Research on a Flexible Humidity Sensor Based on LCP Substrate*

2017-11-03,,

, ,

(Key Laboratory of MEMS of Ministry of Education,Southeast University,Nanjing 210096,China)

项目来源:国家863项目(2015AA042602)

ResearchonaFlexibleHumiditySensorBasedonLCPSubstrate*

ZHANGDan,HUANGJianqiu*,WANGLifeng

(Key Laboratory of MEMS of Ministry of Education,Southeast University,Nanjing 210096,China)

AbstractAnovel flexible capacitive humidity sensor is presented . We took advantage of liquid crystal polymer(LCP)as the substrate,copper(Cu)interdigitated(IDT)structureas electrodes and polyimide as the sensing film.The senor is flexible with the aid of the LCP substrate. Compared with conventional humidity sensors based on silicon(Si)substrate the flexible humidity sensor has advantages of low cost,simple structure and easy fabrication process. Theaverage sensitivity and the maximum hysteresisof the humidity sensor are 0.04% pF/%RH and ±4.16%RH,respectivelyat 25 ℃. The average sensitivity of the humidity sensor is hardly affected by the temperature in the range of 25 ℃~70 ℃. In addition,the response time and recovery time of the flexible humidity sensor are 36 s and 39 s,respectively. This flexible humidity sensor can be applied in environmental humidity monitoring,artificial skin and wearable devices etc.

flexible;humidity sensor;LCP;capacitive sensor

Humidity sensors are widely adopted toimprove the quality of everyday life or enhance industrial processes.Many materials have been studied for their potential applicationsin humidity sensors,including polymers[1],porous silicon[2]and composites[3]. Most humidity sensors are based onrigid substrates,such as ceramics or silicon(Si),which limitstheir applications inartificial skin and wearable devices etc.

Nowadays,a lot of fields have requirementsof flexible humidity sensors such as wearable devices for human-breath monitoring[4-5],radio frequency identification(RFID)[6]and electronic skin[7].By making use of flexible materials as the substratea humidity sensor could possess deformableproperties[8-9].Polyethylene terephthalate(PET)[8],polyimide(PI)[10]and parylene[11]have been used as the substrate of flexible humidity sensors because of their characteristics of elasticity. LCP(liquid crystal polymer)is also an excellent flexible material. In this work,a simple-structured and low-costflexible humidity sensor was designed based on LCP substrate and a fabrication process was developed.

LCP has been used in the past mainly for electronic packaging applications. Herein,LCP was chosen as the flexible substrate material of the humidity sensor due to its good dimensional stability,robustness,flexibility and ease of micro-machining[12]. The proposed humidity sensor has goodperformances. Simultaneously,it offers advantages of low-cost and simplicity in device fabrication as well as versatility of detecting on a non-plane surface.

1 Structure and fabrication of the flexible humidity sensor

Generally,two types of humidity sensors are often used:resistive type[13],and capacitive type[14]. The capa-citive type was adopted in this paper and polyimide(PI)was chosen as the sensing material. PI is flexible as well,so it is wise enough to utilize PI as the sensing film.

Meanwhile,there are two structural types of capaci-tive humidity sensors:sandwiched type and interdigitated(IDT)type. In our work,the IDT type was adopted.

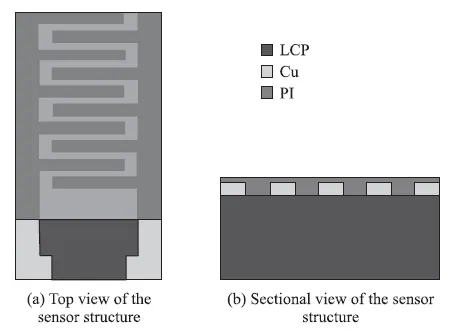

Fig.1 presents the structure of the flexible humidity sensor. Fig.1(a)is the top view of the sensor structure and Fig.1(b)is the sectional view of the sensor structure.

