电磁处理提升采棉机摘锭力学性能和耐磨性

2018-04-11张有强蔡志鹏孟永钢

张有强,蔡志鹏,田 煜,孟永钢※

电磁处理提升采棉机摘锭力学性能和耐磨性

张有强1,2,蔡志鹏2,田 煜2,孟永钢2※

(1. 塔里木大学机械电气化工程学院现代农业工程重点实验室,阿拉尔 843300; 2. 清华大学摩擦学国家重点实验室,北京 100084)

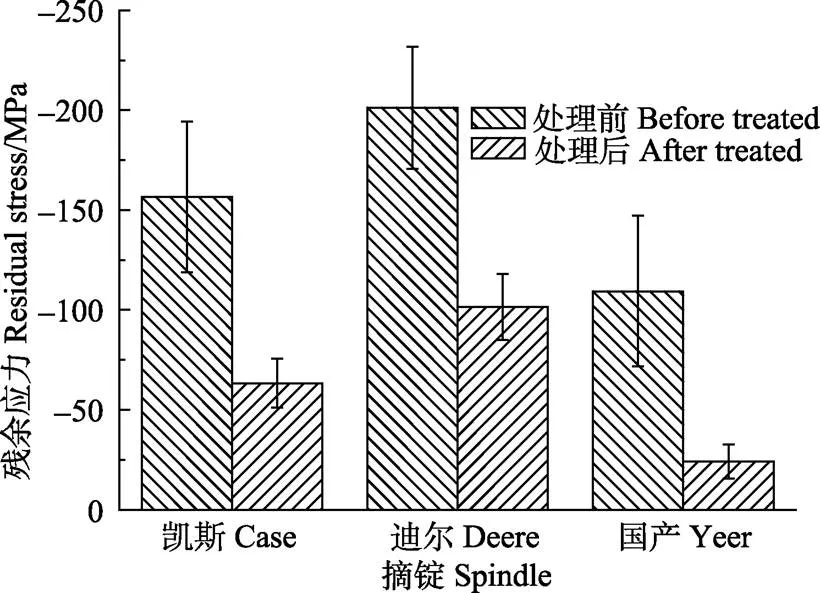

棉花机械化收获程度逐年提高,新疆生产建设兵团部分团场已实现100 %机械化采收,整体达到85 %以上。摘锭是采棉机的核心部件,其表面耐磨性能直接决定了采棉机的作业效率和机采棉品质,因此进一步提高摘锭表面耐磨性一直是重点关注的科学和技术问题。本文在不改变采棉机摘锭结构的基础上,基于电磁处理技术对市场化凯斯摘锭(Case)、迪尔摘锭(Deere)和国产摘锭(Yeer)进行电磁强化处理,并对3类摘锭电磁处理前后的力学性能进行实验室对比分析。摘锭电磁处理后试验结果表明:凯斯和国产摘锭残余应力下降60 %,迪尔摘锭下降50 %;凯斯、迪尔和国产摘锭涂层弹性模量与硬度的比值(/)都小于处理前的21,分别为18、17和20;电磁处理后凯斯和国产摘锭的磨痕宽度下降较迪尔显著,且随着载荷增大磨痕宽度下降趋势也随之增大,但仍是凯斯和国产摘锭下降较迪尔明显。相比较迪尔和国产摘锭,凯斯摘锭经电磁处理后力学性能提升效果最为显著,建议对凯斯摘锭电磁处理后进行田间耐磨性试验验证与评价。

棉花;收获机;力学性能;摘锭;电磁处理

0 引 言

提升高端农机装备是中国制造2025的主要发展领域之一,采棉机是棉花收获机械中的高端装备。随着农机与农艺的深度融合和拾花劳动力向稳定的二三产业的转移,棉花100%机械化采收是大势所趋,也是实现棉花全程机械化种植的关键所在。摘锭是采棉机的核心部件,一方面是使用最多的零件(一台采棉机安装2 500多个),更换周期短(使用寿命400 ha)且价格较高,增加采棉机的运营成本。另一方面,摘锭在采摘过程中不可避免地产生表面磨损,导致田间采摘效率和棉花品质的降低。为此,进一步提高摘锭表面耐磨性一直是重点关注的科学和技术问题。

目前,摘锭的结构和表面电镀技术较为成熟。研究者主要针对摘锭的力学分析[1-3]、运动仿真分析[4-6]和采摘系统设计[7]等方面进行了研究,但对提升摘锭表面耐磨性仍未开展相关研究工作。相比较先进表面处理技术,如物理气相沉积[8-9](physical vapor deposition,PVD)、化学气相沉积[10-12](chemical vapor deposition,CVD)、激光熔覆等技术,摘锭表面电镀铬涂层技术有其独特的表面耐磨性好、价格低、工艺简单等优势。因此课题组近年来一直在寻求不改变摘锭现有结构的基础上,进一步提高摘锭表面耐磨性的改性方法。电磁处理技术已有几十年发展历程,在改善材料晶粒尺寸、残余奥氏体的转化、残余应力改善等方面具有突出表现,极大提升了相关零部件的耐磨性能。

1965年Zagoruiko实验发现NaCl晶体塑性可以通过脉冲磁场改变[13],Alshits等[14-15]研究了不包含自由电子的非金属的塑性在稳恒磁场中的变化,证实稳恒磁场改变NaCl晶体塑性的现象。此后,许多研究表明外加磁场对材料力学行为产生影响[16-19],如金属材料拉伸过程力学性能中屈服阶段将会明显延长、疲劳极限与寿命也会提高。其原因是磁处理改变了铁磁性材料的晶体缺陷集中程度,如位错密度、空位密度等微观结构发生改变提高了材料的强度。另外,大量的实验研究证实外加磁场能够显著降低残余应力[20-25],如稳恒磁场对残余应力变化影响较小,低频交变磁场使残余应力下降显著;应力峰值降低的同时残余应力曲线也同步下降。同时研究表明残余应力下降水平与初始应力有关,并与作用频率相关;不同磁场激励方向对金属材料残余应力也会产生影响,垂直于主应力方向的磁场对残余应力改变幅值较大,但平行于该主应力方向作用的磁场对残余应力的改变不是很明显[26-28]。这些研究结果表明外加磁场能够改善材料的残余应力和力学性能。

