical solution of rotor strength for high speed segmented surface mounted permanent magnet synchronous machine (SPMSM) with a carbon fiber sleeve, the analytical solution of rotor strength was proposed based on the plane stress model. The displacement method and stress potential method in polar coordinates were employed to deduce the analytical solution, and the influences of different densities and coefficients of thermal expansion of permanent magnets and pole fillers were taken into account. Then the effectiveness of the analytical solution was validated by finite element method. The effects of design parameters on rotor strength, such as rotational speed, thickness of carbon fiber sleeve and interference fit between the carbon fiber sleeve and the permanent magnet, were further investigated based on the analytical solution proposed. It is shown that the results calculated by the analytical solution and finite element method are in good agreement with each other. The analytical solution proposed can predict the stress distribution of the high speed segmented SPMSM′s rotor with a carbon fiber sleeve, considering the effects of difference in density and coefficient of thermal expansion between permanent magnets and pole fillers.

Keywords:surface mounted permanent magnet synchronous machine (SPMSM); carbon fiber sleeve; analytical solution; strength analysis; stress potential method

0 引 言

高速表貼式永磁同步电机(surfacemounted permanent magnet synchronous motor,SPMSM)具有结构简单、可靠性强、效率高、功率密度高等优点,已得到了广泛的应用[1-2]。稀土永磁材料因其高剩磁、高矫顽力及高磁能积等特点而被广泛应用于永磁电机[3]。在高速SPMSM中永磁体既可加工成整体结构也可制作成分块结构。在整体结构中,永磁体常加工成圆柱型或圆筒型;在分块结构中永磁体常加工成瓦片型,磁极间采用非磁性材料填充,填充块能保证转子结构的整体性并起阻尼作用,同时也有助于永磁体的固定。整体永磁结构具有结构简单,易于加工,机械强度高等优点,但永磁材料的利用率较低。分块永磁体结构提高了永磁材料的利用率,还可以通过选取合适的极弧系数来优化电机气隙磁场,其缺点是加工工艺较复杂,机械强度较低。

由于稀土永磁材料的抗压强度较大而抗拉强度很小,容易被电机高速运行时产生的巨大离心力所破坏,因此需要采用非导磁保护套对永磁体进行保护。目前,非导磁保护套主要有高强度复合材料护套及非导磁金属护套2类。常用的高强度复合材料有碳纤维和玻璃纤维,常用的非导磁金属材料则有钛合金及高强度合金钢。与非导磁金属护套相比,高强度复合材料护套具有强度高、质量轻、无高频涡流损耗等优点,但复合材料是热的不良导体,不利于永磁体的散热[4-6]。在工程实际应用中,永磁体与保护套之间采用过盈配合,借助过盈配合产生的预压力来抵消转子高速运行时永磁体离心力产生的巨大拉应力,进而保护永磁体。为了选取合适的护套厚度及护套与永磁体间的过盈量,需要对转子强度进行深入分析。

目前,针对高速SPMSM转子的强度分析方法主要有有限元法和解析法两类。与有限元法[7-10]相比,解析法的计算量小、效率高、且转子强度与过盈量、护套厚度等参数之间的物理关系明确,有利于电机转子强度的优化设计,缺点是复杂转子结构的强度解析解难以得到。

国内外学者对高速SPMSM的转子强度解析解已经开展了一些研究。文献[11-16] 对非导磁金属护套保护下的永磁转子的强度解析解进行了研究。Borisavljevic等[11]和Chen等[12] 研究了非导磁金属护套保护下圆柱型永磁体转子的强度解析解。王继强等[13]和张超等[14]分别从平面应力和平面应变的角度研究了非导磁金属护套保护下圆筒型永磁体转子的强度解析解。程文杰等[15]对圆柱型永磁体转子和圆筒型永磁体转子的强度解析解进行了比较分析。陈亮亮等[16]研究了未考虑转子发热时非导磁金属护套分块永磁体转子的强度解析解。文献[17-19]研究了碳纤维护套保护下的永磁转子的强度解析解。Binder等人[17]提出了未考虑材料各向异性及转子发热影响的碳纤维护套圆柱型永磁体转子的环向应力及接触压强的解析解。陈亮亮等[18]研究了考虑碳纤维材料各向异性及转子发热影响的碳纤维护套圆筒型永磁体转子的强度解析解。Borisavljevic 等[19]分别研究了未考虑和考虑碳纤维护套各向异性特性时圆筒型永磁体转子的强度解析解。张凤阁等[20]比较分析了非导磁金属护套和碳纤维护套保护下圆柱型永磁体转子的强度解析解。目前所建立的碳纤维护套分块永磁体转子的强度解析解均没有考虑永磁体和极间填充块的密度及热膨胀系数不同对转子应力分布的影响。

