Effects of Seaweed Extracts on Promoting Growth and Improving Stress Resistance in Sugarcane

2019-05-24DiwenCHEN1YingHUANG1DachunSHEN1WenlingZHOU1JunhuaAO1YongJIANG1ZhenruiHUANG2HassanMunirFahdRasul

Diwen CHEN1*, Ying HUANG1, Dachun SHEN1, Wenling ZHOU1, Junhua AO1, Yong JIANG1, Zhenrui HUANG2, Hassan Munir, Fahd Rasul

1. Guangdong Bioengineering Institute (Guangzhou Sugarcane Industry Research Institute)/Guangdong Key Lab of Sugarcane Improvement & Bio-refinery, Guangzhou, China 510316; 2. Crops Research Institute, Guangdong Academy of Agricultural Sciences, Guangzhou,China 510640; 3. Department of Agronomy, University of Agriculture, Faisalabad, Pakistan 38040

Abstract A field investigation was executed in sugarcane producing area of Zhanjiang, Guangdong Province with YT03-373 as the test variety to understand the possible impacts of seaweed extracts on phenology, yield and quality attributes of sugarcane. Foliar application of seaweed extracts were carried out on sugarcane at seedling and tillering stages. Agronomic traits, yield, sugar content, leaf drought resistance and pest resistance of sugarcane were analyzed for optimization of application time at proper phenological stages. The results that compared to the control, the application of seaweed extracts at different stages of sugarcane enhanced production of sugarcane with increase rate of 10.83%-12.87%, and improved theoretical sugar yield of sugarcane up to 1.9 t/ha while enhancing water retention capacity and water content of sugarcane leaves that consequently led to wilting risk reduction by escaping drought and improved resilience to drought impact on sugarcane. Seaweed extracts also performed excellent in pest management of sugarcane, and they exerted different control effects on sugarcane borers, aphids and thrips. An increase in output of sugarcane was observed to be 15.09% compared to control, while the net income was improved by up to 32.64% in the seaweed extracts application treatment. Foliar application of seaweed extracts not only enhanced growth, cold resistance, pest resistance, output value but also improved economic returns, giving a positive affirmation for the recommendation of seaweed extract application.

Key words Seaweed extracts, Foliar application, Sugar recovery, Drought resistance, Pest resistance

1 Introduction

Seaweed extracts, also known as seaweed bio-stimulants, are one of the eight major classes of bio-stimulants. They are a class of substances with biological activity extracted from seaweed[1]. In addition to mineral nutrients, they also contain seaweed polysaccharides, sugar alcohols, amino acids, vitamins, betaines and phenolic compounds, as well as natural hormones (e.g. auxins, cytokinins and abscisic acid)[2]. They have been widely utilized in the chemical, food, medicine and agriculture industries across the world[3-6]. As one type of biostimulants, seaweed extracts not only improve soil[7-8], plant growth and development[9-11]but also improve the resistance of crops to pests, drought, diseases and stresses[12-14]. At present, research on application of seaweed extracts in crops such as maize[15-16]has been conducted worldwide and good results have been achieved. Sugarcane, as the most important sugar crop in China played a positive role for ensuring the supply of sugar and income of farmers. Sugarcane is mostly planted in the dry sloping land lacking irrigation in the southern part of China, and often suffers from seasonal drought. In addition, the problem of sugarcane pests had become increasingly serious in recent years, which had an adverse effect on yield and sugar content of sugarcane[17]. Studies have explicated that the application of seaweed extract containing seaweed active substances has certain prevention and control effects on late blight, leaf mold, root rot, gray mold and virus in tomato. In particular, it has stern control on soil-borne diseases[18]. The active substances isolated by Argandoaetal.[19]fromPlocamiumcartilagineumhave antifeedant effects on different insects such as potato beetles, strong repellent effect on peach aphids, and selective cytotoxicity against ovarian tissue cells ofSpodopterafrugiperda. An acyclic diterpenoid has been isolated fromSargassum, and it can also inhibit insect growth[20]. In addition, seaweed extracts have a significant effect on improving drought resistance of crops. It has been currently reported that seaweed extracts can improve the drought resistance of crops such as wheat[21], tomato[22]and tobacco[23]. Studies on sugarcane seedlings have shown that seaweed extracts can promote the growth of sugarcane[24]. Application of seaweed extracts under drought stress can elevate the activity of antioxidant enzymes such as POD, SOD and CAT, decrease the MDA content, conductivity and dehydration rate of leaves, significantly increase the relative water content, and relieve drought stress damage, thus increasing plant height and biomass of sugarcane[25]. However, there has been limited reports on the application of seaweed extracts in sugarcane field production. This study has been planned therefore to evaluate seaweed extracts in sugarcane field production. Sugarcane leaves were sprayed with unmanned aerial vehicle (UAV)-agricultural drone with spraying capability to investigate the effects on growth, yield, sugar content, drought resistance and insect resistance of sugarcane to quantify the efficacy of seaweed extracts application for sustainable sugarcane production.

