支毛管安装射流三通的滴灌系统水力性能研究

2019-05-24王新坤薛子龙肖思强樊二东徐胜荣张晨曦

王新坤,薛子龙,肖思强,樊二东,徐胜荣,王 轩,张晨曦

支毛管安装射流三通的滴灌系统水力性能研究

王新坤,薛子龙,肖思强,樊二东,徐胜荣,王 轩,张晨曦

(江苏大学国家水泵及系统工程技术研究中心,镇江 212013)

为分析脉冲水流对滴灌系统水力性能的影响规律,该文基于射流附壁和切换原理设计了一种支管射流三通,并与毛管射流三通开展组合试验。在毛管铺设长度为60 m,4种支管三通进口水头(9.5、12、14、15.5 m)条件下,研究支毛管安装射流三通或普通三通时灌水小区的灌水均匀度、脉冲频率与水头损失变化规律,并建立描述支管射流三通出口流量和压力的拟合关系式。结果表明,当支毛管三通均采用射流三通时,支毛管中均为间歇性脉冲水流,脉冲频率随支管进口水头增加而递增;毛管滴头流量在1.2~2.2 L/h之间,沿程水头损失在0.9~1.6 m之间;灌水均匀性系数在95.88%~98.56%之间,流量偏差率在8.35%~15.14%之间,灌水均匀度最高。根据研究结果,确定了灌水小区中支毛管三通的最优组合方式,可为射流技术在脉冲滴灌系统的研究、开发与应用提供理论依据。

压力;流量;射流三通;水力性能;支毛管;均匀度;脉冲频率;水头损失

0 引 言

滴灌是一项较为成熟的灌水技术[1-3],利用安装在毛管上的滴头、孔口、滴灌带上的滴头等不同形式的灌水器,灌溉水沿着灌水器均匀、缓慢的滴入作物根区[4],具有节水、节肥、节约劳动力的优点[5]。由于滴灌工作水头(10 m以下)较低,水流在滴灌带及灌水器流道内的流速较缓,杂质容易沉淀在滴灌带内,水中较小颗粒也易堵塞灌水器流道,影响灌水器的灌水均匀性[6-7]。为提高低压滴灌抗堵性能和灌水均匀性,徐尧权等[8-10]提出了脉冲滴灌技术。脉冲滴灌技术工作原理是在毛管中提供间歇性供水,产生的水流具有周期性且脉冲动能大的特点,水流能对滴灌带和灌水器流道起到冲刷作用,具有抗堵塞能力强,灌水均匀度高的特点[11-13]。杨玉超等[14]对比了35~80 kPa工作压力下,射流脉冲三通与普通三通的水流振幅、脉冲频率、灌水均匀性与流量偏差率。肖思强等[15]对不同滴灌带长度和进口水头下射流三通与普通三通的灌水均匀系数和流量偏差率进行了研究。目前对滴灌灌水器堵塞类型、形成机理及防治措施方面的研究较多[16-18],毛管水力设计方法的研究较为成熟[19-22],但未有支管与毛管的射流三通组合试验研究。

因此本文基于射流附壁和切换原理设计了一种支管射流三通,与毛管射流三通组合,构建4种灌水小区,分析支毛管安装射流三通对脉冲水流灌水器水力性能的影响,旨在为射流技术在脉冲滴灌系统的研究、开发与应用提供理论依据。