目前,高速SPMSM转子的强度解析解主要针对整体永磁体转子,而对于碳纤维护套固定的分块永磁体转子的强度解析解的研究还较少。在碳纤维护套分块永磁体转子中,由于永磁体和填充块的密度及热膨胀系数不同,护套/转子铁心与永磁体和填充块间的接触压力出现明显的差异;同时碳纤维材料的各向异性特性也进一步增加了求解转子强度解析解的难度。

针对高速SPMSM中碳纤维护套保护的分块永磁体转子结构,本文基于平面应力模型,综合运用极坐标下的位移求解法及应力函数求解法,推导了考虑永磁体和极间填充块密度及热膨胀系数不同对转子应力影响的碳纤维护套分块永磁体转子的强度解析解,并利用有限元方法对解析解进行了验证。在转子强度解析解的基础上,研究了转速、碳纤维护套厚度及过盈量等参数对转子强度的影响,分析了碳纤维固定的高速分块SPMSM转子的强度变化规律。

1 转子结构

本文研究的高速SPMSM的转子主要由碳纤维护套、永磁体、非磁性填充块和转子铁心4部分组成。其中,永磁体为分块结构,呈瓦片状并粘贴于转子铁心外表面,极间填充块为非磁性材料。图1为4极结构的碳纤维护套分块永磁转子,碳纤维护套的内外半径分别为Ris及Ros;永磁体的内外半径分别为Rim和Rom;极间填充块的内外半径分别为Ria和Roa,一般情况下填充块的内外半径与永磁体相同;转子铁心的半径为Ror。

5 结 论

根据碳纤维护套分块永磁转子的强度解析解的理论推导、有限元验证以及基于解析解的转子强度分析讨论,可以得出以下结论:

1)本文提出的针对碳纤维护套分块永磁转子的强度解析解能计算考虑转速和转子发热影响时转子各部件的应力分布,为此类电机转子的优化设计提供了理论支持。

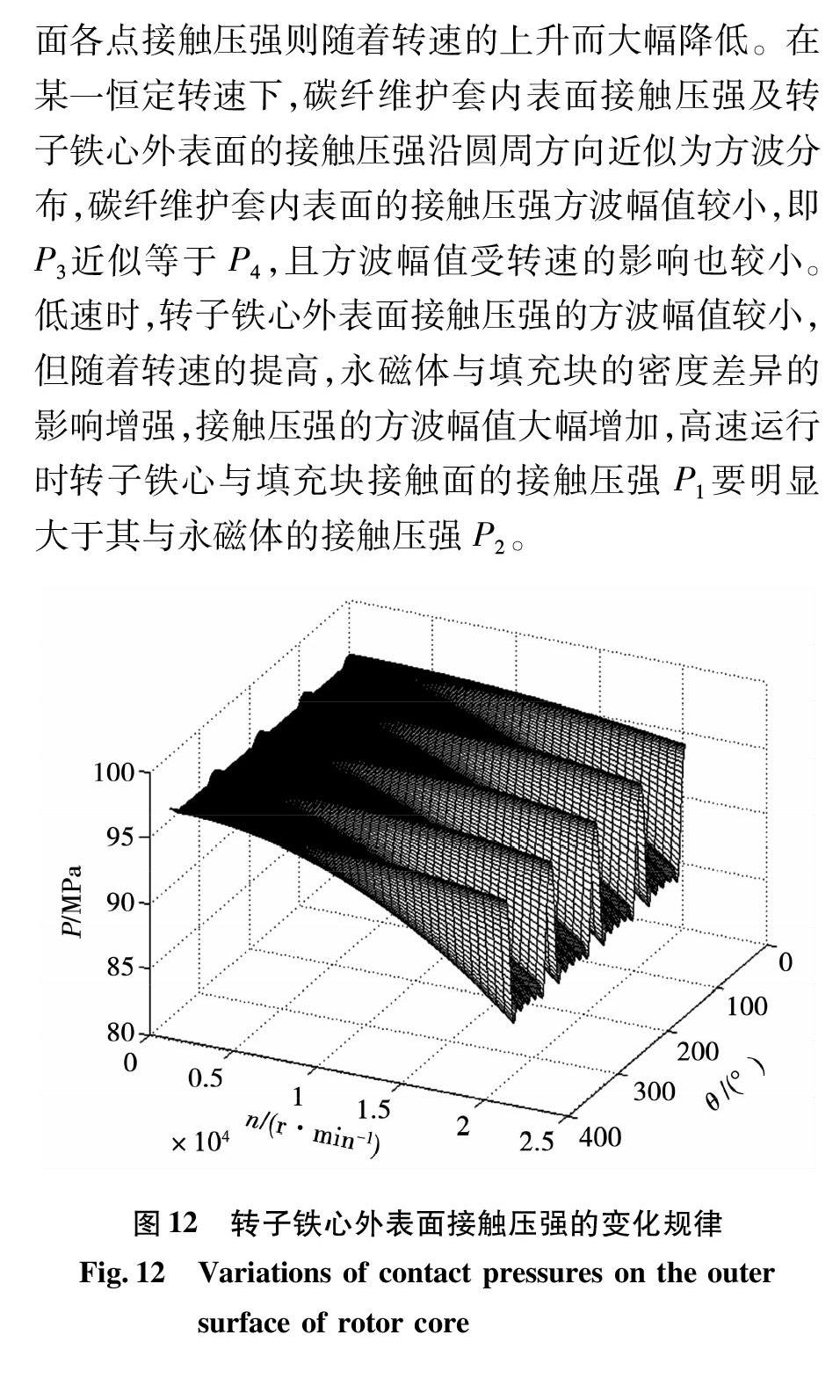

2)永磁体和填充块的密度及热膨胀系数不同对转子的应力分布有较大的影响,在其影响下护套/转子铁心与永磁体和填充块间的接触压力出现明显的差异。为了减小护套/转子铁心与永磁体和填充块的接触压力差异对转子强度的影响,可考虑选择密度及热膨胀系数与永磁体较为接近的非磁性材料作为填充块,比如钛合金材料。

3)转速和转子温度对碳纤维固定的高速分块SPMSM转子的应力分布有较大影响,因此,在设计过程中,需要分别校验电机在静态、冷态及热态运行时的转子应力分布。

参 考 文 献:

[1] ALBERTO T, SILVIO V, ALESSANDRO V. Electrical machines for highspeed applications: design considerations and tradeoffs [J]. IEEE Transactions on Industrial Electronics, 2014, 61(6): 3022.

[2] 赵祥,范瑜,夏静,等. 一种减小永磁电机转子损耗的转子结构[J]. 电机与控制学报,2019, 23(2):62.

ZHAO Xiang, FAN Yu, XIA Jing, et al. Rotor structure to reduce rotor losses of permanent magnet electric machines[J].Electric Machines and Control, 2019, 23(2): 62.

[3] 郑大伟,朱明刚,郑立允,等. 稀土永磁材料在永磁電机中的应用[J]. 微特电机,2015,43(4):81.

ZHENG Dawei, ZHU Minggang, ZHENG Liyun, et al.Application of rare earth permanent magnetic materials for permanent magnet machines[J]. Small and Special Electrical Machines, 2015, 43(4):81.

[4] KOLONDZOVSKI Z, ARKKIO A, LARJOLA J, et al. Power limits of highspeed permanentmagnet electrical machines for compressor applications [J]. IEEE Transactions on Energy Conversion, 2011, 26(1): 73.

[5] KOLONDZOVSKI Z, BELAHCEN A, ARKKIO A. Comparative thermal analysis of different rotor types for a highspeed permanentmagnet electrical machine [J]. IET Electric Power Applications, 2009, 3(4): 279.

[6] 张超,朱建国,佟文明,等.高速内置式永磁转子强度分析与设计[J]. 电机与控制学报,2017,21(12):43.

ZHANG Chao, ZHU Jianguo, TONG Wenming, et al. Strength analysis and design of high speed interior permanent magnet rotor[J]. Electric Machines and Control, 2017,21(12): 43.

[7] HONG D, WOO B, KOO D. Rotor dynamics of 120000 r/min 15 kW ultra high speed motor [J]. IEEE Transactions on Magnetics, 2009, 45(6): 2831.