2 Materials and methods

2.1 Test site and materialsThe test site was selected in Yangqing Town (21°19′28.61″ N, 110°03′39.57″ E), Suixi County, Zhanjiang City, Guangdong Province. It is located in Leizhou Peninsula and belongs to the core sugarcane-producing area in western Guangdong. It belongs to subtropical climate with frequent occurrence of seasonal droughts and pests. The sugarcane variety tested was Yuetang 03-373. The test soil was latosol with pH of 5.24, total nitrogen of 0.98 g/kg, total phosphorus of 0.68 g/kg, total potassium of 1.38 g/kg, available phosphorus of 54.84 mg/kg, available potassium of 104.57 mg/kg, and organic matter of 12.74 g/kg. The test fertilizers included urea (46% N, Luxi Chemical Group Co., Ltd.) and compound fertilizer (N∶P2O5∶K2O=20∶10∶15, Shenzhen Batian Ecological Engineering Co., Ltd.). The pesticide used in the test was monosultap carbofuran 3% granules (Hubei Qinong Chemical Co., Ltd.).

2.2 Test designTotal four treatments were designed: CK, conventional planting, no application of seaweed extracts; T1, conventional planting + application of sea weed extracts at 3 kg/ha in seedling stage; T2, conventional planting + application of seaweed extract at 3 kg/ha in tillering stage; T3, conventional planting + application of seaweed extracts at 3 kg/ha in seedling and tillering stages, respectively. There were three repetitions for each treatment. Thus, a total of 12 plots were arranged. There were 8 rows (length 20 m, width 1.1 m) in each sub plot, and the area of each sub plot was 176 m2. The test sugarcane was planted on February 15, 2017. It was applied with 300 kg/ha of compound fertilizer as base fertilizer, 75 kg/ha of pesticide, and 30 kg/ha of seaweed extracts (diluted with water, sprayed by drone). On April 6, 2017, spraying of seaweed extracts at seedling stage (T1 and T3) was carried out. On May 18, 2017, spraying of seaweed extracts at tillering stage (T2 and T3) was carried out. In addition, top dressing was carried out with 1 200 kg/ha of compound fertilizer and 300 kg/ha of urea. Other daily management was consistent with field production. The sugarcane was harvested on January 30, 2018.

2.3 Determined indicators and methodsAt the elongation stage of sugarcane, three plants were selected randomly from each plot on August 12, 2017. The 1st, 2nd and 3rd leaves from bottom of each plant were collected for analysis of water-related parameters. For the determination ofinvitrodehydration rate, the fresh weight of the 1st leaf from bottom (W1) was weighed first. After placed at room temperature for 12 h, the weight of the 1st leaf from bottom (W2) was weighed again. Theinvitrodehydration rate was calculated according to Formula (1)[26]. The relative water content (RWC) was determined by saturated weighing method[26]. The fresh weight of the 2nd leaf from bottom (Mf) was weighed immediately after picked off. Then, it was immersed in distilled water for 4 h. After taken out from the water, the water on the surface of the leaf was wiped off. The saturated weight of the leaf (Mt) was weighed. Then, the leaf was dried at 105℃ for 30 min and at 70℃ till constant weight. The dry weight of the leaf (Md) was weighed. The relative water content was calculated according to Formula (2). For determination of electrical conductivity (EC), the 3rd leaf from bottom was cut off. A certain amount (0.5 g) of the leaf pieces was immersed in 25 mL of pure water (32℃) for 2 h. The original electrical conductivity was measured with a conductivity meter. Then, the leaf pieces were bathed in boiling water for 20 min, and the total electrical conductivity was measured. The electrical conductivity (EC) was calculated according to Formula (3).