Fig.1 The structure of the proposed flexible humidity sensor

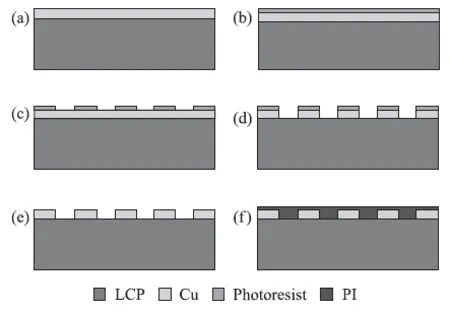

Fig.2 Overview of the fabrication process flow for the proposed humidity sensor

The fabrication process is described in the schematic shown in Fig.2. For the fabrication of the flexible humidity sensor,we used a 125 μm thick LCP film(R-F705T,Panasonic Corp provided)with copper cladding on one sideas shown in Fig.2(a). The thickness of the copper layer is 12 μm. First,photoresistwas deposited on the copper side by spin-coating as shown in Fig.2(b). Second,it was patterned by lithography as shown in Fig.2(c). Third,the exposed copper cladding areawas etched by an aqueoussolution of FeCl3(0.5 mol/L)and HCl(0.5 mol/L).

The remained copper was used as the IDT electrodes of the flexible humidity sensor as shown in Fig.2(d)and Fig.2(e). Finally,the PI(ZKPI-600-Ⅱ)was spun onto the top of the IDT electrodes as presented in Fig.2(f). Because the PI was photosensitive,it was exposed to ultraviolet for 100 s and then heated in a furnace for 60 minutesat 180 ℃ for the imidization of PI. Nitrogen was used as protective gas in the whole heating process.

Fig.3(b)presents a photo image of the fabricated flexible humidity sensor. The sizes of the chip are 10 mm×6 mm. The width of all the fingersand the gap between each finger are 400 μm and 200 μm,respectively. As seen in Fig.3(a),the humidity sensoris bendable. The flexible humidity sensor can be easily tailored to small chips.

Fig.3 Photograph of the humidity sensor

2 Static test

The static properties of theflexible humidity sensor were tested within an environmentchamber(OMEGA 205,VötschIndustrietechnik Co.,Jiangsu province,China)and the capacitance of the sensor was measured byaLCR meter(at 1V,100 kHz)as shown in Fig.4.

Fig.4 Schematic of the test system

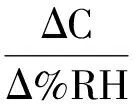

All the tests were run over atemperaturerange from 25 ℃ to 70 ℃ with a step of 15 ℃. The results of the tests are presented in Fig.5. The sensitivity of the humidity sensor can be characterized by the average sensitivity S that is defined as:

(1)

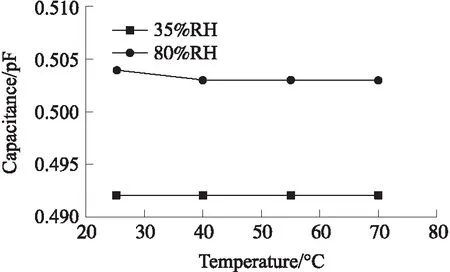

Where,Δ%RH is variation of the relative humidity and ΔCisvariation of the capacitance. The average sensitivity of the flexible humidity sensor is 0.04% pF/%RH and the maximum hysteresis of the humidity sensor is ±4.16%RH at 25 ℃.The temperature has little effect on the average sensitivity of the sensor but it affects the hysteresis of the device. Furthermore,the linearity of the humidity sensor is about 10.83% at 25 ℃. It can be seen from Fig.5,the output of the humidity sensor varies slowly with the humidity before 65%RH whilethe capacitance changes rapidly with the humidity after that point.Under high relative humidity conditions,capillary condensation leads to dramatic increases of water molecules inside the sensing material. As a result both the dielectric constant of PI and the sensing capacitance rise quickly with the humidity.Output capacitance of the sensor is hardly affected by the temperature as shown in Fig.6.

