Pilot-scale Study on NCMBR Process for Upgrading of Sewage Treatment Plant in Industrial Park

2019-06-27*

*

1. College of Resources, Environment and Materials, Guangxi University, Nanning 530004, China; 2. Academy of Environmental Protection Sciences, Guangxi Zhuang Autonomous Region, Nanning 530022, China; 3. Guangxi Environmental Protection Industry Association, Nanning 530022, China; 4. Guangxi Biqingyuan Environmental Protection Technology Co., Ltd., Wuzhou 546899, China

Abstract A pilot-scale research was conducted on nanostructured ceramic membrane bio-reactor (NCMBR) for treatment of comprehensive wastewater from industrial park. The quality of the effluent water was stable and good. During stable operation, the COD, NH3-N and TP concentrations of the influent water were 147-475, 42-23.5 and 0.65-0.85 mg/L, respectively, and those of the effluent water were 147-475, 0.08-0.82 and 0.18-0.26 mg/L, respectively, so the average removal rates of COD, NH3-N and TP were 82%, 97% and 72%, respectively, meeting the standard for Class-A emissions of Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant (GB18918-2002). In addition, the process has certain anti-impact capacity and ability to mitigate membrane fouling, meeting the objectives of upgrading and transformation. This study will provide reference for upgrading of existing sewage treatment plants.

Key words Nanostructured, Ceramic membrane, MBR, Industrial park wastewater, Sewage treatment, Upgrading

1 Introduction

With the advancement of industrialization and the proceeding of "industry shall retreat from the urban area and shift to industry zones", a large number of enterprises have settled in industrial parks. Most of the park wastewater is treated in a centralized manner. In theory, centralized treatment of wastewater can reduce emissions of pollutants and improve quality of the water. As the types of enterprises are diverse, and the production cycle of each enterprise is different, the types, emissions and quality of wastewater are quite different, endowing wastewater from industrial parks the characteristics of complicated quality, great changes in quality and quantity and high content of toxic substances, making it difficult to treat[1]. These features are magnified as more and more enterprises move to industrial parks, and the effluent of the original process cannot meet the expected treatment standards, producing a certain degree of pollution to the receiving water bodies.

In recent years, environmental protection has always been the focus of attention in China. The water quality requirements for wastewater discharge have become stricter, and relevant regulations and policies have been introduced, such as theActionPlanforPreventionandControlofWaterPollutionandThirteenthFive-YearPlanforEcologicalandEnvironmentalProtection. The Thirteenth Five-Year Plan for Ecological and Environmental Protection puts forward the requirement for rectification within a time limit for the industrial park sewage treatment plants with unstable standards[2]. The Wanggao Industrial Park in Hezhou City, Guangxi was taken as an example. There are currently 36 enterprises in the park, involved in food, chemical, pharmaceutical, rare earth and other industries. The quality of wastewater produced by the enterprises is quite different, belonging to typical industrial park wastewater, which is an intractable wastewater in the field of wastewater treatment[3]. After the wastewater discharged from enterprises reaches theWastewaterQualityStandardsforDischargetoMunicipalSewersafter pre-treatment, it is introduced to sewage treatment plant in the park together with domestic sewage through the sewage pipe network. As companies continue to settle in, the original A/O process can no longer meet the standard for Class-A emissions ofDischargeStandardofPollutantsforMunicipalWastewaterTreatmentPlant(GB18918-2002). The receiving water body of effluent from the park is Hejiang River, which is the primary tributary of the Xijiang River in the Pearl River Basin. The Pear River is one of the seven major rivers in China and belongs to the national key control basin. In order to protect the Pearl River Basin, comprehensively improve the water environment and maintain the sustainable and healthy development of the park, it is imperative to upgrade the sewage treatment plant in the park.

