Effects of Different Times of Bagging on Fruit Quality and Disease and Pest Incidence of Fuji Apple

2019-01-14,,,

, , ,

Shandong Institute of Pomology, Tai’an 271000, China

Abstract The effects of bagging at different times in Mengyin area on the fruit quality and disease and pest incidence of Huimin short-cut Fuji apple were investigated, with unbagged fruit as the control. The results showed that among the apples bagged on May 5, May 15, May 25, June 2 and June 12, the single fruit weight and fruit shape index of the apples bagged on June 2 were highest, 308.1 g and 0.868, respectively; the peeled harness of the apples bagged during May 5-25 was higher than that of the control; the peeled harness of the apples bagged on June 2 and June 12 was lower than that of the control; the soluble solids content of bagged fruit was lower than that of unbagged ones, and no significant differences were found among different treatments; the coloring index of the apples bagged on June 2 was up to 100%; the smooth finish index of the apples bagged on May 5 reached 96.67%, the highest; the red chromatic value (a*) of bagged fruit was higher than that of unbagged ones, and there were no significant differences among different bagging treatments. The earlier the bagging was, the higher the incidence of black spot and bitter pit was. The incidence of black spot and bitter pit in bagged fruit was higher than that in unbagged ones. In conclusion, in Mengyin area of Shandong Province, bagging is better to be carried out on June 2, 45 d after the full bloom.

Key words Apple, Bagging time, Quality, Diseases and pests

1 Introduction

Appropriate fruiting bagging time can increase the commercial value of fruits. There are many researches on bagging cultivation, mostly focusing on the influence of bagging on peel structure[1], color change[2]and aromatic substances[3], as well as bagging methods[4], while the effects of bagging time on fruit quality and disease and pest incidence in apples are rarely reported[5-6]. This study investigated the effects of different bagging time on fruit quality and disease and pest incidence of Fuji apple, aiming to provide reference for timely bagging in production.

2 Materials and methods

2.1OverviewofexperimentalsiteThe experiment was carried out at the Red Fuji Apple Orchard in Yijiajuan Village, Yedian Town, Mengyin County, Linyi City, Shandong Province (Huimin Short-branch Fuji, grafting stockMalusmicromalus). The plant and row spacing was 3.5 m×4.5 m, north-south direction. The age of the trees was 22 years. The height of the trees was 3.9 m. The crown diameter was 3.7 m. The trees were small sparse crown-shaped, with normal robust growth. The texture of the soil in the orchard was hilly sand loam, and the management level was above average.

2.2ExperimentaldesignandmethodsThe fruit bagging experiment was conducted in 2014, using Kobayashi fruit bags (double layer, inner red and outer brown). A total of six treatments were designed, bagging on May 5, bagging on May 15, bagging on May 25, bagging on June 2, bagging on June 12, and unbagging (control). A total of three growth-uniform trees, 1.2-1.5 m high were arranged for each treatment. One big branch of the same size in the northwest of each tree was selected for fruit bagging experiment (single-branch plot, three replicates). The bags were removed synchronously on October 8.

2.3DeterminationoffruitqualityindicatorsandcountingofdiseasedandinfectedfruitThe mature fruit was harvested on October 20. A total of 30 apples were collected randomly from the selected branch of each tree, thus there were total 150 apples for each treatment. The collected apples were transferred to the laboratory to determine the quality indicators (each indicator was determine three times, and the final result was expressed as their mean). The single fruit weight was measured using an electronic platform scale. The fruit vertical and horizontal diameters were measured using a vernier caliper. The fruit peeled hardness was measured by GY-1 fruit hardness tester. The soluble solids content was measured by WYT handheld sugar meter. The fruit color was measured with CI-410 color difference meter (Japan).

Fruit coloring index (%)=(Number of fruit at each level×Representative value of each level)/(Total number of fruit×Value of the highest value)×100.

The grading standards for fruit coloring were as follows: level 0, 0%-5% of fruit surface colors; level 1, 5%-25% of fruit surface colors; level 2, 25%-50% of fruit surface colors; level 3, 50%-75% of fruit surface colors; level 4, 75%-100% of fruit surface colors.

Smooth finish index (%)=(Number of fruit at each level×Representative value of each level)/(Total number of fruit×Value of the highest value)×100.

