Experimental investigation of p-section concrete beams under contact explosion and close-in explosion conditions

2018-10-18ZhenLiYnLiuJunYnWenliYuFengleiHung

Zhen Li,Yn Liu,Jun-o Yn,Wen-li Yu,Feng-lei Hung

aState Key Laboratory of Explosion Science and Technology,Beijing Institute of Technology,Beijing,100081,China

bDepartment of Nuclear Engineering,Xi'an Research Institute of High-Tech,Shanxi Xi'an,710025,China

Keywords:P-section concrete beam Contact explosion Close-in explosion Explosive breach

ABSTRACT This paper presents the results of an experimental investigation on explosive breaching of p-section concrete beams.Twenty three p-section concrete beams with a 100 cm length were tested.TNT charges were placed at three positions:contact detonation in the center,contact detonation above the web and close-in detonation in the center.The external and internal breach parameters of the panels were evaluated by measuring the diameter of the ejection crater,spalling crater and breach hole created by the charge detonation.The experimental results were compared to predict values obtained by the analytical models proposed by McVay,Morishita and Remennikov.A modified breach with crater limit line and breach without crater limit line were put forward based on the experimental results.The maximum cross-sectional destruction area ratio(MCDAR)values were used to evaluate the damage degree.The maximum value of MCDAR reached 0.331 corresponding to the C5 experimental condition,of which explosion occurred above the web.

1.Introduction

Reinforced concrete bridges are the most common type of bridges and have a simple structure,low cost and long durability.Among these bridges,reinforced concrete bridges composed of psection bridge components are among the most widely used bridge types and are used in road bridges and as railway bridges.In recent years,due to the threat of terrorism,the ability of bridges to resist accidental explosions has become a focus and challenge of bridge structure design.Due to the bearing structure design of p-section reinforced concrete beams,which have different characteristics from those of conventional concrete slabs and concrete beams,it is of great significance to study and analyze the anti-accident explosive performance of p-section reinforced concrete beams.

Many scholars have conducted a series of studies on the effect of accidental explosions on bridge protection.Yahia M.Tokl-Ahmed[1]compared results obtained from ELS analysis and single degree of freedom(SDOF)analysis to evaluate the global response of a typical highway bridge subjected to blast hazards.It was observed that for large standoff distance values,the two methods are in good agreement.However,as the value of the standoff distance decreases,the difference between the two methods starts to increase.Marek Foglar[2]performed tests using real scale precast slabs(0.3×1.5×6m3)and 25 kg of TNT charges placed at a distance from the slab.The experiments showed the beneficial effect of added fibers and an increased concrete compressive strength on the blast performance of the specimens.

Tang and Hao(2010)[3,4]presented a numerical model of the bridge structure and simulation results of four main bridge components(pier,tower,back spandeckand main span deck)for a blast load from a 1000 kg TNT explosion at standoff distances of 0.5 m and 1.0 m.Progressive collapse analyses of the bridge structure after damage to any of the four main bridge components was performed.Wei and Quintero[5,6]conducted finite element analysis to investigate the residual capacity of piers and arches and the damage area of the deck of the Tenza Viaduct bridge under blast loading conditions using ABAQUS/Explicit software;they also developed curves to relate the explosive charge to the residual capacity.

Deng[7]developed a three-dimensional nonlinear finite element model of the Minpu II Bridge in Shanghai.The propagation of the blast wave and its interaction with the structure was studied.A multi-Eulerdomain method was developed by Pan[8]to simulate the blast wave propagation process and its interaction with the bridge.The blast-resistant capacities of three different detonation scenarios were investigated,including one above-deck detonation and two under-deck detonations,with different TNT equivalent charge weights.

