An experimental and numerical approach-characterisation of power cartridge for water-jet application

2018-12-25BhupeshAmadasParateSunilChandelHimanshuShekhar

Bhupesh Amadas Parate,Sunil Chandel,Himanshu Shekhar

aArmament Research&Development Establishment(ARDE),Dr.Homi Bhabha Road,Pashan,Pune 411021,India

bDefence Institute of Advanced Technology(DIAT),Giri Nagar,Khadakwasala,Pune,411025,India

cHigh Energy Material Research Laboratory(HEMRL),Sutarwadi,Pashan,Pune,411021,India

Keywords:All fire current Closed vessel Booster Characterisation Disruptor Finite element method Ignition delay Maximum pressure No fire current Power cartridge Propellant&water-jet

A B S T R A C T Power Cartridges are pyrotechnic devices where hot combustion gases utilized to do mechanical work for disruption of suspected Improvised Explosive Devices(IEDs).It plays a vital role either in destroying the suspicious object or making them non-functional by generating the gas pressure on burning of propellant against the water column inside the barrel.Present work is focused on characterisation,numerical solution such as deformation;strain;stress using FEM(Finite Element Method),design qualification,performance and evaluation of power cartridge for disruptor application.Experimental trials for pressure-time(P-t)measurement in closed vessel(CV),various electrical parameters like allfire current(AFC),no fire current(NFC)and ignition delay have been measured.Further,mechanical properties for brass material have been determined.An attempt has been made to characterise the power cartridge by FEM and carrying out the experiments for water-jet application.

1.Introduction

Power Cartridges are called as Propellant Actuated Devices(PAD)which gives certain performances to perform various tasks.Upon initiation,they generate the gases which give certain specifi ed performances.These cartridges are single-shot operating device and their performance can't be tested by Non Destructive Techniques(NDT).Propellants on burning produce high pressure and high temperature gases.It is combination of squib,pyrotechnic&the propellant in hermetically sealed metallic container.They provide propulsive forces through combustion phenomenon.Such a phenomenon includes complex physiochemical changes from solid to liquid and gas accompanied by rapid exothermic reactions[1].They are suitably initiated either electrically or mechanically.Power Cartridges are filled with different types of propellants as energetic material,either single or double base propellants,or pyrotechnic composition as a booster[2].In addition to this,other ingredients are also added to improve the performance.Constantin et al.have studied water-jet propulsion during high explosives detonation.They have carried out numerical simulation and experimental tests on explosively-induced water-jet phenomena[3].Marek Radomski has carried out analysis concerning the recoil effect as well as development of a mathematical model describing the internal ballistics of a two-chambered projected water disruptor[4].O'Rourke patented a disruptor apparatus that is fired from a shotgun[5].Chiu et al.patented a modular disruptor system.This modular disruptor system is comprised of interchangeable components-enabling it to replicate the firing capabilities of three different disruptor systems[6,7].The cartridge used for present study is used in destruction of suspected improvised explosive devices(IEDs)by creating high velocity water-jet.

1.1.Description of cartridge

The cartridge used for the present study for water-jet application is comprises of end cap,case&foil assembly.The cartridge has internal threads to accommodate the end cap.The end cap has central squib at one end.Case and end cap both are made up of brass.The cartridge is filled with single base propellant as main charge and pyrotechnic composition(Aluminium&Potassium perchlorate)as booster.Fig.1 shows cartridge model and its detail parts.

The characterisation of power cartridge in terms of internal ballistics(pressure)and various electrical parameters were generated experimentally by conducting various trials.The main aim of this paper is to study the characterisation&numerical analysis of cartridge case of power cartridge for water-jet application.

