Outdoor Aging Performance of HDPE Geogrid

2018-04-17TONGJunDINGJinhuaSUNHui

TONG Jun, DING Jin-hua, SUN Hui

(Key Laboratory of Geotechnical Mechanics and Engineering of Ministry of Water Resources,Yangtze River Scientific Research Institute, Wuhan 430010,China)

1 Introduction

Geogrid, as an important polymer material, has been widely used in permanent works as reinforcement material to strengthen soft foundations, reinforced soil retaining walls, bridge abutments and in other engineering fields[1-3]. In practical engineering, polymer geogrid is subjected to long-term effect of ultraviolet rays of sunlight, which is recognized as a dominant degradation factor in many polymers including those used in geosynthetics. The wavelength of the sun’s radiation extends from the infrared (>700 nm), through the visible spectrum (approximately 400-700 nm) and into the UV (<400 nm), with a cut-off at around 300 nm depending on atmospheric conditions. When solar radiation strikes the polymer surface, photons with energy similar, or higher than the chemical bond strength of the polymer cause a series of reactions that could lead to polymer chain scission and eventual degradation of polymer properties. The degradation may weaken the strength gradually, threatening the stability of the reinforcement structure. As in the service life of the structure, the mechanical properties of geogrid have a decisive influence on the stability of the structure. Studying the aging properties of geogrid as a typical polymer material is of great significance, and in particular, accurate prediction of the service life of geogrid has become a hot research topic.

InChineseHighwayGeotechnicalSyntheticMate-rialApplicationTechnologySpecification, the decrease of strength induced by aging, creep, etc. is expressed by a single reduction factor, with no specific reduction factor corresponding to different application conditions[4].Single reduction factor leads to the inapprop-riate selection of reinforcement material. Scholars in many countries, such as in the United States, have attempted to conduct in-depth research on the aging and creep behavior, respectively[5-8].Different reduction coefficients in consideration of the induced decrease of strength are put forward in ASTM D5970,and ASTM D5819[9-10].The reduction coefficient is much greater than the single reduction factor. Moreover, according to design practice and experience, the single reduction factor is conservative and uneconomical. As previous studies focus on the laboratory acceleration aging pro-perties without simulating the real atmosphere, there is few research data available regarding the long-term outdoor aging properties of geogrid. For the UV-susceptible polymer geogrid, it is imperative to take environmental conditions into consideration and study the long-term mechanical aging properties, so as to provide fundamental aging data for putting forward reasonable aging reduction factor in future.

In this paper,an outdoor aging test base for geosynthetic materials established by Yangtze River Scientific Research Institute in Wuhan, China is introduced in detail. Preliminary test results are given and the variation of the mechanical strength of high density polyethylene (HDPE) geogrid in the outdoor aging process is analyzed.

2 Outdoor Aging Test

The ideal way of assessing the service life of geogrid would be by examining actual field samples over the service life.By exposing polymer materials in the atmospheric environment close to the actual service field[9-12], we could obtain more reliable results of the durability of materials with simple test equipment through outdoor aging tests. The durability could be assessed through the appearance and the performance in periodic changes (i.e. aging). Long-term outdoor aging test could obtain highly reliable aging properties of mechanical indexes, and provide fundamental data for the prediction of the aging properties with indoor accele-rated aging method.