1 材料与方法

1.1 试验装置

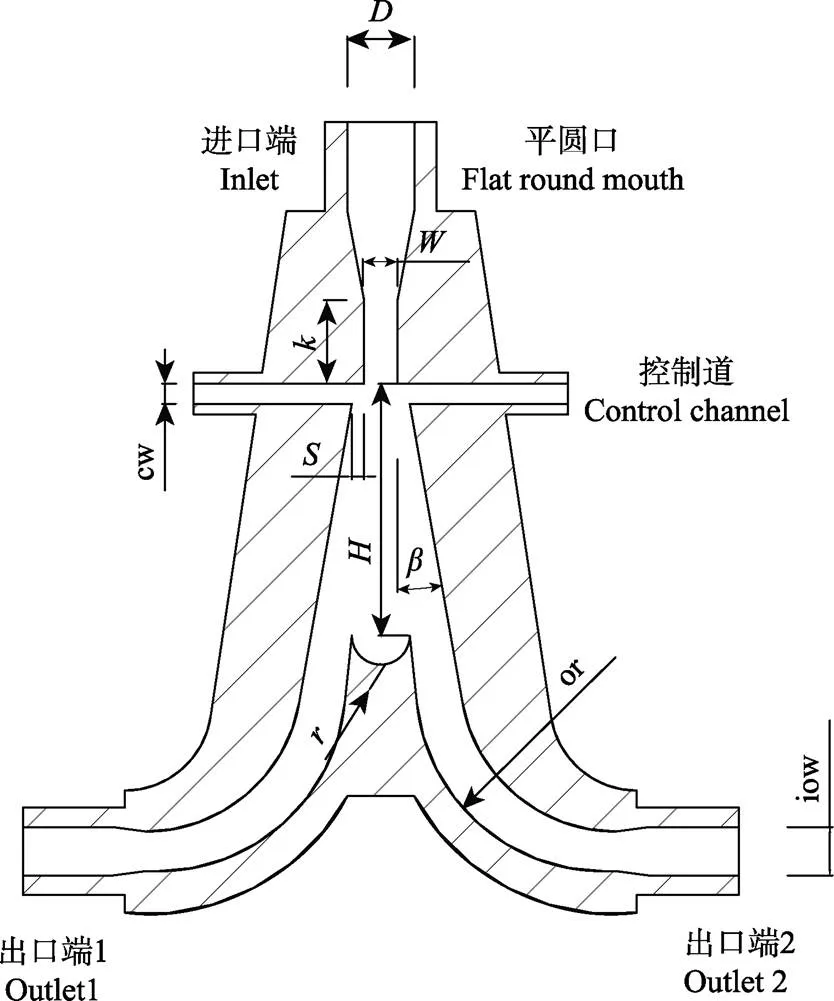

试验装置包括支管射流三通、毛管射流三通、普通三通、单相自吸泵、高速摄影相机、管路、涡流流量计、量筒、压力表与阀门等。支管射流三通由进水段、射流元件、出口段组成,其中射流元件是射流三通的核心部件[23]。射流元件包括收缩段、导流段、喷嘴、射流空间、左右侧壁、输出口、分流劈和左右输出道[22],如图1。射流三通利用射流附壁[24]及负载反馈切换技术[25-26]形成脉冲水流,从而实现水流在左右输出道之间的往复运动。工程应用时,射流三通的进水口与灌溉管路上游端相连,出水口与灌溉管路下游端相连。当灌溉管道中的压力水流通过进水段进入射流元件时,假设水流先附壁于左侧壁,由于射流存在卷吸作用[27-28],在左侧壁面产生低压涡流区。低压通过控制道传递到右侧壁,从而导致左右侧壁之间形成压力差,对射流产生向右的推力。当压力差达到一定程度时,射流发生偏转,附壁于右侧壁,并沿右侧壁下方的右输出道流出。同理,当水流附壁于右侧壁时,由于卷吸作用产生的压力差,射流向左偏转附壁于左侧壁。如此循环往复,分别在射流三通的左右输出道形成一定频率与振幅的脉冲水流,水流流出输出道进入滴灌带后,滴灌带内亦形成相同频率的脉冲水流。

注:D为进口内直径,mm;W为喷嘴宽度,mm;k为进口深度,mm;S为位差,mm;cw为控制道内直径,mm;H为劈距,mm;β为侧壁倾角,(°);r为劈尖半径,mm;or为外流道半径,mm;iow为出口内直径,mm。