Compared with the traditional activated sludge process, MBR has high processing efficiency and strong impact load resistance. The device has a small footprint. The small footprint makes MBR widely concerned in the upgrading of land-limited sewage treatment plants[4-6]. Liao Zhiming[7]uses a facultative MBR process to treat domestic sewage, achieving synchronous degradation of COD and gasificating dephosphorization. However, the problem of membrane fouling has been an important factor limiting the further development of MBR. Ceramic membrane has strong chemical stability and is easy to clean compared to organic membrane, so it has been commonly used in industrial wastewater treatment[8]. In this paper, the nanostructured ceramic membrane bio-reactor (NCMBR) process, a water treatment technique that combines a facultative MBR with a ceramic membrane having a large number of nanoporous structures was adopted. The nano-coating on the surface of the nanostructured ceramic membrane makes it impossible for contaminants to bind firmly[9], slowing down membrane fouling.

In this paper, the NCMBR process was used to treat wastewater from Wanggao Industrial Park. The water quality indicators such as COD, NH3-N and TP which did not meet the standards for Class-A emissions in the original A/O process were monitored so as to make the wastewater from the industrial park meet the discharge standards and provide reference for the upgrading and reconstruction of existing sewage treatment plants.

2 Materials and methods

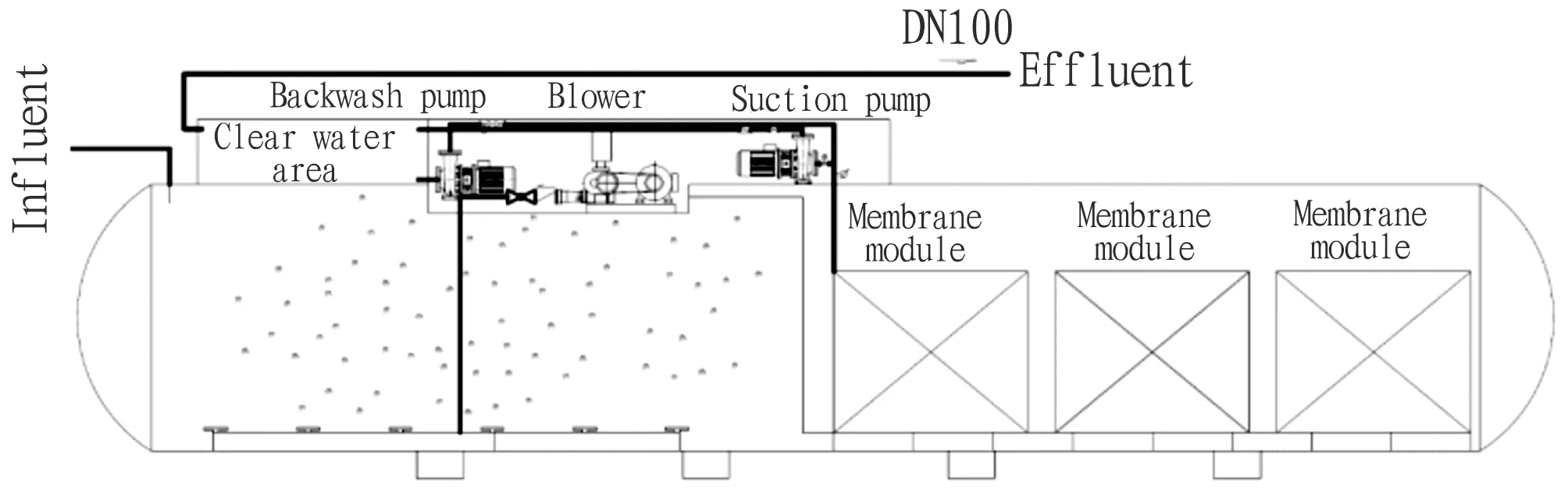

2.1 Experiment device and operation modeThe pilot-scale project used an independently designed MBR reactor (Fig.1). The main body of the tank was a cylinder with radius of 1.1 m and length of 7.1 m, and the effective volume was 27 m3. The designed treatment scale was 100 m3/d. The wastewater was pumped into the MBR reactor. The membrane modules were placed side by side in the MBR reactor. Aeration was performed at the bottom of the membrane modules. The membrane modules were flat ceramic membranes, partially made of SiC, with a nominal pore size of 0.1 μm, membrane flux of 40-60 L/(m2·h) and effective membrane area of 0.5 m3.

