BiPO4/Ag3PO4/CNTs复合光催化剂的制备、表征及其光催化性能

2019-06-06马克龙胡世伟崔玉民李一俊朱慧如

马克龙,胡世伟,苗 慧,崔玉民,李一俊,朱慧如

(阜阳师范学院 化学与材料工程学院,安徽 阜阳 236037)

In the past few decades,environmental pollution and energy shortages have caused widespread attention.Photocatalytic process,as an advanced technology,has been an intensively hot title since it has been considered as a vanguard solution focused on the viewpoint of environmental accountability and energy conversion[1-3].It is different from conventional biodegradation or activated carbon adsorption methods,photocatalytic technology provides a powerful oxidation process for removing non-biode-gradable organic pollutants(such as dyes,pesticides,surfactants),completely converted to carbon dioxide and water,so no hazardous decomposition products will be left[4].There are generally two distinct areas in the development of a photocatalytic system.First,the focus is on designing and synthesizing nanoscale porous photocatalysts with high activity under visible light irradiation[5-7].Second is to establish a novel photocatalytic system which creates large active surface area and facilitates efficient mass transfer on the photocatalyst surface[8-10].

According to reports in the literature,composite semiconductors can reduce the photorecombination rate of photocatalysts by reducing the recombination rate of photogenerated electrons and holes[11-12].Among many semiconductor materials,Bi-based and Ag-based materials have many advantages as photocatalysts,which have attracted wide attention.BiPO4,as one of the Bi-based materials,is a p-type semiconductor with a bandwidth of about 3.85 eV[13-14],which exhibits high photocatalytic activity during the decomposition and degradation of organic dyes.Ag3PO4is an n-type semiconductor[15],which can absorb sunlight with a wavelength of less than 520 nm and improve the absorption rate of light.Both semiconductors have great potential as photocatalysts.However,in practical applications,there are still many shortcomings that hinder its application.Therefore,development of a photocatalyst having high reactivity in sunlight is of great significance for overcoming the disadvantages of BiPO4and Ag3PO4.At present,BiPO4has poor adsorption performance and large size[16-17],affecting the migration rate of electron and hole pairs,and photocatalytic activity is affected[18].Insufficient presence of Ag3PO4,the use of silver-based compounds in the manufacturing process increases the cost of the material and causes severe photo-etching during the catalytic process.Among various composite materials,p-n heterojunction structures have proven to be a very effective method for separating electron and hole pairs[19-20].By constructing a heterojunction,these drawbacks can be effectively avoided,and the application value of the material can be maximized.

In recent years,carbon nanotubes(CNTs)have attracted attention due to their unique structure,electrical,thermal and mechanical properties[21],and it has been used in various applications,including drug delivery[22],chemical sensing[23],electronic sensing[24]and as reinforced fillers for polymers[25].In particular,due to its low cost and non-toxic properties,carbon nanomaterials are seen as an effective carrier to form nanocomposites with semiconductors,thus increasing its photocatalytic efficiency.Therefore,it is expected that CNTs modification could improve the photocatalytic performance of BiPO4/Ag3PO4.

In this work,a heterojunction was constructed by ultrasonic-assisted coprecipitation,and BiPO4/Ag3PO4/CNTs were prepared by carbon nanotube loading.Various characterization techniques such as SEM,PL and UV-vis spectroscopy studies.The photodegradation activity of cal-5-0.5-350 for MB was greatly enhanced under visible light as compared to pureAg3PO4or cal-5-0.5-X.

1 Experiment

1.1 Chemicals and apparatus

All chemicals used were of an analytical grade and of the higher purity available.AgNO3,Bi(NO3)3·5H2O,NaH2PO4·2H2O,MB,HNO3and NH3·H2O,deionized water used throughout the whole experiments.CNTs were refluxed in HNO3(65 wt%)for 4 h at 110℃.After acid treatment,the CNTs were centrifuged,washed with demonized water,and dried at 60℃.

