Thermoelastohydrodynamic analysis of misaligned bearings with texture on journal surface under high-speed and heavy-load conditions

2019-06-03YuZHANGGuodingCHENLinWANG

Yu ZHANG,Guoding CHEN,Lin WANG

School of Mechanical Engineering,Northwestern Polytechnical University,Xi'an 710072,China

KEYWORDS Journal bearing;Lubrication properties;Misalignment;Surface texture;Thermoelastohydrodynamic

Abstract Hydrodynamic journal bearings are used to support the planetary gears in the transmission system of a Geared Turbo Fan engine,and they operate under severe working conditions,such as misalignment,high speed,and heavy load.Surface texture is regarded as an effective approach to improve mechanical properties under severe working conditions.However,the effects of surface texture on misaligned journal bearings under severe conditions have not been well studied.Therefore,a thermoelastohydrodynamic(TEHD)lubricating model with a textured and misaligned journal is presented in this study.Solid deformation,heat transfer between oil and the bearing,and heat convection between air and the bearing are considered in the model.The effects of cavitation and viscosity-temperature are also taken into account.The impacts of surface texture parameters and the misalignment angle on lubricating properties are investigated in the model.Results indicate that the bearing lubricating performance is greatly improved by optimal surface texture considering journal misalignment.The maximum oil film pressure and load-carrying capacity of a journal bearing increase with journal misalignment.Meanwhile,the oil film temperature increases sharply while considering misalignment.

1.Introduction

Geared Turbo Fan(GTF)engines are applied to civil aircraft,as they feature higher thrust and bypass.Compared to other aero engines,a planetary gear transmission system is installed between the low-pressure turbine rotor and the fan rotor of a GTF engine.1,2The low-pressure turbine rotor and the fan rotor can run at optimal operating speeds owing to the planetary gear transmission system,and stages of the compressor and the turbine decrease while the bypass ratio increases so that civil aircraft run under smaller noise and lower fuel consumption.3

The planetary gears in a transmission system are supported by hydrodynamic journal bearings which are called GTF journal bearings.The journal is fixed while the bearing bush can rotate as a result of the structural arrangement of a GTF engine,and the journal is misaligned frequently owing to the limit of its stiffness.In addition,GTF journal bearings are subjected to severe operating conditions,such as heavy external load and high rotating speed.For these reasons,improving GTF journal bearing performance has been one of crucial technologies of GTF engines,and all these issues constitute the engineering background of journal bearings under severe operating conditions.

So far there have been less analyses of GTF journal bearings,but research on misaligned bearings has been conducted.Bouyer et al.4carried out experiments of misaligned journal hydrodynamic bearings and analyzed the journal bearing performance.Their results showed that both the maximum oil pressure and the minimum oil film thickness decreased because of journal misalignment.He et al.5used a finite difference method to study the effects of misalignment on bearing performance.Their work revealed that journal misalignment had a big impact on oil film pressure distribution,but little influence on lubricant leakage.Pierre et al.6presented a thermohydrodynamic analysis of misalignment journal bearings using theoretical and experimental approaches.They stressed that journal misalignment impelled the maximum oil pressure and the maximum oil temperature to increase,especially with light external load.Zhang et al.7developed a comprehensive thermoelastohydrodynamic model of misaligned plain journal bearings,and proposed that a misaligned journal caused more changes in bearing performance,especially thin oil film lubrication.Because of the adverse effects of misalignment on bearing performance,more approaches have been developed to improve the performance of misaligned journal bearings. Thomsen et al.8proposed that bearing flexibility and compliant liners could be used to improve the lubricating property of journal bearings.However,it was at the cost of deceasing the loadcarrying capacity,so it cannot be applied to journal bearings with heavy external load.

Surface texture is another method to improve bearing performance under severe operating conditions.Tala-Ighil et al.9carried out analysis of the lubricating performance of journal bearings with surface texture,and their work indicated that surface texture had positive effects on bearing lubricating performance.Since then,surface texture has received more and more attention and is treated as an effective way to improve bearing lubricating performance.

Tala-Ighil et al.10analyzed effects of the surface texture location on bearing lubricating performance, and results showed that partial surface texture could generate a greater hydrodynamic load capacity compared with that of full surface texture,while Kango et al.11also confirmed the conclusion.Then,scholars carried out research on influences of the surface texture location when partial surface texture was applied to numerical models.Lin et al.12used a fluid-structure interaction approach to study journal bearing performance.They thought that surface texture might enhance or impair bearing performance,depending on the surface texture position.Cupillard et al.13investigated performance of large-eccentricity hydrodynamic bearings,and results indicated that an additional hydrodynamic pressure was produced when surface texture was in the region of the maximum hydrodynamic pressure.Wang et al.14gained the same conclusion when thermoelastodrodynamic effects were considered.

Zhang et al.15proposed that not only the surface texture location but also the texture density and size were important parameters for improving bearing performance.This finding was also proven by Tala-Ighil et al. 16 and Liang et al.17Then,scholars studied effects of texture structural parameters on bearing lubricating performance.Kango et al.18analyzed effects of surface texture on hydrodynamic bearing performance through a finite difference approach, and demonstrated that surface texture was fruitful in increasing the load-carrying capacity and decreasing the friction coefficient of journal bearings.Brizmer et al.19discovered that the optimum texture parameters could greatly enhance the loadcarrying capacity of journal bearings.Yu et al.20used the Winkler elastic foundation model to develop an elastodrodynamic bearing lubrication model in which surface texture structural parameters and layouts were discussed,and results showed that parameters could change journal bearing static characteristics.

From the existing results,it can be found that there is little research on analyses in which surface texture is applied to misaligned journal bearings,especially the situation where the journal is fixed while the bearing bush can rotate.Considering excellent lubricating properties of surface texture and severe operating conditions of GTF journal bearings,it is necessary to analyze influences of surface texture and a misaligned journal on bearing performance when TEHD effects are considered.It is not only helpful to promote performance of the planetary gears in a transmission system,but also efficient in grasping the regularity of journal bearing property under severe operating conditions and seeking new approaches to promote bearing performance.

