芳纶1313/PANOF针刺滤料的制备及性能

2019-01-10王艳丽吴玲娜金万慧胡国樑

王艳丽 吴玲娜 金万慧 胡国樑

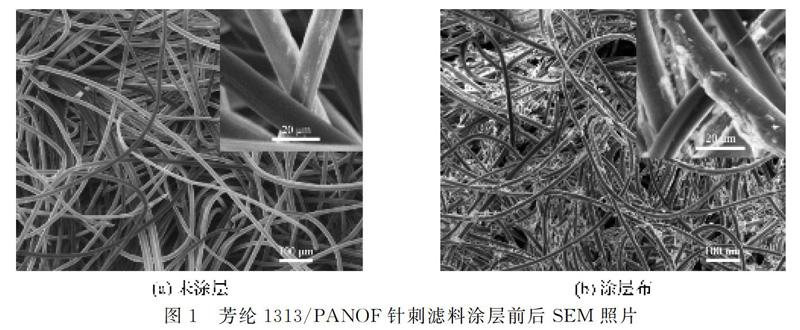

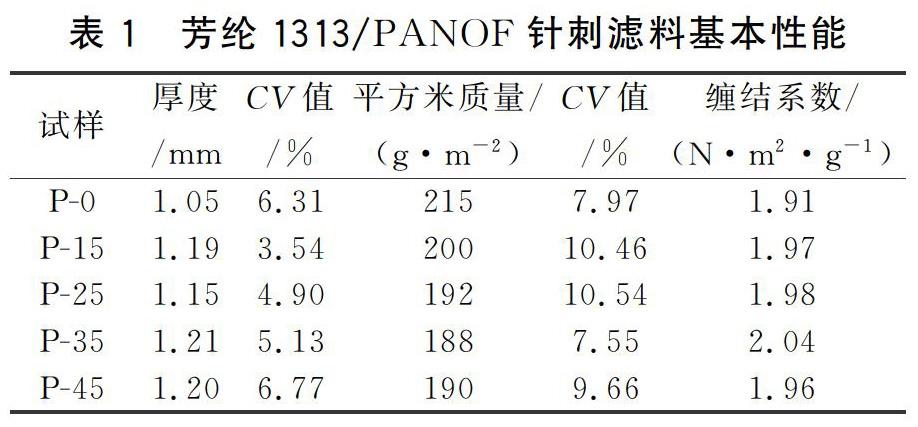

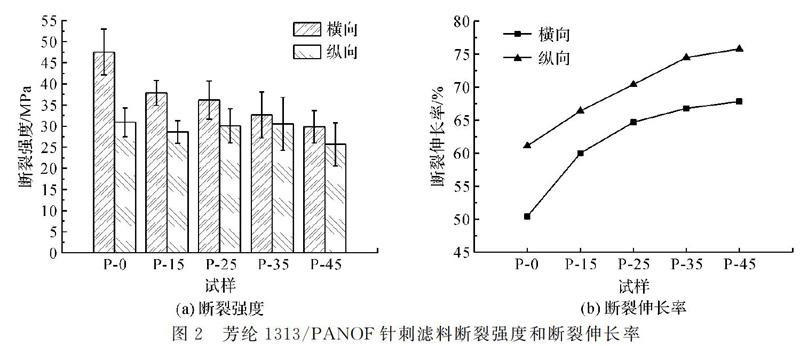

摘 要:为提高芳纶滤料的耐高温性并降低滤料的生产成本,以芳纶1313纤维为主要原料,通过混入不同质量分数的PAN预氧化纤维,制备了芳纶1313/PANOF复合针刺毡,并对其进行PTFE涂层整理。通过对所得复合针刺毡结构、力学性能、过滤性能以及耐高温性能等进行表征和分析,结果表明:添加PAN预氧化纤维,提高了芳纶1313/PANOF复合滤料的缠结性能,减小了滤料的孔径尺寸,滤料透气量降低,过滤阻力增大;对于粒径0.3 μm的微粒,PANOF质量分数低于35%时,滤料过滤效率随PANOF含量的增加而明显提高;随着PANOF含量的增加,滤料横向断裂强度逐渐降低,横向和纵向断裂伸长率均逐渐增大;5组试样均具有优良的耐高温性,200 ℃高温下,滤料的纤维结构没有发生明显变化,该滤料适用于200 ℃的高温条件。

关键词:芳纶1313;PAN预氧化纤维;过滤;耐高温

中图分类号:TS174

文献标志码:A

文章编号:1009-265X(2019)06-0026-05

Abstract:In order to improve the resistance to high temperature of aramid filter material and reduce its production cost, aramid 1313/PANOF composite needled felt was prepared by mixing pre-oxidation PAN fiber of different mass fractions into aramid 1313 fiber, and was coating finished with PTFE. The structure, mechanical performance, filtration performance and high temperature resistant performance of the composite needled felt were characterized and analyzed. The result show that the addition of pre-oxidation PAN fiber can improve the entanglement of aramid 1313/PANOF composite filter material, and decrease the pore size, so that the air permeability of filter material decreases, and the filtration resistance increases. For particles with diameters at 0.3μm, the filtration efficiency of the filter material is significantly increased with the increase of content of pre-oxidation PAN fiber in the case that the mass fraction of pre-oxidation PAN fiber is lower than 35%. The transverse breaking strength of filter decreases gradually, and the breaking elongation of transverse and longitudinal increases gradually with the increase of pre-oxidation PAN fiber. All samples of the five groups have good high temperature resistance. The fiber structure of the filter material has no obvious change at 200 ℃, so the filter material is suitable for the high temperature of 200 ℃.

Key words:aramid 1313 fiber; pre-oxidized PAN fiber; filtration; high temperature resistance

芳綸1313纤维(MPIA),全称“间苯二甲酰间苯二胺”,是由间苯二胺和间苯二甲酰氯缩聚后经溶液纺丝而成,具有低刚度、高伸长、耐高温、耐酸碱等优良特性,是制备耐高温滤料的较理想材料[1]。由于间位芳纶纤维大分子结构中苯环与酰胺键之间存在空间位阻,在强碱或强酸的高温环境中酰胺键会水解断裂[2-3],这使得芳纶1313在电厂烟气除尘领域的应用受到一定限制。

PAN预氧化纤维(PANOF)极限氧指数大于40%,热稳定性优良,在火焰中燃烧不软化收缩、无熔滴,具有优异的耐酸碱腐蚀性[4-6]。PAN预氧化纤维作为碳纤维的前驱体,价格低廉且性能优异,添加PAN预氧化纤维可以降低芳纶滤料的生产成本,弥补芳纶纤维高温强酸碱环境下水解这一缺点,从而提高芳纶滤料在高温烟气过滤领域的综合应用价值。本文以芳纶1313纤维为主要材料,通过与不同质量比的PAN预氧化纤维混合,制备过滤基材,将基材进行轧光和PTFE涂层整理得到芳纶1313/PANOF复合滤料。通过测试滤料的表观形貌、拉伸性能、过滤性能和耐高温性能来分析PAN预氧化纤维质量分数对芳纶1313/PANOF针刺滤料性能的影响。

1 实 验