NCMBR was started by continuous water intake and no sludge discharge and run in suction/backwash mode, using intermittent drainage and programmable logic controller (PLC), 9.5 min for suction and 0.5 min for backwash. The effluent was pumped out by a suction pump. The dissolved oxygen (DO) in the reactor was controlled at 0.5-2.0 mg/L. The inoculated sludge was taken from a sewage treatment plant in Hezhou City.

Fig.1 Schematic diagram of the experimental set-up

2.2 Experimental waterThe experimental water was taken from the outlet of vortex grit chamber of the sewage treatment plant of Wanggao Industrial Park in Hezhou, Guangxi. In raw water, the concentrations of chemical oxygen demand (COD), ammonia nitrogen (NH3-N) and total phosphorus (TP) were 92-475, 2-19 and 0.11-0.89 mg/L, respectively.

2.3 Monitoring items and analysis methodThe conventional water quality indicators COD, NH3-N and TP were determined according toWaterandWastewaterMonitoringandAnalysisMethods[13].

The water sample was taken once every 3 d. The effluent sample was taken from the outlet of suction pump, and the influent sample was taken from the outlet of the vortex grit chamber.

3 Results and analysis

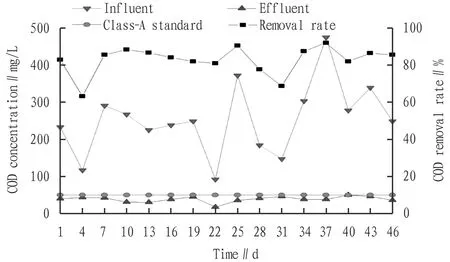

3.1 Removal of CODThe removal effect of COD during the experiment is shown in Fig.2. During the start-up period (1-22 d), in the reactor, the MLSS was lower; the species and content of microorganisms were less, and they had weak biodegradability for COD; and the membrane modules had a certain retention effect on organic matter, prolonging the residence time of macromolecular organics in the MBR reactor, conducive to the removal of organic matter, so that the effluent COD concentration was always less than 50 mg/L, with average COD removal rate of 81.72%. During the experiment, in the reactor, the concentration of COD in the influent was 92-475 mg/L, which was highly volatile; and the concentration of COD in the effluent was less than 50 mg/L, with an average of 37 mg/L, so that the average removal rate of COD was 82.32%. The system’s high degradation efficiency of COD benefited from the membrane retention, which increased the mixed liquid suspended solids (MLSS) in the reactor and kept the system with a lower sludge load, thereby endowing the system a certain anti-impact load capacity.