Fig.5 Capacitance vs RH at different temperature

Fig.6 TemperaturevsCapacitance at 35%RH and 80%RH,respectively

3 Dynamic test

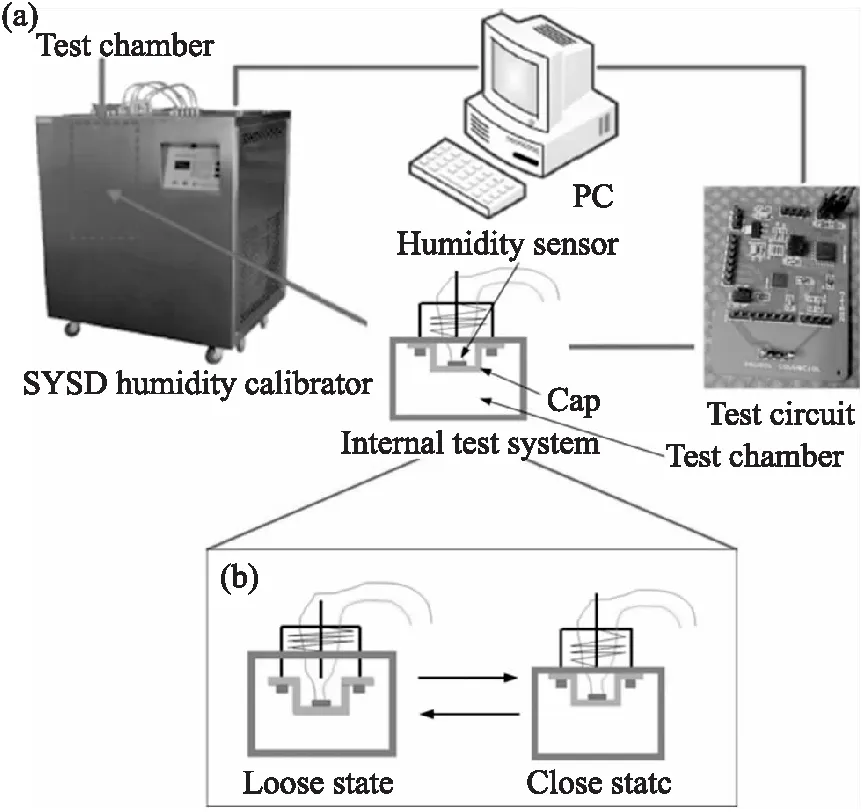

Dynamictests were performed using a test system as described in Fig.7(a). The system consists of a humidity calibrator(Beijing GreatSmart New Technology Co.,Ltd.,Beijing,China),atest circuit and a personal computer(PC). Inside the humidity calibrator,a test chamber with special mechanical elements was designed to achieve a step change of the humidity. As shown in Fig.7(b),first,the relative humidity inside the test chamber was set to be 15%RH. Second,the sensor was sealed into a cap.The humidity inside and outside the cap were both 15%RH. Third,the humidity outside the cap was increased to 90%RH and kept for 10 mins. At last,the cap was moved downwards quickly to achieve an abrupt increase of relative humidity(15%RH to 90%RH). Then,the capacitance data was collected bythe test circuit(Pcap02)and the response time of the flexible humidity sensor could be obtained.Meanwhile,using the same system the recovery time of the sensor was tested as well.

