基于色饱和度三维几何特征的马铃薯芽眼识别

2019-01-14李玉华李天华牛子孺吴彦强张智龙侯加林

李玉华,李天华,牛子孺,吴彦强,张智龙,侯加林,2

基于色饱和度三维几何特征的马铃薯芽眼识别

李玉华1,李天华1,牛子孺1,吴彦强1,张智龙1,侯加林1,2※

(1. 山东农业大学机械与电子工程学院,泰安 271018;2. 山东省园艺机械与装备重点实验室,泰安 271018)

芽眼准确识别是马铃薯种薯自动切块的前提,为降低误识别率,提高芽眼识别率和可靠性,提出基于色饱和度三维几何特征的马铃薯芽眼识别方法。对分量在三维几何空间进行分析提出了以其纵向截面曲线及其一阶导数为基础的4个特征向量,利用四特征综合判定准则进行芽眼纵向识别,然后根据芽眼横向特点对芽眼纵向识别结果进行再次筛选,降低芽眼误识别率。试验结果表明:该方法芽眼识别率达91.48%,其中,未发芽芽眼识别率92.21%,已发芽芽眼识别率89.00%,芽眼误识别率4.32%,识别单幅图像的平均耗时为2.68 s。因芽眼误识别造成种薯切块无芽眼的概率小于1.01%。试验证明该方法抗干扰能力强,能有效降低误识别率,防止种薯切块无芽眼引起的缺苗现象,可为马铃薯种薯自动切块机芽眼识别提供参考。

农作物;图像处理;图像识别;马铃薯芽眼识别;色饱和度;三维几何特征

0 引 言

马铃薯是中国第四大粮食作物,近几年马铃薯种植面积逐年增加,马铃薯已经成为重要的粮菜兼用作物[1-3]。为确保马铃薯早出苗、苗壮、提高产量及节省种薯,马铃薯播种前需根据农艺要求对种薯进行切块,切块的芽眼位置、切块质量对马铃薯后期生长具有重要的影响[4-5]。由于种薯切块要求高,当前马铃薯切块主要通过人工完成。人工种薯切块劳动强度大、要求作业人员经验丰富、不同人员加工的切块差异显著且人工成本高。市场迫切需求一款自动化程度高、可靠高效的种薯切块机器。但由于马铃薯芽眼识别困难且准确率低严重制约了种薯切块机的发展。

目前,国内外利用机器视觉技术对马铃薯检测及分级进行了广泛研究。如郝敏等[6]利用Zernike特征参数对马铃薯薯形检测,并剔除畸形马铃薯。汪成龙等[7]利用流行学习算法对马铃薯机械损伤进行检测。孔彦龙等[8]通过机器视觉检测马铃薯质量和形状。周竹等[9]通过高光谱成像技术[10-13]对常见马铃薯外部缺陷进行检测。Noordam等[14]、Razmjooy等[15]利用机器视觉对马铃薯进行检测及分级。上述研究能利用图像识别方法对马铃薯进行有效检测及分级。Moallem等[16]利用多层感知神经网络[17-19]对马铃薯图像进行分割。田海韬等利用欧式距离及动态阈值分割进行芽眼区域识别[20]及标记[21-22]。邢作常等[23]采用形态学进行芽眼分割。张国强[24]提出采用边缘检测及形态学处理提取芽眼区域。Martínez等[25]利用模糊逻辑视觉系统对马铃薯幼苗的腋芽进行识别。上述研究能够对表面无破皮等机械损伤的马铃薯芽眼准确的识别,但由于马铃薯生长在地下,其生长环境复杂并且挖掘时较易产生损伤,提高芽眼识别算法的抗干扰能力是实际生产中亟待解决的问题。

利用分类器[26-28]或深度学习[29-33]对物体局部特征识别已经取得了良好的效果。但是马铃薯表面为不规则的椭球体且局部有较多凸起及凹陷,对光线反射不均匀,难以通过灰度图像进行芽眼的识别;芽眼特征不明显且易与斑点、泥土及破皮等机械损伤混淆。而与图像亮度相关的图像分割法则极易产生芽眼误判。因此,借鉴马铃薯检测及分级采用的相关机器视觉算法,寻找马铃薯芽眼识别的新算法具有重要的现实意义。

1 材料与方法

1.1 图像的获取装置

图像采集装置如图1所示,包括计算机、支架、4个环形补光灯、USB摄像头和黑布组成。USB摄像头的最大分辨率1 600Í960像素,帧率30帧/s,USB3.0接口。计算机操作系统Windows 7,搭载Intel @ Core(TM) i5-6200U CPU @ CPU 2.30 GHz处理器,内存8 GB,分析软件为MATLAB R2016a。选用的环形补光灯功率25 W,以提高采集的图像质量,避免因自然光引起的干扰。

图1 马铃薯图像采集装置

1.2 色彩空间选择及图像预处理

对常用的色彩空间对比分析发现,以物体表面对三色的反射量为基础[34]的RGB色彩空间对芽眼特征识别较易受光照条件的影响,识别准确度低。HSV、NTSC、HSI色彩空间均以亮度、色调、色饱和度为分量描述色彩[35-38],利用芽眼色调或色饱和度进行芽眼识别可以避免光照不均匀造成的干扰。其中,HSI色彩空间利用圆锥空间模型进行描述,能准确描述色调、亮度和色饱和度的变化。通过对各色彩空间不同分量进行对比分析,发现HSI色彩空间中的色饱和度分量中芽眼特征最明显,且受光照条件影响较小,因此选用HSI色彩空间中的色饱和度分量为芽眼识别主要依据。