Sona[9]studied the performance of a hollow steel box and concrete- filled composite pylons in a cable-stayed bridge subjected to blast loads.A coupled numerical approach with combined Lagrangian and Eulerian models was used to consider the interaction of the deck and pylon with the air that transferred the explosion effect to the bridge.Wang[10]analyzed the structural failure of a bridge due to an accidental fireworks explosion.The equivalent TNT mass of fireworks explosion and the structural response of the bridge due to the explosion were modeled by engineering algorithms and numerical simulations.Williams[11,12]studied the cross-sectional response mechanisms that caused spalling of sidecover concrete in blast-loaded slender reinforced concrete members.A simplified procedure for predicting blast loads acting against bridge columns was proposed based on numerical simulations.

At present,research on the effect of contact explosion and close in explosion loads on the bridge structure has mostly focused on the basic components,such as slabs,piers.Accident explosion such as car bomb may happen on real p-section bridges.Therefore,it is important to study the anti-explosion performance of p-section reinforced concrete beams.Due to limitations of experimental conditions,1:6 p-section reinforced concrete beam specimens other than 1:1 specimens were designed and constructed.And TNT explosives were used to conduct contact explosion and close-in explosion tests on the target beams,and the damage to the target plates was evaluated.

2.Experimental program

2.1.Design of specimens

The decks of prototype reinforced concrete bridges consist of five p-section beams.The span of a single-piece beam is 25 m,flange thickness is 25 cm, flange width is 180 cm,web thickness is 20 cm,total girder height is 175 cm and volume reinforcement ratio is 1.6%.Concrete with a strength grade of 35MPa was used on the prototype bridge.

The specimens were 1/6 models of the prototype bridges and were designed as p-section beams considering that explosions may have occurred at different positions.The total specimen lengths of were 1000 mm.Webbed steel bars(HPB235)with a diameter of 6 mm and nominal yield strength of 235 MPa were used as the longitudinal reinforcement and web reinforcement components,respectively.The detailed dimensions and rebar layout of the test specimen are shown in Fig.1.

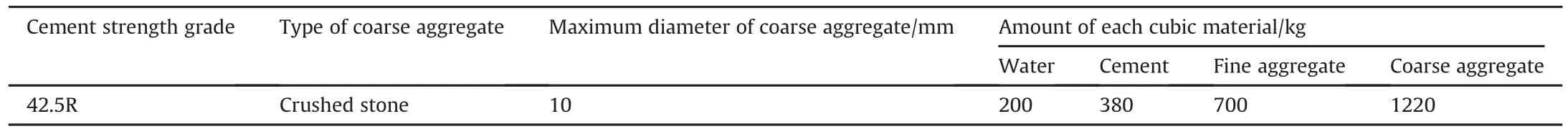

A p-section beam pouring mold was constructed using steel plates.When pouring,the woven mesh was first placed in a mold,poured into a mixture of mortar and aggregate,and finally vibrated and compacted.Ready-mix concrete with of cement grade P.O.42.5 and aggregate size ranging from 4.5mm to 10mm was used to cast the specimen.The composition of the p-section beams is listed in Table 1.Four 10 cm×10cm×10 cm test cubes were tested for their compressive strength and the average compressive strength was 38 MPa.The concrete compressive strength was 36.1MPa when taking into the scatter coefficient 0.95.The results showed that the concrete strength met the requirement.

Fig.2(a)shows a three-dimensional model of a p-section concrete beam,and Fig.2(b)displays a schematic view of the internal reinforcement.The flange reinforcement and web reinforcement were connected together by welding.Fig.2(c)presents a woven steel reinforcement mesh placed into a mold waiting to be poured.A completed p-section beam specimen is shown in Fig.2(d).

2.2.Test set-up

According to the different explosion locations,three types of experimental conditions were used:contact explosion in the center,close-in explosion in the center and contact explosion above the web,as shown in Fig.3.This setup was aimed to simulate a car bomb attack occurring at different positions.