Fig.7 Test system of the sensor for dynamic measurements

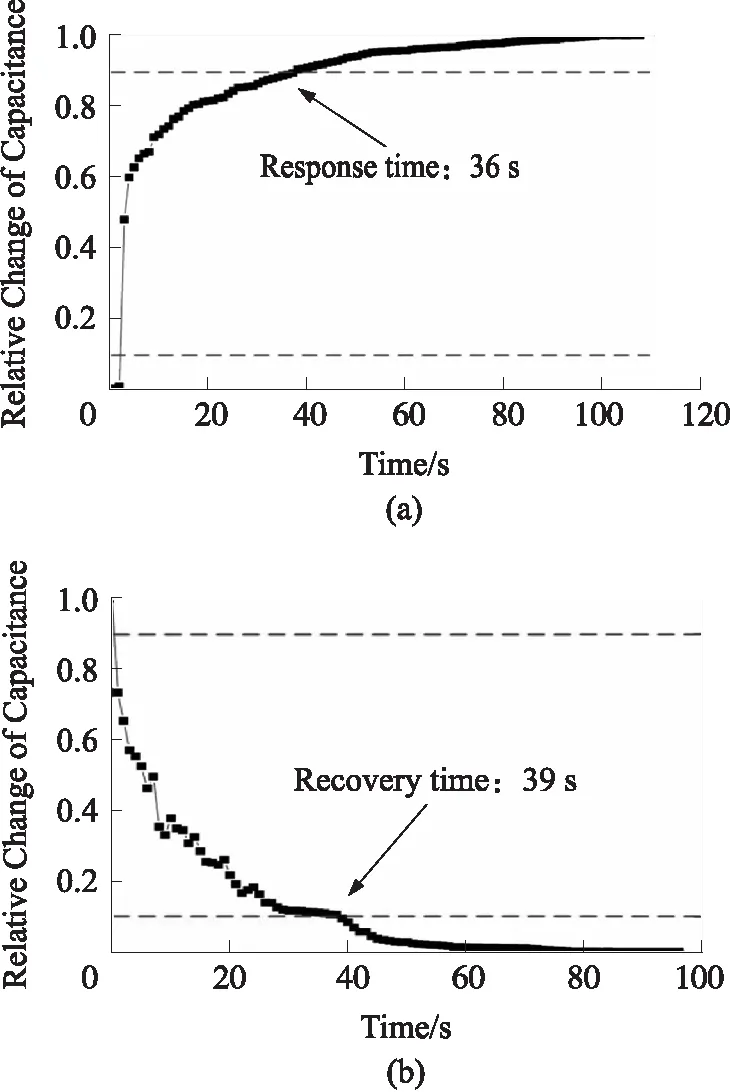

Fig.8 Dynamic test results of the humidity sensor at 25 ℃

The dynamic test results are presented in Fig.8. Both a response process and a recovery process were performed at 25 ℃. It can be seen from Fig.8 the response time of the humidity sensor is 36 s when the relative humidity increased from 15%RH to 90%RH and the recovery time of the humidity sensor is 39 s when the relative humidity decreased from 90%RH to 15%RH. The results show that the recovery time is longer than the response time because desorption process takes more time than absorption.

4 Conclusions

We developed a flexible humidity sensorbased on LCP substrate.Both the structure and the fabrication process of the flexible humidity sensor were designed. The experiment results showthat the average sensitivity of the humidity sensoris 0.04% pF/%RH at 25 ℃ and the maximum hysteresis of the sensor is ±4.16%RH. What is more,the response time and recovery time of the humidity sensor are 36 s and 39 s respectively.Due to its flexibility,the proposed flexible humidity sensor can be used in a quite widerange of applicationsincluding artificial skin,biomedicineand wearable devices etc.

[1] Gao Y,Jing P,Yan N,et al. Dual-Mode Humidity Detection Using a Lanthanide-Based Metal-Organic Framework:Towards Multifunctional Humidity Sensors[J]. Chemical Communications,2017,53(32):4465.

[2] Nayef U M,Khudhair I M. Study of Porous Silicon Humidity Sensor Vapors by Photoluminescence Quenching for Organic Solvents[J]. Optik-International Journal for Light and Electron Optics,2017,135:169-173.

[3] Toloman D,Popa A,Stan M,et al. Reduced Graphene Oxide Decorated with Fe Doped SnO2,Nanoparticles for Humidity Sensor[J]. Applied Surface Science,2017,402:410-417.

[4] Takei Y,Matsumoto K,Shimoyama I. Wearable Sweat Monitoring Sensor Based on Ionic Liquid Gel[C]//IEEE,International Conference on MICRO Electro Mechanical Systems. IEEE,2016:924-925.