采棉机摘锭在采摘过程中受多激励、多参数的动力学与摩擦学耦合作用,摘锭表面随工作时间不断发生磨损演化。以往的研究中人们已经对采棉机摘锭的结构设计、运动学行为等进行了大量研究,但对摘锭表面涂层改性进一步提高耐磨这一关键的科学和技术问题缺乏深入了解。本文在不改变摘锭现有结构和表面涂层的基础上,采用电磁处理技术对其进行改性处理,旨在提高表面耐磨性。基于电磁处理技术对凯斯摘锭(Case)、迪尔摘锭(Deere)和国产摘锭(Yeer)进行处理,借助电子扫描显微镜、X射线衍射仪、纳米压痕仪等先进的测试手段系统地分析摘锭电磁处理前后的残余应力、基体显微硬度及涂层微观力学性能变化,并通过划痕和磨损试验表征摘锭电磁处理前后的耐磨性能。

1 摘锭结构及电磁处理

1.1 摘锭结构

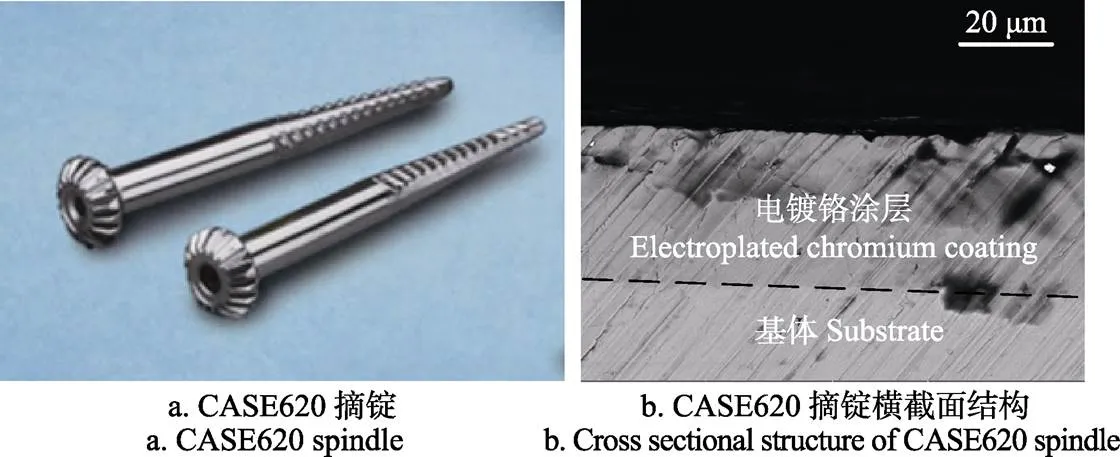

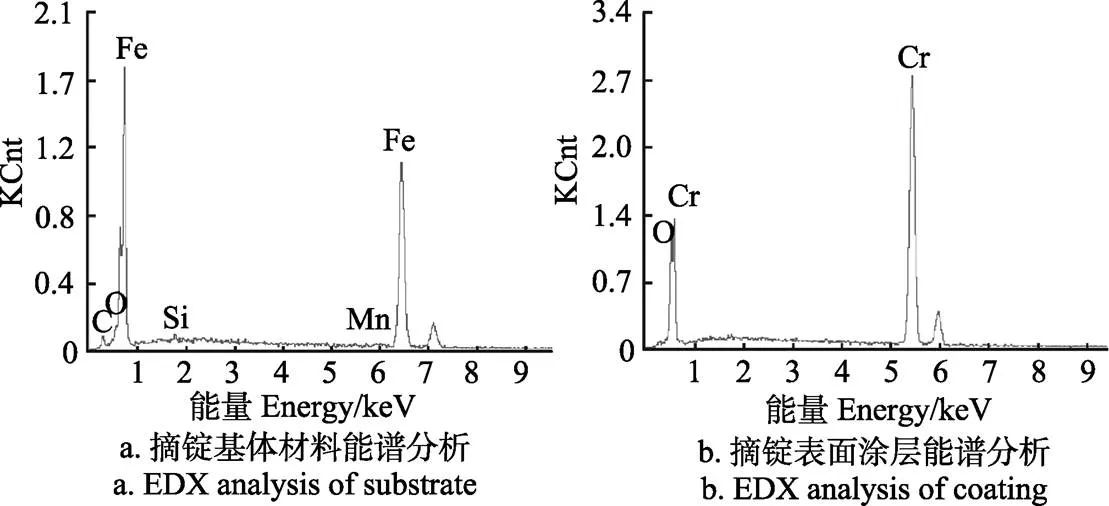

采棉机田间收获工况复杂,受多种因素(棉花的成熟度、地面不平度、气候和地理条件等)影响,采摘过程中摘锭表面与多种介质(棉花/秆/壳、细小沙粒等)接触产生磨损。为了有效提高钩取缠绕盛开在棉铃中的棉纤维及脱棉顺利,摘锭采摘工作部分的设计结构为圆锥形,表面加工有一定倾斜角度的钩齿,并且表面进行电镀铬涂层以提高耐磨性。以凯斯(CASE620)采棉机摘锭为例,头部球面直径5.4 mm,根部直径12 mm,长度120 mm,质量0.094 kg。通过能谱分析表明摘锭基体材料为低碳合金钢,表面为耐磨性较高的铬涂层,如图1、图2所示。

图1 CASE620采棉机摘锭及横截面结构

注:KCnt为X射线计数,其强度值与元素含量有关。

1.2 电磁处理平台

电磁处理平台整体系统如图3所示,包括电源、铜线圈、屏蔽体、循环水冷系统和控制系统5个部分。将待处理的工件放置到铜线圈内,电源提供并输入特定波形和强度的电流,使铜线圈产生所需要参数的电磁场;为了防止电磁泄露和干扰,整机系统外面采用纯铁电磁屏蔽壳体;另外,为了保证系统长时间工作的可靠性和稳定性,采用循环水冷却系统对铜线圈进行冷却;装卡待处理的工件后,通过控制系统和人机交互面板实现温度检测、冷却系统控制、处理时间以及电磁场参数设定。

电磁处理工作过程及工艺可参考文献[29-30]。摘锭电磁处理过程主要参数范围:磁感应强度0.2~0.5 T,脉冲电流密度102~104A/cm2,单个脉冲的作用时间为0.1~50 ms。