Basing on the structure and the operating condition of GTF journal bearings,this paper uses the CFD method to develop a TEHD numerical model in which surface texture is applied on a misaligned journal.The deformations of the bush and the journal,the heat convection on the air-bearing surface,and the thermal conduction between solid and lubricant are considered in company with cavitation and viscositytemperature effects.The influences of the texture position,the texture extend,and misalignment on bearing lubricating properties are discussed base on the model.The impact mechanism of surface texture and the misaligned journal on journal bearing lubricating properties is also discussed under high speed and heavy load.

2.Governing equation and numerical model

2.1.Structure of a textured GTF journal bearing

The geometry of a journal bearing with surface texture is shown in Fig.1.There are regular square dimples on the journal surface.From φ=0°,the starting angle of texture is φ=β1,and the texture extend is β.A coordinate system x′y′z′is set up according to the central point O′of the journal.As shown in Fig.1,r is the radius of the journal;b is the axial length of surface texture;B is the length of the journal bearing;n is the rotating speed of the bushing;θ and e are respectively the attitude angle and eccentricity of the journal bearing;hminis the minimum oil film thickness;hdis the depth of the oil groove.The lubricant goes into the oil groove through the axial and radial oil holes of the bearing journal,fills the bearing clearance,and outflows from the two ends of the journal bearing.

Fig.1 Structure of a textured GTF journal bearing.

The structure and layout of surface texture are shown in Fig.2.The texture spacing in the axial and radial directions is equal,and is expressed as kc.s is the texture area ratio that means the ratio of the dimple area to the control cell area,and it is expressed as

where w is the dimple length.hcis the dimple depth.h0is the nominal film height that denotes the distance between the un-textured part and the counter face.

2.2.Governing equation

Based on the geometry of the textured GTF journal bearing,the details of the governing equation for carrying out a TEHD analysis of the textured journal bearing are shown in this section.

2.2.1.Fluid governing equation

According to the assumption that the lubricant is incompressible and Newtonian fluid, the Navier-Stokes equation is expressed as

where ρ and μ are respectively the density and dynamic viscosity of the lubricant;V represents the velocity vector of the lubricant;p represents the fluid pressure.The fluid continuity equation remains as

The energy conservation equation of the lubricant field is expressed as

where cvis the specific heat at a constant volume;T is the temperature of the lubricant;k is the heat transfer coefficient;q represents the heat flux of the lubricant.The kinematic viscosity varies as a function of the fluid temperature,and the temperature-viscosity relationship is

where ν is the kinematic viscosity of the lubricant.

2.2.2.Film thickness and solid deformation equations

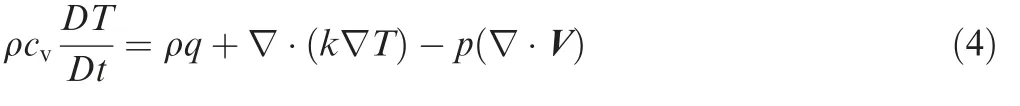

The film thickness equation takes journal misalignment into account because misalignment is not ignored under severe operating conditions. The misaligned bearing schematic is shown in Fig.3,where α is the misalignment angle;ψ is the angle between the vertical of the journal center line and the coordinate y;e′is the eccentricity of the journal at both ends; C1, C2, and C are respectively the center points of the journal axis with the front,middle,and rear planes of the journal.

Fig.2 Schematic of surface texture.

Fig.3 A misaligned journal bearing.

The derivation process of the film thickness equation with the misaligned journal bearing is described in detail.When journal misalignment is not considered,the film thickness equation is related to the nominal film height h0,total deformation of the bushing and the journal δ,the dimple depth hc,and the oil-grooved depth hd.Therefore,the film thickness in different regions is given as

where Ωtrepresents the surface texture region,and Ωois the oil-grooved region.

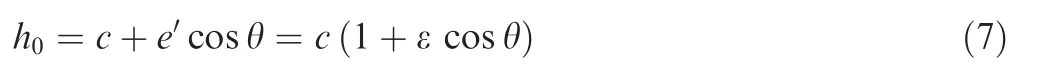

The nominal film height h0is calculated with the following formula:

where c is the bearing radius gap,and ε is the bearing relative eccentricity ratio.

When journal misalignment is considered,only the nominal film height changes.Then,the center points of different cross sections change.The eccentricity e′and the angle ψ are functions of the z coordinate.Thus,the nominal film height h0is expressed as

Assuming that the C coordinate is(x1,y1,0),the axis center coordinate of the z cross-section is given by

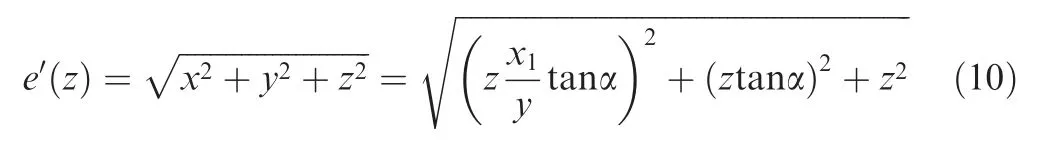

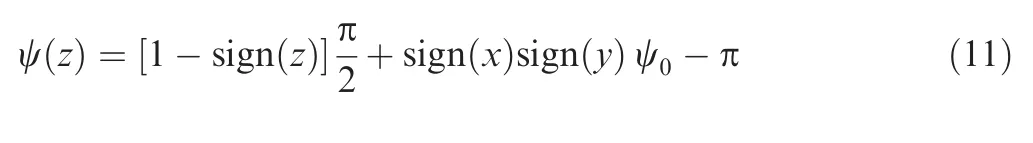

Then,the eccentricity e′(z)and the angle ψ(z)are expressed as

and

where Ψ0is defined as

Therefore,the film thickness equation of the misaligned bearing with surface texture is got according to Eq.(6)to Eq.(12).