本试验中普通支管三通采用内径32 mm的T型三通,普通毛管三通采用内径16 mm的T型三通,支管射流三通结构与毛管射流三通基本尺寸如表1所示。

表1 支管与毛管射流三通尺寸

1.2 试验方案与装置

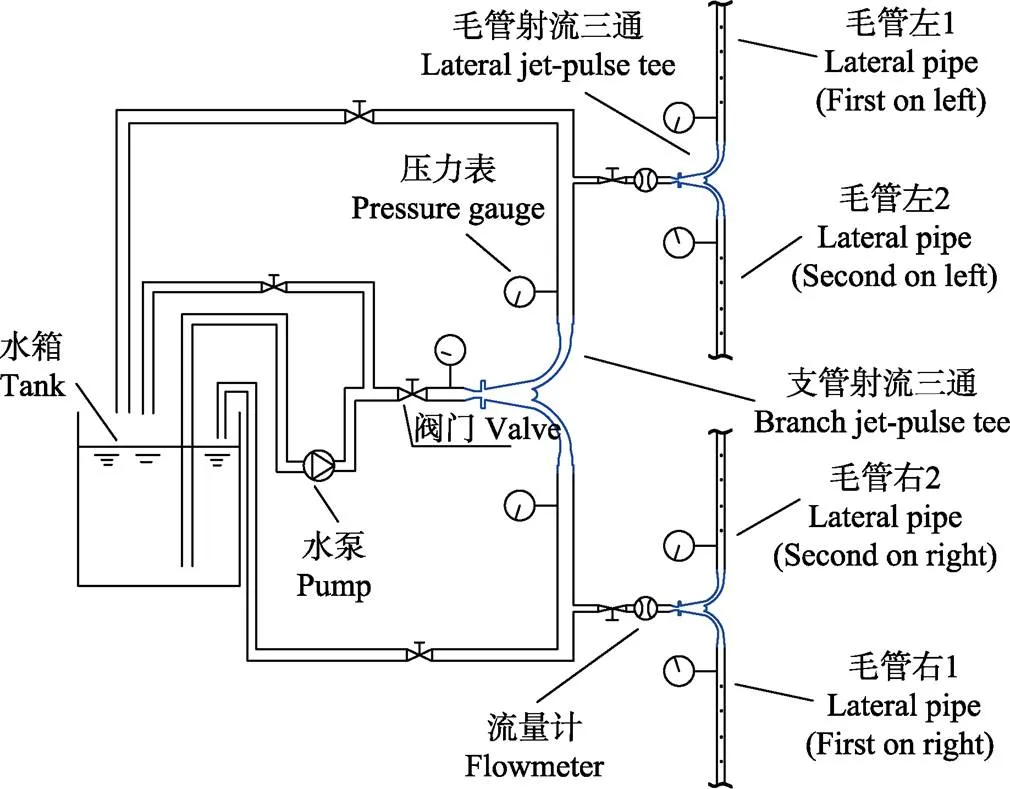

根据支毛管三通采用射流三通或普通三通的不同安装方式,构建了4种灌水小区,每个小区试验重复3次取平均值(I,支毛管均为射流三通;II,支管为射流三通、毛管为普通三通;III,支管为普通三通、毛管为射流三通;IV,支毛管均为普通三通)。小区毛管铺设长度为60 m,支管进口水头设定为9.5、12、14、15.5 m(对应毛管进口水头为6、8、10、12 m)。试验所用毛管为华维节水有限公司生产的内镶式滴灌带,滴头间距为30 cm,滴灌带内径16 mm,10 m额定水头下滴头流量为2.7 L/h,灌水器流量-压力关系式为=0.215P0.549(为滴头流量,L/h;P为滴头出水压力,kPa),试验装置如图2所示。

图2 灌水小区滴灌试验系统示意图

在不同支管进口水头进行试验,确定支管三通的进口水头和观察脉冲特性;选用OLYMPUS 生产的i-SPEED 3型摄像机(帧率10 000 f/s,焦距为50 mm)拍摄压力表指针摆动情况,记录脉冲频率与压力最值。试验时间为10 min,所有毛管每15个滴头设置1个流量监测点,监测点流量为左1和左2(或右1和右2)毛管相同位置滴头流量的平均值。在支管三通出口处安装流量计,支管三通出口流量由试验前后流量计数值的差值得出,灌水小区总流量为支管三通两侧出口流量之和。

1.3 滴灌灌水均匀性评价方法

灌水均匀系数与流量偏差率是衡量滴灌系统灌水质量的一个重要参数,使用克里斯琴森[29]公式表示如下:

流量偏差率[30-31]计算公式为

式中q为滴头流量偏差率,%;max为灌水小区内滴头最大流量,L/h;min为灌水小区内滴头最小流量,L/h;q为滴头平均流量,L/h。

灌水小区沿程水头损失计算公式为

式中h为沿程水头损失,m;0为支管三通进口水头,m;max为毛管三通出口的最大水头,m。

2 结果与分析

2.1 安装射流三通对毛管沿程流量的影响

在滴灌带铺设长度为60 m、支管进口水头分别为9.5、12、14、15.5 m(对应毛管进口水头为6、8、10、12 m)时,4个灌水小区沿程各监测点流量分布如图3所示。当支毛管三通均采用射流三通时,毛管滴头流量在1.2~2.2 L/h之间。灌水小区滴头流量呈中间高两端低不完全对称趋势,这是因为灌水小区从滴灌带首部至滴灌带尾部沿程存在水头损失,Ⅰ号灌水小区滴灌带首部与尾部流量差均最小,说明其滴灌带沿程水头损失最小;由于三通制造工艺上的误差与试验系统误差,三通两端流量曲线不完全对称。

注:Ⅰ,支管和毛管均为射流三通;Ⅱ,支管为射流三通及毛管为普通三通;Ⅲ,支管为普通三通及毛管为射流三通;Ⅳ,支管和毛管均为普通三通。横坐标数值正号表示滴头在三通出口右侧,负号表示滴头在三通出口左侧。下同。

当支管进口水头分别为9.5、12、14、15.5 m时,4个灌水小区总流量大小关系为Ⅰ号灌水小区<Ⅱ、Ⅲ号灌水小区<Ⅳ号灌水小区(表2)。由图3c看出,由于Ⅰ号灌水小区支管与毛管中均为间歇不持续的脉冲水流,Ⅱ、Ⅲ号灌水小区毛管中亦为间歇不持续的脉冲水流,因此当支管进口水头为14 m(毛管进口水头为10 m)时,3个灌水小区滴头流量小于10 m水头下的额定流量(2.7 L/h);Ⅳ号灌水小区支管与毛管中均为持续恒压水流,因此滴头流量与额定滴头流量较为接近。

表2 不同灌水小区监测点流量统计

注:同行不同小写字母表示不同小区处理间差异显著(<0.05)。下同。

Note: Different letters in same line indicate significant difference among different districts (<0.05). Same as below.

