直线振荡电机谐振频率跟踪控制技术研究

2019-07-22余海涛张涛

余海涛 张涛

关键词:直线压缩机;振荡电机;谐振频率跟踪;二阶广义积分;坐标变换

DOI:10.15938/j.emc.2019.06.000

中图分类号文献标志码:A 文章编号:1007 -449X(2019)06 -0000 -00

Abstract:Linear compressor driven by linear oscillatory actuator is more efficient and easier to control than traditional rotary motor.In order to improve the efficiency of linear compressor,a new method based on second order general integral resonant frequency tracking control (SOGIRFTC) is proposed. The steadystate displacement signal x and current signal i are sensed under the control of stroke stability. Based on theory that phase shift between actuator displacement and current is 90°when drive frequency equals to mechanical resonant frequency, the AC signal is transformed into DC signal by frequency locked loop and coordinate transformation. Then PI controller is used to achieve zero steadystate error. Besides, the second order general integral controller is adopted to filter out the sampling noise and high frequency interference of the input signal, which improves the stability of the controller. The simulation and experimental results show that the proposed resonant frequency tracking control can quickly track the inherent mechanical frequency of the Actuator and improve the efficiency of the system.

Keywords:linear compressor; linear oscillatory actuator; resonant frequency tracking; second order general integral;coordinate transformations

0 引 言

冰箱用压缩机分为旋转电机驱动的传统压缩机和采用直线电机驱动的直线压缩机。传统压缩机采用旋转电机驱动,利用曲柄联杆将旋转电机的旋转运动转换为往复直线运动,由于采用曲柄等机械转换环节,增加摩擦损耗,增大噪声[1]。同时由于机械结构的限制,最大转速得不到提高,性能提升空间小。采用直线电机直接驱动的直线压缩机,取消了传统压缩机的曲柄连杆机构,通过直线电机,以电磁共振的方式进行驱动,结构简单,体积减小,没有机械零件之间相互运动,大大减小摩擦损耗,降低噪声[2]。由于直线电机只有轴向推力,没有径向压力,在工作时只需少量的润滑油或者不用潤滑油。压缩机的活塞与直线振荡电机的动子直接相连,从而可以根据需要调节活塞行程和余隙,控制方式灵活[3]。

压缩机用直线电机主要的控制目标是在安全可靠性的前提下使压缩机高效运行。通过控制直线振荡电机的行程,保证其可靠运行。直线压缩机是直线电机与机械弹簧组成共振系统,其负载为气体工质。当电机驱动频率等于压缩机的机械谐振频率时,系统效率达到最大[4]。随着气体工质、排气量的变化,等效机械频率发生变化,通过不断改变电机的驱动频率,使其追随机械频率,实现压缩机系统高效运行。

在最初电机设计时,将振荡系统的固有机械谐振频率设计为50 Hz或60 Hz,采用固有频率控制,该方法控制简单,成本低,但当负载变化时,不能有效跟踪谐振频率,降低效率[5]。2004年,韩国学者Chun通过分析振荡电机特性,得出当振荡谐振系统效率最优时,电流波形滞后位移90°,并采用相角控制方式实现谐振频率跟踪控制[6]。Yoshida等采用判断反电势的相位或位移与电流的相位的方法,实现频率跟踪[7]。上述控制方法在相角检测时存在过零检测带来的误差问题。Chun等采用控制位移与电流乘积的平均值的方法进行压缩机效率的最大化控制,解决了电流的过零点检测带来误差的问题[8]。在控制过程中,频率不断改变,从而给平均值的计算带来困难。上述的控制方法建立在振荡电机工作时特有的工作特性上,是一种间接控制的控制策略。Lin等采用扰动和观测的搜索方法,直接以输出功率为目标量,通过改变频率扰动量,直接对最大输出功率点进行跟踪[9]。于明湖等人采用模糊算法搜索一定行程下电流(功率)最小时的共振频率[10]。采用扰动观测法,控制简单,但跟踪响应受扰动步长的影响,同时在最大功率点附近出现频率振荡现象[13-14]。