1.2.Applications of power cartridges

Important application of power cartridges are

a)To disrupt the suspected IED's

b)To set time delay mechanisms

c)To operate fire extinguisher bottle

d)To release of armaments from the aircraft

e)To jettison of fuel tanks

f)Signaling during air traffic control

g)To deploy kits for retardation system stores

h)For stage separation in missiles and satellites

i)To escape the pilot from the disabled aircraft in emergency

The paper is organized as follows:Section 2 includes Design Assumptions&Considerations;Sections 3 discussed about Determination of Thermo-Dynamic properties of the Propellant;Section 4 is related toMaterials&Methods;Section 5 present Experiments;Section 6 gives information about the Design Qualification Tests.Examples of the results of numerical computations are provided in Section 7,and Section 8 presents Results&Discussions.

2.Design assumptions&considerations

The important considerations in designing this cartridge are pressure,volume available for loading the propellant,and safety aspects.The volume of the cartridge depends on its length and diameter.The following assumptions and considerations are made in the cartridge case design.

2.1.Cartridge case design and manufacturing

The main purpose of cartridge case is to accommodate the propellant charge,hold the ignition and protect the propellant[8].The cartridge design depends on following factors:

a)Type of initiation:mechanical or electrical

Electrical method is selected as battery power is readily available and it is highly reliable being no tear&wear mechanical contact between the parts.

b)Type of propellant selected:single or double base

Single base propellant is selected as it meets the ballistic requirements,high performance and safe during handling,storage and transportation.

c)Pyrotechnic material as a booster

It has the capability to boost the flame of created by the squib.

d)Case material:brass or aluminium.The brass material is selected while designing the cartridge case.It withstands the maximum pressure,obturation requirements,strength of the material and compatibility with the explosives.This material is used worldwide and proved for use in various ammunition.The breech of the system governs the diameter of the cartridge case.The length is governed by the quantity of the propellant needed and the space required to house the electric moulded squib and closing disc for releasing the propellant gases after its burning.

Cartridge cases are generally made from ‘cartridge brass’which is 70/30(Cu&Zn percentage).

The other aspects are explained in the succeeding paragraphs.

2.2.Estimation of pressure(Pi)

Internal pressure generated inside the cartridge case can be determined by using the following relation

Where F and C are the force constant&charge mass of propellant,and V is the volume available for loading the propellant inside the metallic case.

2.3.Estimation of cartridge case thickness(tc)

Based on thin cylinder formula,the thickness of the cartridge case(tc)can be determined if the internal diameter(d)of the case is known[9].

Where h is Hoop stress and n is the Factor of Safety.The factor of safety is considered as 1.3.

3.Determination of thermo-dynamic properties of the propellant

3.1.Mathematical forms

Thermodynamic properties of propellant can be determined in following ways.

3.2.Gas volume(V)

For ideal gas,the gas volume generated by propellant can be determined using state equation[10].

where m=nM.

M is molecular weight,m is mass of gaseous products and n is the Number of moles of gas per unit mass.

But for real gases,volume of gas generated is calculated by applying correction factor for volume.

where b is co-volume of combustion gas and depends upon the type of gas created by combustion of propellant and p is the absolute pressure of gas.

These equations are based on assumption of complete reaction to yield maximum volume.The volume of the gases is generally calculated at a pressure of 1bar and temperature 0°C(273 k0)and it lies between 700 and 1000cm3for military explosives[11].

3.3.Gas temperature(T)

Re-write equation(6)and arranged as

M is Molecular weight,knowing all the variables on right hand side,the gas temperature can be determined.

3.4.Adiabatic flame temperature(Te)

It is the maximum temperature,that the gaseous products of propellant can reach if there no heat loss to the surroundings.Teis observed to lie between 2500 and 40000k for military explosive.It can be calculated quiteeasily if the quantities and nature of gaseous products and heat generated(Q)are known[11].

3.5.Force constant(F)

Force constant is the chief performance parameter for the propellant i.e.the maximum amount of energy,which can be obtained by burning unit mass of propellant.It gives the energy by burning unit mass of propellant in a given fixed volume[11].As applied to internal ballistics,it is the measure of flame temperature&number of moles of combustion gas per unit mass.

R is the gas constant for products of combustion.

Alternatively,Force constant is also determined by burning known weight(C)of the propellant in Closed Vessel(CV).

Equations(1)and(10)are same except the term(v-b)which is applied as correction to volume.