图3 电磁处理系统示意图

2 材料与方法

2.1 试样制备

选择目前普遍使用的市场化凯斯摘锭、迪尔摘锭和国产摘锭为电磁处理样品。为了便于制样,将摘锭中部圆柱体切割成直径12 mm、长15 mm的样品。圆柱体底面采用机械抛光,表面粗糙度为Ra=0.2m。电磁处理前后摘锭样品使用无水乙醇和丙酮进行超声清洗10 min。

2.2 残余应力测试

摘锭表层电磁处理前后的残余应力采用高分辨X射线衍射仪(清华大学材料科学与工程研究院中心实验室)进行检测,测试参数特性谱线为Cu-Kα;X光管工作电压为30 kV,工作电流为6~8 mA。扫描过程:初步在60°~120°范围内扫描,选择一个衍射晶面指数较高的衍射峰作为对象峰。按照残余应力测量要求设置不同角度(0°、15°、30°、45°)、以慢速扫描方式测量不同角度下的单峰衍射谱[31],进而通过X射线衍射仪自带软件计算得到残余应力。

2.3 显微硬度测试

摘锭结构由基体和表面电镀铬涂层构成,其硬度需要分别进行表征。摘锭基体硬度采用显微硬度计(Tukon 2500,美国威尔逊)进行测试。

摘锭表面电镀铬涂层的显微硬度采用纳米压痕仪表征。在纳米压痕测试前,将摘锭样品冷镶嵌后对横截面仔细抛光,使横截面平整无划痕、涂层结构清晰。摘锭表面电镀铬涂层硬度和弹性模量采用纳米压痕仪(瑞士CSM仪器公司)测试,载荷范围为0.1~1 N。测试过程采用金刚石材料的布氏压头,载荷加载方式为线性加载,最大载荷为50 mN,加载速率为100 mN/min,卸载速率为100 mN/min,工程实际应用中金属材料的泊松比通常选取0.25。

2.4 划痕测试

采棉机在田间采摘过程中与摘锭表面相接触产生摩擦行为的不仅仅是棉纤维,还伴有许多硬质颗粒(沙粒、棉秆/壳节点)的参杂。在这些硬质颗粒的作用下,采摘过程中会导致摘锭表面产生划痕、犁沟效应,引起摘锭磨损。

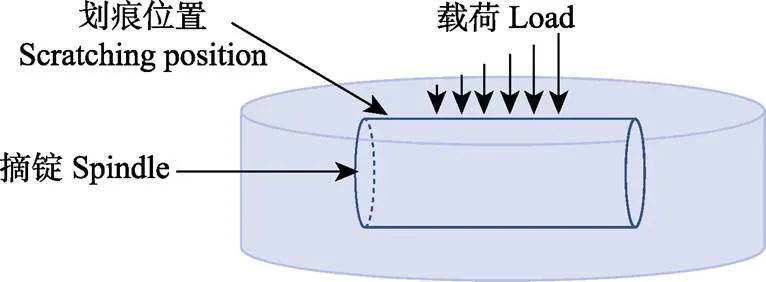

摘锭样品采用环氧树脂进行冷镶嵌,经过抛光后恰好露出摘锭圆柱体母线为划痕测试位置,如图4所示。划痕试验在商用标准摩擦磨损试验机(UMT-3,Center of tribology,USA,垂直位置分辨率1m)上进行测试。采集每个时刻载荷和对应的划痕深度(垂直位移量),每个摘锭样品进行3次划痕测试取平均值。划痕测试过程中采用金刚石压头(100m),载荷20~100 N线性连续变化加载,划痕长度4 mm,时间2 min。