TNT explosive was used in the test because it is standard high explosive and safe to operate.TNT columns with a diameter of 4cm,3cm and 2cmat the bottom were used in this experiment,the density of which was 1.6 g/cm3.The height of the column ranged from 1 cm to 5cm.All explosive charges were ignited by an electronic detonator,which was inserted into the middle of the TNT charge from the top surface(Fig.4(a)).The edge of the target plate was placed on the concrete base,which was confined to be a simple support.The experimental setup is shown in Fig.4.

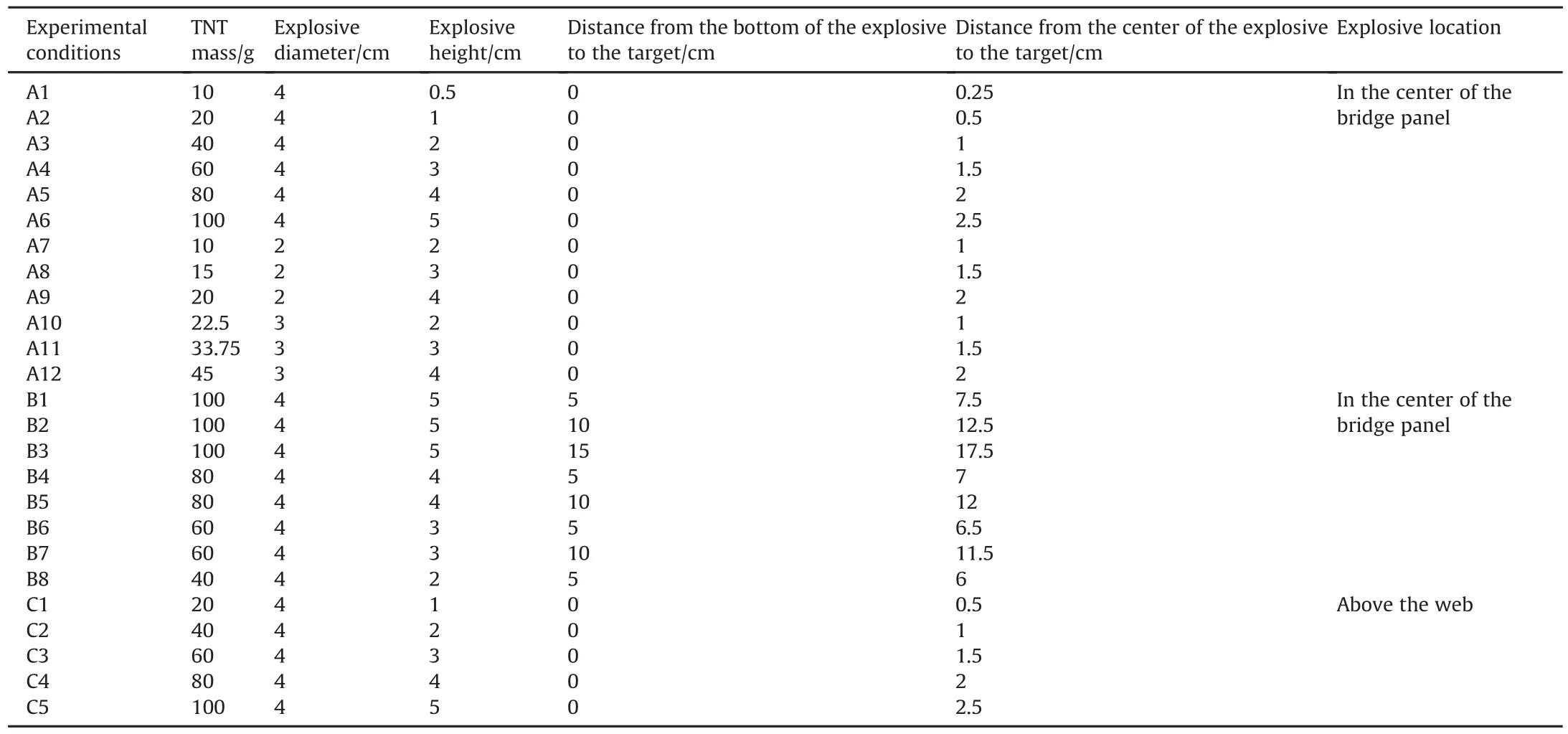

In the experiment,the influence laws of the explosive mass,diameter of the explosive,distance from the bottom of the explosive to the target and location of the explosive were taken into consideration.Twenty-three types of experimental conditions were established,and the detailed information of each condition is listed in Table 2.