[8] BAILEY C, SABAN D M, GUEDESPINTO P. Design of highspeed directconnected permanentmagnet motors and generators forthe petrochemical industry [J]. IEEE Transactions on Industry Applications, 2009, 45(3): 1159.

[9] SOONG W L, KLIMAN G B, JOHNSON R N, et al. Novel highspeed induction motor for a commercial centrifugal compressor [J]. IEEE Transactions on Industry Applications, 2000, 36(3): 706.

[10] ZHANG F, DU G, WANG T. Rotor retaining sleeve design for a 1.12-MW highspeed PM machine [J]. IEEE Transactions on Industry Applications, 2015, 51(5): 3675.

[11] BORISAVLJEVIC A, POLINDER H, FERREIRA J A. On the speed limits of permanentmagnet machines[J]. IEEE Transactions on Industrial Electronics, 2010, 57(1): 220.

[12] CHEN L, ZHU C. Rotor strength analysis for high speed permanent magnet machines [C]// Proceedings of the International Conference on Electrical Machines and Systems (ICEMS), October 22-25, 2014, Hangzhou, China. 2014: 65-69.

[13] 王继强,王凤翔,鲍文博, 等. 高速永磁电机转子设计与强度分析[J]. 中国电机工程学报, 2005, 25(15): 140.

WANG Jiqiang, WANG Fengxiang, BAO Wenbo, et al. Rotor design and strength analysis of high speed permanent magnet machine [J]. Proceedings of the CSEE, 2005, 25(15): 140.

[14] 张超,朱建国,韩雪岩. 高速表贴式永磁电机转子强度分析[J]. 中国电机工程学报, 2016, 36(17): 4719.

ZHANG Chao, ZHU Jianguo, HAN Xueyan. Rotor strength analysis of highspeed surface mounted permanent magnet motors [J]. Proceedings of the CSEE, 2016, 36(17): 4719.

[15] 程文杰,耿海鹏,冯圣, 等. 高速永磁同步电机转子强度分析[J]. 中国电机工程学报, 2012, 32(27): 87.

CHENG Wenjie, GENG Haipeng, FENG Sheng,et al. Rotor strength analysis of highspeed permanent magnet synchronous motors [J]. Proceedings of the CSEE, 2012, 32(27): 87.

[16] 陈亮亮,祝长生,蒋科坚. 含极间填充块的高速表贴式永磁同步电机转子强度分析[J]. 浙江大学学报(工学版), 2015, 49(09): 1738.

CHEN Liangliang, ZHU Changsheng, JIANG Kejian. Rotor strength analysis for highspeed surfacemounted permanent magnet synchronous motor with filled blocks between magnetic poles [J]. Journal of Zhejiang University (Engineering Science), 2015, 49(09): 1738.

[17] BINDER A, SCHNEIDER T, KLOHR M. Fixation of buried and surfacemounted magnets in highspeed permanentmagnet synchronous machines [J]. IEEE Transactions on Industrial Electronics, 2006, 42(4): 1031.

[18] 陈亮亮,祝长生,王萌. 碳纤维护套高速永磁电机热态转子强度[J]. 浙江大学学报(工学版), 2015, 49(01): 162.

CHEN Liangliang, ZHU Changsheng, WANG Meng.Strength analysis for thermal carbonfiber retaining rotor in highspeed permanent magnet machine [J]. Journal of Zhejiang University (Engineering Science), 2015, 49(01): 162.

[19] BORISAVLJEVIC A, POLINDER H, FERREIRA J A. Enclosure design for a highspeed permanent magnet rotor [C]// Proceedings of the 5th IET International Conference on Power Electronics, Machines and Drives, April 19-21, 2010, Brighton, UK. 2010: 1-6.

[20] 張凤阁,杜光辉,王天煜. 高速永磁电机转子不同保护措施的强度分析[J]. 中国电机工程学报, 2013, 33(S): 195.

ZHANG Fengge, DU Guanghui, WANG Tianyu. Rotor strength analysis of highspeed permanent magnet under different protection measures [J]. Proceedings of the CSEE, 2013, 33(Supplement): 195.

[21] CALME O, BIGAUD D, JONES S, et al. Analytical evaluation of stress state in braided orthotropic composite cylinders under lateral compression [J]. Composites Science and Technology, 2006, 66(15): 3040.

(编辑:刘琳琳)