Effect of Toasting Intensity and Wood Grain on Polyphenolic Compounds and Aroma Components in Oak (Quercus petraea) Heartwood

2017-10-11ZHANGBoHEFeiCAIJianWANGYunheDUANChangqingHANShunyu

ZHANG Bo, HE Fei, CAI Jian, WANG Yunhe, DUAN Changqing, HAN Shunyu*

(1. Gansu Key Laboratory of Viticulture and Enology, College of Food Science and Engineering, Gansu Agricultural University,Lanzhou 730070, China; 2. Center for Viticulture and Enology, College of Food Science and Nutritional Engineering,China Agricultural University, Beijing 100083, China)

Effect of Toasting Intensity and Wood Grain on Polyphenolic Compounds and Aroma Components in Oak (Quercus petraea) Heartwood

ZHANG Bo1,2, HE Fei2, CAI Jian2, WANG Yunhe2, DUAN Changqing2, HAN Shunyu1,*

(1. Gansu Key Laboratory of Viticulture and Enology, College of Food Science and Engineering, Gansu Agricultural University,Lanzhou 730070, China; 2. Center for Viticulture and Enology, College of Food Science and Nutritional Engineering,China Agricultural University, Beijing 100083, China)

It is important for winemakers to understand the chemical constituents of oak heartwood used for barrels as different grain types and toasting regimes influence wine flavor. Changes induced by different heating regimes in lowmolecular-weight (LMW) phenolics and volatile compounds of oak heartwood of different grain types were evaluated. The results showed that a higher temperature during the toasting process changed the chemical compositions of the heartwood and increased the amounts of several key soluble and volatile compounds as a result of various heat-induced reactions.Moreover, independent of toasting, the fine-grained oak samples had higher concentrations of volatile compounds, e.g.,cis/trans-oak-lactone, cis/trans-isoeugenol, furanic aldehydes, syringol, and LMW phenolics, particularly sinapaldehyde,coniferaldehyde, vanillin, and syringaldehyde, while the medium- and coarse-grained oak samples showed higher levels of total phenol, tannins, ellagic acid and gallic acid. Principal component analysis (PCA) showed that the moderately and heavily toasted samples of medium- and fi ne-grained oak displayed higher positive correlations with the level of volatile compounds, while the untoasted and lightly toasted heartwood of coarse-grained oak were positively correlated with total tannin and ferulic acid contents.

oak heartwood; grain type; toasting level; phenolic compounds; volatile compounds

Aging wine in oak barrels is a traditional vinification practice employed by winemakers for improving wine quality in particular[1]. During barrel aging wines undergo a series of complex processes, including extraction of many substances from the wood matrix[2], in part, due to the slow pick-up of oxygen permeating through the slightly porous wood[3].Also there is steady clarification while in the barrel[4].These changes modify the color and tannin profi le of the wine and thus, contribute to the development of the wine’s sensory profi le.

In general, American white oak (Quercus alba) and French red oak (Q. robur and Q. petraea) are the most commonly used species for wine barrels and have been used as for thousands of years[5]. The basic compositions of oak are not significantly different from one species to another.Cellulose (40%) and hemicellulose (25%), which comprise the structure of the heartwood, are the major constituents of oak, while lignin, a phenolic polymer, is present mainly in the cell walls, accounts for 20% of the dry weight[1,6]. However there are also important minor components, such as terpenes and lipids, which may comprise up to 0.5% on a weight basis. Some are volatile and when extracted into a wine, they contribute an oaky note to the sensory profi le of the wine[7].The low-molecular-weight (LMW) phenolics and oak tannins affect color and astringency of the wines. Thus the extraction of a wide variety of compounds from the oak during the barrel aging has been considered as to contribute positively to wine quality[8].

Previous studies have shown that the concentrations of oak compounds in aged wine depended on the amount of the potential extractable constituents originally present in the barrels’ wood and the aging conditions[1,6]. Furthermore,factors such as geographical origin[9-10], silvicultural practices[5], and barrel production process[11]all infl uence the composition of the wood and are directly responsible for the fi nal sensory character of the wine.

Among these factors, wood heat treatment is a major factor determining the sensory and physicochemical modifications of a wine during barrel aging[12]. During the heat treatment, diverse hydrothermolysis and pyrolysis reactions occur, causing degradation of lignins,polysaccharides and lipids, and leading to the production of numerous aromatic compounds such as furanic aldehydes[13].Moreover, the thermal treatment of oak wood also reduces the level of tannins (ell agitannins) and increases the amount of ellagic acid[14-15].