3.Experiment results

3.1.A-series experiment results

The diameter of the TNT columns used in the A1-A6 experiments was 4cm,and the height increased from 0.5 cm to 5cm.As a consequence,the mass of the columns ranged from 10 g to 100 g.The damage effects of the front side and back side under the six experimental conditions are shown in Fig.5.The failure mode of the p-section beam was partial destruction without overall deformation.The damage area was limited to the area within 11cm ofthe radius of the flange plate,and the web plate was not affected.The failure modes were a front side crater and back side spall,both of which were funnel-shaped.The front side crater area and back side spall area were not penetrated under the A1 experimental condition.Under the A2-A6 experimental conditions,the front side crater area and back side spall area were interpenetrated,resulting in a breach failure.Under the experimental conditions of A1-A5,there were no obvious cracks in the flange plate;however,a large V-shape crack extended to the free surface on one side of the psection beam under the A6 experimental condition.Overall,the size of the breach increased with the increase in TNT quality,but the increase was increasingly smaller.

Table 1 Concrete composition.

Under the experimental conditions of A7-A9,the diameter of the TNT columns was reduced to 3cm and the heights of the columns were 2cm,3cm and 4 cm,respectively,which were the same as those of A3,A4 and A5.The double T beam was breached under the above three experimental conditions;that is,the frontal crater area and the backside spall area were penetrated.However,in the case of the same TNT height,the diameter of the broken hole under the experimental condition with a diameter of 3 cm was smaller than the diameter of the broken hole with a diameter of 4cm.Under the A10-A12 experimental conditions,the diameter of the TNT column shrank to 2cm,corresponding to heights of 2 cm,3 cm and 4cm.The failure mode of the p-section beam under the above three experimental conditions was the same as that under the A1 experimental condition.Increasing the diameter of the column caused more damage when the height of the TNT column was the same.Increasing the diameter of the column also caused more damage in the case of the same height.In other words,in the case of a contact explosion,the damage extent of the p-section beams was positively related to the diameter and height of the TNT column.

Table 2 Experimental test matrix.