图4 摘锭划痕测试位置

2.5 磨损测试

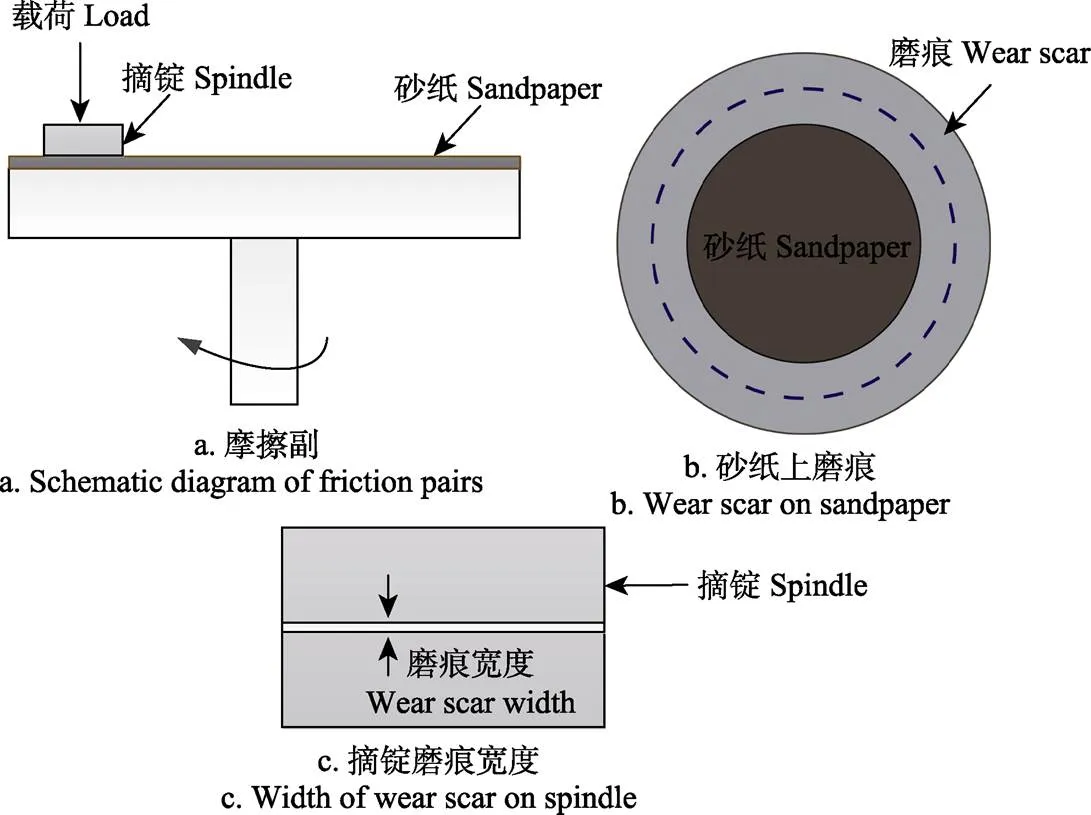

耐磨性是评价和表征摘锭使用性能的主要指标,电磁处理前后摘锭的耐磨性在商用标准摩擦磨损试验机(UMT-3)进行评价。磨损试验中上试样为电磁处理前后摘锭样品,采用自制圆柱体夹具装卡后安装在UMT-3上试样位置。下试样为砂纸(SiC,FEPA P#1200,粒径尺寸为15m,Struers)。磨损过程中上试样固定、竖直方向加载,下试样旋转,线接触方式进行,其摩擦副示意图如图5a所示。下试样的运动速度1 m/s(驱动下试样工作平台转速300 r/min,上试样长度中心位置设置在砂纸直径65 mm处,图5b中虚线位置所示)。磨损时间180 s,载荷分别为10 和20 N。磨损结束后,测量摘锭样品的磨痕宽度,如图5c所示。

图5 摘锭电磁处理前后磨损试验

3 结果与分析

3.1 残余应力分析

图6为摘锭样品处理前后残余应力结果。由图6可知,在磁场作用下3类摘锭样品处理后残余应力均有所下降、且幅值较大。相比处理前,凯斯和国产摘锭残余应力下降达60%,最大平均残余应力分别降低约90和75 MPa;迪尔摘锭下降50%左右,最大平均残余应力降低约100 MPa。

图6 摘锭残余应力

一般而言电磁处理后残余应力降低是由于材料内部发生了应力松弛的结果[14]。其原因是材料中存在的位错可能与外加脉冲磁场发生了相互作用,导致非弹性局部塑性变形不断累积,甚至位错开动造成[20]。研究结果表明残余应力的降低将会消除或改善涂层微观结构的局部塑性变形,也会使涂层表层内应力重新分布达到使用过程的形变稳定,提高疲劳寿命[23]。

3.2 微观硬度分析

摘锭基体硬度压痕形貌如图7a所示,图7b为摘锭电磁处理前后沿径向的维氏硬度分布。由图7可以看出,以电镀铬涂层内边缘为测量起点,摘锭基体材料的显微硬度沿径向逐渐降低,主要是因为摘锭基体结构机械加工完成后,表层进行了渗碳处理,随渗碳层深度增加含碳量逐渐减小,然后经淬火热处理后表层硬度呈现逐渐降低的梯度分布。另外,图7b表明,凯斯和国产摘锭的渗碳层厚度约600m、迪尔摘锭约1 000m。同时通过对比同类摘锭电磁处理前后硬度,整体来看电磁处理对摘锭基体材料硬度影响不大,基本保持处理前硬度。局部来看靠近涂层区域电磁处理后的硬度有所提高,远离涂层区域(凯斯和国产迪尔摘锭大约400m,迪尔摘锭约800m)的硬度略有下降。

