The law of barrel wear and its application

2018-12-25JishengMa

Ji-sheng Ma

School of Mechanical Engineering,Xijing University,1 Xijing Road,Chang'an District,Xi'an City,Shaanxi Province,710123,China

Keywords:Barrel life Prediction model Law of barrel wear Curve fitting

A B S T R A C T A power function relation between number of rounds and barrel wear amount is created based on the test data from firing of large-caliber barrels.The function is optimized to fully fit the test data.A new concept of diameter change rate of bore is proposed and the law of barrel wear is put forward by means of comparing the diameter change rates for large-caliber barrels with different calibers.It is shown that the law of barrel wear is successful in barrel life prediction.

1.Introduction

A large-caliber barrelis avery important partof a gun for it takes almostone-third of thewhole cost of the gun,and it is difficult to be repaired when the erosion and wear reach to a certain amount.For most of artillery,barrel life basically determines the life of the whole artillery.The study of barrel's ablation rules can predict barrel life effectively which is of great significance for combat mission and effective support for the gun.With increases in gun performance,the working conditions of the barrel become worse which highlights the importance of the study of barrel wear.The erosion and wear result in the increasing of the bore diameter,which is referred to as barrel wear in this paper.Lawton B[1]studied the relationship between the amount of ablation of the uncoated tube and the maximum wall temperature in the bore.There are 7 parameters in the formula of the relationship.Chung[2]presented an equation that accurately calculates the erosion rate of large-caliber cannon barrels while contains 7 parameters.There are as many as 11 parameters in Rauf Imam's empirical equation of barrel wear[3].Obviously,the application of the above methods is very inconvenient,because the value of the parameters should be determined in advance.Jianjie Zhu[4]commented on the above methods and made a qualitative analysis of barrel life prediction and life extension technology.Jitendra Jain[5]gave a fit equation for measured wear with respect to EFC for 155 mm gun tube and compared with estimated wear of several wear theories.The comparison results show that there is a large gap between the theoretical and experimental values.Jitendra's research shows that thetheories of barrel wearare notonlycomplex but also inaccurate.So the study of barrel life must be based on experimental data and discovery of new laws.

A large number of experiments have shown that the maximum wear position is at the commencement of rifling.The diameter variation of the maximum wear position is regarded as the barrel wear amount.In this paper,a power function relation between number of rounds fired and barrel wear amount is built based on test data from firings of three kinds of large-caliber gun barrels.This relation is a barrel life prediction model and is optimized to be highly consistent with the test data.On the basis of this model,a new concept,that is diameter change rate of bore,is put forward and the law of barrel wear is obtained by the comparing of the diameter change rates of different caliber barrels.A method of barrel life prediction is obtained which is verified by the test data from firing of a medium-caliber barrel.The results show that the barrel life prediction method is effective.

2.Prediction model and optimization of barrel life

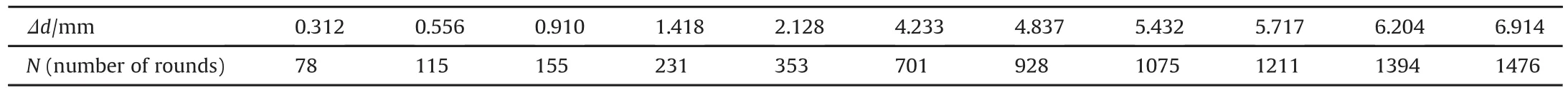

As shown in Table 1,Δd is the radial wear amount at the commencement of rifling,number of rounds is the effective full charge,which denotes the shooting number under the standardfiring condition and can be obtained by standardization of natural shooting number.

Table 1 Test data from firings of large-caliber gun A.

A barrel life prediction model can be obtained by fitting the data in Table 1 by means of the least square method,which expresses the relationship between the number of rounds and the wear amount at the commencement of rifling.The function is shown as following:

The test data from firing and the fitting results are illustrated in Fig.1.As shown in the figure,there is an obvious deviation between the fitting results and the test data.

In order to eliminate the above obvious deviation,an optimization method is put forward.As the number of rounds fired increases,the bore diameter increases,and the corresponding measurement error is smaller and smaller,so the later test data is of higher credibility and representativeness.So,the error function is defined as:

Where,qiis a weight value,the number of discrete data is 1000,qi=iα,0 ≤ α ≤ 0.2,indicates the later data is corresponding to a greater weight value.Nniis the fitted value of the ith discrete data corresponding toΔdi,calculated by formula(1),Nsiis the experimental value corresponding toΔdi,obtained by interpolation of the test data.Parameters a,b of the formula N=a·Δdbare the optimization variables,and their initial values are a0and b0.Let a,b range linearly from 0.5a0to 1.5a0,0.5b0to 1.5b0,taking a,b corresponding to the minimum error as the final values of a,b.The result of optimization for large-caliber gun A is as following:

Fig.2 shows the test data curve,the fitting curve and the optimization curve,it is obvious that the optimization curve is closer to the test data curve.Results of the optimization for gun B is shown in Fig.3 using the same method.