2.2 流量-压力拟合关系式

调节支管三通进口阀门,监测不同进口水头下对应的支管三通出口流量,并拟合4个灌水小区的支管三通出口流量和压力关系式,如图4所示,4个灌水小区支管三通出口流量与压力均呈非线性幂函数关系(2>0.96),RMSE<28 L/h,远小于流量均值801.72 L/h,说明流量与压力之间的关系采用幂函数拟合的精度较高。

图4 各灌水小区支管三通出口流量-压力关系式

2.3 支毛管安装不同三通处理对灌水均匀性的影响

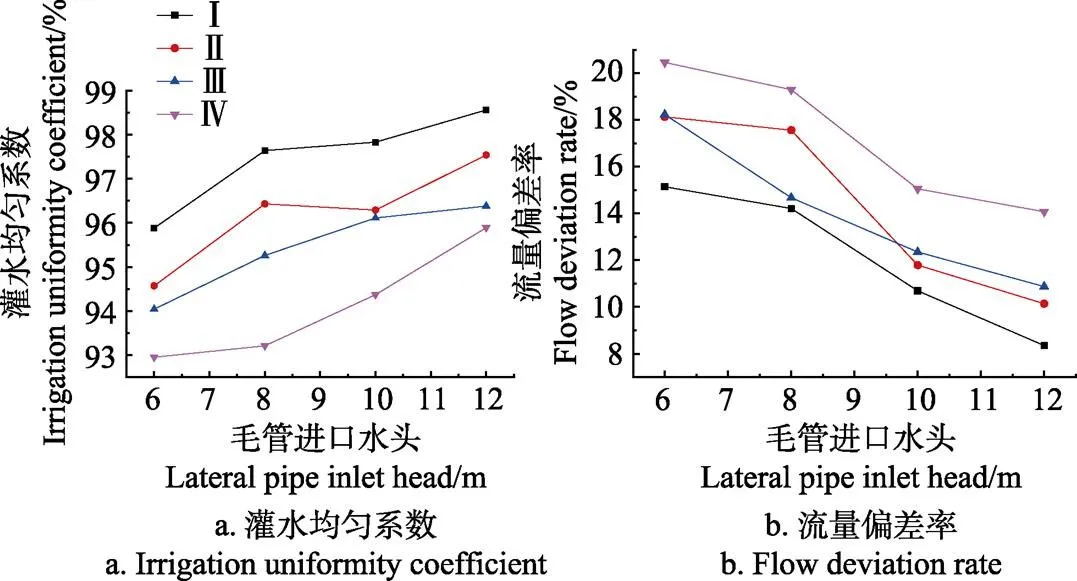

监测点流量最大值与最小值的差值(即极差)能够反映灌水小区灌溉均匀性,4个灌水小区各流量监测点数据如表2所示。按式(1)和式(2)计算在滴灌带铺设长度为60 m,毛管三通进口水头分别为6、8、10、12 m时4个灌水小区的灌水均匀度,结果如图5所示。通过对比可以看出,在上述4种毛管三通进口水头下,Ⅰ号灌水小区灌水均匀系数95.88%~98.56%之间,在比其他3个灌水小区提高了1.02%~4.43%;流量偏差率流量偏差率在8.35%~15.14%之间,比其他3处理降低0.46%~5.72%;在同一灌水小区中,随着毛管进口水头变大,灌水均匀系数总体呈上升趋势,流量偏差率总体呈下降趋势。

图5 安装射流三通后各灌水小区灌水均系数和流量偏差率

因为Ⅰ号灌水小区支毛管三通均为射流三通,支毛管内能够诱发形成间歇性水流,可同时对支管、毛管以及灌水器流道起到冲刷作用,因此灌水均匀性最好。Ⅳ号灌水小区支管与毛管均为普通三通,支管与毛管内均是持续恒压水流,无脉冲效果,所以灌水均匀性最差。Ⅱ号灌水小区支管是射流三通,支管内与毛管进口处是脉冲间歇水流,因为其毛管是普通三通,对水流无脉冲效果,因此毛管内是与支管相同频率的脉冲间歇水流;Ⅲ号灌水小区支管是普通三通,支管内与毛管进口处是持续恒压水流,因为其毛管是射流三通,其毛管内是脉冲间歇水流,故Ⅱ号灌水小区灌水均匀性总体上优于Ⅲ号灌水小区,且介于Ⅰ、Ⅳ号灌水小区之间。这验证了在支管与毛管组合试验中,支毛管均安装射流三通时能提高灌水小区的灌水均匀系数和降低流量偏差率。