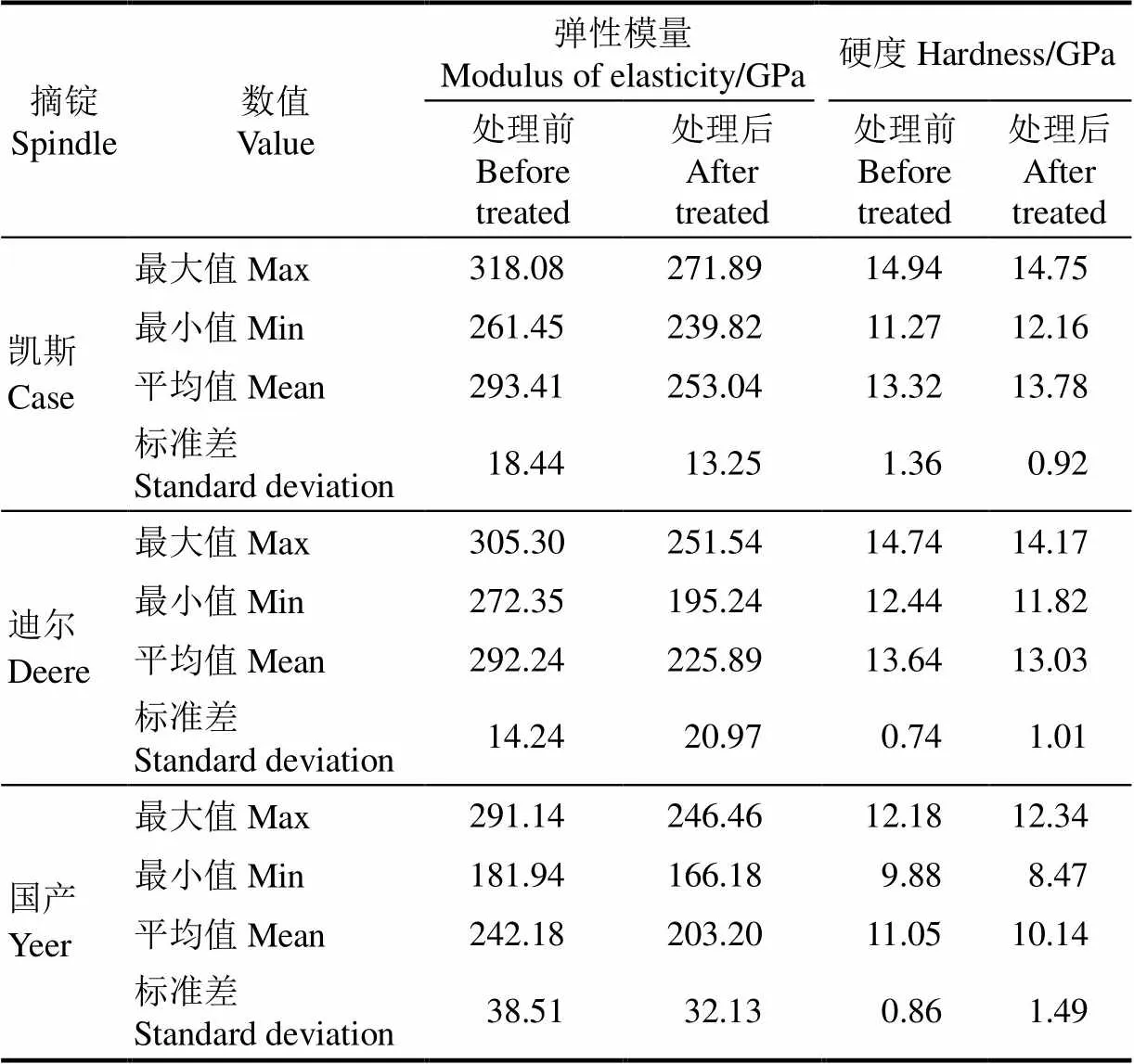

摘锭涂层弹性模量和显微硬度结果如表1所示,相比电磁处理前涂层特性,凯斯和迪尔摘锭电磁处理后涂层硬度平均值几乎无差异,国产摘锭稍有下降;弹性模量平均值均有所下降,凯斯、国产和迪尔摘锭依次降低约13%、16%和22%。其可能原因摘锭在磁处理过程中残余应力降低,材料晶体结构、点缺陷等畸变产生了回复,处于高能状态的晶粒比例减小,从而使得材料整体的弹性模量降低。

材料的弹性模量()与硬度()的比值(/)来衡量其相对耐磨性,一般情况材料的/值越小相对耐磨性越高[32]。表1结果显示电磁处理前3种摘锭涂层的弹性模量和硬度的比值(/)都超过21,电磁处理后凯斯、迪尔和国产摘锭涂层的/值分别约为18、17和20,均低于处理前。表明电磁处理将会引起涂层的/值减小,导致弹性变形增加,减少粘附磨损[33-35],有利于提高耐磨性。

注:C-凯斯摘锭;D-迪尔摘锭;Y-国产摘锭;T-进行电磁处理;N-未进行电磁处理。下同。

表1 表面涂层弹性模量和纳米硬度

3.3 划痕结果分析

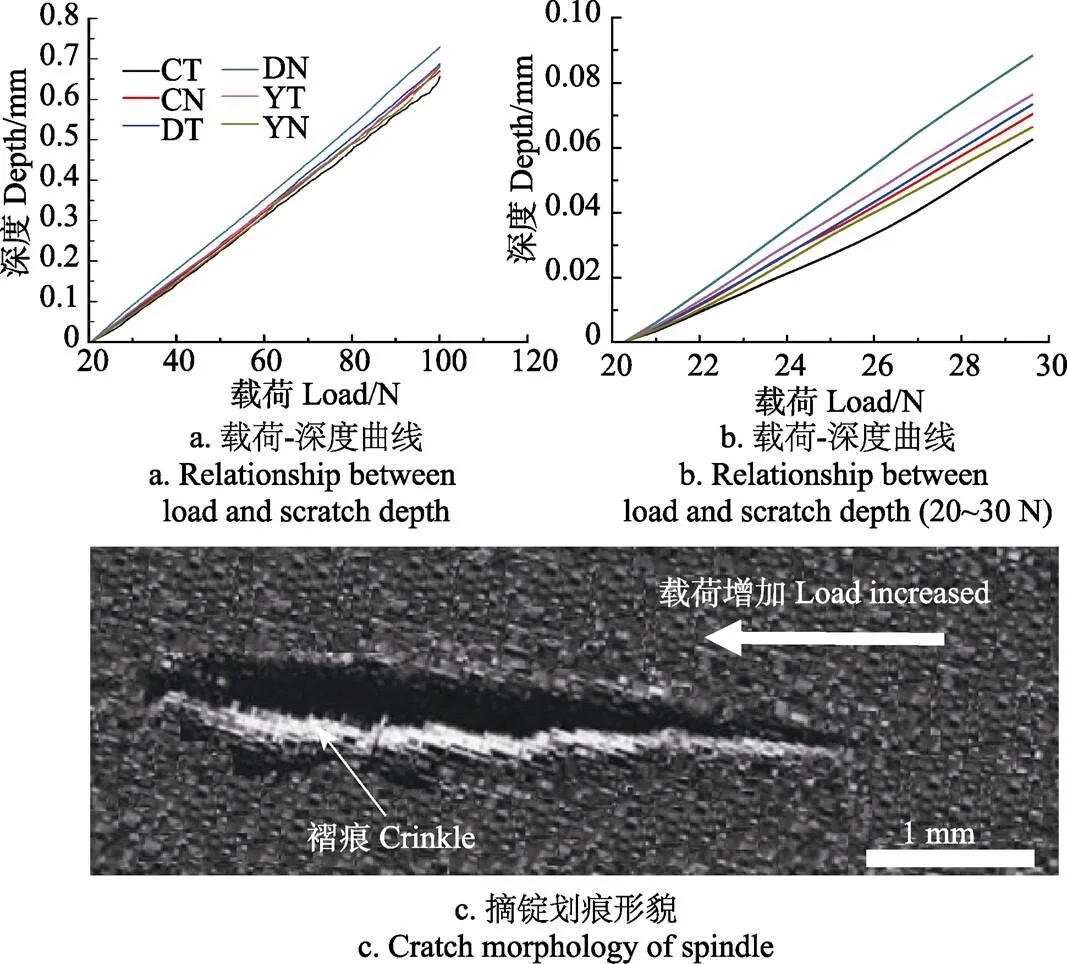

图8a为划痕深度与载荷变化关系。由图8a可以看出,划痕深度与载荷基本成线性关系,3种摘锭样品划痕测试结果较为集中。图8b为局部放大图,进一步展示了载荷在20~30 N之间的划痕细节,可以看出与电磁处理前相比,凯斯和迪尔摘锭在同一载荷下处理后划痕深度明显变小,表明电磁处理后涂层抵抗外力破坏的综合承载能力提高。另外,在划痕试验中并未明显观察到涂层与基体界面临界载荷的转折点,主要是原因是基体表层进行渗碳处理后淬火,基体表层硬度与电镀铬涂层硬度较接近所致。

