Friction surfacing of AISI 316 over mild steel:A characteriation study

2018-08-25GeorgeSahayaNixonMohantySathish

R.George Sahaya Nixon,B.S.Mohanty,R.Sathish

aDepartment of Mechanical,Sathyabama University,Chennai 600119,Tamilnadu,India

bDepartment of Mechanical Engineering,St.Joseph's College of Engineering,Chennai 600119,Tamilnadu,India

cDepartment of Mechanical Engineering,SRM Easwari,Chennai 600089,Tamilnadu,India

Keywords:Friction surfacing Rotational speed Traverse speed Axial load Salt spray test Microstructure XRD analysis Ram tensile test

A B S T R A C T An attempt has been made with overlaying of stain-less steel on mild steel by the technique of friction surfacing.This investigation elaborates the excellence acquired by different combination of the process parameters used in friction surfacing specifically traverse speed of the cross slide,speed of rotation of the spindle and the uniaxial compressive load.Excellent overlaying has been obtained amongst the chosen materials.To which,the coating can be done with various set of process parameters.It has been observed that the bond strength of the coating was found to be at a maximum of 502 MPa by ram tensile test.Based upon this results the surface methodology was characterized with scanning electron microscope.For authenticating the results,the coated specimen was subjected to salt spray test.The bonding microstructure was characterized using optical microscopy and X-ray diffraction.Corrosion resistance of surfaced coatings was found to be more inferior to that of mechtrode material and greater with the substrate.

1.Introduction

Surface science and engineering truces with the exterior of the hardest material and it is sub restraint of materials science.The solid material includes a granular or lumpy mixture of material protected through an exterior surface and it is called outward phasing.The external surface of a solid interrelates with the adjacent atmosphere[1].Friction surfacing is a superior surface alteration process,this technique was comparatively very simple,with which overlaying of the materials will be empowered after reconstruction of friction welding processes(Fig.1).This process was much greater with related to resources of other surface modification processes and energy management[2].Wear can be curtailed by amending the surface possessions of solids by surface finishing or by use of lubricants.Approximately the entire kind of materials,polymers and composites were able to be bonded on materials which are alike or unlike[3].This phenomenon was obtained by creating the strengthened surface to the location in which it will be made to protect fromwear and corrosion to prolong its life and also develop artistic manifestation of the substrates.This means that proper maintenances and the standby of scratched components are not continuously essential,limited maintenances of faults will be permissible,and that was achieved by friction surfacing of nonferrous materials[4].In this process,tool steels which are contained with rigid stages cannot be easily formulated by deposition of materials.Here the melting process was not in bulk form and during the process of friction surfacing plasticization of materials due to dynamic re-crystallization has been highlighted[5].It is promising to weld the different materials that can be mismatched or challenging to overlay the consumable by non dilution processes[6].Related with these friction based processing techniques,by avoiding the deprivation on properties of material leads to lowering the heat input as well[7].Bedford et al.reported,that the non appearance of melting leads to lesser residual stages and disappearance of dilution meanwhile the solidification shrinkage does not occur in dissimilar steels[8].

It consists of a rotating cylinder-shaped rod which is fed towards a plate with uniaxial compressive load performing at the same time.The difference in temperature is engendered amongst the plate and the rod.By the time of coating end of the rod is appropriately changed into the state of plasticization,the plate is intersected parallel with reference to the consumable rod[9].As the traverse speed was initiated at a definite amount,the metal undergone dilution consumed over it.A close view of friction surfacing process was shown in Fig.2.The axial force on the consumable,traverse speed on the substrate and rotational speeds on the rod is the primary process parameters for the aforementioned process[10].The effect of speed of the cross slide over the dimensional variables,bond uniqueness of the interface and mechanical characteristics of the bond has been reported by Khalid Ra fiH.et al.[11].

2.Materials and experimental methods

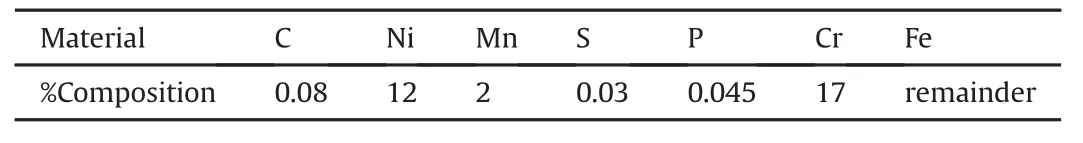

Mild steel plate of 10mm thickness as a substrate was machined to 75 mm width 150 mm length.AISI316 stainless steel bar of 20 mm in diameter and 100mm length was used as a coating rod.The chemical compositions of these base metals are shown in Tables 1 and 2,respectively.