On December 28, 2017, the plant height, millable cane number and steam diameter of sugarcane were measured and counted. At harvest, the yield of sugarcane was measured. Total six plants were selected randomly from each plot, and the cane stems were mixed and squeezed into juice for analysis of sugar content.

For the investigation and analysis of control efficacy for borers, on May 27, the total number of seedlings and the number of dead seedlings in each plot were counted, and the heart beat loss of borers was calculated according to Formula (4). On July 12, the number of aphids and the number of plants infected with aphids in each plot were counted, and the relative control efficiency for aphids was calculated according to Formula (5)[27]. On July 22, the number of rolled leaves and the number of total plants investigated in each plot were counted, and the leaf rolling rate and relative control efficacy for thrips were calculated according to Formula (6) and Formula (7), respectively[28].

Invitroleaf dehydration rate (%) = (W1-W2)/Dehydration time×100%

(1)

RWC(%)=(Mf-Md)/(Mt-Md) ×100%

(2)

EC(%)=Original electrical conductivity/Total electrical conductivity ×100%

(3)

Heart beat loss of borers (%) = Number of dead seedlings/Total number of seedlings investigated ×100%

(4)

Relative control efficacy for aphids (%) = (Number of plants infected with aphids in the control group-Number of plants infected with aphids in the treatment group)/Number of plants infected with aphids in the control group ×100%

(5)

Leaf rolling rate (%) = Number of rolled leaves/Number of plants investigated ×100%

(6)

Relative control efficacy for thrips (%) = (Leaf rolling rate in the control group-Leaf rolling rate in the treatment group)/Leaf rolling rate in the control group ×100%

(7)

2.4 Data collection and processingThe means and standard deviations of the test data were calculated using Microsoft®Excel 2010, and Duncan’s multiple range tests were performed using SPSS 19.0 statistical software.

3 Results and analysis

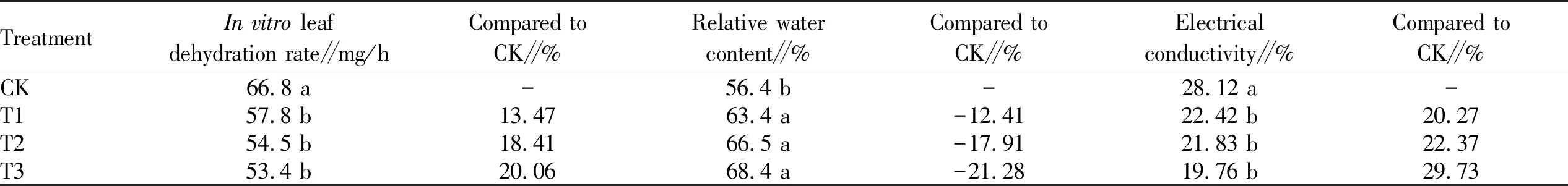

3.1 Effects of different treatments on leaf water parameters and EC of sugarcane seedlingsAs shown in Table 1, theinvitroleaf dehydration rates of the three seaweed extracts treatment groups were lower than that of the control group by 13.47%-20.06% (P<0.05). There were no significant differences between the three seaweed extracts treatment groups (P>0.05). The RWCs of the three seaweed extracts treatment groups were higher compared to the control group by 12.41%-21.28% (P<0.05). The ECs of the three seaweed extracts treatment groups were lower than that of the control group by 20.27%-29.73% (P<0.05). These results indicated that after sprayed with seaweed extracts, the leaves of sugarcane showed stronger water retention capacity and higher water content, thereby reducing the damage caused by drought and improving the drought resistance of sugarcane.

Table 1 Effects of different treatments on leaf water parameters and electrical conductivity of sugarcane

TreatmentIn vitro leafdehydration rate∥mg/hCompared toCK∥%Relative watercontent∥%Compared toCK∥%Electricalconductivity∥%Compared toCK∥%CK66.8 a-56.4 b-28.12 a-T157.8 b13.4763.4 a-12.4122.42 b20.27T254.5 b18.4166.5 a-17.9121.83 b22.37T353.4 b20.0668.4 a-21.2819.76 b29.73