1.2 Catalyst preparation

The BiPO4/Ag3PO4/CNTs(cal-5-0.5-X)photoactive emulsifier was synthesized via a simple ultrasonic-assisted the coprecipitation method.In a typical synthesis,a certain amount CNTs was dissolved in a beaker containing 100 mL deionized water(named A).Then,AgNO3and Bi(NO3)3·5H2O were added to A and also sonicated for 10 min.After that,an aqueous solution of NH3·H2O(104 mL,0.10 mol·L-1)was added to the above-mentioned mixture.Finally,Na2HPO4aqueous solution(48 mL,0.15 mol·L-1)was added dropwise to the mixture,and the reaction mixture was kept sonicated for 2 h.After the products were collected by centrifugation,the precipitates were washed with demonized water several times,and dried at 60℃for 24 h.After,the product was transferred to a crucible and a certain temperature roasting for 4 h.The final samples with weight percents of CNTs of 0,0.5 and 5.0 wt%,were denoted as 0,0.5%and 5.0%BiPO4/Ag3PO4/CNTs,respectively.For comparison,pure Ag3PO4particles were synthesized by the direct reaction of AgNO3with NaH2PO4solution,and the BiPO4/Ag3PO4catalysts were simply prepared by replacing the CNTs aqueous solution with water.

1.3 Catalyst characterization

The morphologies and microstructures of the products were obtained by scanning electron microscope(SEM,Hitachi)with 5.0 kV scanning voltages.Ultraviolet visible(UV-vis)diffuse reflection spectra were examined on a UV-vis spectrophotometer(Hitachi U-1901)in the range of 200 to 700 nm with BaSO4as a reference.Photoluminescence(PL)spectroscopy was measured at the excitation wavelength of 450 nm on MDX 1000 spectrofluorimeter at room temperature.

1.4 Photocatalytic reaction

Photocatalytic activities of BiPO4/Ag3PO4/CNTs photocatalysts were evaluated by the degradation of MB in an aqueous solution.The visible light source was a 350 W xenon-arc lamps with cutoff filter.A general steps was carried out as follows.First,40.0 mL MB solutions(40.0 mg·L-1)were employed in an internal-irradiation quartz reaction cell maintained.The suspension was stirred vigorously for 60 min in the dark and then irradiated under visible light.About 4.5 mL solution was removed from the reactor periodically and centrifuged and analyzed.For the assessment of photocatalytic activities of resultant photocatalyst,the degradation efficiency=C/C0×100%was used,whereCandC0is the concentrations of MB at a real-time and the initial concentration of MB.

2 Results and discussion

2.1 Catalyst structure

The morphology and microstructure of the material were characterized by SEM are displayed in Fig.1.Fig.1A shows that pure Ag3PO4is composed of heterogeneous spherical nanoparticles with a diameter of about 200~600 nm;BiPO4/Ag3PO4(Fig.1B)has a small particle attached to the surface of the spherical particles,which may be BiPO4formed.The particle diameter is 600~800 nm,and the composite particles are significantly increased compared with the pure Ag3PO4,which may be that BiPO4promotes the growth of the particles.Fig.1C and Fig.1D show SEM images of the catalysts at different calcination temperatures,respectively.The cal-5-0.5-350 composite(Fig.1C)is obviously composed of CNTs,resulting in a decrease in the size of BiPO4/Ag3PO4particles in the BiPO4/Ag3PO4/CNTs composite.The BiPO4/Ag3PO4particles are distributed on the surface of the CNTs.This structure can provide sufficient contact surface area between CNTs and BiPO4/Ag3PO4particles,and can also promote charge carrier transport.An SEM image of the cal-5-0.5-550 composite is shown in Fig.1D.It is agglomerated by irregular BiPO4/Ag3PO4/CNTs crystals,which may be due to high temperature sintering,resulting in grain phagocytosis,reduced material specific surface area,and electron transport channels,which are not conducive to carrier transport,possible affect the catalytic properties of the material.

2.2 DRS

Fig.1 SEM images of the samples(a)Ag3PO4;(b)cal-5-0-350;(c)cal-5-0.5-350;(d)cal-5-0.5-550