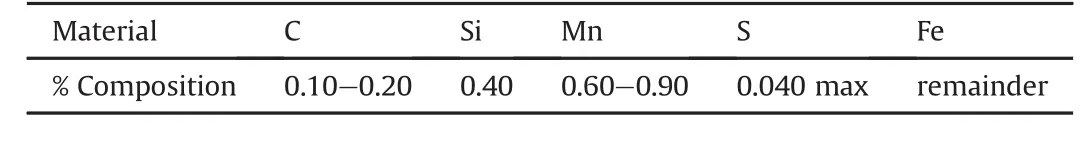

The geometry of the material used for friction surfacing process prior to coating was shown in Fig.3.Flatness of the consumable rod ends has been safeguarded by lathe machining.Surface grinding and milling was performed on the substrate to ensure flatness and the surface has to be restricted from oxides.Both consumable rod and the plate have to be washed with acetone earlier to surfacing towards reduction of the impurities during the process.Experimentations are piloted to define the operational assortment of the aspects,such as rotational speed of mechtrode,substrate traverse speed and axial force on mechtrode.The friction surfacing operation was done when the coating rod consumes about 30 mm from its length and the welding bead was at a distance of 50 mm to be overlaid.This process was done under the surfacing conditions of L9 orthogonal array as shown in Table 3.

Table 1 Chemical composition of stainless steel AISI 316.

Table 2 Chemical composition of mild steel.

The interfacial strengths of the coating and the substrate were determined by a tailor made ram tensile strength method.The specimen is loaded in UTM and the tensile strength values in MPa were measured by using the ram tensile test setup as shown in Fig.4.Transverse segments were taken from the overlay were equipped for fractographic characterization for typical metallographic examination.X-ray diffraction(XRD)investigations were carried out by using A Philips X'pert PRO diffractometer at Cu Ka radiation for phase analysis.FS coated samples was carried out with XRD analysis.To evaluate the intensity over the bond,the d-ferrite quantity in FS coatings were found out by means of a Fischer-make polished specimens were electrolytically imprinted with 60%HNO3aqueous solution then the specimen were investigated by Leicamake optical microscope and an FEI-make SEM.AISI316 and mild steel were exposed to unfavorable chemical surroundings for the process of studying the durability and strength of AISI316-mild steel coatings under chemical resistance test.Salt spray tests of bonded specimen before and after acquaintance to 3.5%NaCl mist environment has been conducted.

The tensile strength of the friction surfaced specimens was determined to find their effective coherence.The ram tensile fixture was specifically designed as per MIL-J-24445(SH)standard for estimating the tensile strength of the coating.The material coated and the substrate was made to lay upside down,coated surface facing the machining table and the substrate facing the tool.The Substrate was machined in the form of an inner circle or a hole to form an annular space between the substrate and the intact coating.Appropriate machining of the surfaces was made to facilitate effective clamping of the specimen on the designed fixture[12].The inner circular area in the annular space was meant only for loading.The Universal Testing Machine was utilized to test the specimens.The specimen is loaded in UTM and the tensile strength values in MPa were measured by using the ram tensile test setup as shown in Fig.4.The materials failed upon the action of regions where force is applied by push off tool.It is noticed that strong bonding between the materials has been obtained by applying tensile forces towards the materials.For the other samples the tensile testing were done to find the strength of the coating.It is observed that higher the axial load considerable rotational speed and traverse speed give more tensile strength and more ductility.Also when input process parameters are lowered it indicates lower tensile strength[13].Further studies have been made with the sample of greater bond strength i.e.the specimen with the highestvalue of bond strength was preceded for the characterization study.

Table 3 Design matrix and measured bond strength.