2.4 支毛管安装不同三通处理对水力特性的影响

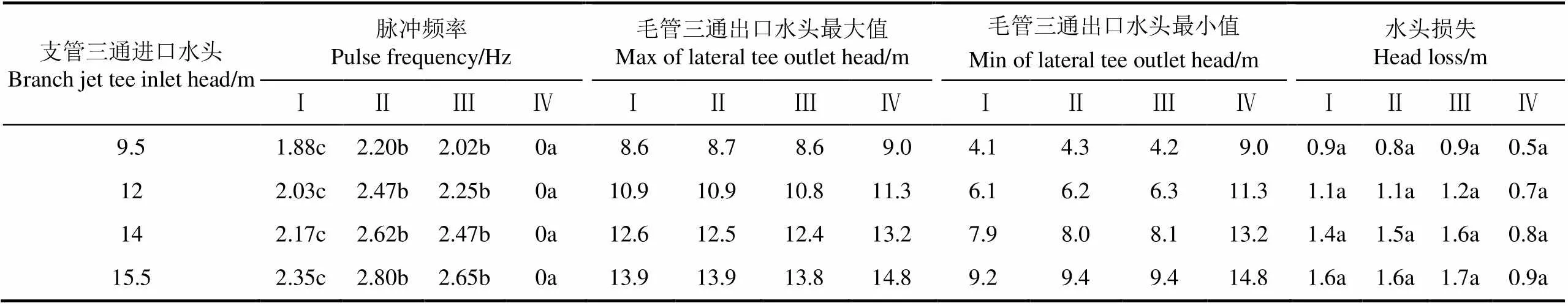

将支管三通进口水头分别设定为9.5、12、14、15.5 m,灌水小区的脉冲频率与水头损失如表3所示。在支管射流三通进口水头分别为9.5、12、14、15.5 m时,Ⅰ、Ⅱ、Ⅲ号灌水小区中支毛管射流三通脉冲频率随支管进口水头增加而递增,这是由于支管进口水头越大,流速与水流动能越大,射流到达射流三通劈尖的时间越短且水流在射流三通左右流道切换越快。在上述4种支管进口水头下,Ⅰ号灌水小区的水头损失在0.9~1.6 m之间,与其他3个灌水小区无显著差异(>0.05);其脉冲频率比Ⅱ号灌水小区小0.32~0.45 Hz;比Ⅲ号灌水小区小0.14~0.30 Hz(<0.05)。

表3 安装射流三通后各灌水小区滴灌系统水力特性

3 结 论

本文设计了一种支管射流三通,并与毛管射流三通、普通三通开展了组合试验研究,得出以下结论。

1)在毛管射流三通进口水头为10 m时,按照射流三通的Ⅰ、Ⅱ、Ⅲ号灌水小区均存在脉冲水流,因此滴头流量均小于额定滴头流量(2.7 L/h),其中支毛管均安装射流三通的Ⅰ号灌水小区滴头流量最小;而按装普通三通的Ⅳ号灌水小区中为恒流,滴头流量与额定滴头流量相近。

2)支毛管均采用射流三通的Ⅰ号灌水小区灌水均匀度最高,与Ⅱ、Ⅲ、Ⅳ号灌水小区相比,其灌水均匀系数提高1.27%~4.43%,流量偏差率降低0.46%~5.72%,灌水均匀度提高较显著。

3)灌水小区中支毛管三通的脉冲频率随射流三通进口水头增加呈递增关系,Ⅰ号灌水小区支管三通进口至毛管三通出口段的水头损失与其他3个小区无显著差异(>0.05),且其滴灌带首部与尾部滴头流量差最小,说明滴灌带沿程水头损失最小。

因此,在滴灌带长度为60 m、支管进口水头9.5、12、14、15.5 m条件下的组合试验中,灌水小区支毛管最优组合为支毛管均采用射流三通,在不损失水头的情况下,能够提高灌水小区的灌水均匀度。本文研究了滴灌带长度60 m、滴灌时间10 min情况下灌水小区水力性能,当灌溉时间延长时,由于水中含有一定杂质,灌水均匀度会有一定程度的降低。后期会开展延长灌溉时间和滴灌带长度对灌水均匀度影响的研究。

[1] 袁寿其,李红,王新坤. 中国节水灌溉装备发展现状、问题、趋势与建议[J]. 排灌机械工程学报,2015,33(1):78-92. Yuan Shouqi, Li Hong, Wang Xinkun. Status, problems, trends and suggesstions for water-saving irrigation equipment in China[J]. Journal of Drainage and Irrigation Engineering, 2015, 33(1): 78-92. (in Chinese with English abstract)

[2] 徐林,李杨瑞,黄海荣. 地下滴灌技术的研究进展[J]. 广西农业科学,2008,39(6):800-803. Xu Lin, Li Yangrui, Huang Hairong. Advance in subsurface drip irrigation[J]. Guangxi Agricultural Sciences, 2008, 39(6): 800-803. (in Chinese with English abstract)

[3] 范文波,吴普特,马枫梅. 膜下滴灌技术生态-经济与可持续性分析:以新疆玛纳斯河流域棉花为例[J]. 生态学报,2012,32(23):7559-7567. Fan Wenbo, Wu Pute, Ma Fengmei. Socio-economic impacts of under-film drip irrigation technology and sustainable assessment: A case in the Manas River Basin, Xinjiang, China[J]. Acta ecologica sinica, 2012, 32(23): 7559-7567. (in Chinese with English abstract)