Fig.2 Dynamic of COD with running of the system

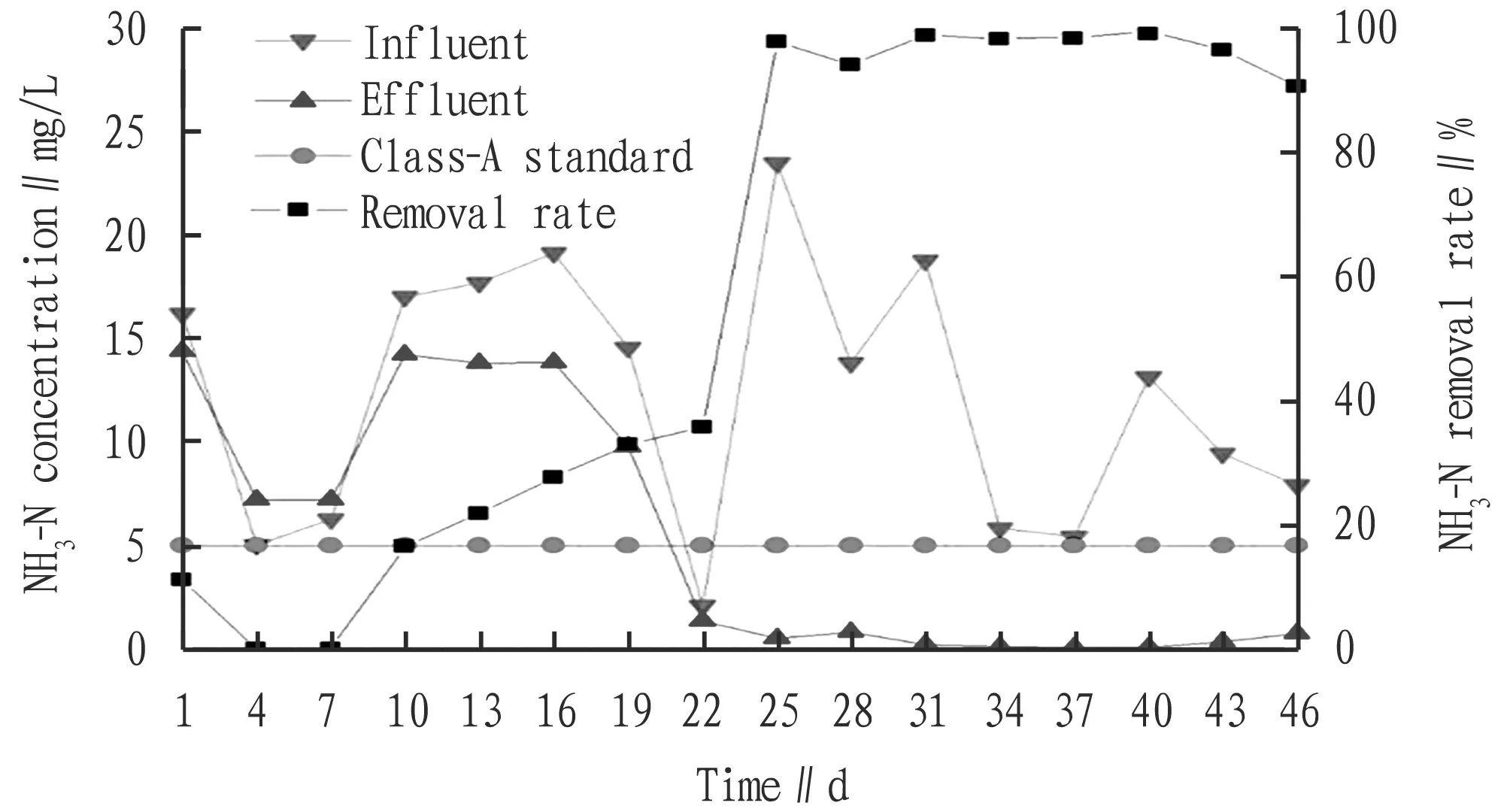

3.2 Removal of NH3-NThe removal effect of NH3-N during the experiment is shown in Fig.3. NH3-N is free to pass through the micropores of the membrane modules, so that NCMBR removes NH3-N mainly by microbial nitrification[6]. As shown in Fig.3, during the start-up period (1-22 d), the removal effect of NH3-N was unsatisfactory. On the 4th and 7th d, the concentration of NH3-N in the effluent was even higher than that in the influent. The reason for this phenomenon was that the organic nitrogen in the inoculated sludge was converted to NH3-N under anaerobic conditions[10]. In the initial stage of running, the quantity of nitrifying bacteria and nitrosating bacteria with a long generation period was relatively low[11], and the conversion efficiency to NH3-N was low, resulting in higher NH3-N concentration in effluent than influent. With the accumulation of nitrifying bacteria and nitrosating bacteria in the reactor and their gradual adaptation to the environment, the quantity of nitrifying bacteria and nitrosating bacteria gradually increased. After 7 d of running, the removal rate of NH3-N gradually increased. After 25 d of running, the treatment effect on NH3-N tended to be stable. The concentration of NH3-N in the influent was 5.42-23.5 mg/L, and that in the effluent was 0.08-0.82 mg/L, with an average of 0.30 mg/L, so the average removal rate of NH3-N was as high as 97.71%, with maximum up to 99.54%.