The grading standards for smooth finish were as follows: level 0, 0-10% of fruit surface is bright and clean; level 1, 10%-30% of fruit surface is bright and clean; level 2, 30%-60% of fruit surface is bright and clean; level 3, 60%-85% of fruit surface is bright and clean; level 4, 85%-100% of fruit surface is bright and clean.

The number of diseased and infected fruit and the total number of investigated fruit in each treatment were counted. The percentage of diseased and infected fruit was calculated. The data were analyzed using DPS software (Zhejiang University) (Duncan’s multiple comparison).

3 Results and analysis

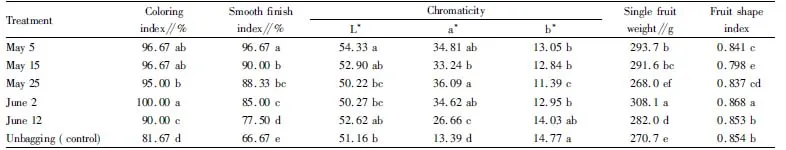

3.1EffectsofdifferenttimesofbaggingonappearancequalityofFujiappleAs shown in Table 1, The coloring indexes of bagged apples were all greater than that of the control (81.67%). The coloring index of the apples bagged on May 5 and May 15 were both 96.67%. The coloring index of the apples bagged on May 25 was 95.00%. The coloring index of the apples bagged on June 2 was the highest, 100.00%. The coloring index of the apples bagged on June 12 was the lowest, 90.00%. The coloring indexes of the apples bagged on May 5, May 15 and June 2 showed no significant differences, but they all higher than those of the apples bagged on May 25 and June 12.

The smooth finish index showed a downward trend with the delay of bagging time. The smooth finish indexes of the bagged fruit were higher than that of the control. Among the five bagging treatments, the smooth finish index of the fruit bagged on May 5 was the highest, 96.67%, while the smooth finish index of the fruit bagged on June 12 was the lowest, 77.50%. There were significant differences among different bagging treatments.

The L*value (indicating the luster brightness) of the fruit bagged on May 5 was the highest (54.33), and it was significantly higher than those of the fruit bagged on May 25 (50.22), June 2 (50.27) and the fruit unbagged (51.16). The change trend of a*value (indicating red) was basically consistent with that of the L*value. The a*value of the fruit bagged on May 25 was the highest (36.09), and it was significantly higher than those of the fruit bagged on May 15 (33.24), June 12 (26.66) and the fruit unbagged (13.39). The b*value (indicating yellow) decreased first and then increased. The b*value of the control was highest (14.77). Among different bagging treatments, the b*value of the fruit bagged on June 12 was the highest (14.03), and it was significantly higher than those of the other four bagging treatments. The b*value of the fruit bagged on May 25 was lowest (11.39). It indicates that too early or too late bagging is not good for the appearance quality of fruit.

The single fruit weight of the apples bagged on June 2 was highest (308.1 g), and it was significantly higher than those of the other bagging treatments. The single fruit weights of bagging treatments were significantly higher than that of the control. The fruit shape index of the apples bagged on June 2 was highest (0.868), and it was significantly higher than those of the other bagging treatments and the control. The fruit shape index of the other bagging treatments were significantly lower than that of the control.

Table 1 Effects of different times of bagging on appearance quality of Fuji apple

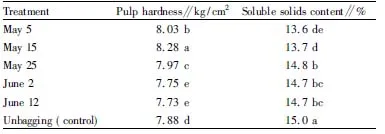

3.2EffectsofdifferenttimesofbaggingoninternalqualityofFujiappleAs shown in Table 2, the fruit peeled hardness changed stepwise with the delay of bagging time. The peeled hardness of the fruit bagged on May 5 (8.03 kg/cm2), May 15 (8.28 kg/cm2) and May 25 (7.97 kg/cm2) was significantly higher than that of the control (7.88 kg/cm2), and the peeled hardness of the fruit bagged on June 2 (7.75 kg/cm2) and June 12 (7.73 kg/cm2) was significantly higher than that of the control.