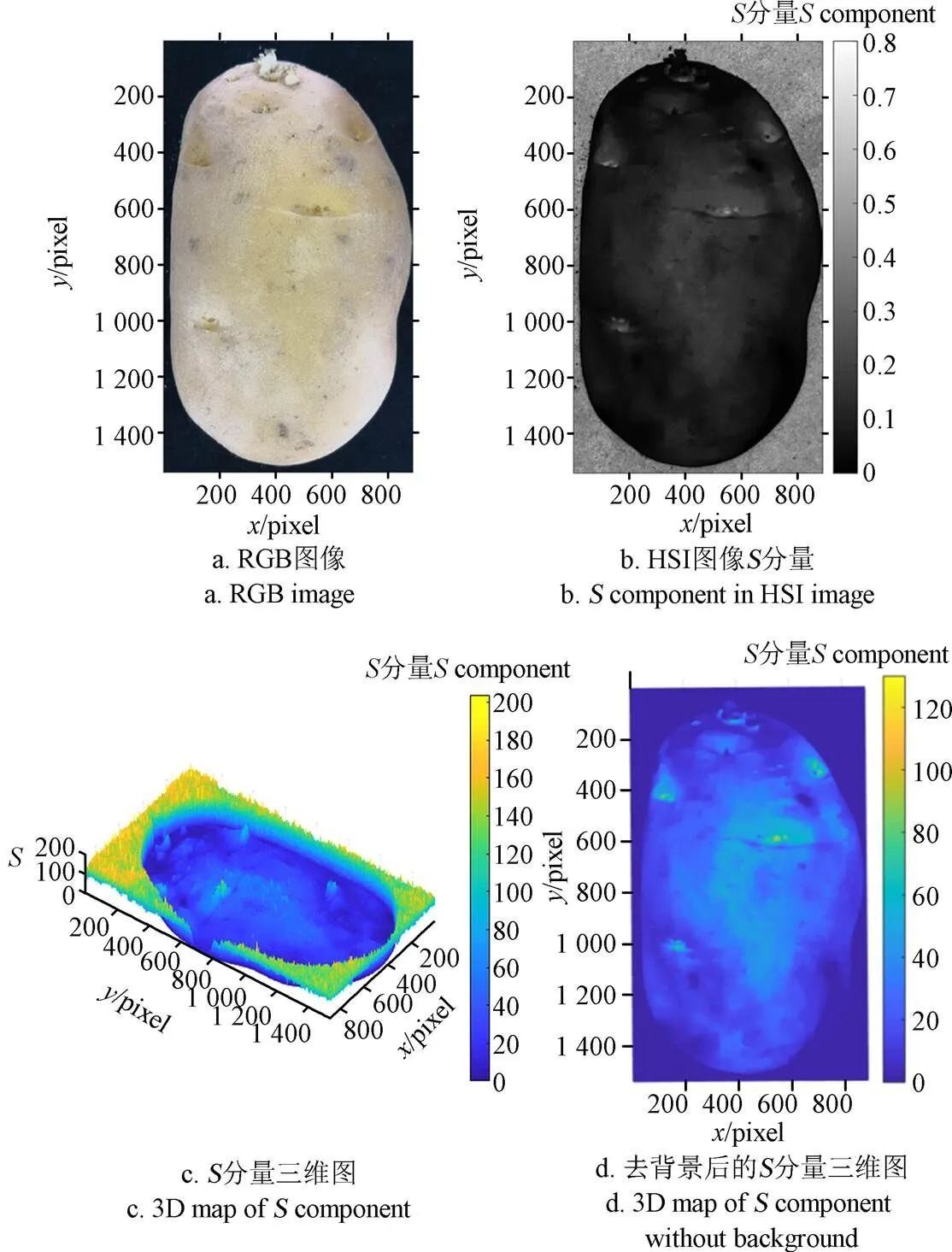

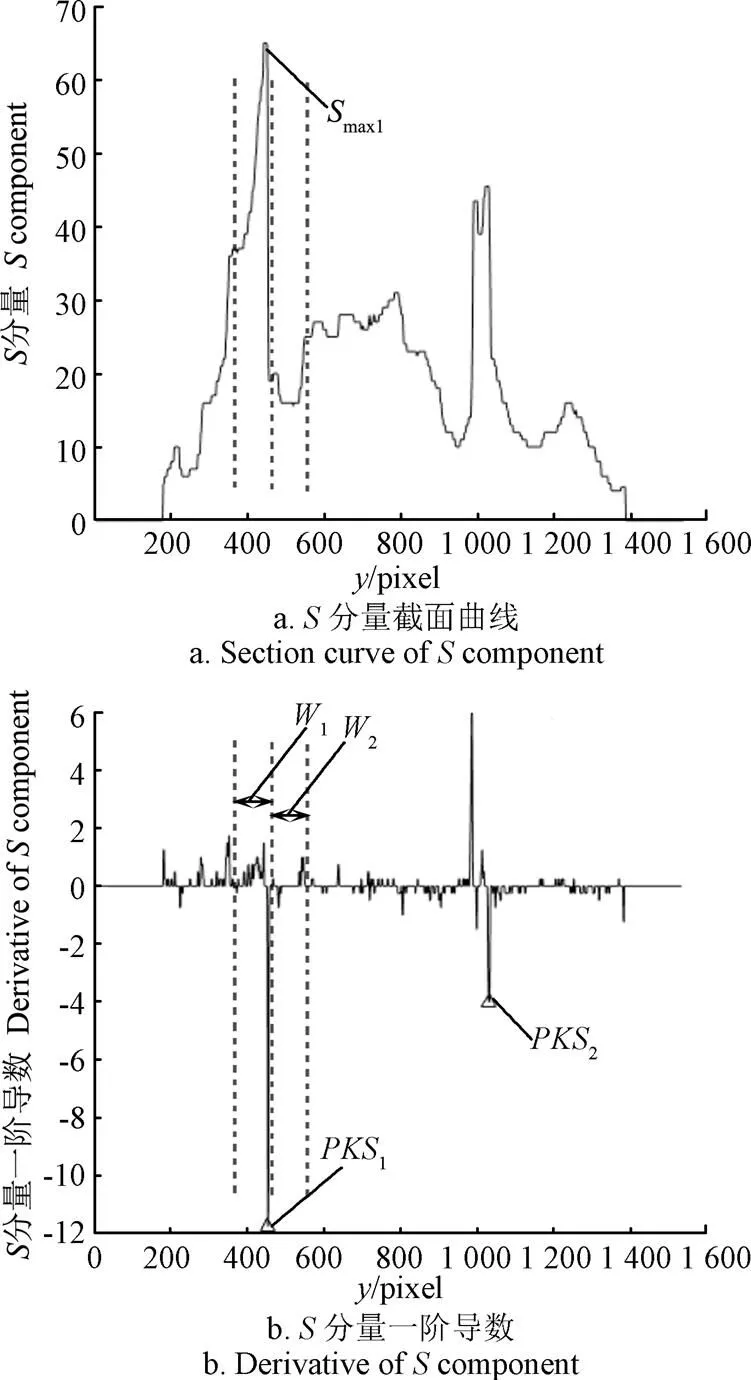

为消除噪音及背景区域对芽眼识别的干扰,提高识别准确度,对JPG图像进行预处理,分析软件MATLAB R2016a,其效果如图2所示,方法如下:

1)通过MATLAB读取图像采集系统采集的JPG格式的图像并转换到RGB色彩空间,然后转换到HSI色彩空间[39]并提取色饱和度分量,如图2b所示。

2)以分量矩阵的行列数为和坐标,将色饱和度分量扩大255倍并以其为坐标转化为三维图示,如图2c所示。

3)对原始RGB图像进行二值化处理以区分背景区域和马铃薯区域,背景区域为1马铃薯区域为0,然后分量与该二值化矩阵点乘得到背景区域的分量,对原分量减去背景区域的分量得到马铃薯区域的分量。最后通过中值滤波降噪得到预处理后的色饱和度分量图,如图2d所示。

1.3 特征选择

马铃薯芽眼呈狭长的凹陷,形状类似人眼,凹陷由中心向外逐渐变浅,芽眼长边与马铃薯长轴垂直,芽眼长边呈弧线状凸起。芽眼的这些特征极明显,并且其结构约束条件多,泥土残留、病斑、污斑和机械损伤等偶然形成的轮廓与芽眼轮廓类似的概率极低。

色饱和度分量的三维图能准确表达上述芽眼的独有特征,如图3所示,观察发现芽眼区域具有显著的特点。刚发芽的芽眼分量三维几何图的特征是:一侧有一弧形的凹陷,紧接着是陡峭的山峰且中间为很深的圆形凹陷;短型芽眼分量三维几何图的特征是:下侧有一弧形的凹陷,紧接着是陡峭的山峰,然后是相对平缓的高原状;已发芽的芽眼分量三维几何图的特征是:下侧有一弧形的凹陷,紧接着是多个陡峭的山峰;狭长芽眼分量三维几何图的特征与短型芽眼类似。非芽眼区域的分量三维几何图都较为平坦且分量值较小。

图2 RGB原始图像与S分量三维几何图

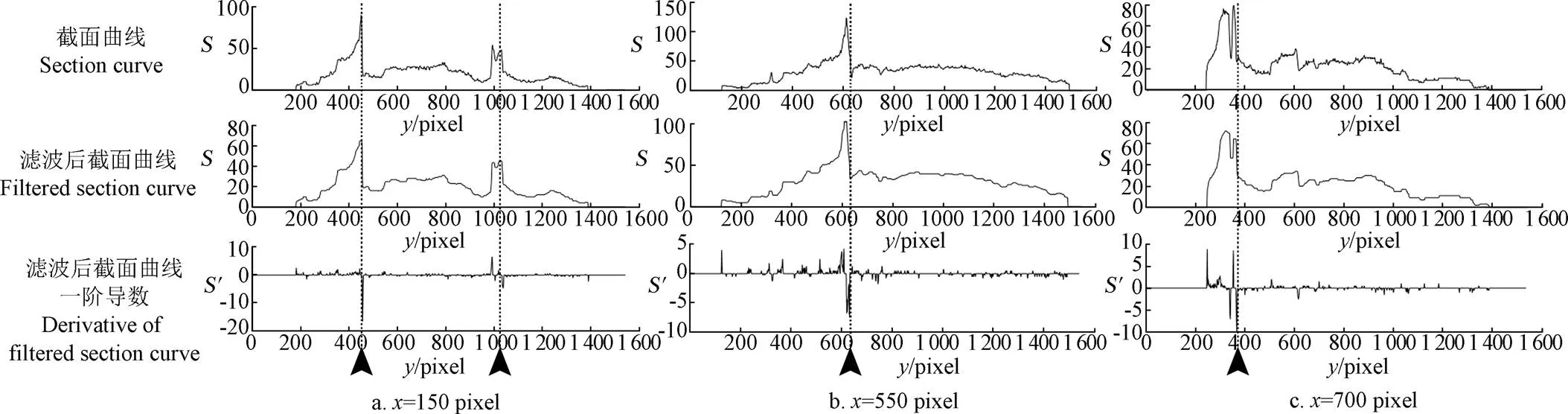

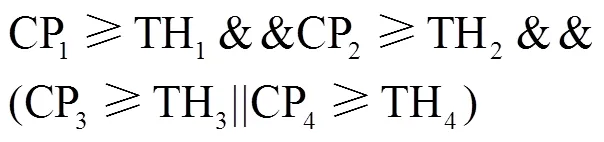

进一步通过对色饱和度分量三维图进行纵向截取并分析找到合适的特征量,图4分别为3个不同芽眼区域的典型截面曲线分析图。很明显在芽眼位置的曲线为波峰,且该波峰左侧快速上升右侧接近垂直下降。如图5所示,分量截面曲线的一阶导数在芽眼位置有一个明显波谷,且波谷左侧一定长度区间曲线与横坐标形成的面积比右侧一定长度区间曲线与横坐标形成的面积大。

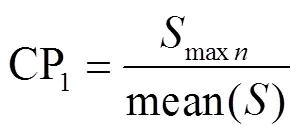

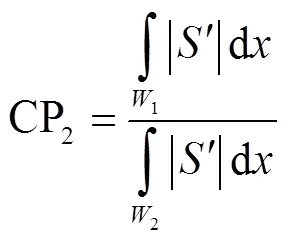

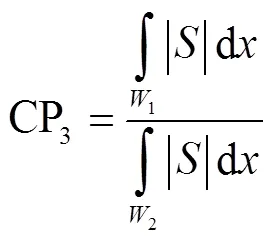

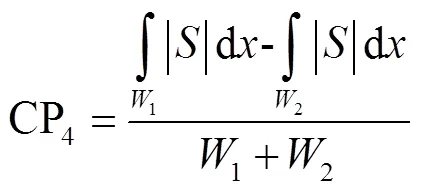

通过上述分析,选取分量截面曲线一阶导数波谷对应峰值的相对大小(相对整条截面曲线的均值)、峰值前、后一定窗口内的积分的比值及差值的大小和一阶导数波谷前、后一定窗口内的积分比值为芽眼特征参数。采用多特征参数进行筛选能有效防止因机械损伤等因素产生芽眼误判,避免因芽眼误判产生的种薯切块无芽而导致缺苗现象。