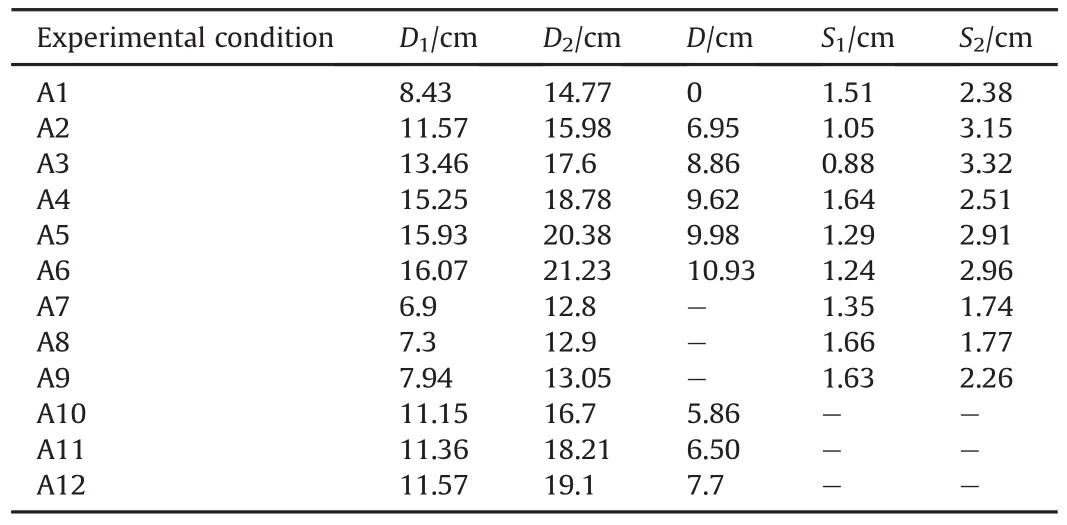

The visual representation of the measured parameters is shown in Fig.6.These measurements were the diameter of the ejection crater(D1),diameter of the spalling crater(D2),and breach clear hole diameter(D).Furthermore,distances S1and S2were measured around the circumference of the craters.In summary,the five measured parameters(D,D1,D2,S1and S2)allowed for a complete damage representation for each tested concrete panel.

The failure area parameters under the A-series experimental conditions are listed in Table 3.

3.2.B-series experiment results

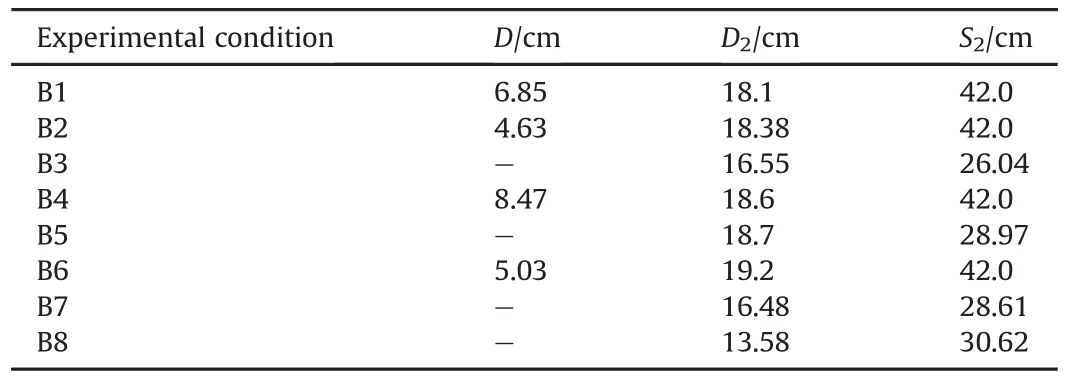

TNT columns were placed directly above the target at a certain distance,which corresponded to a close-in explosion in the center in Fig.3.The p-section beam damage effect is shown in Fig.7.Under the B1-B3 experimental conditions,the mass of the TNT column was 100g and the damage effect gradually decreased as the distance of the explosive core from the target plate increased.With regard to the damage shape,the damage shapes of the B1 and B2 experimental conditions were different from those of the A2-A6 experiments.There was no front side cater area,and only the back side spall area was visible.In this failure mode,D1 was equal to D.S1 was meaningless,and S2 was equal to H.The damage shape of B4-B12 was similar to that of B1-B3.When the diameters of the TNT columns were 4 cm,the limit breach distance(distance from the bottom of the target explosive)was between 10 cm and 15cm for 100g of TNT explosives;between 5cm and 10 cm for 80 g and 60 g of TNT explosives,respectively;and between 0cm and 5cm for 40 g TNT explosives.As the mass of the explosives decreased,the limit breach distance decreased.

The failure area parameters of the B-series experimental conditions are listed in Table 4.