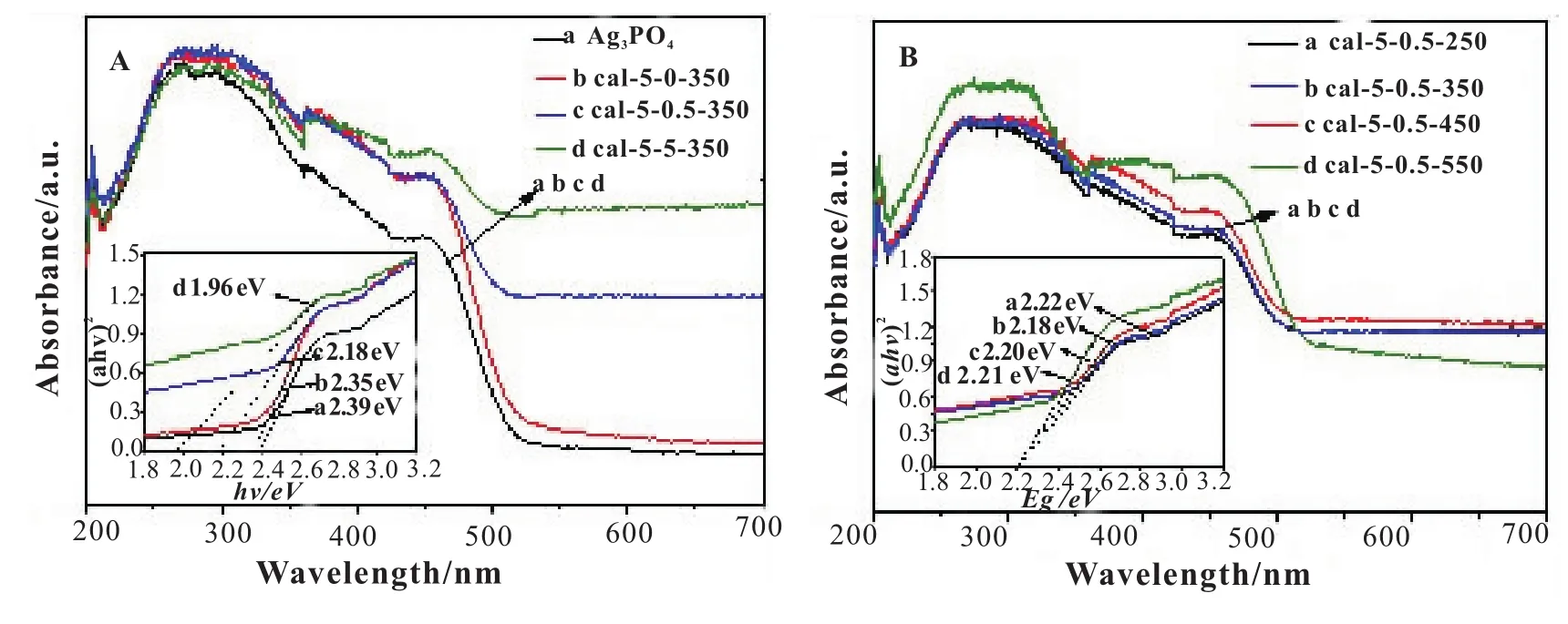

The UV-Vis absorption spectra of Ag3PO4,Bi-PO4/Ag3PO4(cal-5-0-350),cal-5-0.5-350 and cal-5-0.5-550 composite is displayed in Fig.2.Since many factorssuchasresidualwater,particlesize,roughness,and the weight of samples affect the light absorption intensity during measurements,the comparison of light absorption intensity of as-prepared samples is always inaccurate.Generally,the absorption edges of as-prepared samples are used to characterize the optical absorption properties,which could eliminate the influence of base absorption lines(about 525~800 nm).It can be seen that the Ag3PO4(line a)sample can absorb UV and visible light with wavelengths less than 550 nm,corresponding to a band gap energy of 2.39 eV,which is not agrees with the light-absorption properties of Ag3PO4powders reported by other groups[26].The absorption of BiPO4/Ag3PO4(line b)is located at approximately 450 nm,corresponding to a band gap energy of 2.35 eV.This result also suggests that Ag3PO4and BiPO4have been composited successfully.Thus it can be concluded that the heterojunction composite is more easily excited by visible light and the utilization ratio of visible light is enhanced.Compared with pure Ag3PO4,both cal-5-0.5-350(line c)and cal-5-0.5-550(line d)display continuous strong absorption,which implies that these two complex photocatalysts may have higher photocatalytic activity for target reactions and CNTs may play important roles in utilizing sunlight.In Fig.2A,the band gaps of the samples were 2.18 and 1.96 eV,corresponding to cal-5-0.5-350 and cal-5-0.5-550,respectively.From the plot of(ahv)2 versus hv in Fig.2B,the transition band-gaps estimated from the onset of the curve edges are about 2.22 eV,2.18 eV,2.20 eV and 2.21 eV for 250℃,350℃,450℃and 550℃,respectively.It is obvious that the ability of visible light absorption is enhanced and the cal-5-0.5-350 composite exhibits the strongest absorption intensity.The relatively narrow bandgap energy observed for cal-5-0.5-350 may be due to the strong interaction in the hybrid structure,which results in more efficient use of the solar spectrum.