3.6.Heat generation(Q)

Amount of heat generated by burning of propellant in CV at constant volume can be determined as[11].

whereγis ratio of specific heat for gases.

4.Materials&methods

4.1.Propellant composition

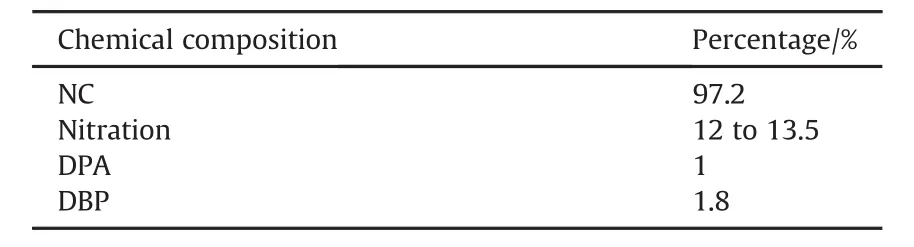

The energy produced by unit volume is known as‘energy density’which is important property of the propellant.The method for determination of internal ballistic properties using CV consists of burning of the given mass of propellant.The chemical composition&physical properties of propellant are given in Tables 1 and 2 respectively[12].The in-gradients of pyrotechnic composition used as booster are made up of Potassium perchlorate,aluminium powder&binder.

The single base propellant used for testing in the power cartridge is shown in Fig.2.

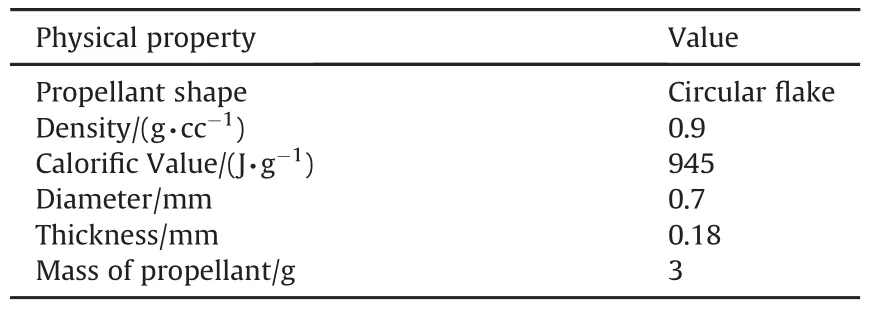

Electrical initiation is selected means of initiation,as it gives consistent,repeatable performance,long shelf life,offers the excellent environmental characteristics,highest reliability and the greatest power-to-weight ratio.The nichrome wire or similar type of heating element is soldered between the two leads of the squib.The electrical energy is given through the lead wires to the squib.

Fig.3 shows the photo of squib which is used in experiment of water-jet disruptor for initiation of cartridge.It consists of bulb of sensitive composition on bridge wire,moulded plug and lead wires for electrical connection.

The squib used for various experimental studies are manufactured using the Nichrome&Polyamide materials.The physical properties of Nichrome&Polyamide materials used for construction of squib are given in Table 3.