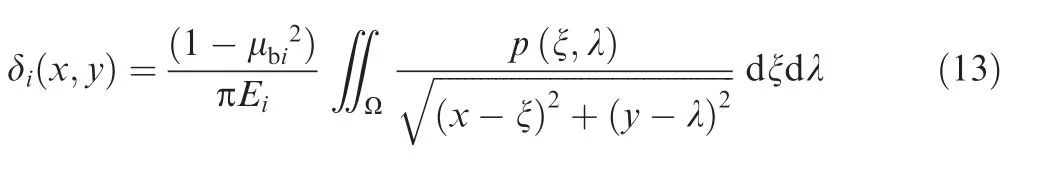

The bushing and the journal become deformed as a result of the oil pressure.The deformation of the bearing δi(x,y)can be expressed as

where ξ and λ are the local coordinates relating to x and y,respectively.Ω is the fluid region.Eiand μbiare respectively the elastic modulus and Poisson ratio of the bearing.The subscripts of i=b and i=s represent the bushing and the journal,respectively.

Total deformation of the bushing and the journal δ is given as

where δband δsare the bushing and journal deformations,respectively.

2.2.3.Liquid-solid heat transfer and heat convection equations

Heat transfer between the lubricant and the journal bearing and heat convection between air and the journal bearing are considered in the numerical model due to severe operating conditions.To realize coupled thermal analysis,heat transfer and heat convection equations are established.

Heat transfer is shown as

where Qtand Atare the heat and area between the oil film and the journal bearing,respectively;k is the heat transfer coefficient;ΔTtis the temperature difference between the lubricant and the bearing.Heat convection is given as

where Qcand Acare the heat and area between air and the journal bearing,respectively;h means the convectional heat transfer coefficient;ΔTcis the temperature difference between air and the bearing.

When coupled thermal analysis is considered,the heat flux and temperature of the interface meet the following conditions:

where qfand Tfare the heat flux and temperature of the fluid,respectively,and qsand Tsare the heat flux and temperature of the solid,respectively.

2.3.TEHD numerical model of the misaligned bearing with surface texture

2.3.1.3-D structure of the numerical model

Based the structure of the misaligned bearing with surface texture,a 3-D structure of the numerical model is established in Fig.4.3-D structures of the fluid and solid regions are shown in Fig.4(a)and Fig.4(b),respectively.Oil supply holes are simplified without affecting the accuracy of the model.A tetrahedron element is adopted in the oil supply holes of the fluid region,and a hexahedral element is adopted in other fluid regions.A hexahedral element is also applied to the solid region.

2.3.2.Boundary conditions of the numerical model

Boundary conditions of the TEHD numerical model of the misaligned bearing with surface texture are shown in Fig.4,specified as follows:1:the rotating speed is applied to the outer wall surface of the fluid region;2:the inner wall surface is stationary;3:the mixture model is adopted to simulate the twophase flow of oil and gas in the fluid region.The Schnerr-Sauer model is used to describe the cavitation effect,and the cavitation pressure is set to 105Pa.21The slip of the interface is ignored;4:the oil supply pressure and temperature are set in oil supply holes;5:oil outflows from the two ends of the journal bearing,and the pressure is set to one bar;6:heat convection is applied between air and the journal bearing;7:heat transfer is applied between oil and the journal bearing.

2.3.3.Calculation illustrations of the numerical method

The TEHD numerical model of the misaligned bearing with surface texture is analyzed by the commercial code in ANSYS Workbench.The ANSYS Fluent module is used to solve the fluid region.The Static Structural module and Steady-state thermal module are used to solve the solid region.Finally,results of the fluid and solid regions are calculated iteratively in the System Coupling module.The convergence condition is that the difference between the pressure and the heat flux twice is less than 10-3.

2.4.Validation of the mesh independence and numerical method

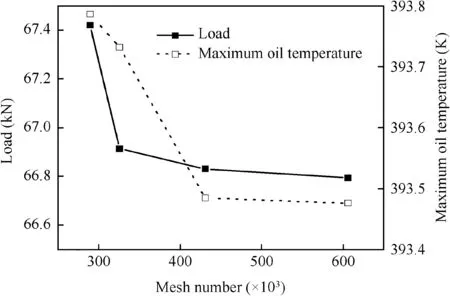

Considering large numbers of calculations,it's necessary to choose an appropriate mesh number.Therefore,a mesh independence analysis is carried out,and calculation results are shown in Fig.5.When the mesh number is greater than 431000,the load-carrying capacity and the maximum oil temperature of the journal bearing almost have no change.Therefore,the mesh number is set to 431,000 in the following analysis.

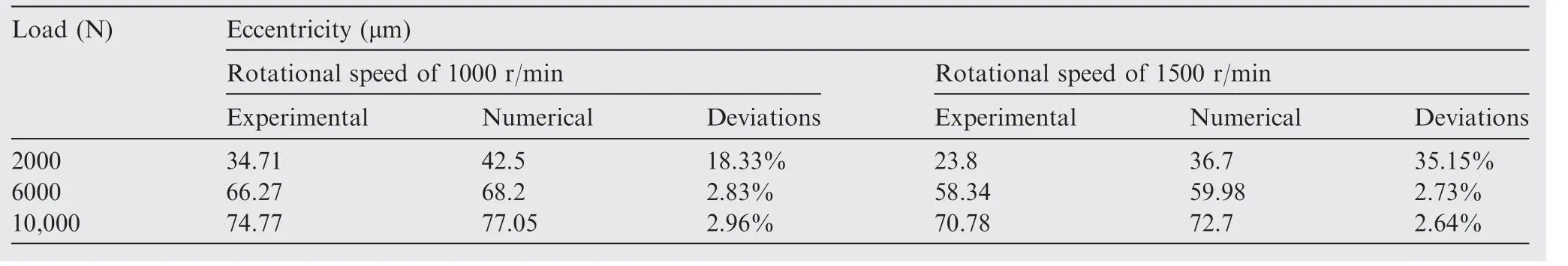

To verify the numerical method in this paper,the calculation results are compared with EHD experimental results as shown in Table 1.Numerical and experimental results of eccentricity under two speeds and three loads are given,and it can be seen that numerical and experimental results of eccentricity correspond well with each other under heavy load.The numerical model is used for the journal bearing under heavy load,so the results of the numerical model are reliable.

3.Results and discussion

Fig.5 Mesh independence.

Fig.4 Structure and boundary conditions of the numerical model.

Table 1 Comparison between numerical and experimental results.