图8c展示了划痕试验中的划痕形貌,明显可以看出划痕深度随着载荷的增加逐渐加深、划痕宽度随着载荷的增加逐渐变宽,划痕两侧呈现出犁沟褶皱。

图8 摘锭划痕测试

3.4 磨损结果分析

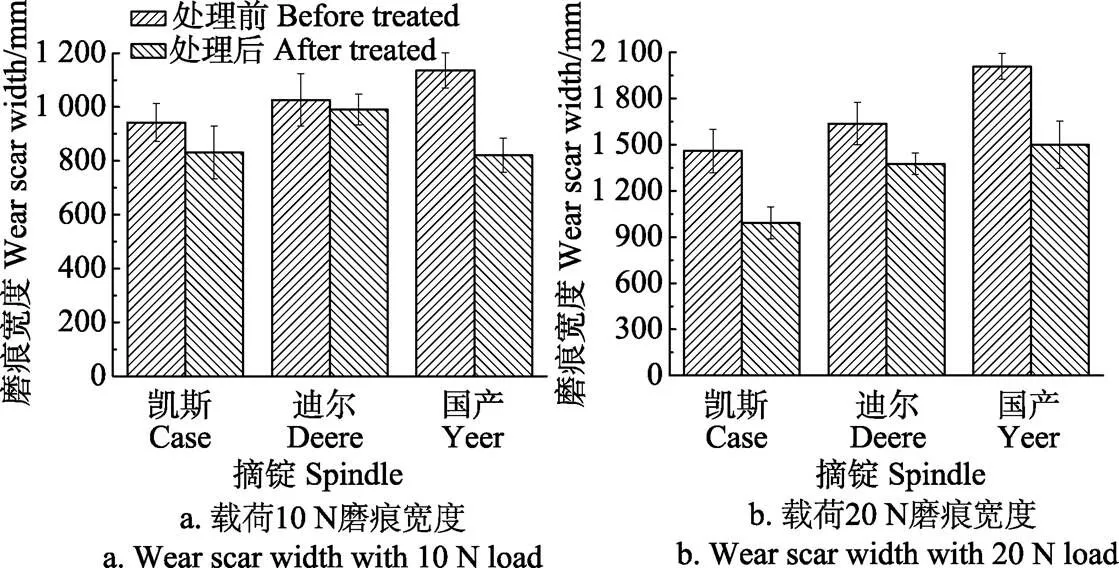

由于磨损过程中摘锭圆柱体样品与砂纸在接触区域的线速度不一致,导致磨痕宽度随线速度增大变宽,因此磨痕宽度采用摘锭样品沿长度方向中间位置处的宽度表征。图9a和图9b分别展示了载荷为10和20 N时磨痕宽度变化(摘锭样品进行3次磨损测试的平均值)。与未处理摘锭相比,电磁处理后的摘锭与砂纸对磨时磨痕宽度减小,在载荷10 N时,凯斯、迪尔和国产摘锭磨痕宽度分别下降11.8%、3.4%和19%;随着载荷增大磨损宽度下降趋势也随之增大,在载荷20 N时,凯斯、迪尔和国产摘锭磨痕宽度分别下降32%、15.9%和25.3%。与处理前相比,磨痕宽度较电磁处理前均呈现下降趋势,表明经电磁处理后的摘锭抵抗磨粒磨损的能力有所提高。相比较迪尔摘锭,凯斯和国产摘锭电磁处理后的耐磨性提升效果更为显著。综合划痕与磨损试验结果,凯斯摘锭电磁处理强化效果最优。

从磨损结果来看,对于处理前后的磨痕宽度整体规律符合/理论,但弹性模量经电磁处理变小后,磨痕宽度取决于弹性模量的实际值。从表1可以看出,电磁处理后凯斯摘锭的弹性模量明显大于迪尔摘锭,表明相同载荷下接触半径迪尔摘锭大于凯斯摘锭。在干摩擦状态下磨痕宽度分布于整个Hertz接触区域,主要原因是在微观粗糙表面上磨损的发生只与接触区域相关(粗糙峰塑性变形只与接触区域相关),与外载荷大小无关[36]。因此,磨损测试结果为迪尔摘锭的磨痕大于凯斯摘锭。处理前两者的弹性模量凯斯摘锭略高于迪尔摘锭,但硬度相差不大,因此迪尔摘锭磨痕宽度略高。此外,相比凯斯和迪尔摘锭,国产摘锭的硬度和弹性模量都低,所以磨痕宽度相对较高。

图9 摘锭的磨痕宽度

4 结 论

1)本文在不改变现有采棉机摘锭结构的基础上,基于电磁处理技术过对市场化的凯斯、迪尔和国产摘锭进行电磁强化处理,并对3类摘锭电磁处理前后的力学性能进行实验室对比分析。

2)电磁处理能够使材料内部发生了应力松驰,改善残余应力水平。3类摘锭经电磁处理后残余应力下降显著,凯斯和国产摘锭残余应力下降达60 %,迪尔摘锭下降50%左右。

3)电磁处理后摘锭基体材料显微硬度、电镀铬涂层纳米硬度未显著变化、涂层弹性模量下降。3类摘锭电磁处理前弹性模量与硬度的比值(/)都超过21,经电磁处理后凯斯、迪尔和国产摘锭涂层的/值都低于处理前,分别约为18、17和20。电磁处理将引起涂层的/值减小,导致弹性变形增加,减少粘附磨损,有利于提高耐磨性。

4)通过电磁处理前后的磨损试验,相比较未处理摘锭,在载荷10 N时凯斯、迪尔和国产摘锭磨痕宽度分别下降11.8%、3.4%和19%,载荷增加到20 N时分别下降32%、15.9%和25.3%。磨痕宽度较电磁处理前均呈现下降趋势,表明电磁处理后的摘锭抵抗磨粒磨损的能力显著提高。结合划痕试验结果,综合比较迪尔和国产摘锭,凯斯摘锭经电磁处理后耐磨性能提升效果最为显著,建议对凯斯电磁处理后摘锭进行田间试验验证。

在实验室结果的基础上,下一步将进行电磁处理后凯斯摘锭的田间试验,选择不同区域(南疆棉花纤维上依附的沙尘较多、棉秆较坚硬;北疆沙尘较少、湿度较大)进行大面积田间实际评价与验证。

[1] 毕新胜,王维新,武传宇,等. 采棉机水平摘锭的工作原理及采摘力学分析[J]. 石河子大学学报,2007,25(6):786-789. Bi Xinsheng, Wang Weixin, Wu Chuanyu, et al. Working principle and picking mechanics analysis of level spindle on cotton pickers[J]. Journal of Shihezi University, 2007, 25(6): 786-789. (in Chinese with English abstract)

[2] 张有强,王伟,廖结安. 采棉机摘锭磨损失效分析[J]. 农业工程学报,2017,33(18):45-50. Zhang Youqiang, Wang Wei, Liao Jiean. Wear failure analysis on spindle of cotton picker[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(18): 45-50. (in Chinese with English abstract)

[3] Meng F M, Chen N W, Chen Z W. Hard chromium coating effects on tribological performances for nonlubricated and lubricated spindle of cotton picker[J]. Journal of Materials: Design and Applications, 2016, 230(2): 446-453.