In the last few years, several studies have analyzed the contribution of oak wood to the chemical composition of barrel aged wine. However these investigations generally focused on aspects such as oak species, geographical sources, and processing methods[7,14,16-17]. The composition of aromatics and phenolics as a function of the wood grain has been rarely studied[18-19].

Typically, coopers classify oak grain as one of three types∶ fi ne, medium and coarse, according to both the width of annual growth rings and the texture of wood. The grain properties would infl uence the wood chemical compositions and ultimately affect the contribution of barrel aging to wine quality[5]. In addition, other factors such as toasting at cooperage also affect the sensory and chemical characteristics of woods, especially their wood-related volatile composit ion[19].Hence, it would be important to know more information about the chemical compositions of wood grains along with different toasting treatments. In this study, we have quantified the changes, induced by the toasting process, in the LMW phenolics and volatiles in oak (Q. petraea) heartwoods of different grain types. The cooperage industry needs to develop criteria for controlling raw materials[20]and also toasting regimes. Understanding these two parameters and how they interact will assist coopers and winemakers.

1 Materials and Methods

1.1 Wood samples and chemicals

The heartwood oak samples provided were the same as would be used as staves for making barrels by Yantai Demptos Oak Barrel Co. Ltd. (Yantai, Shandong, China). The selected oak wood was from 160-year old Q. petreaea oak species grown in the Troancais forest located in the centre region of France. The raw wood was naturally seasoned for 24 months during which the moisture content dropped to 15%.Heartwood of three different grain tightness was selected: fi ne(1 to 2 mm), medium (2 to 4 mm) and coarse (4 to 5 mm).All staves were about 23 mm in thickness and toasted in ourlaboratory oven according to the method of Ribereau-Gayon and coworkers with some appropriate modi fi cations[21]: light(150 ℃ for 15 min), medium (175 ℃ for 15 min) and heavy(200 ℃ for 20 min). Heartwood samples were taken from the untoasted and toasted staves, and four staves of each grain type and toasting degree combination were used. The heartwood pieces were cut from the center and the extemities of these staves. From toasted stave samples, a layer of toasted heartwood was cut off to a depth of 4 mm. The heartwood pieces were ground and sieved, the sawdust ranging from 0.28 to 0.80 mm in size were taken.

These standards, included ellagic acid (CAS No.∶ 476-66-4), gallic acid (149-91-7), vanillic acid (121-34-6),syringic acid (530-57-4), ferulic acid (1135-24-6),coniferaldehyde (20649-42-7), syringaldehyde (134-96-3),sinapaldehyde (4206-58-0), o-vanillin (148-53-8), vanillin(121-33-5), 3,4-dimethylphenol (95-65-8), eugenol (97-53-0),phenol (108-95-2), o-guaiacol (90-05-1), 4-vinylguaiacol(7786-61-0), cis/trans-isoeugenol (5912-86-7/97-54-1),syringol (91-10-1), γ-caprolactone (695-06-7), cis/transoak-lactone (55013-32-6/39638-67-0), furfural (98-01-1),5-methylfurfural (620-02-0), and 5-hydroxymethylfurfural(67-47-0) were supplied by Sigma. Deionised water (<18 MΩ resistance) was obtained from a Milli-Q Element water purification system (Millipore, Bedford, MA, USA).HPLC grade acetic acid and methanol were obtained from Honeywell (Burdick & Jackson, USA). All the other chemicals (analytical grade) were obtained from Beijing Chemical Co. Ltd. (Beijing, China), unless noted specially.

1.2 Instruments and equipments

1100 MSD HPLC-MS with a DAD UV-Vis detector coupled to a mass spectrometer (Trap-VL) and equipped with an ESI interface (Agilent, Palo Alto, CA, USA); C18steel column (250 mm × 4.0 mm i.d., 5 μm) was obtained from Zorbax SB, Agilent (USA); 7890A/5975C GC-MS, Innowax fused-silica capillary column (60 m × 0.25 mm i.d., 0.25 μm fi lm thickness) was also obtained from Agile nt (USA); UV-2450 UV-Visible spectrophotometer was purchease from Shimadzu Corporation (Kyoto, Japan).