3.Diameter change rate of bore and law of barrel wear

A barrel life prediction formula in the form of power function,namely N=a·Δdb,can be achieved by optimizing the test data.Diameter change rate of barrel is the radial wear amount corresponding to one shot,denoted by V.Formula N=a·Δdbgives:

The derivation ofΔd with respect to N,that is V,can be obtained by differentiating formula(4)for N and simplifying the result,which yields:

The radial wear amount at the commencement of rifling will reach a maximum,that isΔdmaxat the termination of barrel life.The calculation ofΔdmaxfor different caliber barrels is given by the following formula[6]:

Where,tshis the height of rifling,A is a constant.For a large-caliber barrel with deep grooves,A is 1.0-1.6 mm,for the barrel whose caliber is under 37mm with shallow grooves,A takes the values of tsh.

In order to compare the diameter change rates of different caliber barrels,the wear amount can be expressed in terms of a dimensionless value Δd/Δdmax,simply dividing Δdmaxby formula(5)yields:

where Vnis the diameter change rate of bore corresponding to the dimensionless wearamount,Δd/Δdmax,which can be referred to as the relative value of barrel wear,in which,0 indicates no wear,1 indicates the wear amount reaching the maximum,meaning the termination of barrel life.Dimensionless diameter change rate curves of large-caliber guns A,B and C are shown in Fig.4.

Due to the introduction of a dimensionless wear amount,the diameterchange rateat the same relativewearamount fordifferent guns can be compared for further research.The curves of diameter change rates ratio between gun A,B and C,B are shown in Fig.5.It is obvious that the two ratio curves approximate to constant curves,which indicates the lawof barrel wear.The lawcan be expressed as:the ratio of the diameter change rates at different relative wear amount between two kinds of barrels is constant.Based on the consistency mechanism of barrel wear,the law can be applied to other caliber barrels as well.

4.Application of the barrel wear law

Barrel life can be predicted by means of the barrel wear law.Its implementation is as follows:the known conditions include the diameter change rate curve of gun A,denoted by VAn,the maximum barrel wear amount of gun X at the commencement of rifling,denoted byΔdXmax,and the diameter change rate VXni,or number of rounds NXicorresponding to awear amount of gun X,denoted by ΔdXi,then,the number of rounds NXjcorresponding to another wear amountΔdXjcan be predicted.Assuming the ratio of the diameter change rates for gun A and gun X is a constant c,then

So

Substitution of formula(7)into(9)yields:

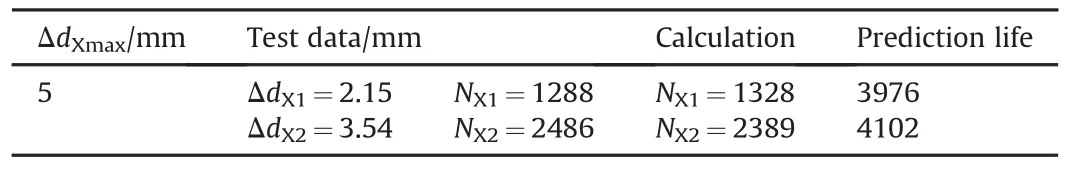

Applying formula(10)in a certain medium-caliber gun barrel,the test data from firing and the results of barrel life prediction are shown in Table 2.

Table 2 Test data and calculation results of a medium-caliber barrel.

As shown in Table 2,it is easy to see the calculation results at a certainrelativewearamountareveryclose tothe test data(1328 vs.1288,2389 vs.2486),and the results of the barrel life prediction are very close as well(3976 vs.4102).This supports the validity of the law of barrel wear proposed in this paper.

5.Conclusions

Based on gun firing data,a power function relation between the number of rounds fired and the barrel wear amount at the commencement of rifling is established.A new concept of diameter change rate of barrel and the law of barrel wear are put forward which indicates that the ratio of diameter change rates corresponding to dimensionless wear amount of different caliber barrels is close to a constant.Using this finding,the law has been used to predict the barrel life of a medium-caliber gun successfully.Although the law of barrel wear was proposed for large-caliber guns,it can also be used for medium-caliber barrel.Furthermore,in view of the consistent mechanism of barrel wear,the law should also be applicable to small-caliber gun barrel.

杂志排行

Defence Technology的其它文章

- Novel approach to quantify the chemical stability and shelf life of modified double-base propellants

- Influence of control strategy on stability of dual-spin projectiles withfixed canards

- Study on buffering performance of thin-walled metal tube with different angles

- Path planning in uncertain environment by using firefly algorithm

- An experimental and numerical approach-characterisation of power cartridge for water-jet application

- Analysis and use of fuzzy intelligent technique for navigation of humanoid robot in obstacle prone zone