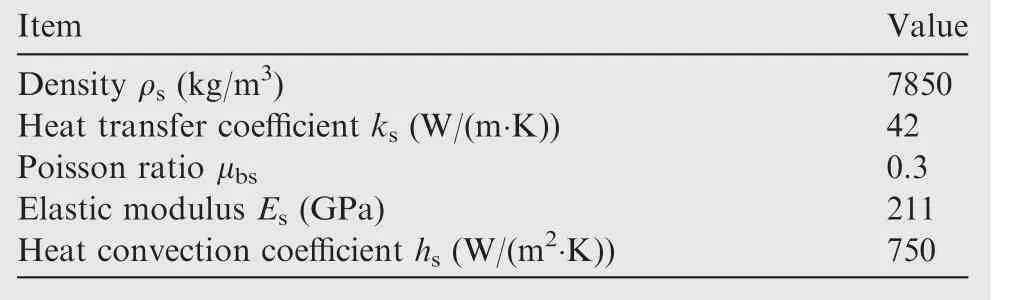

Table 2 Mechanical properties of the bushing.

Table 3 Mechanical properties of the journal.

Table 4 Performance parameters of the lubricant.

The TEHD lubricating property of the misaligned hydrodynamic bearing with surface texture is investigated in detail,and the effects of surface texture parameters and journal misalignment on the bearing property are analyzed.The bushing is made of babbitt metal(ZChSnSb11-6)while the journal is made of alloy steel(40Cr),and their mechanical properties are listed in Table 2 and Table 3,respectively.Performance parameters of the lubricant are shown in Table 4,and structural and operating parameters of the journal bearing with texture are given in Table 5.

3.1.Influences of surface texture parameters on misaligned bearing performance

3.1.1.Surface texture location

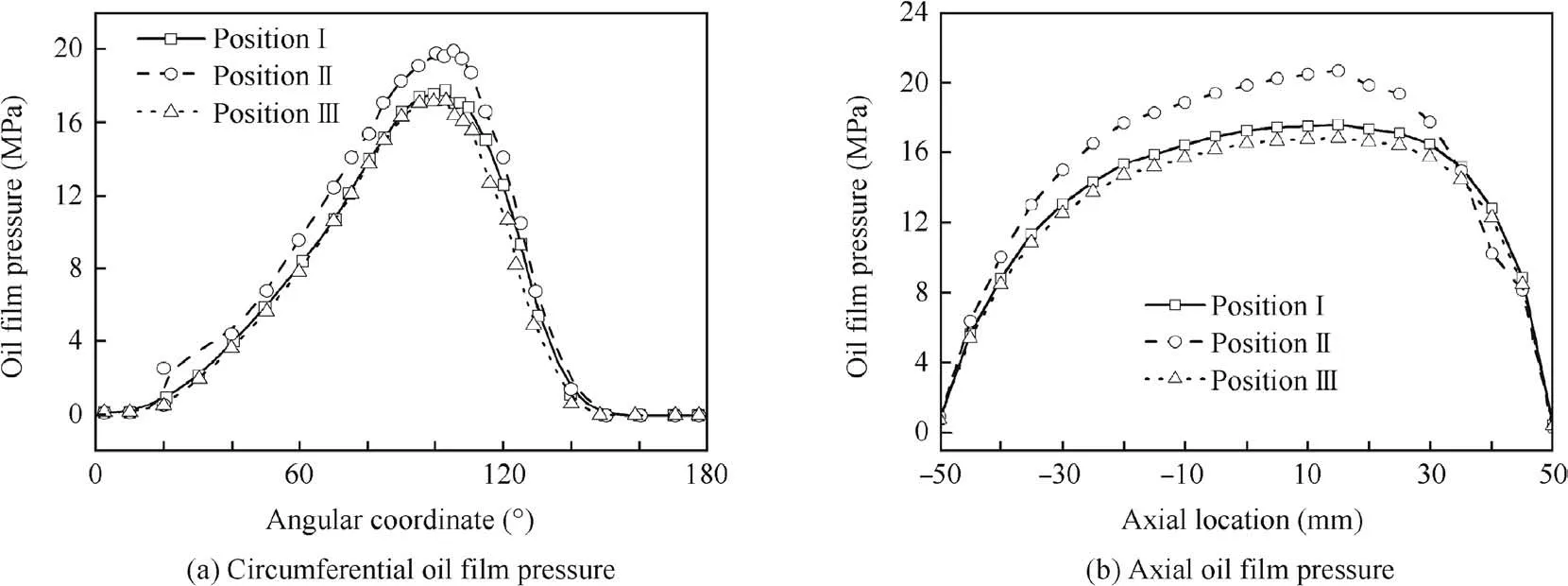

Under a condition with a texture extend of 40°and a misalignment angle of 0.003°,a bearing TEHD analysis is carried out in three texture locations shown in Fig.6.Positions I,II,and III are respectively located near the oil supply groove,the minimum film thickness region,and the oil film rupture region.The corresponding texture starting angles of the three locations are 40°,80°,and 120°.

Table 5 Structural and operating parameters of the journal bearing.

Fig.6 Surface texture circumferential locations.

Fig.7 shows the circumferential oil film pressure distribution in the cross section of z=0 and the axial oil film pressure distribution in the direction of the minimum film thickness when texture is located in the three locations.It is clear that the oil film pressure of the Position II condition is greater than those of others for not only the circumferential oil film pressure distribution but also the axial oil film pressure distribution. The result is consistent with the finding when misalignment is not considered in the literature 14,and it means that the journal bearing oil pressure and load-carrying capacity are enhanced when surface texture is arranged in the maximum oil film pressure region.This is because a greater oil film pressure enhances the back flow effect in dimples when dimples are located in the maximum oil film pressure region,so an additional hydrodynamic pressure is produced,and the load-carrying capacity of the journal bearing is greater.

Fig.7 Oil film pressure distribution under three texture locations.