图3 S分量三维几何图及不同芽眼区域局部放大图

注:箭头标示芽眼位置。

1.4 芽眼识别算法

芽眼识别算法如下:

1)采集的图像从RGB颜色空间转化为HSI颜色空间并提取色饱和度分量。

2)对分量三维图进行纵向(马铃薯的长轴方向)逐列截取分量曲线并求该曲线的一阶导数。

3)寻找分量一阶导数曲线的波谷位置,见图5所示,波谷值PKS满足式(1)。

式中PKS为第个波谷值;1为高度系数,该值为常数,通过对芽眼曲线统计得到,系数过大将造成芽眼漏识别,过小将引起误识别;为分量导数。

4)对步骤3)的所有波谷根据式(2)~(5)求芽眼特征参数。

式中CP1、CP2、CP3、CP4为芽眼特征参数。1、2表示PKS对应的前后窗口;max n表示PKS对应的窗口1和2内的最大值。

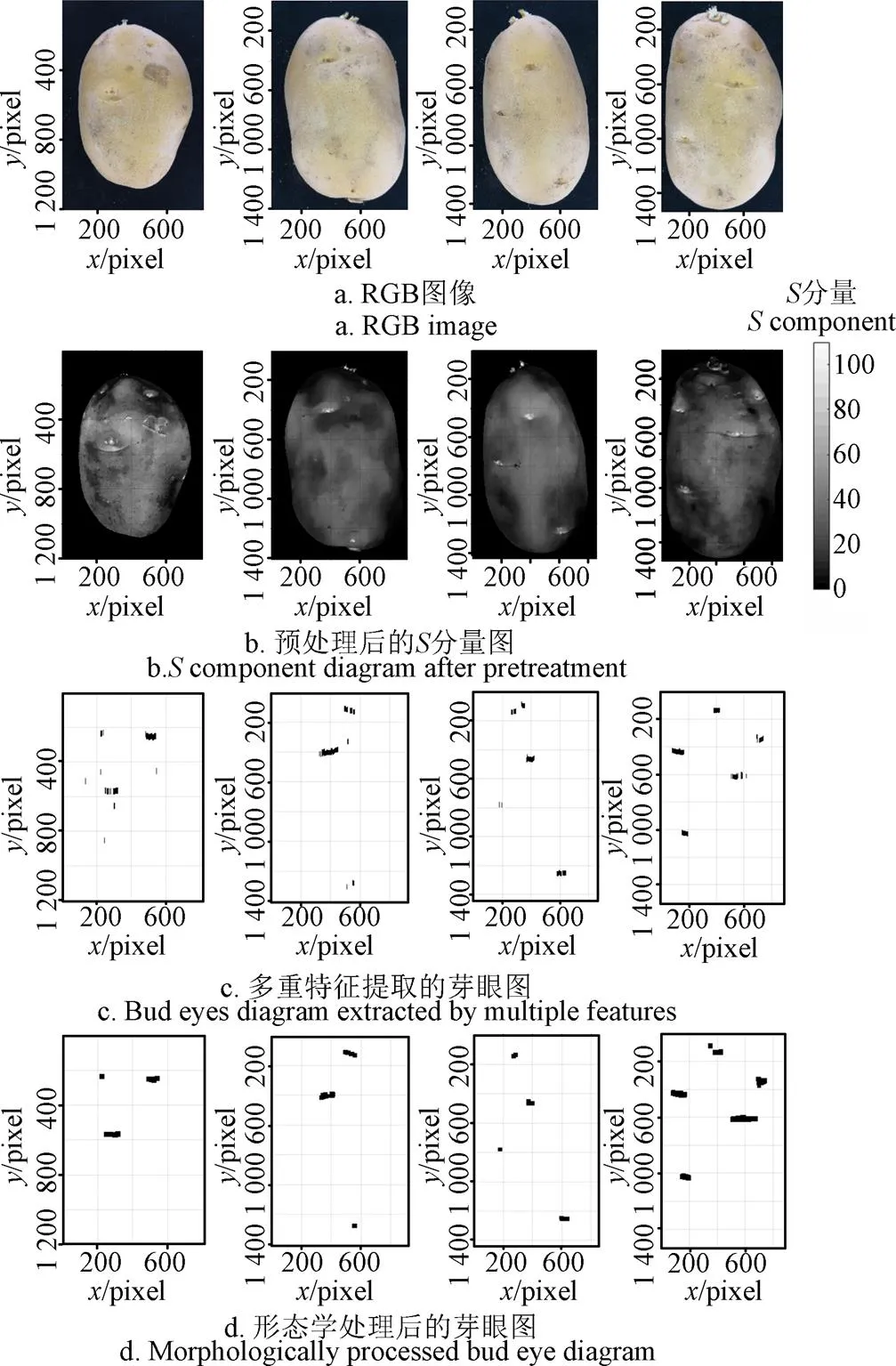

5)根据式(6)判定规则对芽眼进行识别,当特征参数CP1、CP2同时大于响应的阈值且当特征参数CP3、CP4任意一个大于相应的阈值时则相应的行列置为0,否则置为1。

式中TH1、TH2、TH3和TH4为特征参数的阈值。

6)重复步骤2)~5)对分量三维图所有纵向列进行芽眼特征判定,得到芽眼二值化矩阵。

注:PKSn为第n个波谷值;W1、W2为PKSn对应的前后窗口;Smax n为PKSn对应的窗口W1和W2内的最大S值。

7)根据芽眼横向连续性及芽眼下边缘呈弧状结构的特点选择合适的结构元素,然后利用已选择的结构元素对芽眼二值化矩阵进行形态学处理。腐蚀操作可去掉二值化矩阵中宽度比芽眼的长度明显小的区域,这些小的区域是伪芽眼引起的,然后利用膨胀操作恢复因腐蚀操作而缩小的芽眼区域。此步骤能进一步去掉伪芽眼,芽眼识别结束。