2.1.Ram tensile test

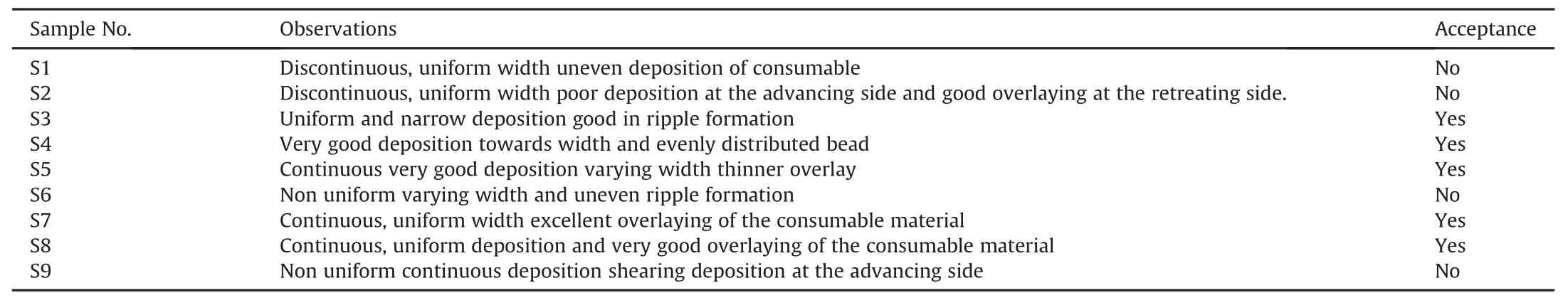

There are various methods of mechanical testing were done with the friction surfaced samples like shear test,bend test and chisel test.Among these mechanical characterizations the bond strength can be evaluated by a tensile test method called as method called ram tensile test.These techniques make certain breakdown of the sample in the interface by a normal tensile force which signifies the bond strength.The bond strength of overlay is shown in Table 3.From Table 3 it can be concluded that the highest tensile strength of 502 MPa and the lowest bond strength of 259 MPa were acquired on the AISI 316 bonding created in the present investigation[14]All ram tensile test samples were noticed that it will deform at the substrate interface.Representing sketch and image of ram tensile test sample are shown in Fig.4.

3.Results and discussion

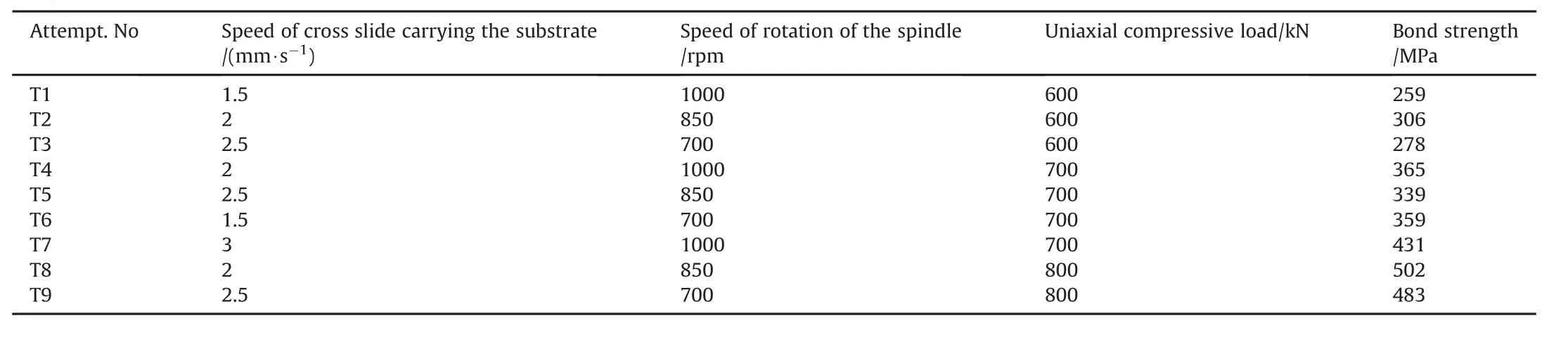

3.1.Quality of deposition

Initially the bond quality has been predicted by visual inspection.Deposit appearance and the images are given in Fig.5.Deposits are classified into narrow deposit,deposit due to shear,greater width,variable width,decreasing width,continuous,uniform and non-uniform are attained by several combinations of the process parameters[14].The dependency on the coating conditions might be the purpose for quantity of the deposit since surfacing was maintained in accordance with the length of the mechtrode.The exterior of the bonding varies upon the parameter levels.The schematic diagram after the process is shown in Fig.3.It was evidently shown that the circularity patterns become visible on the plate by the rotation of the spindle i.e.,the rod which has been consumed,apart from of the speed of the cross slide.The exterior of bond was alike other nonferrous materials[15].Sample S3 gets thinner deposit and it was uniform throughout the bead.Similarly sample S6 and S9 deposits are also in the same case since the deposit geometry are found to be excellent in ripple formation.In the overlaid samples S2 and S8 it is observed that the bonding was discontinuous with constant rotational speed.The coating interpretation for the entire specimen was shown in Table 4.The roughness of the deposits has been measured and that is in the range of 1.5 μm-3.5 μm.The bonding with length was between 100.5 and 110.8±0.05mm,coating width of 23.5-24.5±0.05mm and coating thickness of 2.21±0.05mm,were formed by the known process parameters[16].