Fig.8 shows the circumferential oil film temperature distribution in the cross section of z=0 and the axial oil film temperature distribution in the direction of the minimum film thickness when texture is located in the three locations.It is seen that the oil film temperature is 423 K.It means that the oil film temperature is violent when a TEHD analysis of the misaligned journal bearing is considered.It is clear that the oil film temperature of the Position II condition is lower than those of others for not only the circumferential oil film temperature distribution but also axial the oil film temperature distribution,which means that surface texture located in Position II can relieve the violent oil film temperature rise.Surface texture can result in sucking additional fluid into the lubricating film and store more heat so that the temperature rise is lower.In addition,the oil film temperature rise of the Position II condition is the most violent,so it is helpful to reduce the temperature rise when surface texture is located in Position II.

Fig.9 shows bushing and journal circumferential deformations distributions in the cross section of z=0 and axial deformation distributions in the direction of the minimum film thickness when texture is located in the three locations,and a negative sign represents compression deformation.Bushing and journal deformations of the Position II condition are greater than those of other cases due to an additional hydrodynamic pressure.In addition,journal deformation is less than bushing deformation because it has a greater elastic modulus and structural stiffness.

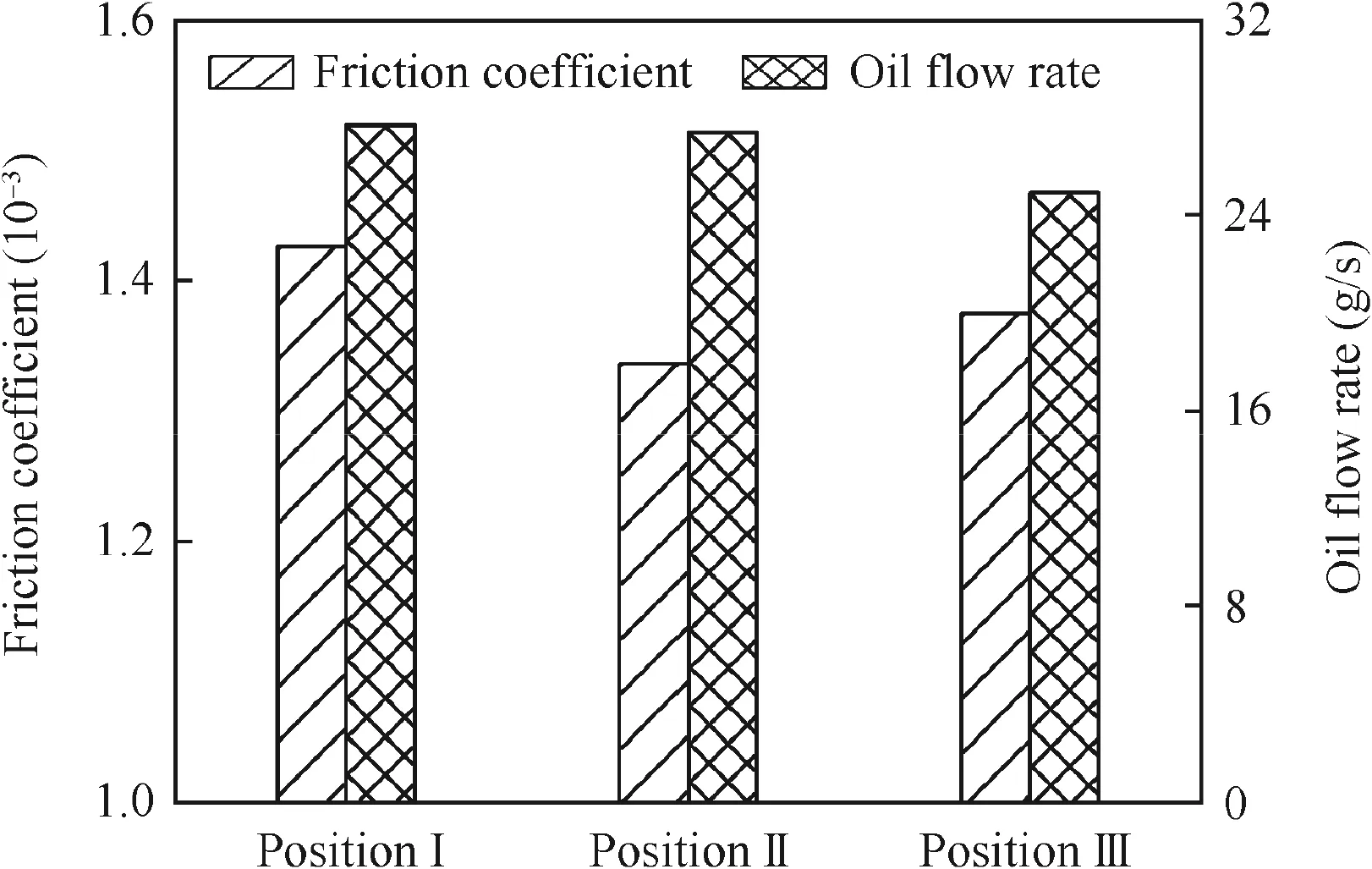

When texture is located in the three surface texture locations,the friction coefficient and oil flow rate of the misaligned journal bearing are shown in Fig.10.Surface texture locations have few effects on the oil flow rate of the journal bearing.Compared with Positions I and III conditions,the friction coefficient of the Position II condition is lower because the load-carrying capacity of Position II is the greatest,and the friction force has little change.