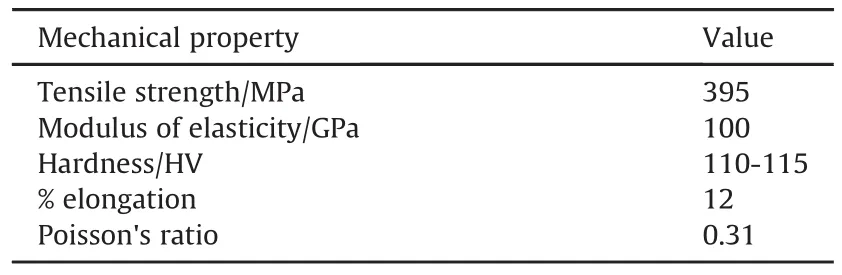

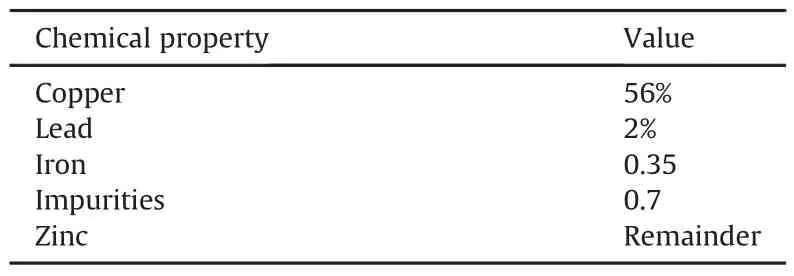

The cartridge case(60/40:Cu/Zn)used for this application and has a yield strength of 250 MPa[13].The mechanical and chemical properties of brass material are given in Tables 4 and 5 respectively.

The tensile test conducted for brass material in the form of stress-strain curve is illustrated in Fig.4.The stress-strain graph is obtained by subjecting test specimen on ultimate tensile machine.

Table 1 Chemical composition of the single base propellant.

Table 2 Physical properties of the single base propellant.

5.Experimental

5.1.Test set up

An experimental test set-up consists of CV,Gauge Adaptor having pressure sensor,Yokogava Scope Corder DL850E and charge amplifier.An experimental set-up is shown in Fig.5.

The CV test is cylindrical in shape consists of burning a weighed quantity of propellant in a vessel having constant volume.The vessel is made up of Nickel-Chrome-Molybdenum steel material.CV firings of a cartridge having single base propellant were carried out in hot&cold conditions.A hole of diameter 5mm is drilled to the body for tapping the pressure.The internal diameter and length of the vessel are 40&118 mm respectively.The cartridge is loaded in the cartridge holder at one end&screws the end plug at other end of the vessel.Gas pressure is generated in CV by burning the propellant under constant volume.This pressure is transmitted to the pressure&fitted in radial direction and perpendicular to theaxis of body.It converts this pressure into voltage,which is further amplified by amplifier.The rate of charge produced is proportional to the rate of change of pressure applied as input.As charge produced is very small,a charge amplifier is essential so as to produce an output voltage which is enough to be measured.This proves that the device is best applicable for dynamic measurement.The result is recorded in the form of Pressure-time(P-t)curve.The pressure rises smoothly and continuously to a maximum pressure and time corresponding to maximum pressure.Ignition delay is measured from the start of current to the point where pressure start rising as indicated in Fig.6.

Table 3 Properties of Ni-chrome wire&squib-polyamide.

Table 4 Mechanical properties of brass material.

Table 5 Chemical properties of brass material.

An extension of CV method is to determine the burn rates of propellants in the pressure region of 9.8-75 MPa were introduced by D Vittal[14,15].The method consists of burning of a known charge weight&web size of the test propellant along-with a known charge weight of standard propellant whose burning rate is very fast compared to the test propellant.When the propellant burns inside the vessel,a large quantity of gas in terms of moles per unit mass is generated.The gas(combustion products of propellant)acts as a working fluid on the walls of vessel.A typical P-t curve obtained during CV firing using single base propellant is seen on the screen of scope corder.These firing graphs in Hot(Red colour)&Cold(Black colour)conditions are superimposed for comparative study as depicted in Fig.6.

