Photon Detector Research at Helsinki Institute of Physics (HIP) and at Ruer Boš Institute (RBI)*

2018-12-20olovlova

ü , ä ,3, , , ,- , , olovlova , , , , äö

(1.Helsinki Institute of Physics, Gustaf Hällströmin Katu 2, University of Helsinki, Helsinki FI-00014 Finland;2.Ruer Boš Institute, Cesta 54, Zagreb 10000 Croatia;3.Advacam Oy, Tietotie 3,Espoo FI-02150 Finland ;4.Specom Oy, Tekniikantie 2 A 326,Espoo FI-02150, Finland)

Abstract:In this report,we describe the design, fabrication process and characterization of photon detectors made of bulk Cadmium Telluride (CdTe) crystals, silicon drift detectors (SDD) and silicon detectors attached with conversion layer scintillator materials (SiS). The Si wafer and chip-scale CdTe detector processing with related interconnection processing was carried out in clean room premises of Micronova center in Espoo, Finland. Unlike Si wafers, CdTe processing must be carried out at the temperatures lower than 150 ℃. Thus, we have developed a low temperature passivation layer processes of aluminum oxide (Al2O3) grown by atomic layer deposition (ALD) method. The CdTe crystals of the size of (10×10×1) mm3 were patterned with proximity-contactless photo-lithography techniques. The detector properties were characterized by I-V,C-V, transient current technique (TCT) and scanning micrometer precision proton beam methods. The experimental results were verified with TCAD simulations with appropriate defect and material parameters.

Key words:silicon drift detectors;cadmium telluride (CdTe) ;I-V,C-V and TCT methods;atomic layer deposition(ALD) method

The photon detectors are made of high atomic number semiconductor materials, silicon or silicon detectors attached with conversion material layer. Such detectors are utilized for wide variety of applications such as for example spectroscopy of nuclear isotopes or medical imaging. Generally desired properties of spectroscopic or imaging detector systems are full width half maximum (FWHM) energy resolution (ΔE/E) and image quality with contrast as high as possible. Depending on the application, different photon energies need to be measured with maximized signal-to-noise ratio. In medical imaging applications a typical photon energy range of interest is from 20 keV to 200 keV. In this report, Chapter 2 describes direct conversion CdTe X-ray detectors that are suitable for this energy range. In case of satellite space missions, measurement of soft X-rays is desirable. For this purpose, silicon drift detectors are applicable and described in Chapter 3. For many nuclear safety applications, such as spectroscopy of suspicious and potentially hazardous objects (by portable neutron generator illumination), it is necessary to detect gamma rays up to 10 MeV energies. Such high photon energies are very difficult or impossible to directly measure with any relatively inexpensive semiconductor detector. Chapter 4 describes our developments for terbium doped gadolinium oxysulfide scintillator (Tb:GSO) attached to a silicon detector intended to be used for nuclear safety applications.

2 Direct conversion CdTe X-ray detectors

An essential prerequisite for successful detection of high energy photon radiation is adequate absorption in semiconductor material at the given photon energies. One of the semiconductor materials that has been found to be suitable for many spectroscopic and imaging measurements is Cadmium Telluride (CdTe). The relatively high atomic numbers of Cd (Z=48) and Te (Z=52) enables sufficient generation of electrical charge, i.e. electron-hole pairs (ehp) by incident high energy photon quantum. Assuming appropriate signal generation in a CdTe detector of certain thickness, another measure of spectroscopic or imaging performance is the charge collection efficiency (CCE)[1,2]. The CCE is simply the ratio of the electrical charge collected by electrodes and the amount of deposited charge. The charge transport in a semiconductor detector and thus CCE are modelled by the well-known Hecht equation published in 1932[3]. The Hecht equation implies that in addition to geometrical parameters the charge transport in electric field depends on the carrier mobility and trapping lifetime product. Qualitatively, good CCE results in improved energy resolution or better image quality.