3.1.2.Surface texture extend

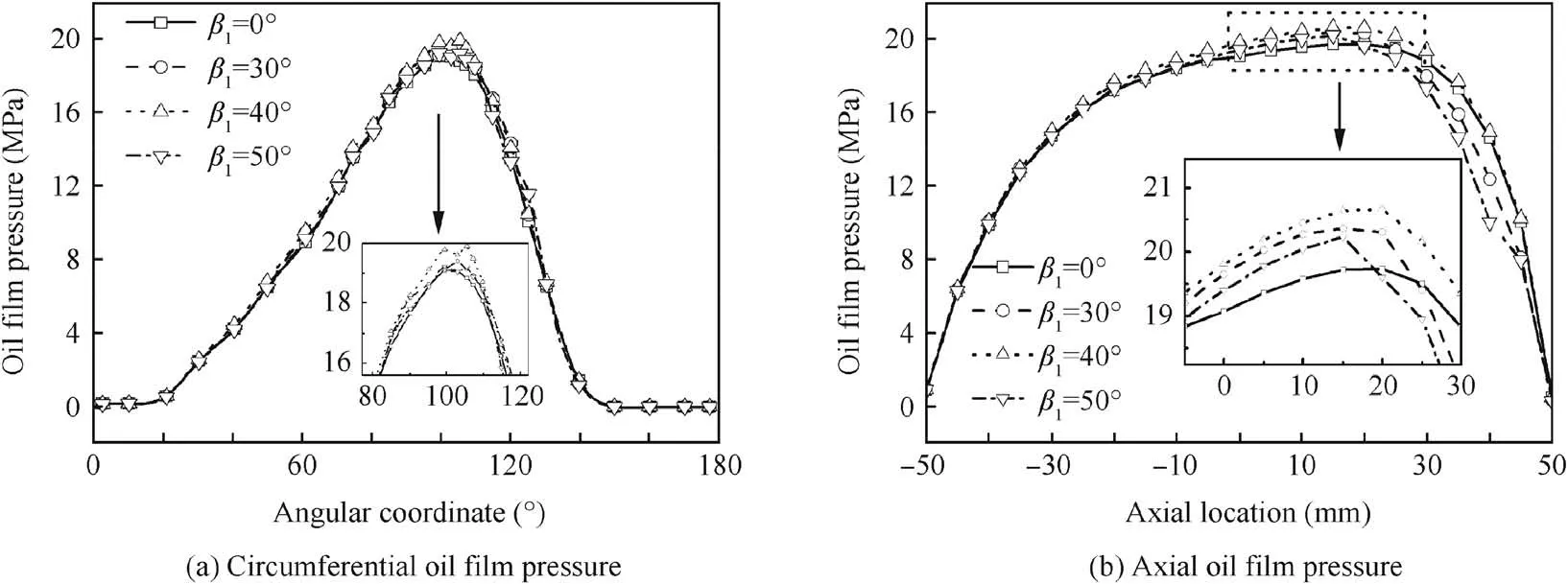

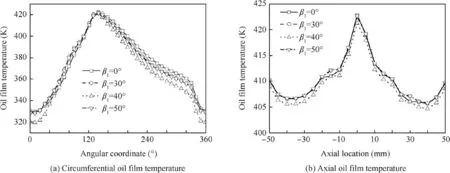

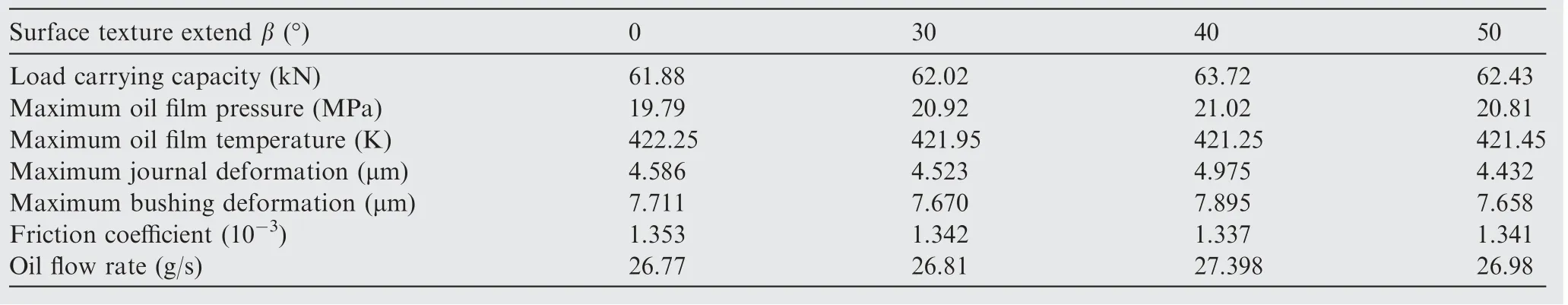

Besides the surface texture location,the surface texture extend also plays an important role in THED lubricating performance.Under a condition with a texture starting angle of 80°and a misalignment angle of 0.003°,a bearing TEHD analysis is carried out when the surface texture extend β is 0°,30°,40°,and 50°,and an un-textured bearing is adopted in the case of β=0°.

Fig.8 Oil film temperature distribution under three texture locations.

Fig.9 Deformation distributions of the journal and the bushing under three texture circumferential locations.

Fig.10 Friction coefficient and oil flow rate of the journal bearing under three texture locations.

Fig.11 shows the circumferential oil film pressure distribution in the cross section of z=0 and the axial oil film pressure distribution in the direction of the minimum film thickness under four kinds of surface texture extend.Compared with the un-textured bearing,the oil film pressure of the textured journal bearing increases for not only the circumferential oil film pressure distribution but also the axial oil film pressure distribution,which is related to the back flow effect in dimples.It is clear that the oil film pressure of the β=40°condition is greater than those of other cases.This is because when the texture extend is smaller,the back flow effect in dimples is not significant.When the texture extend is larger,texture expands to the oil film rupture region so that the oil film ruptures quickly.

Fig.12 shows the circumferential oil film temperature distribution in the cross section of z=0 and the axial oil film temperature distribution in the direction of the minimum film thickness under four kinds of surface texture extend.Compared with the β=0° condition, oil film temperatures of β=30° and β=50°conditions have little change,but the oil film temperature of the β=40°condition decreases.It is because when the texture extend is smaller,the increased heat capacity is limited.When the texture extend is larger,the lubricant heat capacity increases,but the lubricant releases more heat during oil film rupturing,so the positive influence is offset.

Fig.11 Oil film pressure distribution under four kinds of texture extend.

Fig.12 Oil film temperature distribution under four kinds of texture extend.

Fig.13 Deformation distributions of the journal and the bushing under four kinds of texture extend.