[5] Yoko M,Kumiko M,Hirokazu S,et al. Flexible Humidity Sensor in a Sandwich Configuration with a Hydrophilicporous Membrane[J]. Sensors and Actuators B,2009,142(1):28-32.

[6] Oprea A,Barsan N,Weimar U,et al. Capacitive Humidity Sensors on Flexible RFID Labels[J]. Sensors and Actuators B,2008,132(2):404-410.

[7] Kim J,Lee M,Shim H J,et al. Stretchable Silicon Nanoribbon Electronics for Skin Prosthesis[J]. Nature Communications,2014,5(5):5747.

[8] Su P G,Tseng J Y,Huang Y C,et al. Novel Fully Transparent and Flexible Humidity Sensor[J]. Sensors and Actuators B Chemical,2009,137(2):496-500.

[9] Kulkarni M V,Apte S K,Naik S D,et al. Ink-Jet Printed Conducting Polyaniline Based Flexible Humidity Sensor[J]. Sensors and Actuators B,2013,178(3):140-143.

[10] Islam T,Rahat Mahboob M,Khan S A. A Simple MOX Vapor Sensor on Polyimide Substrate for Measuring Humidity in ppm Level[J]. IEEE Sensors Journal,2015,15(5):3004-3013.

[11] Lee C Y,Hsieh W J,Wu G W. Embedded Flexible Micro-Sensors in MEA for Measuring Temperature and Humidity in a Micro-Fuel Cell[J]. Journal of Power Sources,2008,181(2):237-243.

[12] Wang,X F,Engel J,Liu C. Liquid Crystal Polymer(LCP)for MEMS:Processes and Applications[J]. Micromech Microeng,2003,13(13):628-633.

[13] Niarchos G,Dubourg G,Afroudakis G,et al. Humidity Sensing Properties of Paper Substrates and their Passivation with ZnO Nanoparticles for Sensor Applications[J]. Sensors,2017,17(3):379-385.

[14] Bae Y M,Lee Y H,Kim H S,et al. Polyimide-Polyurethane/Urea Block Copolymers for Highly Sensitive Humidity Sensor with Low Hysteresis[J]. Journal of Applied Polymer Science,2017,134:44973.

2017-03-29修改日期2017-05-26

基于LCP衬底的柔性湿度传感器研究*

章 丹,黄见秋*,王立峰

(东南大学MEMS教育部重点实验室,南京 210096)

介绍了一种新型柔性电容式湿度传感器。该柔性电容式湿度传感器采用液晶高分子聚合物(LCP)作为衬底,金属铜(Cu)作为叉指电极,聚酰亚胺(PI)作为湿度传感器的湿敏介质。LCP衬底的应用使得该传感器具有良好的柔性和可弯曲性。该柔性湿度传感器与传统硅基湿度传感器相比较具有成本低廉、结构简单、制作方便等优点。该柔性湿度传感器在25 ℃下的平均灵敏度为0.04% pF/%RH,最大回滞为±4.16%RH,其平均灵敏度在25 ℃~70 ℃范围内受温度影响较小。在25 ℃下其响应时间和恢复时间分别为36 s和39 s。该柔性湿度传感器可以应用于环境湿度检测、人工电子皮肤系统和可穿戴设备等领域。

柔性;湿度传感器;LCP;电容式传感器

TN409

A

1004-1699(2017)10-1478-05

10.3969/j.issn.1004-1699.2017.10.004

章丹(1991-),男,硕士研究生,东南大学MEMS教育部重点实验室,主要从事于柔性MEMS传感器的研究;

黄见秋(1981-),男,副研究员,博士,东南大学MEMS教育部重点实验室,主要从事于MEMS温湿度传感器等项目的研究,hjq@seu.edu.cn;

王立峰(1981-),男,副教授,博士,东南大学MEMS教育部重点实验室,主要从事于无源无线MEMS传感器等项目的研究。