2 试验及结果分析

2.1 试验设计

试验所用马铃薯为市场销售的普通马铃薯,样本数为100,每个马铃薯选2个面进行采集图像,共采集图像200幅,格式为JPG,分辨率1 600Í960像素。整个测试过程操作系统Windows 7,搭载Intel @ Core(TM) i5-6200U CPU @ CPU 2.30 GHz处理器,内存8 GB,分析软件为MATLAB R2016a。

2.2 评价指标

本文将每幅图像识别的芽眼数作为预测值,实际人工识别得到的芽眼数作为真实值。对马铃薯芽眼分为总芽眼、未发芽芽眼和已发芽芽眼3种情况,对3种情况分别通过计算所有图像上算法成功识别的总个数与人工识别的真实个数做比值得到各情况的成功识别率,并计算因破皮、污斑、泥土等干扰造成的误识别芽眼数占总芽眼数的百分比。

2.3 结果与分析

2.3.1 识别结果分析

芽眼识别系统主要有3个模块组成,分别为色饱和度分量提取及预处理、芽眼三维几何特征提取和芽眼形态学处理。各处理效果流程如图6所示。

图6 马铃薯芽眼识别流程

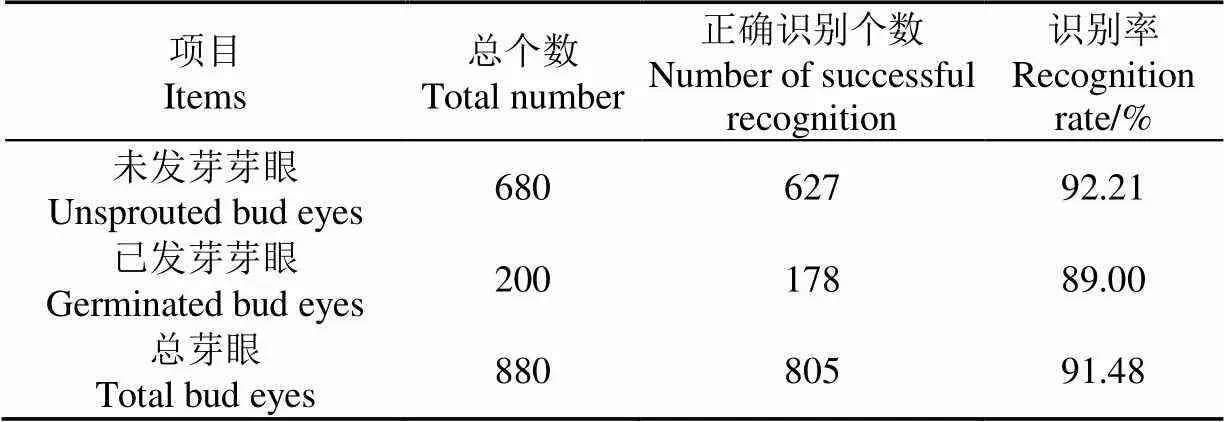

将特征参数的阈值TH1、TH2、TH3和TH4分别设置为3、2.8、1.5和15,对200幅马铃薯图像进行了芽眼识别,识别结果如表1所示。共880个芽眼,成功识别出805个,成功率91.48%,芽眼漏识别率8.52%。其中,未发芽芽眼680,成功识别出627个,成功率92.21%。已发芽芽眼200,成功识别出178个,成功率89.00%。因破皮、污斑、泥土等干扰造成的误识别芽眼38,占总芽眼数的4.32%,识别单幅图像的平均耗时为2.68 s。

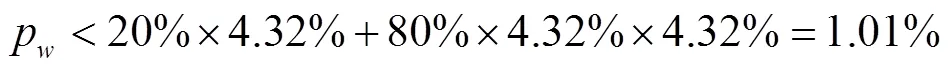

马铃薯种薯切块需要满足质量在30~60 g范围内并且芽眼数至少1个。根据试验分析及传统经验知每个种薯块大于1个芽眼的概率大于80%。因此,由式(7)知,因误识别的芽眼而造成种薯切块无芽眼的概率p小于1.01%。该方法对种薯芽眼识别的准确率完全能满足种薯自动切块机要求。

2.3.2 识别结果可靠性分析

马铃薯形状不规则,且表面随机性出现破皮、色斑、虫眼、泥土和机械损伤等现象,这些现象对芽眼识别将造成较强的干扰,容易引起芽眼误判。芽眼误判将产生马铃薯种薯切块无芽眼,从而在播种后产生缺苗现象并对产量造成严重的影响。芽眼漏识别将引起切块数量减少及切块重量的增加,但对产量没有影响,芽眼漏识别的危害性相对较低。