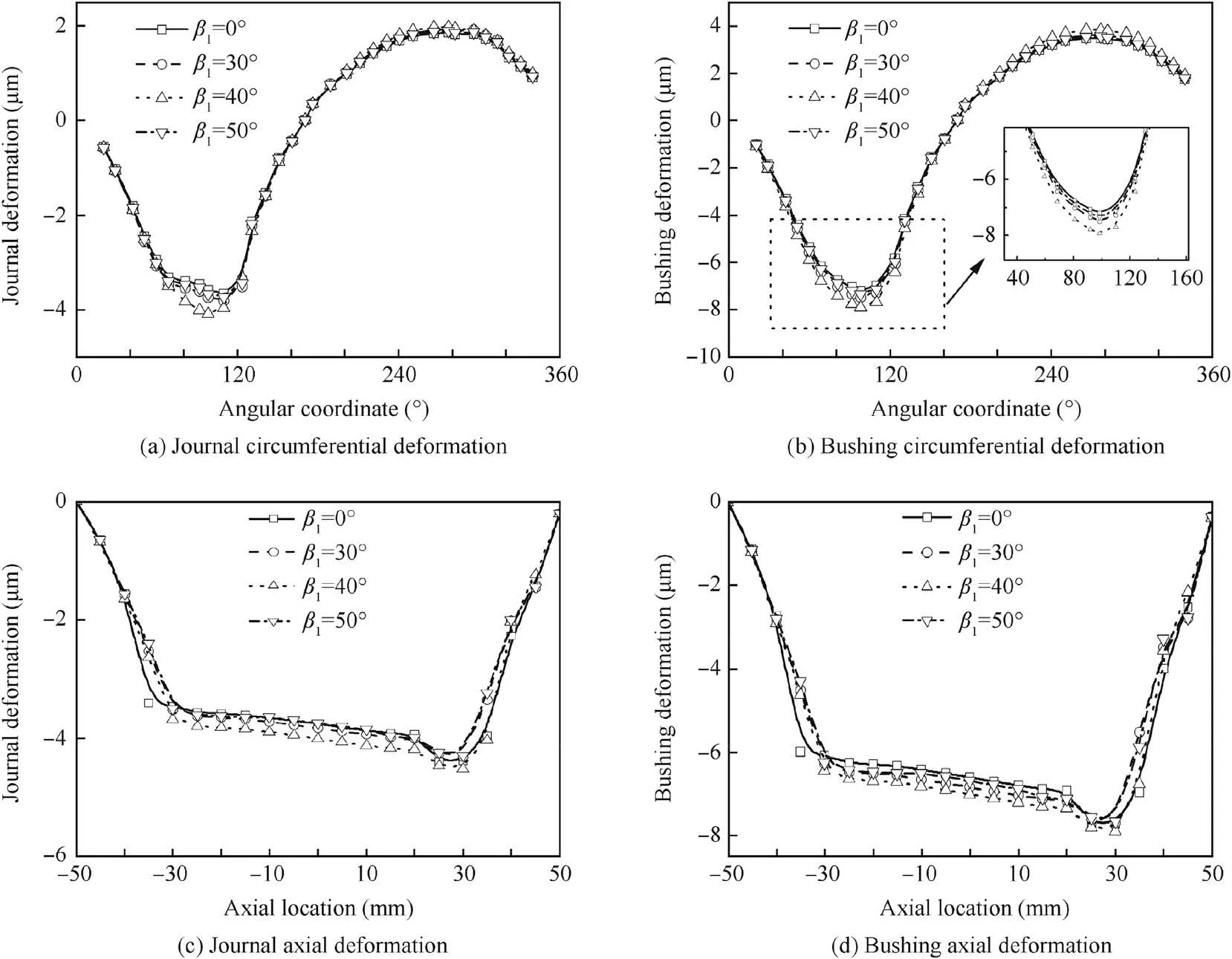

Fig.13 shows bushing and journal circumferential deformation distributions in the cross section of z=0 and axial deformation distributions in the direction of the minimum film thickness under four kinds of surface texture extend.Compared with β=0°,30°,and 50°conditions,bushing and journal deformations of the β=40°condition are greater as a result of a greater oil film pressure.In addition,journal deformation is less than bushing deformation because it has a greater elastic modulus and structural stiffness.

Table 6 shows the bearing TEHD performance under four kinds of surface texture extend. Compared with the untextured journal bearing,surface texture is still efficient for increasing the maximum oil film pressure and load-carrying capacity of the bearing and decreasing the maximum oil film temperature and friction coefficient, especially for the β=40°condition.It is also noted that the oil flow rate is maximum when the texture extend is 40°.This is because a greater oil film pressure promotes oil flow.

Table 6 Bearing TEHD performance under four kinds of texture extend.

Fig.14 Oil film pressure distribution under three kinds of misalignment angle.

Fig.15 Oil film temperature distribution under three kinds of misalignment angle.

3.2.Influence of the misaligned journal on textured bearing performance

According to the above analyses,the texture location and extend both make great impacts on bearing THED lubricating properties.Thus the effects of misalignment on bearing THED lubricating properties are analyzed necessarily when surface texture exists.Under a condition with a texture starting angle of 80°and a texture extend of 40°,a bearing TEHD analysis is carried out when the misalignment angle α is 0°,0.003°,and 0.005°.