[4] 韩启彪,冯绍元,曹林来,等. 滴灌技术与装备进一步发展的思考[J]. 排灌机械工程学报,2015,33(11):1000-1005. Han Qibiao, Feng Shaoyuan, Cao Linlai, et al. Thinking about further development of drip irrigation technology and equipment[J]. Journal of Drainage and Irrigation Engineering, 2015, 33(11): 1000-1005. (in Chinese with English abstract)

[5] 徐文静,王翔翔,施六林,等. 中国节水灌溉技术现状与发展趋势研究[J]. 中国农学通报,2016,32(11):184-187. Xu Wenjing, Wang Xiangxiang, Shi Liulin, et al. Current condition and developing tendency of water-saving irrigation technology in China[J]. Chinese Agronomy Science Bulletin, 2016, 32(11): 184-187. (in Chinese with English abstract)

[6] 何振嘉,傅渝亮,王博,等. 涌泉根灌不同浓度肥液入渗特性及土壤湿润体模型研究[J]. 农业工程学报,2018,34(24):90-99. He Zhenjia, Fu Yuliang, Wang Bo, et al. Infiltration characteristics and wetting body model of bubbled-root irrigation under different fertilizer concentration[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(24): 90-99. (in Chinese with English abstract)

[7] 刘燕芳,李丹,吴普特,等. 不同类型灌水器在硬水滴灌条件下的堵塞特征[J]. 农业工程学报,2018,34(3):96-102. Liu Yanfang, Li Dan, Wu Pute, et al. Clogging characteristics of different emitters in drip irrigation with hard water[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34 (3): 96-102. (in Chinese with English abstract)

[8] 徐尧权. 动态水压滴灌条件下土壤水分运移特性研究[D]. 杨凌:西北农林科技大学,2017:5. Xu Yaoquan. Study on Soil Moisture Transport Characteristics under Dynamic Water Pressure Drip Irrigation[J]. Yangling: Northwest Agricultural and Forestry University , 2017:5. (in Chinese with English abstract)

[9] 姚立红,吴江,张谦脉,等. 脉冲供水虹吸式滴灌控制装置[J]. 北京林业大学学报,1998,20(5):70-74. Yao Lihong, Wu Jiang, Zhang Qianmai, et al. A siphon controlling device for impulse water supplying dripping system[J]. Journal of Beijing Forestry University, 1998, 20(5): 70-74. (in Chinese with English abstract)

[10] 王新坤,肖思强,樊二东,等. 滴灌毛管首部射流脉冲三通水力特性试验研究[J]. 农业工程学报,2017,33(12):116-121. Wang Xinkun, Xiao Siqiang, Fan Erdong, et al. Hydraulic performance experiment of lateral pipe jet-pulse tee[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33 (12): 116-121. (in Chinese with English abstract)

[11] 王聪,芦刚,刘洁,等. 波动水压滴灌系统设计与实验分析[J]. 中国农村水利水电,2012(6):69-72. Wang Cong, Lu Gang, Liu Jie, et al. Design of dynamic pressure drip irrigation system and experimental analysis[J]. Chinese Rural Water and Hydropower, 2012(6): 69-72. (in Chinese with English abstract)

[12] Hu Juan, Wu Jinggui, Qu Xiaojing. Decomposition characteristics of organic materials and their effects on labile and recalcitrant organic carbon fractions in a semi-arid soil under plastic mulch and drip irrigation[J]. Journal of Arid Land, 2018, 10(1): 115-128.

[13] 冀荣华,王婷婷,祁力钧,等. 基于HYDRUS-2D的负压灌溉土壤水分入渗数值模拟[J]. 农业机械学报,2015,46(4):113-119. Ji Ronghua, Wang Tingting, Qi Lijun, et al. Numerical simulation of soil moisture infiltration under negative pressure irrigation based on HYDRUS-2D[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(4): 113-119. (in Chinese with English abstract)

[14] 杨玉超,王新坤,朱燕翔,等. 基于射流脉冲三通的滴灌带实验研究[J]. 中国农村水利水电,2015(9):111-118. Yang Yuchao, Wang Xinkun, Zhu Yanxiang, et al. An experimental study of the jet pulse tee based on drip irrigation pipes[J]. Chinese Rural Water and Hydropower, 2015(9): 111-118. (in Chinese with English abstract)

[15] 肖思强,王新坤,徐胜荣,等. 射流脉冲三通毛管灌水均匀性试验研究[J]. 排灌机械学报,2018,36(7):1-7.Xiao Siqiang, Wang Xinkun, Xu Shengrong, et al. An experimental study on irrigation uniformity of lateral pipe with jet-pulse tees[J]. Journal of Drainage and Irrigation Engineering, 2018, 36(7): 1-7. (in Chinese with English abstract)