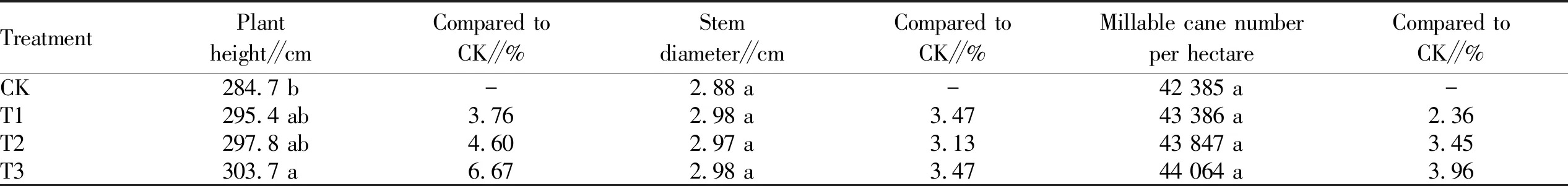

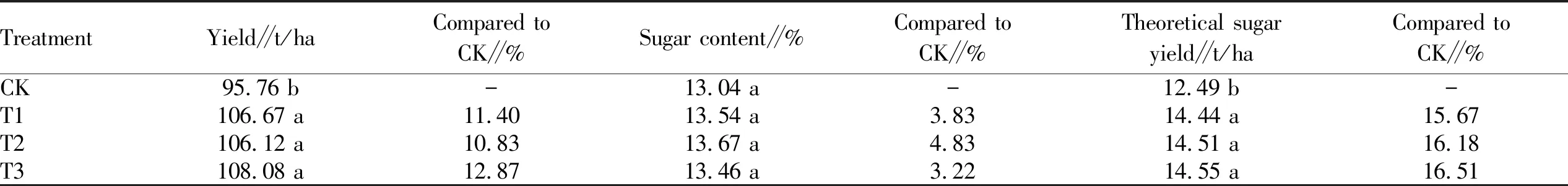

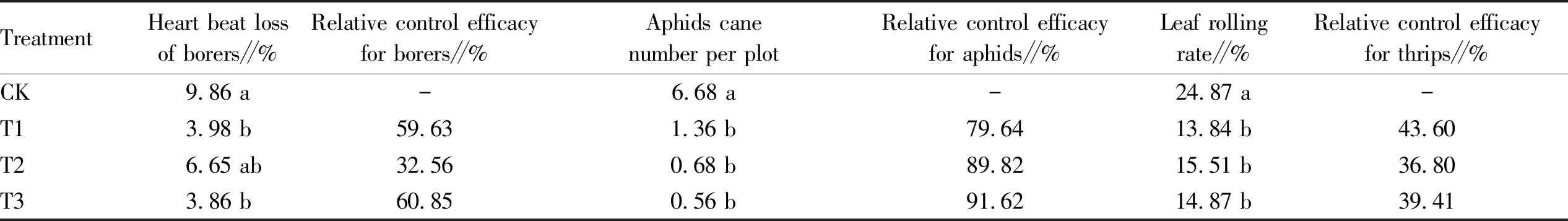

Note: Different lowercase letters in the same column indicate significant differences at the 0.05 level. The same below.

3.2 Effects of different treatments on agronomic traits of sugarcaneAs shown in Table 2, the plant height of sugarcane differed among different treatments. After spraying seaweed extracts, the plant height of sugarcane increased to a certain extent. Among them, T1 and T2 increased by 3.76% and 4.60%, respectively. However, they showed no significant differences compared with the control group (P>0.05). The plant height of sugarcane in the T3 group was significantly higher than that of the control group (by 6.67%,P<0.05). The stem diameter of sugarcane also increased after the application of seaweed extracts. The increase ranged from 3.53% to 5.30%, but the statistical difference between the two was not significant (P>0.05). After applying seaweed extracts, the millable cane number increased by more than 1 000/ha, and the increase was around 3%. There was no significant statistical difference between the two (P>0.05).