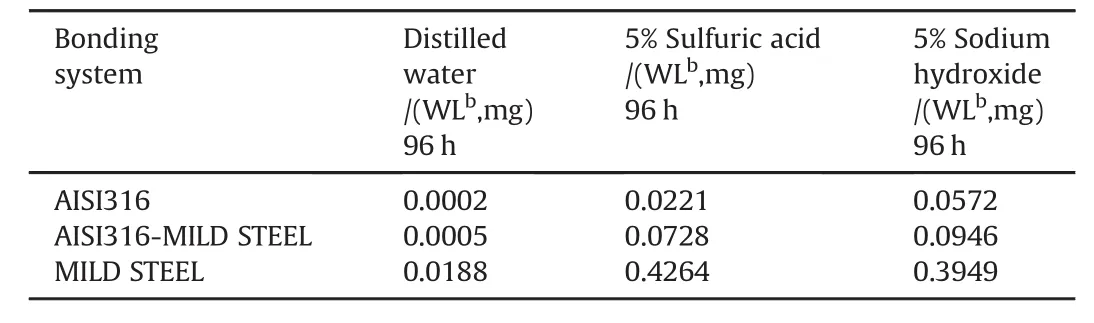

3.2.Chemical resistance test

Chemical resistance test for mechtrode(AISI316)and mild steel substrate.For the chemical resistance test,AISI316 and mild steel were exposed to unfavorable chemical atmosphere viz.H2O,acid and alkali for the process of studying the durability and strength of AISI316-mild steel coatings[17].The data obtained for mechtrode(AISI316)and mild steel substrate have been listed in Table 5.

The MILD STEEL substrate experienced extreme weight loss in aquatic medium while AISI316-MILD STEEL coatings showed no effect in aqueous medium on behalf of that these bonded specimen of(AISI316-MILD STEEL)representing an impervious prevention to the plate of mild steel which would not consent entry for water and other corrosive species,there by authorizing the success in guarding the substrate from rust[18].In addition,the immersion of these test specimens in 5wt%Sulfuric acid and 5wt%Sodium Hydroxide for 24h had their exteriors continue undamaged with a minor weight loss.The enhanced performance exposed by AISI316,AISI316-MILD STEEL coatings may be due to passive film,causing greater reliability of such coatings.However,AISI316-MILD STEEL bonded specimen were said to be temporarily resistant to alkali atmosphere.Significant corrosion attacks did not exhibited in the consumable rod in the friction surfaced bonding and was free from intergranular corrosion[19].

3.3.Microstructure analysis

For the sample,the fractography indicates fusion between the two parent metals,the fractography illustrate ferrite-pearlite grains perceived all over the matrix and next to the heat affected zone presenting fine grains of ferrite-pearlite and somewhat malformed martensite.Higher hardness was denoted due to incomplete martensitic pattern[20].Fig.6(a)and(b)shows the microstructures in the parent metals of substrate and the mechtrode.During friction surfacing,as the parent metals experiences a thermomechanical phenomena, fine grained microstructure is generated by dynamic recrystallization.The microstructure was then found using metallurgical microscope called metascope The etchant used for AISI 316 is 10ml of nitric acid(HNO3)+10 ml of acetic acid+15 ml of hydrochloric acid(HCl)and two drops of glycerol.By this the microstructure revealed that austenite,delta ferrite and small percentage of chromium-n precipitate having a pearlite in a ferrite matrix.After the process microstructure is in the type of eutectic ferrite and pearlite.Grains in Fig.6(c)shows the fusion between the two interfaces.It was observed that the intermingling of both these materials in the fusion zone was bonded with greater coherence[21].This confirms that more amount of heat was generated in friction surfacing of 316 when compared to other grades of steel.Also the diffusion pattern between AISI 316 and mild steel was denser than other grades of steel.The grain size in the HAZ is small which causes the increase in hardness of the material at the joint of two materials.Plastic deformation and heat generation in combination reports full austenization and dynamic recrystallization[22].It has been noticed that bonding geometry may rely on the parametric stages and in addition the grains were dynamically recrystallized due to the speed of the cross-slide on both the progressing and withdrawing sides[23].

Table 4 Process parameters for specimens and the interpretations on the consumable rod and overlay.