5 结 论

本文针对压缩机用直线振荡电机的控制进行了深入的研究。

首先,对直线电机的运性特性进行分析,基于振荡电机的数学模型,分别绘制运行特性曲线、幅频特性曲线和相频特性曲线。得出当电机工作在欠阻尼下,电机驱动频率等于系统的固有机械频率时,效率最大。

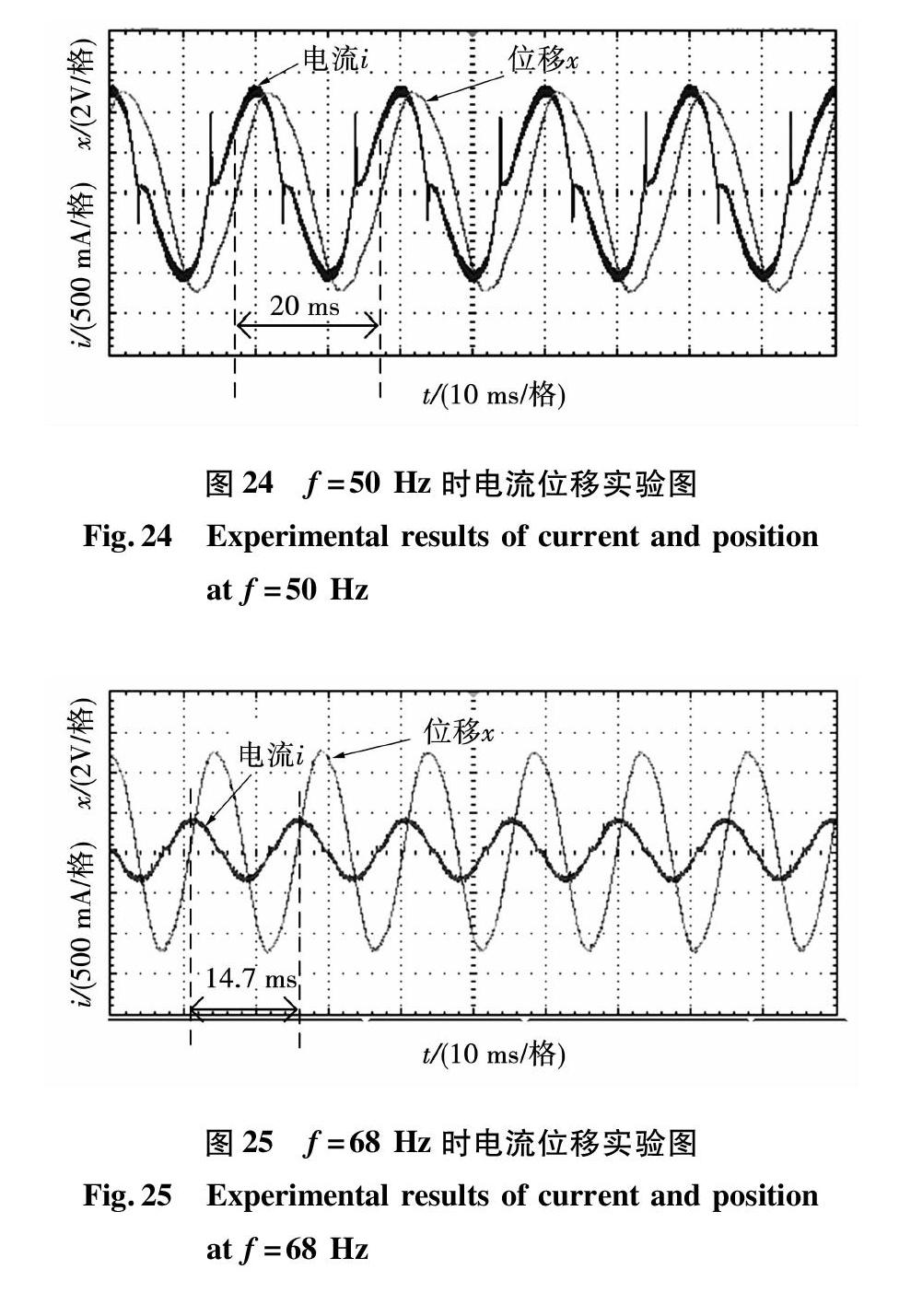

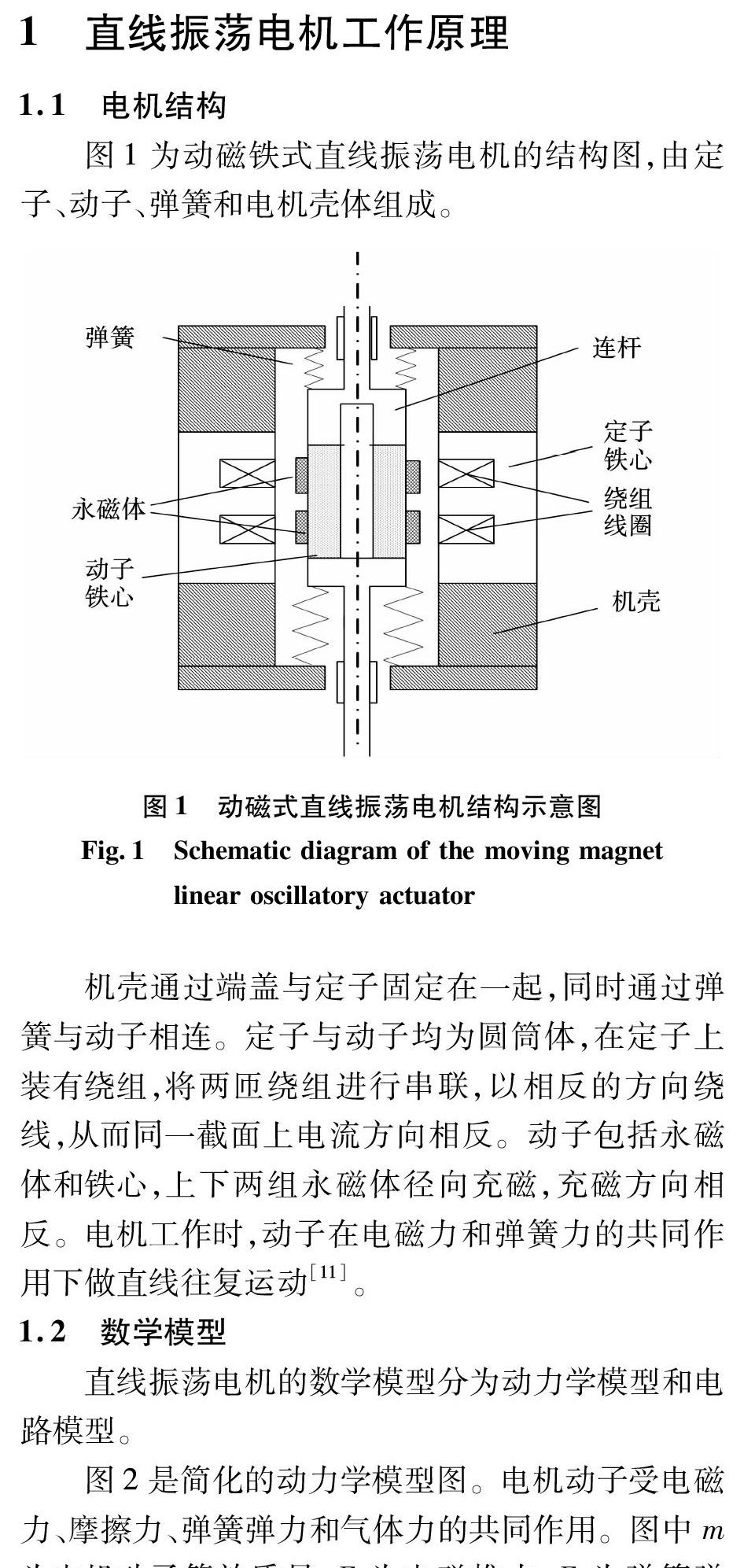

进一步根据系統谐振下电机位移和电流相移为90°的特点,提出一种基于二阶广义积分的谐振频率跟踪控制方法,采样电流和位移经过改进二阶广义积分控制器输出被测信号与其正交信号,因二阶广义积分控制器特点,输出信号有效滤除采样信号的采样噪声。再经过坐标变换,将正弦交流信号转换为直流信号,通过控制坐标变换后电流交轴信号与位移直轴信号差值,实现直线振荡电机谐振频率跟踪控制。该控制方法避免计算位移与电流的相角差,从而避免过零检测带来的频率波动;同时采用坐标变换将交流信号转换为直流信号采用传统PI控制器即可实现无静差控制。