表1 马铃薯种薯芽眼识别结果

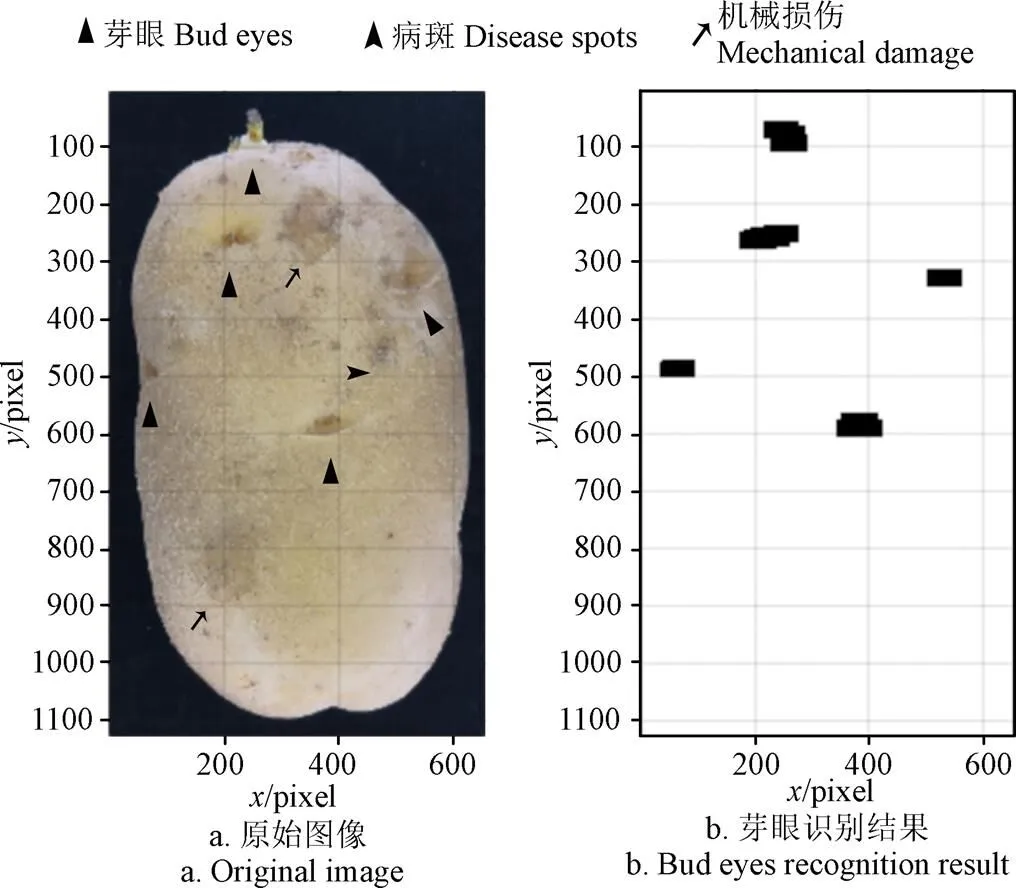

通过色饱和度多个几何特征参数进行芽眼识别能有效降低芽眼误判率,提高识别结果的可靠性。试验结果表明因干扰造成的芽眼误识别率仅为4.32%。图7为本文基于色饱和度三维几何特征的马铃薯芽眼识别算法对干扰因素的识别情况,能有效防止芽眼的误判。

图7 表面缺陷对芽眼识别的影响

2.4 三维状态马铃薯芽眼识别的可能性的讨论

本文算法是针对二维图像给出的,对于三维状态的马铃薯芽眼识别需对不同角度的多张图像进行识别。可以通过镜面[14]或旋转台[40]对马铃薯进行多角图像的采集,分别进行分析得到马铃薯各面的芽眼位置。以此作为准确识别芽眼的算法,然后利用马铃薯的轮廓快速建立近似的三维模型,通过两者的信息融合满足精度和速度的要求,为马铃薯种薯切块机提供算法支持。

3 结 论

1)本文对饱和度分量的三维几何特征、纵向截面曲线及其一阶导数曲线进行分析提出了与芽眼相关的4个特征参数。通过求取各纵向截面4个特征参数并根据判定规则进行纵向芽眼识别,然后根据芽眼横向特点利用数学形态学进行再次芽眼筛选。通过对芽眼多特征筛选,芽眼识别率91.48%。其中,未发芽芽眼识别率92.21%,已发芽芽眼识别率89.00%,芽眼误识别率4.32%。

2)采用基于色饱和度三维几何特征进行马铃薯芽眼识别,能有效降低因破皮、色斑、虫眼、泥土和机械损伤等现象造成的干扰,本方法防干扰能力强,可靠性高,误识别率为4.32%,计算表明:因误识别芽眼而造成种薯切块无芽眼的概率小于1.01%,防止因马铃薯切块无芽眼缺苗造成减产。

[1] 屈冬玉,谢开云,金黎平,等. 中国马铃薯产业与现代农业[J]. 农业技术与装备,2007(7):4-7.

[2] 陈萌山,王小虎. 中国马铃薯主食产业化发展与展望[J]. 农业经济问题,2015(12):4-11.

[3] 杨帅,闵凡祥,高云飞,等. 新世纪中国马铃薯产业发展现状及存在问题[J]. 中国马铃薯,2014,28(5):311-316.

Yang Shuai, Min Fanxiang, Gao Yunfei, et al. Status quo and challenges of China potato industry of the 21st century[J]. Chinese Potato Journal, 2014, 28(5): 311-316. (in Chinese with English abstract)

[4] 樊祖立,牛力立,唐兴发,等. 种薯切块芽位及不同催芽、拌种方式对马铃薯农艺性状的影响[J]. 耕作与栽培,2017(5):17-20.

Fan Zuli, Niu Lili, Tang Xingfa, et al. The effects of seed-cutting buds and different buds on potato agronomic traits[J]. Tillage & Cultivation, 2017(5): 17-20. (in Chinese with English abstract)

[5] 雷雪萍,李勇,白雅梅,等. 相同种薯播量不同种薯切块重量和密度组合对植株和块茎性状的影响[J]. 中国马铃薯,2016,30(6):336-340.

Lei Xueping, Li Yong, Bai Yamei, et al. Effects of various combinations of seed piece weight and in-row spacing on plant and tuber traits planting using equal quantity of seed[J]. Chinese Potato Journal, 2016, 30(6): 336-340. (in Chinese with English abstract)

[6] 郝敏,麻硕士,郝小冬. 基于Zernike矩的马铃薯薯形检测[J]. 农业工程学报,2010,26(2):347-350.

Hao Min, Ma Shuoshi, Hao Xiaodong. Potato shape detection based on Zernike moments[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(2): 347-350. (in Chinese with English abstract)

[7] 汪成龙,李小昱,武振中,等. 基于流形学习算法的马铃薯机械损伤机器视觉检测方法[J]. 农业工程学报,2014,30(1):245-252.

Wang Chenglong, Li Xiaoyu, Wu Zhenzhong, et al. Machine vision detecting potato mechanical damage based on manifold learning algorithm[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(1): 245-252. (in Chinese with English abstract)

[8] 孔彦龙,高晓阳,李红玲,等. 基于机器视觉的马铃薯质量和形状分选方法[J]. 农业工程学报,2012,28(17):143-148.

Kong Yanlong, Gao Xiaoyang, Li Hongling, et al. Potato grading method of mass and shapes based on machine vision[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(17): 143-148. (in Chinese with English abstract)

[9] 周竹,黄懿,李小昱,等. 基于机器视觉的马铃薯自动分级方法[J]. 农业工程学报,2012,28(7):178-183.

Zhou Zhu, Huang Yi, Li Xiaoyu, et al. Automatic detecting and grading method of potatoes based on machine vision[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(7): 178-183. (in Chinese with English abstract)

[10] Camps-Valls G, Gomez-Chova L, Munoz-Mari J, et al. Composite kernels for hyperspectral image classification[J]. IEEE Geoscience & Remote Sensing Letters, 2006, 3(1): 93-97.