2.1 Test Condition and Equipment

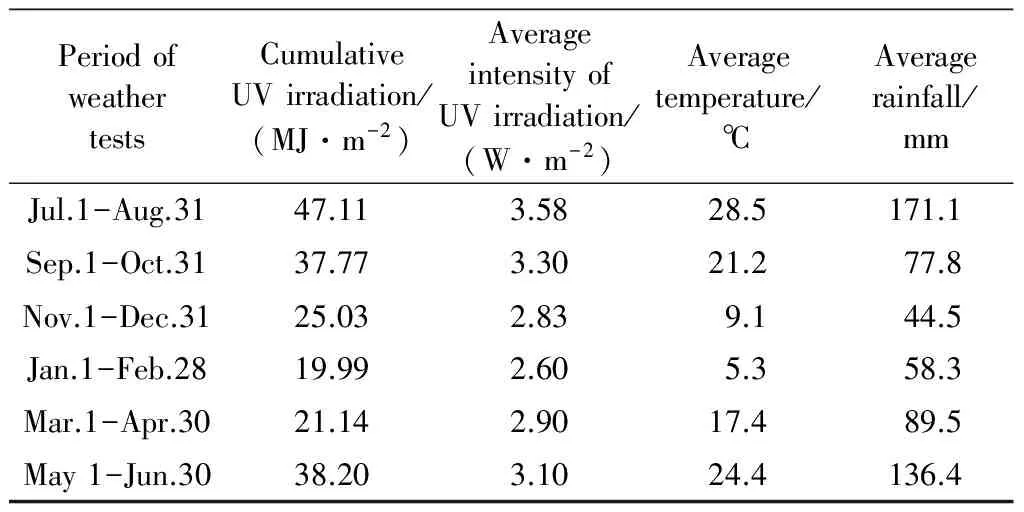

Located in Wuhan City, central China with an area of 600 m2, the site is free from obstruction, trees or other sources of shade. The meteorological conditions of the test site are shown in Table 1. The test started in July 1, 2014 to ensure that the test material is exposed during the maximum intensity of ultraviolet light of the year.

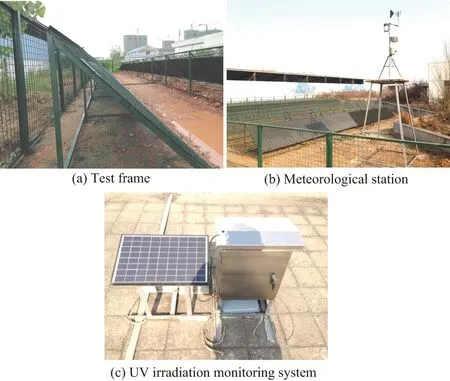

As shown in Figure 1(a),the test frame is placed so that no heat or sun light is reflected on it from surrounding buildings. The frame for holding the coupons during the exposure phase of this test consists of a steel frame suitably braced so that it resides facing south at a 45° angle with the horizontal plane. And the supporting frame is firmly anchored to the earth.

Table 1 Weather conditions during outdoor aging teststarting from July 1, 2014

As shown in Figure 1(b), during the experiment, the temperature, humidity and precipitation of the test field were monitored by the meteorological station. Meanwhile, the cumulative UV irradiation and average intensity of UV irradiation listed in Table 1 could be obtained using the UV irradiation monitoring system, as shown in Figure 1(c).

Fig.1 Outdoor aging test system

The HDPE geogrid were exposed to atmospheric conditions for an incremental period of time up to 12 months in Wuhan from July 1, 2014, following the standard ASTM D5970[9]. The geogrid coupons were fastened with care in such a way that undue stresses that could result in premature failure of the geogrid are not induced. Coupons were sampled at intervals of 0,3,6,9,12 months, respectively.

The strength tests were performed at the universal tensile test machine of type number CMT4304.The machine is equipped with an automatic data logging system to record the applied force and the distance between clamp faces.

2.2 Test Material and Method

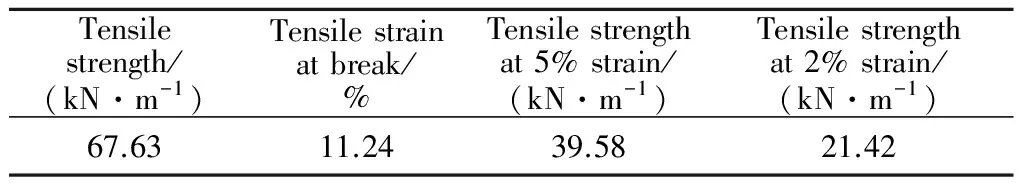

The coupons are unidirectional HDPE geogrid provided by domestic manufacturer in China. The basic mechanical parameters of the coupons are shown in Table 2 at an elongation rate of 20%/min of gauge length following the Chinese standard SL 235—2012[13].Before the tensile tests, all the samples were maintained at a relative humidity of 50% to 70% and a temperature of 21°C for 24 hours to reach equilibrium. The tensile strength and strain were obtained by averaging the value of maximum force at rupture for 6 para-llel specimen results. All tensile tests were performed in the same environment.