The soluble solids content increased with the delay of bagging time. The soluble solids contents of the bagging treatments were all lower than that of the control (15.0%). The soluble solids contents of the fruit bagged on May 25 (14.8%), June 2 (14.7%) and June 12 (14.7%) were higher, and there were no significant differences among them. They were higher than those of the fruit bagged on May 5 (13.6%) and May 15 (13.7%).

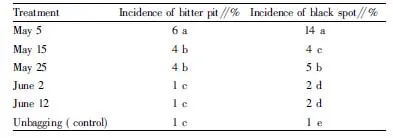

3.3EffectsofdifferenttimesofbaggingonincidenceofdiseasesandpestsinFujiappleAs shown in Table 3, the incidence of black spot and bitter pit decreased with the delay of bagging time. The incidences of these two diseases were both lowest in the control group (both 1%). The incidences of bitter pit in the fruit bagged on May 5 (6%), May 15 (4%) and May 25 (4%) were significantly higher than those of the fruit bagged later (1%, 1%) and the fruit unbagged (1%). The incidences of black spot in the bagged fruit were significantly higher than that the unbagged fruit (1%). The incidences of black spot in the fruit bagged on June 2 (2%) and June 12 (2%) were lowest, and they were significantly difference from those of the fruit bagged earlier.

Table 2 Effects of different times of bagging on internal quality of Fuji apple

Table 3 Effects of different times of bagging on incidence of bitter pit and black spot in Fuji apple

4 Conclusions and discussions

There were significant differences in the appearance quality, internal quality and disease and pest incidence of Fuji apples bagged at different times.

The single fruit weights of the fruit bagged were significantly higher than that of the fruit unbagged. The single fruit weight of the apples bagged on June 2 was the highest. Basically, the sooner the bagging was, the greater the weight of the single fruit was. This is consistent with the findings of Cao Hui and Han Mingsan[5, 7]. However, there are also opposite results[8-9]. It may be because the fruit bags and apple varieties are different and further research is needed.

The smooth finish index of the apples bagged on May 5 was the highest, and that of the apples bagged on June 12 was the lowest. There were significant differences in the smooth finish index among different bagging times. The smooth finish indexes of the fruit bagged were all higher than that of the fruit unbagged. Bagging significantly improved the smoothness of the fruit surface. This is consistent with the results of previous studies[10-12].

The soluble solids content of the fruit increased with the delay of bagging time. Bagging helped to form a high temperature microenvironment for the fruit, which increased consumption of carbohydrates. The green pee of apples has a carbon assimilation of 1/10 of the leaves. The photosynthetic product is stored directly in the fruit. After the fruit is wrapped in a double-layer paper bag, the shading effect makes the fruit basically have no photosynthetic ability, reducing the accumulation of organic substances such as sugar. The earlier the bagging is, the more obvious this effect is. This is the same as the results of previous studies[13-14].

The incidence of bitter pit and black spot in bagged fruit was higher than that in unbagged fruit. Bagging reduced pests and diseases but increased the incidence of black spot and bitter pit. The incidence of bitter pit is related to the lack of calcium in the fruit. This study found that the calcium content of the bagged fruit was significantly lower than that of the unbagged (data not published). This is basically consistent with previous studies[15-17]. The increased incidence of black spot in bagged fruit might be related to the bagging microenvironment. The temperature and humidity inside bags were high, conducive to the propagation of pathogens in calyx depression. The peel was young and vulnerable, and pathogens might invade from the lenticels of the pericarp, leading to black spot. The mechanism needs further study.

In conclusion, in Mengyin area of Shandong Province, bagging is better to be carried out on June 2, 45 d after full bloom.

杂志排行

Asian Agricultural Research的其它文章

- Optimization of Germinated Conditions for Somatic Embryos in Liriodendron Hybrids

- Effects of Bio-organic Selenium on Agronomic Economic Traits and Selenium Absorption and Distribution in Rice

- Effects of Different Water-soluble Fertilizers on Yield and Quality of Strawberry under Integrated Application of Water and Fertilizer

- Land Use Analysis of Yichun-Wanzai Expressway

- MEC Based Study of Brand Building of Hongyue Garden Maker

- Effects of Human Capital Investment on Entrepreneurial Capability of New Generation of Migrant Workers

——An Empirical Study Based on Questionnaire Survey in Chongqing