[4] 张有强,马少辉,丁旺才. 采棉机摘锭采摘过程的动力学分析[J]. 农业工程学报,2012,28(13):54-58. Zhang Youqiang, Ma Shaohui, Ding Wangcai. Dynamic analysis of cotton picker ingots during picking process[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(13): 54-58. (in Chinese with English abstract)

[5] 李世云,孙文磊,洪荣荣. 基于ADAMS的采棉机摘锭运动规律分析及轨迹仿真[J]. 农机化研究. 2016(9):74-77.Li Shiyun, Sun Wenlei, Hong Rongrong. ADAMS-based cotton picker spindle motion analysis and trajectory simulation[J]. Journal of Agricultural Mechanization Research, 2016(9): 74-77. (in Chinese with English abstract)

[6] Meng F M, Chen N W. Study of coating’s effects on mechanical performances for sleeve of cotton picker with fluid–structure interaction method[J]. Journal of Mechanical Engineering Science, 2014, 228(17): 1-12.

[7] 张宏文,康敏,傅秀清,等. 胶棒滚筒棉花采摘头的设计与试验[J]. 农业工程学报,2011,27(2):109-113. Zhang Hongwen, Kang Min, Fu Xiuqing, et al. Design and experiment of rubber-bar roller of cotton harvester[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(2): 109-113. (in Chinese with English abstract)

[8] Rodríguez-Baracaldo R, Benito J A, Puchi-Cabrera E S, et al. High temperature wear resistance of (TiAl) N PVD coating on untreated and gas nitrided AISI H13 steel with different heat treatments[J]. Wear, 2007, 262(3): 380-389.

[9] Holleck H, Schier V. Multilayer PVD coatings for wear protection[J]. Surface and Coatings Technology, 1995, 76(1): 328-336.

[10] Lorenzo-Martin C, Ajayi O, Erdemir A, et al. Effect of microstructure and thickness on the friction and wear behavior of CrN coatings[J]. Wear, 2013, 302:963-971.

[11] Lee H J, Song M Y, Jurng J S, et al. The synthesis and coating process of TiO2nanoparticles using CVD process[J]. Powder Technology, 2011, 214: 64-68.

[12] Nouari M, Ginting A. Wear characteristics and performance of multi-layer CVD-coated alloyed carbide tool in dry end milling of titanium alloy[J]. Surface and Coatings Technology, 2006, 200(18-19): 5663-5676.

[13] Molotskll M T. Theoretical basis for electro-and magnetoplasticity[J]. Materials Science and Engineering:A, 2000, 287: 248-258.

[14] Alshits V I, Darinskaya E V, Koldaeva M V, et al. Magnetoplastic effect: basic properties and physical mechanisms[J]. Crystallography Reports, 2003, 48(5): 768-795.

[15] 林健. 脉冲磁处理降低钢铁材料中残余应力的规律研究[D]. 北京:清华大学,2006. Lin Jian. Study on Reduction of Residual Stress in Steel Materials by Pulsed Magnetic Treatment[D]. Beijing: Tsinghau University, 2006. (in Chinese with English abstract)

[16] 葛世慧. 铁磁性物理[M]. 兰州:兰州大学出版社,2002.

[17] 唐非. 脉冲磁处理降低钢材内部残余应力研究[D]. 北京:清华大学,1999. Tang Fei. Study on Reduction of Internal Residual Stress in Steel by Pulsed Magnetic Treatment[D]. Beijing: Tsinghau University, 1999. (in Chinese with English abstract)

[18] Tang F, Lu A L, Mei J F, et al. Research on residual stress reduction by a low frequency alternating magnetic field[J]. Journal of Materials Processing Technology, 1998, 74(1): 255-258.

[19] Lu B T, Qiao S R, Sun X Y. Exploration on repairing fatigue damage of steel specimens with magnetic treatment[J]. Scripta Materialia, 1999, 40(7): 767-771.

[20] 林健,赵海燕,蔡志鹏,等. 磁处理提高钎杆服役寿命的研究[J]. 材料工程,2006(2):3-11. Lin Jian, Zhao Haiyan, Cai Zhipeng, et al. Study on improving the service life of drill rods by magnetic treatment[J]. Journal of Materials Engineering, 2006(2): 3-11. (in Chinese with English abstract)

[21] Cai Z P, Lin J A, Zhou L A, et al. Evaluation of effect of magnetostriction on residual stress relief by pulsed magnetic treatment[J]. Materials Science and Technology. 2004, 20(12): 1563-1566.

[22] Bose M S C. Effect of saturated magnetic field on fatigue life of carbon steel[J]. Physica status solidi (a), 1984, 86(2): 649-654.

[23] Cai Z P, Zhao H Y, Lin J, et al. Plastic deformation caused by pulsed magnetic treatment of mid-carbon steel[J]. Materials Science and Engineering A. 2007, 458(1-2): 262-267.

[24] Hochman R F, Nselesin T, Drits V. Magnetic fields: fertile ground for materials processing[J]. Advanced Materials and Processes,1998, 134(8): 36-41.

[25] Cai Z P, Lin J, Zhao H Y, et al. Orientation effects in pulsed magnetic field treatment[J]. Materials Science and Engineering A. 2005, 398(1-2): 344-348.

[26] Molotskll M, Kris R E, Fleurov V. Internal friction of dislocations a magnetic field[J]. Physical Review B, 1995, 51(18): 12531-12536.