Table 2 Basic mechanical parameters ofthe HDPE geogrid

3 Test Results and Discussion

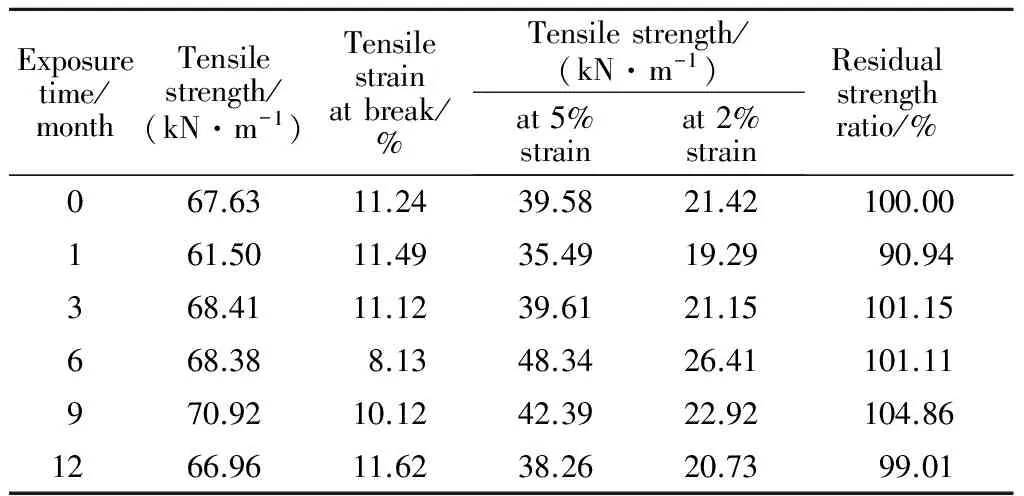

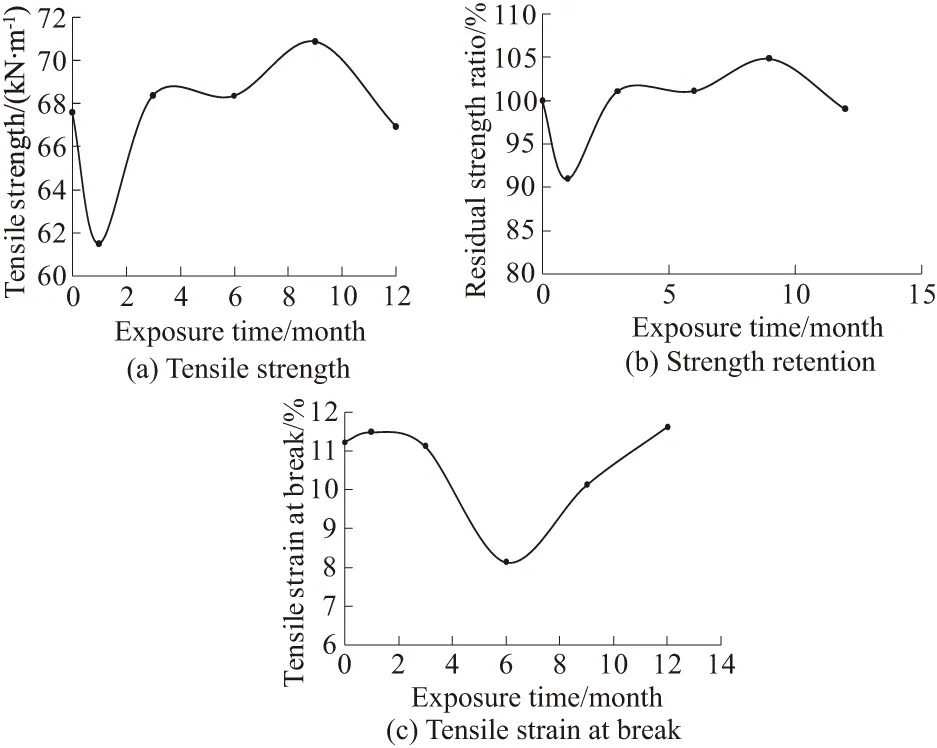

Table 3 and Figure 2 show the curves of tensile strength and tensile strain at break with different aging time for the studied geogrid. The tensile strength is expressed in force per unit width. When geogrid was exposed for 1 month, the tensile strength decreased slightly, and the elongation at break increased slightly; whereas when the exposure time was 3, 6, and 9 months, the maximum tensile strength increased by about 5%, and the corresponding strain at break decreased slightly, exhibiting hard and brittle trend. In the initial nine months, the tensile strength remained basically unchanged or even became larger, which is called the “annealing effect” in the early aging stage of polymer material, namely, the reforming and polymerization of the molecular chain which eliminates the internal stress and internal defects of the material. The initial increase of strength might also be induced by ultraviolet (UV) that provides the required energy for chemical crosslinking[14]. However, the light energy will eventually lead to the failure of the internal mole-cular structure and the degradation of the physical and mechanical properties of polymer geogrid. As shown in Figure 2(c), twelve months later, the strength began to decrease.

Table 3 Physical and mechanical parameters ofthe outdoor aging HDPE geogrid

Fig.2 Tensile strength and tensile strain at breakagainst exposure time in outdoor aging test

4 Conclusion and Prospect

The mechanical properties of HDPE geogrid during the aging process were analyzed as follows based on the outdoor test results: in the initial nine months, the strength retention rate fluctuates slightly but remains basically unchanged or even gets higher due to the “annealing effect” in the early aging stage of the polymer material.

Long-term outdoor aging tests for a variety of typical geosynthetics are scheduled. The long-term research results of the test base could provide first-hand data for the physical and mechanical indexes of the aging properties of geogrid.