[16] 李治勤,陈刚,杨晓池. 浑水引起迷宫灌水器物理堵塞因素实验研究[J]. 西安理工大学学报,2006,22(4):395-398. Li Zhiqin, Chen Gang, Yang Xiaochi. Experimental study of physical clogging factor of labyrinth emitter caused by muddy water[J]. Journal of Xi'an University of Technology, 2006, 22(4): 395-398. (in Chinese with English abstract)

[17] 牛文全,刘璐. 浑水特性与水温对滴头抗堵塞性能的影 响[J]. 农业机械学报,2012,43(3):39-45.Niu Wenquan, Liu Lu. Influence of sediment concentration and water temperature of muddy water on emitter clogging[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(3): 39-45. (in Chinese with English abstract)

[18] 李久生,陈磊,栗岩峰. 地下滴灌灌水器堵塞特性田间评估[J]. 水利学报,2008,39(10):1272-1278. Li Jiusheng, Chen Lei, Li Yanfeng. Field evaluation of emitter clogging in subsurface drip irrigation system[J]. Journal of Hydraulic Engineering, 2008, 39(10): 1272-1278. (in Chinese with English abstract)

[19] 王新坤,蔡焕杰. 微灌毛管水力解析及优化设计的遗传算法研究[J]. 农业机械学报,2005,36(8):55-58. Wang Xinkun, Cai Huanjie. Study on genetic algorithm of hydraulic analysis and optimum design for micro-irrigation laterals[J]. Transactions of the Chinese Society for Agricultural Machinery, 2005, 36(8): 55-58. (in Chinese with English abstract)

[20] 高世凯. 射流振荡三通与滴灌毛管脉冲特性研究[D]. 镇江:江苏大学,2013.Gao Shikai. Study on Pulse Characteristics of Fluidic Oscillating Three Way and Drip Irrigation Capillary [D]. Zhenjiang: Jiangsu University, 2013. (in Chinese with English abstract)

[21] 康跃虎. 微灌系统水力学解析和设计[M]. 西安:陕西科学技术出版社,1999.

[22] 许鹏,王新坤,高世凯,等. 射流振荡三通与滴灌毛管脉冲初步试验研究[J]. 节水灌溉,2014(3):1-4. Xu Peng, Wang Xinkun, Gao Shikai, et al. Preliminary test of jet oscillation tee and pulse flow in drip irrigation lateral pipe[J]. Water Saving Irrigation, 2014(3): 1-4. (in Chinese with English abstract)

[23] 王新坤. 一种射流三通:CN103203293A[P]. 2013-07-17.

[24] 王金枝,肖明,吴晓武. 射流卷吸作用影响射流偏转的理论分析[J]. 山东电力技术,2000(3):4-6. Wang Jinzhi, Xiao Ming, Wu Xiaowu. Theoretical analysis of the jet deflection influenced by entrainment[J]. Shandong Electric Power Technology, 2000(3): 4-6. (in Chinese with English abstract)

[25] 邹久朋,刘学武,程蛟,等. 射流附壁振荡器能效分析与提升[J]. 大连理工大学学报,2017,57(3):233-240. Zou Jiupeng, Liu Xuewu, Cheng Jiao, et al. Analysis and improvement of energy efficiency of jet wall-attached oscillator[J]. Journal of Dalian University of Technology, 2017, 57(3): 233-240. (in Chinese with English abstract)

[26] 汪志明,薛亮. 射流元件附壁与切换流动规律研究[J]. 水动力学研究与进展A辑,2017,22(3):352-357. Wang Zhiming, Xue Liang. Study on the attached flow and alteration flow character in fluidic element of down hole pressure intensifier[J]. Journal of Hydrodynamic A, 2017, 22(3): 352-357. (in Chinese with English abstract)

[27] 刘洁,王聪,魏青松,等. 波动水压参数对灌水器水力性能影响实验[J]. 河海大学学报,2014,42(4):361-366. Liu Jie, Wang Cong, Wei Qingsong, et al. Experimental study of effect of fluctuating water pressure factors on hydraulic properties of drip emitters[J]. Journal of Hohai University, 2014, 42(4): 361-366. (in Chinese with English abstract)

[28] 于洪仕,张涛. 漩涡的卷吸作用对多孔孔板流量计精度的影响[J]. 天津大学学报,2016,49 (5):465-471. Yu Hongshi, Zhang Tao. Influence of the entrainment of vortex on the accuracy of multi-hole orifice flow meter[J]. Journal of Tianjin University, 2016, 49(5): 465-471. (in Chinese with English abstract)

[29] 中华人民共和国国家标准.微灌工程技术规范:GB/T 50485-2009[S]. 北京:中国计划出版社,2009.