最后进行仿真和实验验证。实验结果表明所提出的谐振频率跟踪控制技术,在行程环稳定下,驱动频率快速跟随电机固有机械频率,空载下电机谐振频率f=68 Hz,电机效率提高约为65%。

参 考 文 献:

[1] HOWE D,WANG J.A novel linear drive for nextgeneration reciprocating vapor compressors[J]. IEEE Transactions on Electrical and Electronic Engineering, 2008, 3(5):455.

[2] SM Jang, JY Choi, HW Cho, et al.Comparison and dynamic behavior of movingcoil linear oscillatory actuator with/without mechanical spring driven by rectangular voltage source[C]//IEEE International Conference on Electrical Machines and Systems (ICEMS),October 8-10,2007,Seoul,Korea.2007,874-877.

[3] Z Peng, L Zhihai, Z Shuiying.Control system of linear compressor based on bidirectional triode thyristor[C]//Third International Conference on Measuring Technology and Mechatronics Automation, January 6-7,2011,Shangshai,China,2011,782-785.

[4] 陈梁远,李黎川.压缩机用直线电机及其关键技术发展综述[J].中国电机工程学报,2013,33(15):52.

CHEN Liangyuan, LI Lichuan. Development of the linear motor and its key technologies for compressors[J]. Proceedings of the CSEE, 2013, 33(15):52.

[5] SUN Daming,DIETRICH M,THUMMES G.Investigation on highpower stirlingtype pulse tube coolers for cooling HTS motors[J]. IEEE Transactions on Applied Superconductors, 2012, 22(3): 4703704.

[6] SANADA M,MORIMOTO S,TAKEDA Y.Analyses for sensorless linear compressor using linear pulse motor[C]//IEEE 34th Industry Applications Conference, October 3-7, 1999, Phoenix, USA. 1999, 4:2298–2304.

[7] YOSHIDA M,HASEGAWA S,UEDA M.Driving apparatus of a linear compressor:USA,US6832898[P].2004-12-21.

[8] TW Chun, JR Ahn, HH Lee, et al.Novel strategy of efficiency control for a linear compressor system driven by a PWM inverter[J].Transactions on Industrial Electronics, 2008,55(1): 296.

[9] LIN Z,WANG J,HOWE D.Resonant frequency tracking technique for linear vapor compressors[C]//2007 IEEE International Electric Machines and Drives Conference, May 3-5, 2007, Antalya, Turkey. 2007, 1: 370–375.

[10] 于明湖,张玉秋,叶云岳等.直线振荡电机谐振频率跟踪策略研究[C] //第29届中国控制会议,7月29-31日,2010,北京,中国. 2010,7:3348-3351.

[11] 费腾.用于冰箱压缩机的直线振荡电机设计与性能分析[D].南京:东南大学,2014.32-35.

[12] 辛振,赵仁德,郭宝玲.基于二阶广义积分器-锁频环的异步电机同步角频率估计方法[J].电工技术学报,2014,29(1):32.

XING Zhen, ZHAO Rende, GUO Baoling. New induction motor synchronous angular frequency estimation method based on second order generalized integratorfrequency locked loop[J]. Transactions of China Electrotechnical Society, 2014, 29(1): 32.

[13] 于明湖,张玉秋,叶云岳,等. 双定子直线振荡电机谐振特性分析[J]. 电机与控制学报,2010,14(8): 1.

YU Minghu, ZHANG Yuqiu, YE Yunyue , et al. Resonant frequency characteristic analysis of linear oscillatory motor with two separated stators[J]. Electric Machines and Control, 2010,14(8):1.

[14] 雷美珍,戴文战,夏永明. 直线压缩机用无内定子动磁式直线振荡电机的建模与分析[J]. 电机与控制学报,2014,18(14): 45.

LEI Meizhen,DAI Wenzhan,XIA Yongming. Modeling and analysis of movingmagnet linear motor with no innerteeth for linear compressor[J]. Electric Machines and Control, 2014,18(14):45.

(编辑:刘琳琳)