The CCE is reduced by trapping/recombination of photon generated charge carriers. Trapping/recombination processes take place inside of the active volume of a detector and at the front and back surfaces[4]. If the ratio of detector thickness (L) and drift velocity of charge carriers (vdrift) is less than the trapping lifetime (τe,h) the CCE will be degraded. Theτe,his inversely proportional to the concentration of the trapping centers, i.e. defects in the bulk of semiconductor. Due to the very demanding crystal growth of CdTe, the concentration of bulk defects is almost always very high. The carrier drift velocity is directly proportional to the product of carrier mobility (μe,h) and local electric field (E(x)). Thus, high voltage operation of a CdTe detector is needed in order to reach the saturation drift velocity of electrons. The electron mobility in CdTe is of the order of 1 100 cm2/Vs and it is comparable with e.g.μein silicon. The hole mobility in CdTe is in turn about one order of magnitude less thanμe. This implies that it is more favorable to collect signal, which is dominantly formed by electron, since most of the holes are lost due to trapping in CdTe bulk[1,5]. Moreover, poor transport properties of holes in CdTe are known to cause “hole tailing” effect, which means an asymmetric broadening of energy peaks in measured spectra[2].

Another degradation mechanism of CCE is trapping/recombination at the surfaces. The surfaces of a CdTe detector need to be electrically passivated in order to minimize signal loss due to surface recombination processes. Passivation is needed also in order to provide resistive isolation between the electrodes of a segmented detector and furthermore, provide protection against environmental effects such as moisture, corrosion or mechanical damages. Electrical passivation stands for deposition of a dielectric thin film on the surface. The purpose of the thin film is to bind dangling bonds at the defected interrupted surfaces and consequently reduce the loss of charge carriers into trapping centers at these surfaces. The dielectric thin films have always certain electrical charge, which is a complicated combination of e.g. interface charge, mobile ionic charge and fixed oxide charge[4]. If the oxide charge is positive, the Coulomb force is repulsing holes from the damages at the surface, thus providing electrical passivation of the hole current due to field effect. In case of negative oxide charge, field effect passivation is established for electrons.

The electrical passivation of CdTe by deposition of dielectric thin films is challenging. This is due to thermal expansion properties of CdTe crystals, which limit the maximum processing temperature to about 150 ℃ and it is well-known that the electrical and mechanical quality of dielectric films typically improves with respect to increasing deposition temperature[6]. We have applied atomic layer deposition (ALD) method to grow aluminum oxide (Al2O3). The ALD method is based on the successive, separated and self-terminating gas-solid reactions of typically two gaseous precursors[7-9]. The deposition may take place at low temperature compatible with CdTe detector processing. Moreover, studies performed on silicon solar cells and particle detectors indicate that Al2O3has negative oxide charge[10], thus providing field effect passivation for electrons and allowing preferred signal formation mode for CdTe photon detectors. The passivation effects have been studied by transient current technique (TCT) by recording current transients from laser illuminated CdTe pad detectors.

2.1 Design, processing and characterization of CdTe detectors

The starting material is detector grade (>109Ω·cm resistivity) and (111) oriented die material prepared by Acrorad Ltd. Crystals sizes are (10 × 10) mm2and thickness 1 mm, as shown in Fig.1(a). The CdTe detectors we have developed are symmetrical Schottky-contact titanium tungsten (2% of tungsten in TiW sputtering target) TiW / intrinsic CdTe / TiW structures.

The CdTe detector processing consist of ALD/sputter depositions, three lithography steps and two metal depositions. The fabrication process sequence is described in detail in Reference[11]. The passivation Al2O3thin films were deposited on front and back surfaces of CdTe chips. The back-side passivation was locally opened by mask pattern of 40 μm diameter round openings forming a 80 × 52 double column matrix similar as in pixel detectors used in the compact muon solenoid (CMS) experiment at the CERN large hadron collider (LHC). The purpose of patterned localized back contact is to benefit from the weighting potential described in the Shockley-Ramo theorem. The weighting potential is believed to result in so called “small pixel effect”, which in turn might enhance CCE in detectors made of material where electron and hole mobilities are largely different.