Table 5 Results of chemical resistance tests.

3.4.SEM analysis(scanning electron microscope)

The SEM images of MS laid on SS316 for the sample subjected to maximum bond strength has been done with Leica-make optical microscope and an FEI-make SEM.The images displayed are a)500X magnification and b)1000X magnification respectively.It has been observed that the base metal was highly corroded when compared with the consumable material.The interface of the overlaid materials of SS316 metal exhibits very fine martensitic features as that of the coated metal MS.In advancing and retreating side very fine martensitic features was visible to which it is displayed in Fig 7.1(a)and(b).The cross sectional view show more homogeneous surface compared to the top and bottom surface of metal however some pores are observed in the advancing side[24].The retreating side was the end where the direction of spindle rotation and the direction of the overlaying.The end where path of consumable rod rotation and way to coating development are opposite is referred to as retreating side[25].Owing to the movement of material from one end to the other end there was some microstructural differences are probably will be there in-between the advancing and retreating sides as shown in Fig 7.2(a)and(b)which was free from any pores and considered as more effective bonding between the substrate and mechtrode.The huge force exerted on the base metal SS316 might have disturbed its austenitic matrix further the temperature generated might have been less than 1200°C to form austenitic phase at the interface[26].The Fig 7.3(a)and(b)shows the SEM images parent metal.The high magnification image reveals fine intra-granular lath martensitic features in austenitic matrix[27].

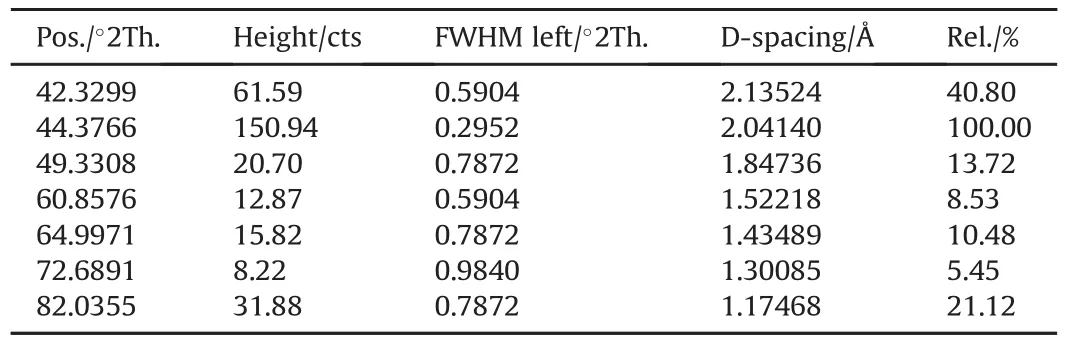

3.5.XRD analysis(X-ray diffraction)

XRD studies were done to assess the presence ofα-ferrite in the deposited austenitic matrix.XRD studies of friction surfaced coating confirmed the absence ofα-ferrite and the presence of strain-induced martensite(Fig.8).The findings were well matched with the observation of microstructural inspection.Throughout the process,the consumable rod becomes austenitized,upon with speedy cooling,changes into martensite,resulting in a solid tool steel bonding[28].The nonexistence ofα-ferrite in the bonding clearly established that the temperature(1000°C)generated during friction surfacing has not exceeded the limit(1200°C)required for the formation ofα-ferrite,and suggest that the mechtrode was made with raise in temperature into theα-ferrite zone field towards the process.Similar results were observed in earlier studies for different metal coating.The absence ofα-ferrite in the bonding is beneficial in improving the corrosion resistance compared to fusion based cladding process[29].The table gives the peak position,intensity,full width half maximum value(FWHM)and dspacing values of MS laid over SS316 Table 6.The XRD analysis confirms the presence of martensitic phase as observed in SEM image[30].Friction-surfaced SS316-coated mild steel specimen seems to be appropriate for usage in coated state.Additional development in fractography and characterization were possible with appropriate post-surfacing heat treatment,which will make stronger martensite and make things easier with carbide precipitation[31].

Table 6 XRD results.