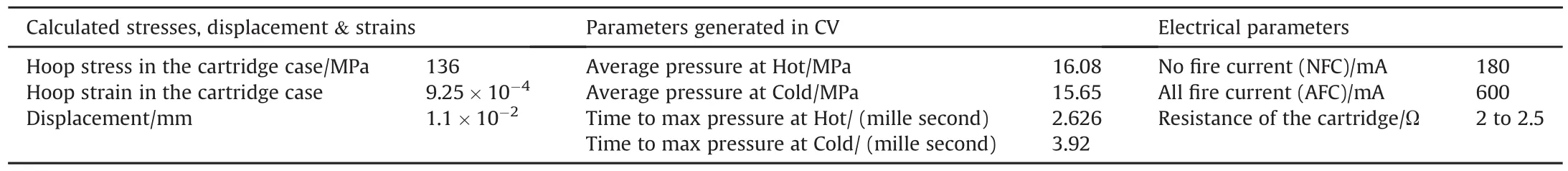

From the above graphs,it is noticed that the pressure is decreasing after reaching the maximum pressure.This phenomenon is due to heat loss to the walls of vessel,due to conduction&convection as explained by B A Parate et al.[16].In practise,there will be always heat loss to the surrounding.The same phenomenon is observed during firing of cartridge in the vessel.Average pressure of 16.08&15.65 MPaat Hot 45°C and Cold-26°C conditions have been generated,whereas time to maximum pressure in hot and cold 2.626&3.92 mille second respectively.The ignition delay is 42.5 mille second.The ignition delay has no effect on the loading of propellant inside the cartridge.A little consideration shows that energy released by the propellant undergoes several conversions.Estimation of such ballistic parameters helps in modelling of propellants through CV tests[17].This energy is used for creation of water-jet for disruptor system.CV tests are generally carried out during manufacturing stages as quality control tool to maintain adherence of specified quality.Pragati Mehta et al.carried out CVfiring of gun propellant at different loading densities for evaluation of its ballistic parameters.The author reported that pressure in CV depends on loading density of propellant[18].Bin XU et al.calculatedthe gas pressure of gunpropellant in the close bomb test using different loading density by simple extended corresponding state principle[19].

6.Design qualification tests(DQT)

After completion of design of power cartridges,certain tests are essential to prove the design.In order to qualify the design aspects of the cartridges,the following tests were performed as per JSG 0102[20].They are explained in the following section.

6.1.Impact test

Cartridges were dropped from height of 1.5 m to ensure safety during handling and transportation.No cartridges should function during testing.This test was carried out to reveal any marked tendency for the cartridges to be function when dropped.

To ensure safety in handling and transportation,cartridges were dropped from 12m height.Cartridges were dropped,in vertical with each in different orientations.No cartridges have found functioned after this test.After,this test revealed that cartridges were safe during handling and transportation.

6.2.Sealing test

The main purpose of this test is to detect the leak from all possible joints.Cartridges were subjected to sealing test at 380mm of Hg so as to confirm hermetical sealing by using suitable adaptor/fi xture.All the cartridges were found leak proof after conduct of this test.At the end of this test,it was concluded that all cartridges were hermetically sealed.

6.3.Vibration test

Cartridges were subjected to vibration tests with the help of vibrationfixture.Sinusoidalvibration with frequency range 5-70Hz and peak-to-peak displacement of 12 mm is applied for 2 and½hrs.This was followed by random vibration having uniform spectral density 0.03g2/Hz in the frequency range from 70 to 2000Hz for½hours on both the axes.The cartridges have been successfully passed through vibrations tests and withstood all the induced forces.The sinusoidal and random vibration graphs are illustrated in Figs.7 and 8 respectively.

6.3.1.Shock test

This test was carried out to simulate the effects of infrequent non repetitive shocks which the cartridges are liable to encounter in service or during handling,transportation.The details of the test are as under.

(i)Peak acceleration:20 g

(ii)No.of shocks:12(6 shocks are in vertical axis&6 shocks are in horizontal axis)

(iii)Time:11 mille second

(iv)Wave form:Terminal peak saw tooth

At the end of above tests,CV firing was carried out at Hot and Cold conditions in equal numbers.All cartridges were function satisfactorily and realised the performance in CV.

7.Energy calculation of squib

Minimum electrical energy is required for initiation of squib,just sufficient to raise the temperature of a bridge wire to the temperature of ignition of explosive composition.This composition is in contact with the bridge wire.The firing current is the characteristic of squib which tells about for safe handling&high confi dence of firing.

The Bruceton stair case method was used to determine the allfire current(AFC)&no fire current(NFC)of the squib[21-23].The energy of squib is calculated by I2Rt method.The energy calculations of squibs for two cases are as follows.

(i)Maximum no fire current(NFC)

(ii)Minimum all fire current(AFC)

where

P is power&t is time

where.