3.3.C-series experimental results

The explosion location of the C-series experimental condition corresponded to a contact blast above the web,as shown in Fig.3.The p-section beam damage effect is shown in Fig.8.After the contact explosion,a V-shaped gap appeared on the flange,with the gap width between 34-36cm and gap depth between 9.5-15cm.Different TNT explosive mass had little effect on the notch width,but had a greater impact on the notch depth.A small amount of concrete fell off the webs,but no visible gap under the C1 experimental condition was observed.However,under the C2-C5 experimental conditions,the TNT explosion mass increased and a semicircular web notch was found.The notched diameter increased with the explosion mass.For the C1 and C2 experimental conditions,no cracks were observed in the webs below the explosion.Under the C3-C5 experimental conditions,two inclined 45-degree cracks in the bottom of the webs were found,and the crack width increased with the TNT mass.Under the C5 experimental condition,a V-shaped concrete spall area appeared at the bottom of the crack.According to the damage pattern of the p-section beam,the damage morphology was characterized by the maximum breaking length of the flange,maximum breaking width of the flange and maximum breaking depth of the web.The three parameters are represented by L1,L2and L3.

Table 3 A-series failure area parameters.

The failure area parameters of the C-series experimental conditions are listed in Table 5.

4.Discussion

4.1.Breach limit

Under the A-series and B-series experimental conditions,the blast damage area was limited to the area of the concrete slab between the two webs.Many investigators have conducted research on the problem of concrete plate resistance under contact explosion and close-in explosion.McVay[13]conducted 40 tests on reinforced concrete walls to investigate the parameters that affect spall and developed a prediction method.Morishita[14,15]carried out a series of contact explosion tests to investigate damage to reinforced concrete slabs with different concrete strengths and reinforcement ratios.The important finding of his work was that the concrete strength and reinforcement spacing did not significantly affect catering and spalling.Morishita also developed predictive formulas using experimental results.Remenikov[16,17]proposed an analytical model to predict the minimum TNT explosive mass for breaching concrete walls,which was compared with experiment results from Morishita.

In the previous study,the effect of target plate damage from severe to mild was divided in to the folloflange four types:explosion punching,explosion penetration,explosion collapse and explosion crater.However,the results of these experiments showed that a crater occurred during the contact explosion and that explosion punching occurred under a large explosive charge and close detonation distance.The front side crater requires a greater mass of TNT and closer detonation distance than the collapse of the back.According to the experimental phenomenon,the damage grade of the target plate was divided into the folloflange four degrees:breach with a crater,breach without a crater,spall with a crater and spall without a crater,as shown in Fig.9.

McVay summarized more than forty experiments on reinforced concrete slabs under air blast and obtained two empirical formulas for the spall and breach limits.

Spall limit:

Breach limit:

where T is the panel thickness(m),W is the applied charge mass(kg),and R is the distance(m)from the center of the explosive to the target.Therefore,the R/W1/3value may vary between 0.02m/kg1/3and 1m/kg1/3.

Morishita proposed a modified breach empirical formula based on his own experiments:

The R/W1/3value may vary between 0.01m/kg1/3and 1 m/kg1/3.

Comparison results of the A-series and B-series experimental conditions with the McVay's spall limit and breach limit are shown in Fig.10.As seen,McVay's breach limit was very accurate for predicting the occurrence of a breach with a crater,but McVay did not study the phenomenon of breach without crater.Additionally,the A1 experimental condition was beyond the range of the independent variable.

A modified breach with a crater limit and breach without a crater limit were proposed to match the experiment results,as

Table 4 B-series failure area parameters.

The R/W1/3value may vary between 0.01m/kg1/3and 1 m/kg1/3.

The breach without a crater limit was as follows:

TheR/W1/3value may vary between0.15m/kg1/3and0.5m/kg1/3.shown in Fig.11.The breach with a crater limit was the same with Morishita's breach formula.

Table 5 C-series failure area parameters.

4.2.Maximum cross-sectional destruction area ratio

In this section,the maximum cross-sectional destruction area ratio(MCDAR)was used to evaluate the damage effect of the psection beam.Due to the difference in the placement of explosives(Fig.3),one type of destruction was the detonation hole in the middle of the target(Fig.9),and the other was the destruction of the edges of the backplane and flange(Fig.8).The maximum crosssectional destruction area ratio(MCDAR)was the maximum value of the concrete exfoliation area(MVCEA)divided by the crosssectional area.