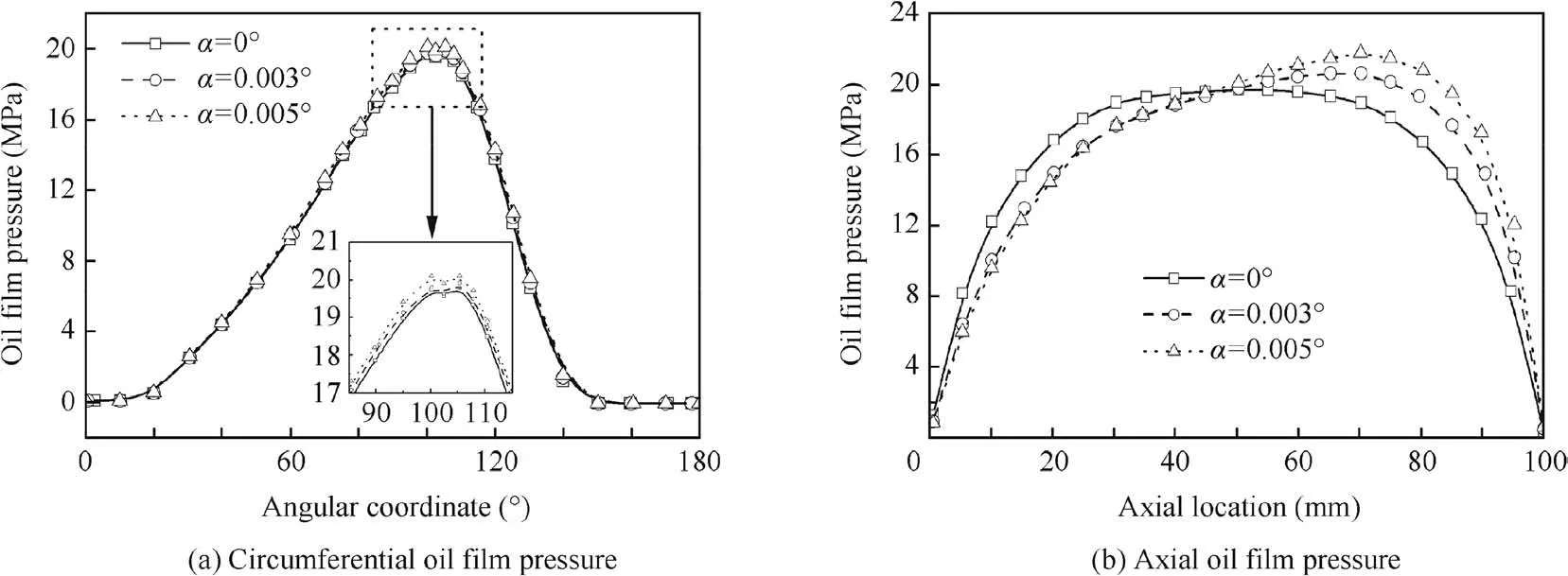

Fig.14 shows the circumferential oil film pressure distribution in the cross section of z=0 and the axial oil film pressure distribution in the direction of the minimum film thickness under three kinds of misalignment angle.Compared with the α=0°condition,circumferential oil film pressure distributions slightly increase when misalignment occurs.However,axial oil film pressure distributions have major changes with the misalignment angle increasing.The oil film pressure tilts to one side of the journal bearing,but that on the other side decreases,and the trend is more pronounced with misalignment increasing.Journal misalignment makes the oil film thin and the oil flow rate increasing so that a hydrodynamic pressure is promoted.

Fig.16 Deformation distributions of the journal and the bushing under three kinds of misalignment angle.

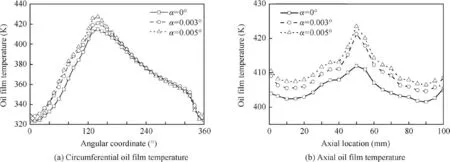

Fig.15 shows the circumferential oil film temperature distribution in the cross section of z=0 and the axial oil film temperature distribution in the direction of the minimum film thickness under three kinds of misalignment angle.Compared with the α=0°condition,the oil film temperature of the journal bearing increases with the misalignment angle increasing for not only the circumferential oil film temperature distribution but also the axial oil film temperature distribution,which is because the frictional resistance increases and the oil film temperature is promoted when misalignment exists.In addition,oil film temperature distributions do not tilt,because though misalignment makes the heat capacity of the oil film decrease,an increasing oil flow rate promotes a heat exchange between the oil film and the bearing.

Fig.16 shows bushing and journal circumferential deformation distributions in the cross section of z=0 and axial deformation distributions in the direction of the minimum film thickness under three kinds of misalignment angle.Bushing and journal deformations increase and tilt with the misalignment angle increasing due to a greater oil film hydrodynamic pressure.In addition,journal deformation is similarly less than bushing deformation because it has a greater elastic modulus and structural stiffness.

The friction coefficient and oil flow rate of the misaligned journal bearing under three kinds of misalignment angle are shown in Fig.17.The friction coefficient of the journal bearing increases with the misalignment angle increasing.It is because the frictional resistance increases greatly though the loadcarrying capacity is greater when misalignment exists,and the ratio of friction resistance and load-carrying capacity increase finally.In addition,the oil flow rate has the same trend because misalignment exists.

Fig.17 Friction coefficient and oil flow rate of the journal bearing under three kinds of misalignment angle.

4.Conclusions

A THED lubricating model considering a misaligned journal under high speed and heavy load is proposed in the paper.The impacts of the surface texture location,texture extend,and misalignment on lubricating properties are discussed based on the model.Then main conclusions of the research are as follows.

(1)The effects of surface texture under a misaligned journal bearing on lubricating performance are investigated in the paper.Surface texture can promote an oil film pressure,increase the load-carrying capacity of the bearing,increase the oil flow rate,lower the oil film temperature,and reduce the friction coefficient,so lubricating properties of the misaligned journal bearing with surface texture are improved.However,surface texture also produces greater deformations of the journal and the bushing.

(2)Surface texture parameters have obvious influences on lubricating properties of the journal bearing.Surface texture with an optimal design can improve bearing lubricating properties in the maximum level.As far as structural and operating parameters of the bearing in the paper are concerned,it is optimal that surface texture is located in the minimum oil film thickness region,and the texture extend is 40°.

(3)Considering that misalignment easily occurs under heavy load,the impacts of misalignment on TEHD lubricating properties are investigated.Though journal misalignment can improve the maximum oil film pressure and load-carrying capacity of the journal bearing,it also increases the maximum oil film temperature due to friction resistance.In addition,the oil film pressure distribution,bushing deformation,and journal deformation all tilt when journal misalignment occurs.

Acknowledgements

This study was co-supported by the National Natural Science Foundation of China(No.51505384)and the Natural Science Foundation of Shaanxi Province of China(No.2017JM5032).

杂志排行

CHINESE JOURNAL OF AERONAUTICS的其它文章

- Guide for Authors

- Effect of W addition on phase transformation and microstructure of powder metallurgic Ti-22Al-25Nb alloys during quenching and furnace cooling

- Role of the inter-pass cooling rate in recrystallization behaviors of Ni-based superalloy during interrupted hot compression

- Crystal orientation and morphology of α lamellae in wrought titanium alloys:On the role of microstructure evolution in β processing

- Three-dimensional finite-time cooperative guidance for multiple missiles without radial velocity measurements

- Data-driven model-free adaptive attitude control of partially constrained combined spacecraft with external disturbances and input saturation