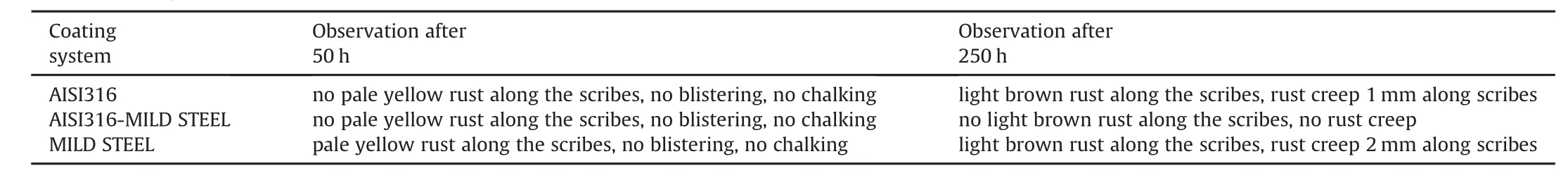

3.6.Salt spray test(corrosion)

Salt spray test was done with samples of 10 mm×10 mm×10 mm with cubic bonded pieces.It is used to create the oceanic atmosphere where the specimen was interpreted according to ASTM B 117-3.Fig.9 provides details of the salt spray results of bonded pieces prior and after acquaintance to 3.5%NaCl mist environment.There was no observable corrosion products on the exterior of the mechtrode at the conclusion of the salt spray test region of sections coated with mild steel.The results of the interpretations made for the coatings AISI316,AISI316-and MILD STEEL after 50 h and 250 h of salt-spray test are seen in Table 7.There was neither corrosion nor bonding imperfections on the parent metal sections shown by the intact flaws.The processes used for cleaning the samples prior to loading and subsequently complete the testing as given as:a)Samples are cleaned mildly before loading:b)Surfaces dried immediately from clean running water slightly to remove salt deposits.The pieces were sensibly noticed for the finding of corroded area on their exterior area and images were taken by digital camera.The period for the development of brown rust and blisters was noticed.The specimen before and after test was displayed in Fig.9 However,rusting without spread was seen at AISI316-MILD STEEL.This indicates an impressive enactment of the originations against salt surroundings[32].Hence AISI316-MILD STEEL formulations produced satisfactory good outcomes without any maximum loss of coating,blazing and eroding of the cross-cut still after 250h of salt-spray testing in the filing cabinet.On the other hand,the substrate mild steel shows pitiable salt-spray resistance[33].The results of the salt spray test was displayed in Table 7.

3.7.Research gap

The corresponding literature show the investigations by several researchers in number of combinations on dissimilar materials in friction surfacing.Also,numerous researchers were conductedexperiments to analyze the mechanical and metallurgical behavior of selected materials.The analysis of the deposit geometry and corrosion analysis over the friction surfaced specimen has been carried out over the deposited material.However,the efforts so for made indicates an insufficiency of attempts towards replacing the substrate material by Mild steel over AISI316 which exhibits poor corrosion resistance,improved mechanical properties and also high machinability having wide commercial applications.The uses for Mild steel are defined by the requirement for a high tensile strength and ductility that,despite its brittleness when compared to other forms of steel,make it the preferred choice.The present work deals with these important concerns[34].

Table 7 Results of salt spray(fog)test.

4.Conclusion

The friction-surfacing development was found prime to substantial particle enhancement.The creative grains were first rigorously cropped and dispersed due to the geometrical consequence of strain.The widespread sub operational enlargement segmented them into minor,irregular-shaped grains,thus evidencing the occurrence of continuous recrystallization.The huge force exerted on the base metal AISI 316 might have disturbed its austenitic matrix further the temperature generated might have been less than 1200°C to form austenitic phase at the interface.The ultimate tensile strength varies from 259 MPa to 504MPa by ram tensile test.The high magnification FESEM image reveals fine intragranular martensitic features in austenitic matrix.The absence ofαferrite in friction the coating is beneficial in improving the corrosion resistance compared to fusion based cladding process.The XRD analysis confirms the presence of martensitic phase as observed in SEM image.There was no observable corrosion products on the exterior of the mechtrode at the conclusion of the salt spray test region of sections coated with mild steel.

杂志排行

Defence Technology的其它文章

- Conceptual design of automobile engine rubber mounting composite using TRIZ-Morphological chart-analytic network process technique

- Evaluation of stiffness in a cellulose fiber reinforced epoxy laminates for structural applications:Experimental and finite element analysis

- Effect of microwave treatment on tensile properties of sugar palm fibre reinforced thermoplastic polyurethane composites

- Hybrid reinforced thermoset polymer composite in energy absorption tube application:A review

- Experimental and simulation studies on delamination strength of laminated glass composites having polyvinyl butyral and ethyl vinyl acetate inter-layers of different critical thicknesses

- A review on machinability of carbon fiber reinforced polymer(CFRP)and glass fiber reinforced polymer(GFRP)composite materials