I-Current in ampere

R-Resistance inΩ

t-Time(duration)in sec

7.1.Power for no fire current(NFC)

This is the maximum current that can be applied at which the probability of ‘squib not firing’is 99.9%.It was determined by Bruceton method.NFC is important as a measure of the energy or power that,if inadvertently induced in a firing circuit,may cause un-commanded initiation of the squib.

I-180 mA.

R-2Ω (Average of 1.5-2.5Ω)

t-5 s

No Fire Energy(J)=0.18×0.18×2×5=0.324J

7.2.Power for all fire current(AFC)

The minimum current that can be applied at which the'probability of squib firing’is 99.9%which will always fire the squib.It was determined by Bruceton method.For each type of squib to function,there is certain value of firing current above which all squibs should function without any failure.AFC is important,as the power source must be capable of supplying this power or energy over the specified life cycle of the system.

I-600 mA.

R-2Ω (Average of 1.5-2.5Ω)

t-10 mille second

All Fire Energy(J)=0.6×0.6×2×0.01=0.0072J or 7.2 mJ

7.3.Trials conducted

The experimental trials were conducted on ply wood and steel targets after completion of design qualification and characterisation of power cartridges.The disruptor is positioned on the tripod at stand-off distances of 0.5 m from the target.The disruptor solid model with cartridge is shown in Fig.9.The firing of disruptor,which shows the penetration on wood&steel plate targets having thickness of 15 mm and 0.5 mm thickness respectively at a stand-off distance of 0.5 m is illustrated in Fig.10.This shows penetration capability of water-jet disruptor with different target material and thickness.

8.Results&discussions

Average pressure of 16.08&15.65MPaat Hot 45°C and Cold-26°C have been generated,whereas time to maximum pressure in hot and cold 2.626&3.92 mille second respectively.These pressures and time to maximum pressure were determined using statistical methods by firing cartridges in CV.The pressure generated by the cartridges indicates that it definitely defeat the target.The ignition delay measured from data acquisition is recorded as 42.5 mille second.The performance of the cartridge using disruptor ensures that it meets the specification of user.The actual firing of the cartridges gives penetration on wood as well steel target.

The numerical values for deformations strains and stresses for brass cartridge case are carried out using FEM tool.The estimation of stresses and strains are important from design point of view.The different contour plots for displacements,strains,stresses are shown in Fig.11(a),(b)and(c)respectively.

Table 6 Numerical values.

Average electrical resistance of the cartridge is also calculated.AFC&NFC were determined as explained in above paragraphs are given in Table 6.Squibs are static sensitive and are more prevalent in low humidity conditions.Shunting of lead wires gives the protection from static charges during handling and transportation.

Three hundred cartridges were fired to generate these data.Characterisation process evolved many parameters such as cartridge dimensions,propellant and materials selection to meet the stringent qualification and operational requirements.In practice,a large number of trial firings with permutations&combinations are required to assess the charge mass to get desired results.

9.Concluding remarks

This article describes the numerical characterisation of power cartridge for water-jet application by conducting different trials.Data for pressure measurement in CV,mechanical properties of brass material&electrical properties were generated.

Conflicts of interest

The authors declare that there is no conflict of interests regarding the publication of this paper.

Acknowledgements

Authors are grateful to Dr.K M Rajan,Distinguish Scientist&Dir.ARDE,Pashan,Pune-411021 for his kind permission to publish this work.The authors also extend their sincere thanks to Shri.D K Joshi,Sc.‘G’,Associate Dir.for his invaluable guidance and support.Authors would like to thank to Range Division for providing the data acquisition facility and vibration facility for smooth conduct of different experimental trials.

杂志排行

Defence Technology的其它文章

- Novel approach to quantify the chemical stability and shelf life of modified double-base propellants

- Influence of control strategy on stability of dual-spin projectiles withfixed canards

- Study on buffering performance of thin-walled metal tube with different angles

- Path planning in uncertain environment by using firefly algorithm

- Analysis and use of fuzzy intelligent technique for navigation of humanoid robot in obstacle prone zone

- The law of barrel wear and its application