[11] Gowen A A, O'Donnell C P, Cullen P J, et al. Hyperspectral imaging an emerging process analytical tool for food quality and safety control[J]. Trends in Food Science & Technology, 2007, 18(12): 590-598.

[12] Zhao W, Du S. Spectral–spatial feature extraction for hyperspectral image classification: A dimension reduction and deep learning approach[J]. IEEE Transactions on Geoscience & Remote Sensing, 2016, 54(8): 4544-4554.

[13] 郑志雄,齐龙,马旭,等. 基于高光谱成像技术的水稻叶瘟病病害程度分级方法[J]. 农业工程学报,2013,29(19):138-144.

Zheng Zhixiong, Qi Long, Ma Xu, et al. Grading method of rice leaf blast using hyperspectral imaging technology[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(19): 138-144. (in Chinese with English abstract)

[14] Noordam J C, Otten G W, Timmermans T J M, et al. High-speed potato grading and quality inspection based on a color vision system[J]. Proceedings of SPIE The International Society for Optical Engineering, 2000, 3966: 206-217.

[15] Razmjooy N, Mousavi B S, Soleymani F. A real-time mathematical computer method for potato inspection using machine vision[J]. Computers & Mathematics with Applications, 2012, 63(1): 268-279.

[16] Moallem P, Razmjooy N. A multi layer perceptron neural network trained by invasive weed optimization for potato color image segmentation[J]. Trends in Applied Sciences Research, 2012, 6(6): 445-455.

[17] Mirjalili S. How effective is the grey wolf optimizer in training multi-layer perceptrons[J]. Applied Intelligence, 2015, 43(1):150-161.

[18] Amakdouf H, Mallahi M E, Zouhri A, et al. Classification and recognition of 3D image of charlier moments using a multilayer perceptron architecture[J]. Procedia Computer Science, 2018, 127: 226-235.

[19] Zhao Y, Zan Y, Wang X, et al. Fuzzy C-means clustering-based multilayer perceptron neural network for liver CT images automatic segmentation[C]// IEEE Control and Decision Conference, Xuzhou, 2010: 3423-3427.

[20] 田海韬,赵军,蒲富鹏. 马铃薯芽眼图像的分割与定位方法[J]. 浙江农业学报,2016,28(11):1947-1953. Tian Haitao, Zhao Jun, Pu Fupeng. A method for recognizing potato’s bud eye[J]. Acta Agriculturae Zhejiangensis, 2016, 28(11): 1947-1953. (in Chinese with English abstract)

[21] 王见,周勤,尹爱军. 改进Otsu算法与ELM融合的自然场景棉桃自适应分割方法[J]. 农业工程学报,2018,34(14):173-180.

Wang Jian, Zhou Qin, Yin Aijun. Self-adaptive segmentation method of cotton in natural scene by combining improved Otsu with ELM algorithm[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(14): 173-180. (in Chinese with English abstract)

[22] Otsu N A. Threshold selection method from gray-level histograms[J]. IEEE Transactions on Systems Man & Cybernetics, 2007, 9(1): 62-66.

[23] 邢作常,田素博,刘思瑶,等. 基于机器视觉的种薯自动切块机设计[J]. 农机化研究,2016,38(10):69-73.

Xing Zuochang, Tian Subo, Liu Siyao, et al. Design of automatic cutter for potato used as seeds based on machine vision[J]. Journal of Agricultural Mechanization Research, 2016, 38(10): 69-73. (in Chinese with English abstract)

[24] 张国强. 马铃薯种薯自动切块机的研究与设计[D]. 呼和浩特:内蒙古大学,2015.

Zhang Guoqiang. The Study and Design of the Potato Seed Auto Cutting Machine[D]. Hohhot: Inner Mongolia University, 2015. (in Chinese with English abstract)

[25] Martínez C L, Martínezrubin E, Floresgarcía F, et al. Identification of axillary buds of potato seedlings based on a vision system with fuzzy logic[J]. Phyton, 2011, 80(1): 79-84.

[26] Brabanter K D, Karsmakers P, Brabanter J D, et al. Confidence bands for least squares support vector machine classifiers: A regression approach[J]. Pattern Recognition, 2012, 45(6): 2280-2287.

[27] Huang H Z, Wang H K, Li Y F, et al. Support vector machine based estimation of remaining useful life: Current research status and future trends[J]. Journal of Mechanical Science & Technology, 2015, 29(1): 151-163.

[28] Huang X, Shi L, Suykens J A K. Asymmetric least squares support vector machine classifiers[J]. Computational Statistics & Data Analysis, 2014, 70(2): 395-405.

[29] Shah M P, Singha S, Awate S P. Leaf classification using marginalized shape context and shape+texture dual-path deep convolutional neural network[C/OL]// IEEE International Conference on Image Processing. Beijing, 2018[2018-09-07]. https://ieeexplore.ieee.org/document/8296403.DOI:10.1109/ICIP.2017.8296403.

[30] 黄双萍,孙超,齐龙,等. 基于深度卷积神经网络的水稻穗瘟病检测方法[J]. 农业工程学报,2017,33(20):169-176.

Huang Shuangping, Sun Chao, Qi Long, et al. Rice panicle blast identification method based on deep convolution neural network[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(20): 169-176. (in Chinese with English abstract)

[31] Babenko A, Slesarev A, Chigorin A, et al. Neural codes for image retrieval[C]// European Conference on Computer Vision. Springer, 2014: 584-599.

[32] He K M, Zhang X Y, Ren S Q, et al. Deep residual learning for image recognition[C]// Conference on Computer Vision and Pattern Recognition (CVPR). IEEE, 2016: 770-778.

[33] Bae W, Yoo J, Ye J C. Beyond deep residual learning for image restoration: Persistent homology-guided manifold simplification[C]//Computer Vision and Pattern Recognition Workshops. IEEE, 2017: 1141-1149.

[34] 李俊峰. 基于RGB色彩空间自然场景统计的无参考图像质量评价[J]. 自动化学报,2015,41(9):1601-1615.

Li Junfeng. No-reference image quality assessment based on natural scene statistics in RGB color space[J]. Acta Automatica Sinica, 2015, 41(9): 1601-1615. (in Chinese with English abstract)

[35] 徐德政,唐新明,祝小勇,等. 基于HSI色彩空间的资源三号影像阴影检测[J]. 测绘与空间地理信息,2017,40(1):56-58.