2.3 Photocatalytic activity

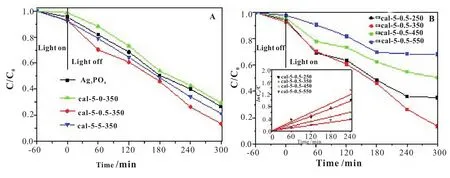

The photocatalytic behavior of the prepared Ag3PO4and the related complex photocatalysts were explored for the degradation of MB dye under sunlight irradiation and with non-sacrificial reagents at room temperature.Fig.3A shows the sunlight photocatalytic activity of Ag3PO4catalyst and BiPO4/Ag3PO4/CNTs samples with different CNTs contents.In the absence of photocatalyst,MB self-degradation was almost negligible.Efficiencies of photocatalytic MB degradation was 73.3%,70.6%,86.6%and 79.5%for Ag3PO4catalyst,cal-5-0-350,cal-5-0.5-350 and cal-5-5-350,respectively,after irradiation for 300 min.It can be seen that cal-5-0.5-350 shows higher photocatalytic activities than Ag3PO4catalyst,cal-5-0-350 and cal-5-5-350 composites.Based on the above results,the effect of temperature on the photocatalytic activity of BiPO4/Ag3PO4/CNTs(cal-5-0.5-X)photocatalysts was evaluated by MB degradation in an aqueous solution under sunlight irradiation.Fig.3B shows the sunlight photocatalytic activity of cal-5-0.5-X samples with different temperatures.The photocatalytic performance of different photocatalysts were in the following order:cal-5-0.5-350>cal-5-0.5-250>cal-5-0.5-450>cal-5-0.5-550.For cal-5-0.5-550,the photocatalytic activity is the lowest and the degradation of MB was only 31.9%for 300 min.For cal-5-0.5-350,the degradation of MB was 86.6%for 300 min.To have a better understanding of the reaction kinetics of the MB degradation by various photocatalysts,the above experimental data are fitted by a first-order model as expressed by eq(1):

Fig.2 UV-vis diffusive reflectance spectra of sample and the plotting of(αhv)2 versus photon energy

Wherekis the rate constant(min-1)that commonly gives an indication of the activity of the photocatalyst,C0andCare the initial concentration and the concentration at different degradation time of the MB dye,respectively.Fig.3A exhibits a linear relationship between ln C/C0and the irradiation time for the degradation of MB.As can be seen from Fig.3B,photocatalytic temperature of the sample at all the different degradation curves and pseudo-firstorder kinetics fit.In addition,the degradation rate constant k shown in Fig.3B indicates that the cal-5-0.5-350 composite indicates the highest degradation rate.

2.4 PL properties

It is well known that the PL signal of a semiconductor material is caused by the recombination of photogenerated charge carriers.In general,the lower the luminescence intensity,the lower the recombination rate of photogenerated electron-hole pairs,and the higher the photocatalytic activity of the semiconductor photocatalyst[27-29].From the PL spectrum,the intrinsic peak position of Ag3PO4catalyst,BiPO4/Ag3PO4and cal-5-0.5-350 photocatalyst is located at 425 nm at room temperature,which is related to the literature[30].The report consistently showed an energy level peak near 525 nm,which may be related to surface defects.In addition,these three samples have broad emission peaks in the wavelength range of 370~700 nm,and the peak shapes are similar.The PL intensity of cal-5-0.5-350 was significantly weaker than that of pure Ag3PO4,indicating that recombination of the photogenerated charge carriers was inhibited by appropriate carbon nanotube incorporation.Therefore,the photogenerated electron-hole pairs are effectively separated.Effective charge separation can increase the lifetime of the charge carrier and increase the efficiency of the interface charge transfer adsorption substrate,thereby increasing the photocatalytic activity.

Fig.3 Activity of the samples for degradation of Methylene blue under irradiation of visible light

Fig.4 PLspectra of samples at room temperature

3 Conclusion

BiPO4/Ag3PO4/CNTs photocatalysts were successfully prepared by ultrasonic assisted coprecipitation.Compared to pure Ag3PO4,cal-5-0-350 or cal-5-0.5-X,the prepared cal-5-0.5-350 exhibited higher MB degradation performance under simulated sunlight.According to the results of band absorption spectroscopy and PL characterization,the improvement of photocatalytic performance of materials can be attributed to the high separation rate of photogenerated electrons and holes generated by BiPO4,Ag3PO4and CNTs composites and the low recombination rate.The method improves the absorption of visible light by Ag3PO4matrix composites,and provides a new modification method for the preparation of high efficiency photocatalyst under visible light.