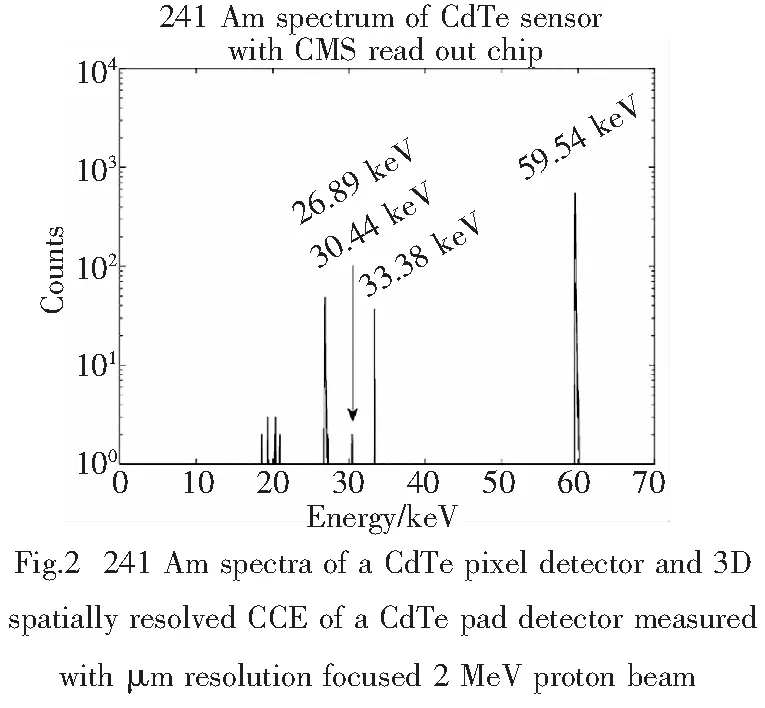

Selected measurement results of CdTe pixel detectors are shown in Fig.2.

3 Silicon drift detectors (SDD)

An essential feature of a SDD is thexy-direction transversal electric field created by a series of ring electrodes that causes soft X-ray generated charge carriers to drift to a small collection electrode. The drift concept of the SDD was applied from particle physics in 1980’s and it allows significant detector count rates simultaneously with a very low capacitance of the detector. The energy resolution (ΔE/E) of a SDD depends mainly on the CCE, thus high purity of Si material and minimal processing induced contamination are mandatory. Furthermore, very high potential drop over the field rings is required. A typical specification is a 500 V voltage drop over 1 cm inxy-direction.

Traditionally, SDDs have been made of n-type Float Zone crystal growth Si material (Fz-Si). In this case, the field plates are moderately p+implanted structures and current signal collected by the center electrode is dominantly hole current. Due to these requirements mentioned above we have on-going activity to produce SDD prototypes on p-type high resistivity Magnetic Czocharalski silicon material (MCz-Si). In this design, the center electrode is n+doped and it collects dominantly electron current. The e-having three times higher mobility than the h+, is less prone for trapping in processing or radiation induced defects, thus presumably resulting in better CCE.

Moreover, the ~500 V potential drop over the field rings is created simply by driving current through the moderately doped rings. We are developing an approach to induce the SDDs transversal electric field inxy-direction by integrated resistors between the separated n+implanted rings. The resistance is implemented by ALD grown or sputter deposited titanium nitride thin film resistors. With thin film metal-nitride resistors it is rather straightforward to implement very high resistance densities. The concept and the layout are illustrated in Fig.3(a) and (b).

4 Silicon detectors with scintillator (SiS) conversion materials

Scintillating conversion materials attached with Si diode or Si photomultiplier are mostly used for radiation instrumentation such as medical imaging, non-destructive testing, detection of hazardous radioactive materials and academic research. The combination of cost efficiency and wide range of usability is a clear advantage of scintillator-based devices. In SiS detectors the scintillator part is introduced to enhance its stopping power with a sufficiently good quantum efficiency. Such detectors can measure both the intensity and the energy of incident radiation. We have developed a Si detector attached with terbium doped gadolinium oxysulfide scintillator (Tb:GSO) to create a revolutionary radiation sensors for high rate multi-spectral imaging. The Si detector and its processing are described in detail in References[12,13].

5 Summary and outlook

The Helsinki Institute of Physics (HIP),Ruer BošInstitute (RBI) and Xiangtan University (XTU) have on-going common effort to develop new, innovative photon detectors with high level of novelty. Our main research lines are CdTe, SDD and SiS technologies. Our results of CdTe 4160 channel pixel detector indicate energy resolution (ΔE/E) <1% at 60 keV, i.e. very close to theoretical limits.

Detectors are processed at Micronova nanofabrication center in Finland. The atomic layer deposition (ALD) technology has many properties, which make it very attractive process method for radiation detectors. The capacitance and resistance densities can be implemented by ALD method. We do close collaboration with companies, Advacam Oy and Specom Oy, focused on radiation detection and with Radiation Safety Authority of Finland (STUK).

6 Acknowledgments

This study has partially been funded by the Horizon 2020 ERA Chair project, grant agreement 669014 and by Academy of Finland project number 314473 “Multi-spectral photon-counting for medical imaging and beam characterization”.