[30] 张林,吴普特,朱德兰,等. 基于制造偏差的滴灌系统综合流量偏差率[J]. 农业机械学报,2013,44(12):135-139. Zhang Lin, Wu Pute, Zhu Delan, et al. Integrated flow deviation rate of drip irrigation system based on manufacturing deviation[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44 (12): 135-139. (in Chinese with English abstract)

[31] 鞠学良,吴普特,朱德兰,等. 基于样本流量偏差率的微灌灌水均匀度评价方法[J]. 排灌机械工程学报,2016,34(2):173-178. Ju Xueliang, Wu Pute, Zhu Delan, et al. Estimation of micro- irrigation water application uniformity based on sample emitter flow variation[J]. Journal of Drainage and Irrigation Engineering, 2016, 34(2): 173-178. (in Chinese with English abstract)

Hydraulic performance of drip irrigation system with branch and lateral pipes installed jet-pulse tee

Wang Xinkun, Xue Zilong, Xiao Siqiang, Fan Erdong, Xu Shengrong, Wang Xuan, Zhang Chenxi

(212013,)

Drip irrigation has the problems of easy blockage and low irrigation uniformity under low head (less than 10 m). Pulse drip irrigation technology can generate periodic and turbulent pulsed flow, which is beneficial to improve the anti-blockage ability and irrigation uniformity of the emitter. In order to analyze the influence of pulsed flow on the hydraulic performance of drip irrigation system, aranch jet-pulse tee was designed based on the principle of wall attachment and switching of jet, and a combined test with lateral jet-pulse tee was carried out. A total 4 irrigation districts were constructed according to different combinations, of which the branch and lateral pipe tees of No. I irrigation district were both jet-pulse tees; in No.II irrigation district, the branch pipe was jet-pulse tee and the lateral pipe was ordinary jet tee; in No. III irrigation district, the branch pipe was ordinary jet tee and the lateral pipe was jet-pulse tee; and the branch and lateral pipe tees of No. IV irrigation district were both ordinary jet tees. In irrigation district, the length of lateral pipe was 60 m, and the inlet head of branch tee was set to 9.5, 12, 14 and 15.5 m, respectively. Turbine flowmeter was installed at branch pipe tee outlet and lateral pipe tee inlet to record branch pipe tee outlet flow rate and lateral pipe tee inlet flow rate, respectively. The flow rate was the difference between the initial value and the final value in the flowmeter test. The high-speed camera captured the oscillation of pressure gauge pointer of lateral jet-pulse tee outlet to record pulse frequency and maximum pressure. Head loss was the difference between the inlet pressure of branch tee and the maximum outlet pressure of lateral pipe tee. The results showed that the total flow rate of No. I irrigation district was the smallest and the dripper flow rate was less than the rated value (2.7 L/h) because the No. I irrigation district with jet-pulse tees installed in both branch and lateral pipes had intermittent pulsed flow. The pressure and flow rate at the outlet of branch tee followed power function relationships with the fitting degree higher than 0.96 and the root mean square error smaller than 28 L/h. The irrigation uniformity coefficient of irrigation system in No. I irrigation districts ranged from 95.88% to 98.56%, which was higher than the other 3 irrigation districts by 1.02%-4.43% respectively. The flow deviation rate ranged from 8.35% to 15.14% in No. I irrigation districts, which was lower than the others by 0.46%-5.72%. It proves that the irrigation uniformity of No. I irrigation districts is the best. In No. I, II and III irrigation districts, the pulse frequency of branch and lateral pipe jets increased with the increase of the inlet head. Head loss from branch tee inlet to lateral pipe tee outlet in No. I irrigation district was 0.9-1.6 m under different branch pipe tee inlet heads, which was not significantly different from the other systems. The results of this study will contribute to the selection of the optimal combination mode of branch pipe tee and lateral pipe tee in irrigation district, and provide valuable information for the research, development and application of jet technology in pulsed drip irrigation system. In the future research, it is necessary to test the loss along the lateral pipe, observe the distribution of pressure, flow rate and pulse performance in the lateral pipe, and further evaluate the uniformity and anti-clogging ability of irrigation.

pressure; flow rate; jet-pulse tee; hydraulic performance; branch and lateral pipes; uniformity; pulse frequency; head loss

2018-09-28

2019-03-10

国家自然科学基金(51579116);江苏省科技计划项目(BE2018373)

王新坤,研究员,博士生导师,主要从事节水灌溉理论与新技术研究。Email:xjwxk@126.com

10.11975/j.issn.1002-6819.2019.08.016

S275.6

A

1002-6819(2019)-08-0134-06

王新坤,薛子龙,肖思强,樊二东,徐胜荣,王 轩,张晨曦. 支毛管安装射流三通的滴灌系统水力性能研究[J]. 农业工程学报,2019,35(8):134-139. doi:10.11975/j.issn.1002-6819.2019.08.016 http://www.tcsae.org

Wang Xinkun, Xue Zilong, Xiao Siqiang, Fan Erdong, Xu Shengrong, Wang Xuan, Zhang Chenxi. Hydraulic performance of drip irrigation system with branch and lateral pipes installed jet-pulse tee[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(8): 134-139. (in Chinese with English abstract) doi:10.11975/j.issn. 1002-6819.2019.08.016 http://www.tcsae.org