Acknowledgements:We thank Ms. ZHOU Hui for performing the geogrid strength tests at Yangtze River Scientific Research Institute.

[1]龚壁卫,童军.土工合成材料在南水北调膨胀岩渠坡加固中的应用[J].长江科学院院报,2009,26(11):81-84.

[2]董健,张明,罗玉珊,等.山区复杂地形条件下超高土工格栅加筋土路堤的稳定性分析[J].长江科学院院报,2014,31(3):134-138.

[3]包承纲.关于环境岩土工程的若干问题[J].长江科学院院报,2003,20(3):32-34.

[4]JTJ/T 019—98,公路土工合成材料应用技术规范[S].北京:人民交通出版社,1999.

[5]GREENWOOD J H, CURSON A. Life Prediction of the Oxidation of Geogrids by Three Different Methods[J]. Geotextiles & Geomembranes, 2012, 34:93-99.

[6]HOLTZ R D, CHRISTOPHER B R, BERG R R. Geosynthetic Design and Construction Guidelines Participant Notebook[R]. Washington D.C.: U.S. Department of Transportation,2000.

[7]HSUAN Y G, LI M. Temperature and Pressure Effects on the Oxidation of High Density Polyethylene Geogrids[J]. Geotextiles & Geomembranes, 2005, 23(1): 55-75.

[8]RANKILOR P R. The Weathering of Fourteen Different Geotextiles in Temperate, Tropical, Desert and Permafrost Conditions[C]∥Proceedings of the Fourth International Conference on Geotextiles, Geomembranes and Related Products. Balkema, The Hague, Netherlands, May 28-June 1,1990: 719-722.

[9]ASTM D5970, Standard Practice for Deterioration of Geotextiles from Outdoor Exposure[S]. West Conshohocken, Pennsylvania, USA:American Society for Testing and Materials,2002.

[10] ASTM D 5819, Standard Guide for Selecting Test Methods for Experimental Evaluation of Geosynthetic Durability[S]. West Conshohocken, Pennsylvania, USA: American Society for Testing and Materials,2005.

[11] ASTM D 638, Standard Test Method for Tensile Properties of Plastics[S]. West Conshohocken, Pennsylvania, USA: American Society for Testing and Materials,2008.

[12] ASTM D 4595, Standard Test Method for Tensile Properties of Geotextiles by the Wide-Width Strip Method[S].West Conshohocken, Pennsylvania, USA:American Society for Testing and Materials,2005.

[13] SL 235—2012,土工合成材料测试规程[S].北京:中国水利水电出版社,2012.

[14] 李晓刚,高瑾,张三平,等.高分子材料自然环境老化规律与机理[M].北京:科学出版社,2011.