For the A-series and C-series experimental conditions,the damage pattern can be represented by the five parameters shown in Fig.6.The maximum value of the concrete exfoliation area(MVCEA)can be expressed as:

For the C-series experimental conditions,the maximum value of the concrete exfoliation area(MVCEA)was equal to the failure area of the webs plus the failure area of the flanges.

The only difference between A2-A6 and C1-C5 was the explosive initiation position.The change of MCDAR is shown in Fig.12.Under the A2-A6 conditions,the MCDAR value increased from 0.084 to 0.115,which increased approximately monotonously with the explosive mass.Under the C1-C5 conditions,the minimum value was 0.157 and the maximum value is 0.331.The C2 experimental condition has a relatively large increase compared to the C1 experimental condition because the webs in the C2 experimental condition were subjected to damage.

The explosive mass and distance from the bottom of the explosive to the target(DBET)were varied simultaneously,thereby resulting in a change in the maximum cross-sectional damaged area ratio(MCDAR),as shown in Fig.13.In general,SDBET and the explosive breaching limit were highly coincident.When the target was subjected to a breach failure,the MCDAR value was between 0.085 and 0.115.When the target was not damaged by a breach failure,the MCDAR value was between 0.04 and 0.065.It can be seen that the destruction pattern of the target plate plays a decisive role in the degree of damage.

The DBET of the A2-A4 experimental conditions and A7-A12 experimental conditions were zero,corresponding to the contact detonation in the center in Fig.3.The variables were the diameter and height of the explosive column,as shown in Fig.14.As illustrated above,breach failure results in greater MCDAR values than non-breach failure,i.e.,more serious damage.The MCDAR value increased monotonously with the explosive column height in both breach and non-breach failure cases.However,the growth rate was not very large,and the maximum growth rate was about 12%.In the condition of contact explosion,the MCDAR value for a breach case was approximately three to four times that of a nonbreach conditon.

5.Conclusions

Twenty three 1:6 scale p-section concrete beams with a 100cm length were designed and tested.TNT charges were placed at three positions:contact detonation in the center,contact detonation above the web and close-in detonation in the center.The external and internal breach parameters of the panels were evaluated by measuring the diameter of the ejection crater,spalling crater and breach hole created by the charge detonation.

Based on an analysis of the experimental results,the folloflange can be concluded:(1)Modified breach with crater limit and breach without crater limit techniques were proposed based on the experimental results.(2)An explosion of explosives above the web can result in a V-notch failure of the flanges and crush failure of the webs,accompanied by V-shaped cracks that extend to the free surface.(3)In the case of the same explosive weight,the damage caused by explosion above the web is more severe than the explosion in the center.The maximum cross-sectional damaged area ratio(MCDAR)of A is 0.331,which corresponds to the experimental condition of C5,while the result of the A6 condition of the same explosive mass is only 0.115.

Acknowledgements

This paper is supported by The National Natural Science Foundation of China under Grant No.11390362 and No.11221202.

杂志排行

Defence Technology的其它文章

- Overview of Al-based nanoenergetic ingredients for solid rocket propulsion

- Implications of fine water mist environment on the post-detonation processes of a PE4 explosive charge in a semi-confined blast chamber

- Systematic research on the performance of self-designed microwave plasma reactor for CVD high quality diamond

- cis-1,3,4,6-Tetranitrooctahydroimidazo-[4,5-d]imidazole(BCHMX)as a part of explosive mixtures

- Joining and machining of(ZrB2-SiC)and(Cf-SiC)based composites

- Structural evolution,optoelectrical and corrosion properties of electrodeposited WO3integration on Zn-TiO2electrolyte for defence super application