Table 2 Effects of different treatments on agronomic traits of sugarcane

TreatmentPlantheight∥cmCompared toCK∥%Stemdiameter∥cmCompared toCK∥%Millable cane numberper hectareCompared toCK∥%CK284.7 b-2.88 a-42 385 a-T1295.4 ab3.76 2.98 a 3.47 43 386 a2.36T2297.8 ab4.60 2.97 a 3.13 43 847 a3.45T3303.7 a6.67 2.98 a 3.47 44 064 a3.96

3.3 Effects of different treatments on yield and sugar content of sugarcaneAs shown in Table 3, compared with the control group, the yields of sugarcane in the seaweed extracts application groups increased significantly (P<0.05). The yields of sugarcane in the T1, T2 and T3 groups were 10.92, 10.37 and 12.33 t/ha respectively higher than that of the control group, with increase of 10.83%-12.87%. The application of seaweed extracts elucidated little effect on sugar content of sugarcane, and no significant difference was found between the treatments. The theoretical sugar yield is the product of sugar and yield. Therefore, the theoretical sugar yields of the seaweed extracts application groups were higher than that of the control group by 15.67%, 16.18% and 16.51%, respectively, with increase more than 1.9 t/ha.

Table 3 Effects of different treatments on yield and sugar content of sugarcane

TreatmentYield∥t/haCompared toCK∥%Sugar content∥%Compared toCK∥%Theoretical sugaryield∥t/haCompared toCK∥%CK95.76 b-13.04 a-12.49 b-T1106.67 a11.4013.54 a3.8314.44 a15.67T2106.12 a10.8313.67 a4.8314.51 a16.18T3108.08 a12.8713.46 a3.2214.55 a16.51

3.4 Effects of different treatments on pest resistance of sugarcaneAs shown in Table 4, the spraying of seaweed extracts showed certain control effects for pests in sugarcane. The application of seaweed extracts reduced the dead heart rate of sugarcane caused by borers. Among the treatments, T1 and T3 had the best effect, and their heart beat losses of borers were significantly lower than that of the control effect, with relative control efficacy more than 59%. The control effect of T2 treatment that sprayed seaweed extracts at the tillering stage was unsatisfactory, and its heart beat loss of borers was insignificantly different from that of the control group. The numbers of sugarcane plants infected with aphids in the seaweed extracts application groups were significantly reduced compared with the control group. Among the treatment groups, T3 showed the beset effect, and its relative control efficacy reached 91.62%. The relative control efficacies of T1 and T2 treatments were also higher than 79%. It indicated that seaweed extracts had better effect on improving the resistance of sugarcane to aphids. In addition, seaweed extracts also had certain control effect for thrips. The leaf rolling rates of the treatment groups significantly declined compared to the control group, and the relative control efficacies ranged from 36.80% to 43.60%. Therefore, the application of seaweed extracts had a certain effect on improving the pest resistance of sugarcane.

Table 4 Pest control efficacies of different treatments for sugarcane

TreatmentHeart beat lossof borers∥%Relative control efficacyfor borers∥%Aphids canenumber per plotRelative control efficacyfor aphids∥%Leaf rollingrate∥%Relative control efficacyfor thrips∥%CK9.86 a-6.68 a-24.87 a-T13.98 b59.631.36 b79.6413.84 b43.60T26.65 ab32.560.68 b89.8215.51 b36.80T33.86 b60.850.56 b91.6214.87 b39.41

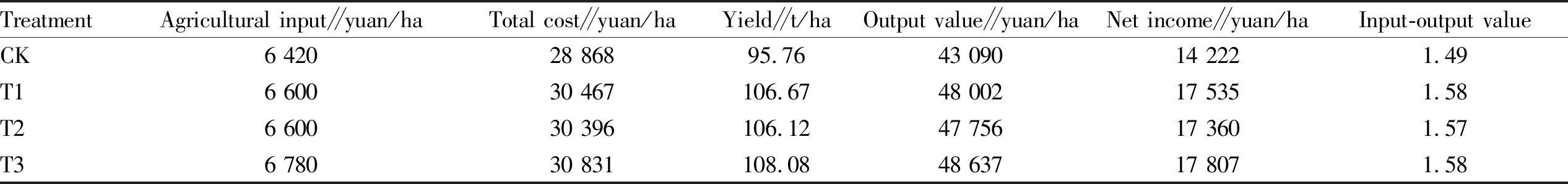

3.5 Effects of different treatments on production cost and economic benefit of sugarcaneThe production costs and economic benefits of sugarcane in different treatments have been shown in Table 5. The application of seaweed extracts added a small amount of cost to agricultural inputs. At the same time, the total cost increased due to the increased cutting cost caused by increased output, and the total costs of the treatment groups were increased by 5.30%-6.80% compared with the control group. The increase in output led to an increase in output value and net income. Compared with the control group, the output values of T1, T2 and T3 groups were increased by 15.68%, 15.09% and 17.21%, respectively, and their net incomes were increased by 33.98%, 32.64% and 36.05%, respectively. The output-input ratios of the seaweed extracts application groups were also improved compared to the control group.