Xu Dezheng, Tang Xinming, Zhu Xiaoyong, et al. The shadow detection algorithm based on HSI color space for ZY-3 satellite[J]. Geomatics & Spatial Information Technology, 2017, 40(1): 56-58. (in Chinese with English abstract)

[36] Ma J, Fan X, Yang S X, et al. Contrast limited adaptive histogram equalization-based fusion in YIQ and HSI color spaces for underwater image enhancement[J/OL]. International Journal of Pattern Recognition & Artificial Intelligence, 2018, 32(7): 1[2018-09-07]. https://www. worldscientific.com/doi/pdf/10.1142/S0218001418540198.

[37] 刘黎明. CLAHE算法在不同彩色空间中的图像增强效果评估[J]. 舰船电子对抗,2016,39(6):62-68.

Liu Liming. Image enhancement effect evaluation of CLAHE algorithm in different color spaces[J]. Shipboard Electronic Countermeasure, 2016, 39(6): 62-68. (in Chinese with English abstract)

[38] Gong L H, He X T, Tan R C, et al. Single channel quantum color image encryption algorithm based on HSI model and quantum fourier transform[J]. International Journal of Theoretical Physics, 2017, 57(1/2): 1-15.

[39] Wu F, Kintak U. Low-Light image enhancement algorithm based on HSI color space[C/OL]// IEEE International Congress on Image & Signal Processing. Shanghai, 2018: 1[2018-09-07]. https://ieeexplore.ieee.org/document/8301957. DOI:10.1109/CISP-BMEI.2017.8301957.

[40] 王传宇,郭新宇,吴升,等. 基于计算机视觉的玉米果穗三维重建方法[J]. 农业机械学报,2014,45(9):274-279.

Wang Chuanyu, Guo Xinyu, Wu Sheng, et al. Three dimensional reconstruction of maize ear based on computer vision[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(9): 274-279. (in Chinese with English abstract)

Potato bud eyes recognition based on three-dimensional geometric features of color saturation

Li Yuhua1, Li Tianhua1, Niu Ziru1, Wu Yanqiang1, Zhang Zhilong1, Hou Jialin1,2※

(1.2710182.271018)

Potato is an important food crop with planting area been increased annually. Potato should be cut according to agronomic requirements before planting to make the potato sprout early and to increase the yield and to save the seed potato. The bud position and the weight of the seed potato cutting have an important influence on late growth of potato. Accurate identification of the bud eye is the premise of automatic cutting of seed potatoes. In addition, bud eyes are easy to be confused with mechanical damages such as growth spots, soil and skin breakage. In order to reduce the false recognition rate and improve the success rate of bud eyes recognition, a method for identifying potato buds based on three-dimensional geometric features of color saturation are proposed. By comparing the color space of potato, it is found that the color saturation componentin the HSI color space is the most obvious. In addition, it is less affected by light conditions, avoiding low recognition accuracy caused by interference of brightness factors. In this paper, four eigenvectors based on their longitudinal section curves and their first derivatives were proposed by analyzing thecomponent in the three-dimensional geometric space. The four-feature comprehensive judgment criterion was used to identify the bud eye longitudinally, and then the bud eye vertical recognition result was screened again according to the lateral characteristics of the bud eye. The modified method can greatly reduce the bud eye false recognition rate. The specific potato bud eyes recognition algorithm was as follows: 1) Color saturationcomponent was obtained by converting the acquired image from RGB color space to HSI color space. 2) Thecomponent curve was obtained by longitudinally column-by-column interception of the three-dimensional map of thecomponent. Then derivative curve was obtained by deriving thecomponent curve. 3) First, all the valley positions of the first derivative curve of thecomponent were obtained, and the four bud eye feature parameters corresponding to the position were obtained. Then, the bud eye was identified according to the determination rule. If the condition was satisfied, the corresponding row and column position was set to 0, otherwise it was set to 1. The bud eye binarization matrix was obtained by performing bud eye feature determination on all longitudinal columns of thecomponent three-dimensional map.4) According to the lateral continuity of the bud eye and the arc-like structure of the lower edge of the bud, the morphological processing of the bud eye binarization matrix was carried out, and the false bud eyes were further removed to complete the bud eyes recognition. The influence of defects such as broken skin, growth spots and mechanical damage on the accuracy of bud-eye recognition was also analyzed in this paper.The data indicated that mechanical damage, growth spots, etc. was not confused with bud eyes and caused misjudgment of the buds. The algorithm can effectively prevent the influence of these interference factors.The experimental results showed that the recognition rate of bud eyes was 91.48%, of which, the recognition rate of non-germinated buds, germinated buds and the false recognition rate of bud eyes was 92.21%, 89.00% and 4.32%, respectively. The probability of seed potato cutting without buds due to false recognition of bud eyes was less than 1.01%. This can effectively prevent the seedling shortage caused by potato cutting without buds, resulting in reduced production. The average time taken to identify a single image is 2.68 s. The results indicated that the method can provide reference for the bud eyes recognition of seed potato automatic cutting machine due to its low false recognition rate of bud eye, strong anti-interference ability and high stability.

crops; image processing; image recognition; potato bud eyes recognition; color saturation; 3D geometric features

李玉华,李天华,牛子孺,吴彦强,张智龙,侯加林. 基于色饱和度三维几何特征的马铃薯芽眼识别[J]. 农业工程学报,2018,34(24):158-164. doi:10.11975/j.issn.1002-6819.2018.24.019 http://www.tcsae.org

Li Yuhua, Li Tianhua, Niu Ziru, Wu Yanqiang, Zhang Zhilong, Hou Jialin. Potato bud eyes recognition based on three-dimensional geometric features of color saturation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(24): 158-164. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.24.019 http://www.tcsae.org

2018-09-07

2018-11-22

十三五国家重点研发计划智能农机装备专项“马铃薯精量播种技术与装备研发”(2017YFD0700705)

李玉华,讲师,博士研究生,主要从事智能农业装备研究。Email:liyuhua@sdau.edu.cn

侯加林,教授,博士生导师,主要从事智能农业装备研究。Email:jlhou@sdau.edu.cn

10.11975/j.issn.1002-6819.2018.24.019

TP391.41

A

1002-6819(2018)-24-0158-07