[27] 蔡志鹏,林健,周亮,等. 磁脉冲改变残余应力方法中磁致振动所起作用[J]. 机械工程学报,2005,(41)7:216-219. Cai Zhipeng, Lin Jian, Zhou Liang, et al. Effect of the magnetic strain vibration in residual stress reduction by pulsed magnetic treatment[J]. Journal of Mechanical Engineering, 2005, (41)7: 216-219. (in Chinese with English abstract)

[28] 鹿安理,唐非,梅俊峰,等. 不同频率的交变磁场处理降低焊接残余应力的研究[J]. 航空工艺技术,1998(4):26-27. Lu Anli, Tang Fei, Mei Junfeng, et al. Study on alternating magnetic treatment of different frequencies for welding residual stress reduction[J]. Aeronautical Manufacturing Technology, 1998(4): 26-27. (in Chinese with English abstract)

[29] 鹿安理,方慧珍,吴甦,等. 用低频脉冲磁处理降低钢铁工件中内应力的方法及其装置[P]. CN1270234,2000.

[30] 蔡志鹏. 一种降低铁磁性金属材料残余应力的方法[P]. CN101713021A,2010.

[31] 周玉,武高辉. 材料分析测试技术[M]. 哈尔滨:哈尔滨工业大学出版社,2007.

[32] 温诗铸,黄平. 摩擦学原理[M]. 北京:清华大学出版社,2012.

[33] Halling J, Nuri K A. The elastic contact of rough surfaces and its importance in the reduction of wear[J]. Proceedings of Institution of Mechanical Engineers, 1985, 199(2): 139-142.

[34] Kogut L, Etsion I. A finite element based elastic-plastic model for the contact of rough surface[J]. Tribology Transactions, 2003, 46(3): 383-390.

[35] Horng J H. An elastic-plastic asperity microcontact model for rough surface[J]. Journal of Tribology, 1998, 120(1): 82-88.

[36] Greenwood J A, Williamson J B P. Contact of nominally flat surfaces[J]. Mathematical and Physical Sciences, 1966, 295(1442): 300-319.

Improvement of mechanical properties and wear resistance of cotton picker spindle by electromagnetic treatment

Zhang Youqiang1,2, Cai Zhipeng2, Tian Yu2, Meng Yonggang2※

(1.843300,;2.100084,)

Cotton is one of the major crops in Xinjiang, China, and has a significant impact on Xinjiang’s economic development and social stability. The mechanization degree of cotton harvest is increasing with the development of productive forces and the progress of science and technology. For part of the mission field of Xinjiang Production and Construction Corps, China, mechanized harvesting has been achieved 100%, and overall, it has reached above 85%. Spindles are the core component of cotton picker; a single cotton picker has about 2 500 spindles, and a spindle uniquely has the structure of 3 rows × 14 teeth. In order to facilitate the removal of cotton, the first 3 teeth have an angle of 30º with respect to the pole axis, and the remaining 11 hook teeth form an angle of 45º to ensure the cotton picking rate, whose performance directly determines operation efficiency and cotton quality of the cotton picker. Moreover, the substrate material of the spindle is low carbon alloy steel, on which a chromium coating is electroplated to increase the wear resistance. In the case of correct installation and good lubrication, the average life span of spindle was picking cotton of about 400 ha. The wear resistance of the surface coating seriously affects the running cost of the cotton picker. Therefore, to further improve the wear resistance of spindle has always been a scientific and technical issue. In order to improve the wear resistance of the spindle, we have proposed electromagnetic treatment method for surface modification of spindle (Case’s spindle made by Case Corp., USA, Deere’s spindle made by John Deere Corp., USA and Yeer’s spindle made by Yeer Corp., China). The main objective of this study was to reveal the mechanical properties of the electromagnetic treated spindle, but not changing the spindle structure that has been existing in cotton picker. The result showed that the residual stress of the 3 types of spindles was decreased significantly after electromagnetic treatment, the residual stress of Case’s and Yeer’s spindle decreased by 60%, and that of Deere’s spindle by about 50%. The main cause of residual stress decrease was that electromagnetic treatment can cause stress relaxation in the material, resulting in local inelastic deformation and stress redistribution, and improve the fatigue life. After electromagnetic treatment, the microhardness of the spindle’s substrate material and the nanohardness of the electroplated chromium coatings did not change significantly, and the elastic modulus of the coating decreased. The ratio of elastic modulus to hardness of the 3 kinds of spindle surface coating was all over 21 before electromagnetic treatment. After electromagnetic treatment, the ratio value of Case’s, Deere’s and Yeer’s spindle was 18, 17 and 20, respectively. The decrease of the ratio of elastic modulus to hardness will increase the elastic deformation, reduce the adhesion and wear, and improve the wear resistance. Through the scratch and wear test, the scratch depth of the spindle surface coating became smaller and the wear scar width decreased after electromagnetic treatment for all kinds of spindles. The wear scar width of Case’s and Yeer’s spindle decreased more significantly than Deere’s spindle. Moreover, the wear scar width decreased with the increase of load in wear test, but the downtrend of wear scar width of Case’s and Yeer’s spindle was more obvious than Deere’s spindle compared with that before electromagnetic treatment. By the comparison, the improved wear resistance of Case’s spindle is the most notable after the electromagnetic treatment. Therefore, the Case’s spindle of electromagnetic treatment is used to carry out the field test for cotton picking, which was to evaluate and verify wear resistance. The research results will be helpful for improving the wear resistance of spindle, which makes it possible to prolong the service life of spindle used, and has important social significance and remarkable economic benefits.

cotton; harvester; mechanical properties; spindle; electromagnetic treated

张有强,蔡志鹏,田 煜,孟永钢. 电磁处理提升采棉机摘锭力学性能和耐磨性[J]. 农业工程学报,2018,34(7):31-37. doi:10.11975/j.issn.1002-6819.2018.07.004 http://www.tcsae.org

Zhang Youqiang, Cai Zhipeng, Tian Yu, Meng Yonggang. Improvement of mechanical properties and wear resistance of cotton picker spindle by electromagnetic treatment[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(7): 31-37. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.07.004 http://www.tcsae.org

2017-12-21

2018-01-23

国家自然科学基金项目(11362020)

张有强,男,副教授,主要从事生物质材料与金属的摩擦磨损研究。Email:zhangyqlzjd@126.com

中国农业工程学会会员:张有强(E041201009S)

孟永钢,男,教授,主要从事微纳系统及微纳制造中的表面界面科学研究。Email:mengyg@tsinghua.edu.cn

10.11975/j.issn.1002-6819.2018.07.004

S225.91

A

1002-6819(2018)-07-0031-07