Table 5 Effects of different treatments on production cost and economic benefit of sugarcane

TreatmentAgricultural input∥yuan/haTotal cost∥yuan/haYield∥t/haOutput value∥yuan/haNet income∥yuan/haInput-output valueCK6 42028 86895.7643 09014 2221.49T16 60030 467106.6748 00217 5351.58T26 60030 396106.1247 75617 3601.57T36 78030 831108.0848 63717 8071.58

Note: The costs of urea, compound fertilizer, seaweed extracts and artificial cutting were 1 900 yuan/ha, 3 400 yuan/ha, 180 yuan/time/ha, and 130 yuan/t, respectively. Other costs were assigned as 10 000 yuan/ha. The purchase price of sugarcane in the output value was assigned as 450 yuan/t.

4 Discussions

According to the European Biostimulants Industry Council (EBIC), biostimulants are a class of substances that contain functional substances or microorganism and their secondary metabolites, which They can increase crop nutrient absorption, enhance nutrient use efficiency, improve crop stress resistance and improve crop quality[29]. Biostimulants are generally classified into eight categories: humic acids, compound organic matter, beneficial chemicals, non-organic minerals, seaweed extracts, chitins, anti-transpiration agents and free amino acids. At present, the application and research of humic acids, amino acids and seaweed extracts are more in-depth. Most of the seaweed extracts on the market are produced by physical, chemical and biological treatments of brown algae, focus, kelp andSargassum. The products are processed into liquid or power. They can be applied directly or in combination with other pesticides, fertilizers,etc. The results of this study indicate that seaweed extracts are not only conducive to the growth and yielding of sugarcane, and they can also improve the drought resistance and pest resistance of sugarcane. On one hand, the application of seaweed extracts is beneficial to the growth of sugarcane, and the plant is stronger and stronger to enhance drought resistance and resist the bite of pests. On the other hand, seaweed extract itself has anti-feeding and avoidance effects on pests, which can effectively reduce the occurrence of pests. The application seaweed extracts as pesticides in agriculture has been received increasing attention. Crewsetal.[30]found that the extract ofPlocamiumtelfairiaehas strong inhibitory effect on tobacco hornworms and mosquito larvae, and its insecticidal effect exceeds thecartap hydrochloride.

China is an agricultural country with abundant seaweed resources. Therefore, the development and application prospects of seaweed extracts are very broad. Seaweed extract related products are now very common in China’s fertilizer market. They have been widely used in the production of different crops. Moreover, because of small use amount and significant growth-promoting effect, they are particularly popular in cash crops, especially fruit and vegetable crops. Different extraction methods and sources may lead to differences in active ingredients in seaweed extracts. The seaweed extracts used in this study were extracted from kelp by a special process, and they retained a high content of active ingredients. In this experiment, the UAV spraying technology characterized by very low input and obviously increased output was adopted, so better economic benefits are obtained. In view of the diversity of sugarcane varieties and the climate differences between different regions, more experiments will be carried out in different regions and sugarcane varieties in the future to verify the application effect of seaweed extracts in sugarcane.

5 Conclusions

The application of seaweed extracts at the seedling and tillering stages is beneficial to increase the yield, enhance the drought resistance and pest resistance, and increase the economic benefits of sugarcane, so it can be further tested and promoted in sugarcane production.

杂志排行

Asian Agricultural Research的其它文章

- Ridge Covering High-yield Cultivation Techniques of Jinhong Apple in Cold Region

- Different Fertilization Modes of Sugarcane in Latosolic Red Soil of Guangxi

- Rules of Changes in Soil Nutrients and Enzyme Activities of Larix principis-rupprechtii in Different Forest Ages

- Cultivation Countermeasures of Farmers’ Ecological Consciousness and Behavior in Eco-civilization Construction——A Case Study of Agricultural Waste Recycling

- Risk Assessment and Service Benefit Evaluation of Forestry Meteorological Disasters in Guangxi

- Survey on Factors Influencing the Decline in Chicken Consumption of Urban Residents in Liaoning Province