Fig.3 Dynamic of NH3-N with running of the system

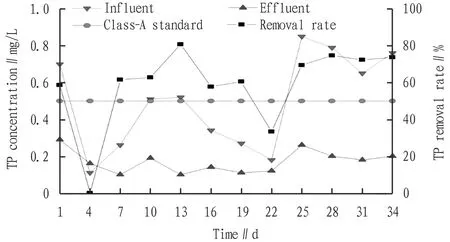

3.3 Removal of TPThe removal effect of TP during the experiment is shown in Fig.4. As shown in Fig.4, during the start-up period (1-22 d), the system did not remove TP effectively. The current research suggests that gasificating dephosphorization is the result of biological reduction of microorganisms using high-energy electrons[12]. In the initial stage, the MLSS was lower, and phosphate-reducing bacteria and other strains are low in content, so the removal rate of TP was not high. As the reaction progressed, the quantity of strains such as phosphate-reducing bacteria in the reactor gradually increased, so the removal rate of TP gradually increased. After 25 d of running, the removal effect of TP tended to be stable. In the effluent, the concentration of TP was 0.18-0.26 mg/L, meeting the standard for Class-A emissions of Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant (GB18918-2002).

Fig.4 Dynamic of TP with running of the system

3.4 Membrane fouling during start-up and stable runningThe membrane modules were not physically or chemically cleaned during the experiment, but the system showed a stable removal effect on COD, NH3-N and TP. This was mainly due to the following two reasons. First, the surface of the membrane modules was washed by aeration. The running mode with 9.5 min of suction and 0.5 min of backwash had a certain slowing effect on membrane fouling. Second, the nano-coating on the surface of the nanostructured ceramic membrane made it impossible for contaminants to bind firmly[9], slowing down membrane fouling. However, in order to slow down the membrane fouling, prolong the service life of the nanostructured ceramic membrane and achieve long-term stable running of NCMBR, corresponding physical and chemical cleaning strategies should also be developed for certain type of membrane fouling in subsequent studies.

4 Conclusions

The NCMBR process was adopted for the treatment of wastewater from Wanggao Industrial Park. After running stably, the concentrations of COD, NH3-N and TP in the effluent meet the requirements (COD<50 mg/L, NH3-N<5 mg/L, TP<0.5 mg/L) by Class-A emissions ofDischargeStandardofPollutantsforMunicipalWastewaterTreatmentPlant(GB18918-2002), suggesting that it is feasible to treat the wastewater from Wanggao industrial Park by NCMBR process. The running mode of scouring the surface of the membrane by aeration, 9.5 min of suction and 0.5 min of backwash has a certain slowing effect on membrane fouling. The nano-coating on the surface of the nanostructured ceramic membrane makes it impossible for contaminants to bind firmly to it, slowing down membrane fouling. In order to achieve long-term stable running of NCMBR, corresponding physical and chemical cleaning strategies should also be developed for different types of membrane fouling.

杂志排行

Asian Agricultural Research的其它文章

- Delimitation and Zoning of Natural Ecological Spatial Boundary Based on GIS

- Career Planning Education Paths for Students of Aquatic Animal Medicine Discipline in the Context of the Belt and Road Initiative: A Case Study of Construction Achievement of Guangdong Ocean University

- Present Situation and Renovation Strategies of Farmhouses in Yingxi Village, Fuliang County, Jingdezhen

- Preliminary Exploration on Design of Green Landscape of Urban Streets: A Case Study of Guangchang East Road in Xihu District of Nanchang City

- Cultivation and Management Technologies for New Banana Cultivar ‘Refen 1’(Musa Spp. ABB, Pisang Awak Subgroup)

- Influence of Sino-US Agricultural Trade on China’s Total Agricultural Output Value Based on Cointegration Model