1.3 Methods

1.3.1 Extraction of phenolic compounds

The phenolic compounds were extracted based on the method previously described by Sanz et al.[22]. A sample of 1 g of each was extracted with 100 mL of methanol/water(1:1) at room temperature and in darkness for 24 h. Then, the extracts were fi ltered in a Büchner funnel, and the methanol in the extracts was removed in a rotary evaporator at below 40 ℃. The aqueous solution obtained was extracted three times with 20 mL of diethyl ether and ethyl acetate. The two organic fractions were evaporated in a rotary evaporator at below 40 ℃. The residues were re-dissolved in 5 mL of methanol solution for further analyses. All the extractions were carried out in triplicate.

1.3.2 Extraction of volatile compounds

Volatile compounds were isolated by making liquidliquid extracts of the hydroalcoholic heartwood extracts,using the following protocol: 1 g of dry heartwood sawdust was soaked in 100 mL of 50% ethanol solution in a glass vial fitted with an elastomer stopper. The vial was heated for 30 min at 50 ℃ in a shaking table to accelerate the diffusion of the heartwood’s volatile compounds.After the mixture was filtered, 40 μL of mixed internal standards (o-vanillin (2.002 mg/L solution in water),3,4-dimethylphenol (1.027 mg/L solution in water) and γ-caprolactone (2.043 mg/L solution in water)) was added in every sample. Then the solution was extracted with 15 mL of dichloromethane, distributed three times. The organic fraction was dried on anhydrous sodium sulfate and reduced to 1 mL under nitrogen fl ux before being submitted to GC-MS analysis. In all cases, the samples were carried out in triplicate.

1.3.3 Determination of LMW phenolic compounds, total phenol, and total tannin

The LMW phenolic compounds were assessed by using HPLC-MS. Chromatographic separation was carried out by using C18steel column, maintained at 30 ℃. The HPLC profiles were monitored at 255, 280, 325, and 340 nm, and the UV-Vis spectra were recorded from 190 to 700 nm.The injection volume was 10 μL. The mobile phase, with a flow rate of 1 mL/min, consisted of a mix of solvents: A(water/acetic acid, 99:1 (V/V)) and B (methanol/acetic acid,99:1 (V/V)) with following elution gradient: 0-3 min, 0% B in A; 3-25 min, 40% B in A; 25-43 min, 60% B in A;43-55 min, 60% B in A; 55-60 min, 80% B in A; 60-65 min,80% B in A; and 65-69 min, 0% B in A. The MS conditions were: ESI, negative ion mode; 35 psi nebulizer pressure;10 mL/min dry gas flow rate, 350 ℃ dry gas temperature, and scanned at m/z 100–1 000. For the quantitative analyses, calibration curves were obtained by using standards of each LMW phenolic compounds, and were quantifi ed as the corresponding compound. The measurements were taken in triplicate.

Folin-Ciocalteu and Folin-Denis procedures were usedto measure the total phenol and tannin respectively[23]. The quantitat ive data were expressed as mg/g of dry heartwood,and all the measurements were performed in triplicate.

1.3.4 Determination of volatile compounds

Analyses were performed using an Agilent 7890A/5975C GC-MS equipped with a HP-Innowax fused-silica capillary column. Helium carrier gas was circulated at 1 mL/min in the constant fl ow mode. The split/splitless injector was used in the splitless mode. Th e injected volume was 1 μL and the injector temperature was 250 ℃. The oven temperatures were programed as follows: the oven temperature was programmed from 50 ℃; 7 ℃/min ramp to 120 ℃ and holding for 5 min;2 ℃/min raised to 200 ℃; 10 ℃/min raised to 240 ℃ and maintained for 20 min. The ion energy for electron impact(EI) was always set at 70 eV. The source temperature was 200 ℃. Identification of the volatile compounds was made by comparing the GC retention times and mass spectra over the mass range 30-500 mass units for the samples with pure standards analyzed under the same conditions. Quantitative data of the identified compounds were measured from the characteristic ion peak areas with regard to the internal standard of o-vanillin for vanillin; 3,4-dimethylphenol for eugenol, phenol, o-guaiacol, 4-vinylguaiacol, cis/transisoeugenol, syringol; and γ-caprolactone for cis/trans-oaklactone, furfural, 5-methylfurfural and HMF. Triplicate analyses were carried out.

1.4 Statistical analysis

The data were analyzed by carrying out univariate analysis with ANOVA, by applying Fisher’s least signifi cant difference test (LSD). In addition, principal component analysis was applied to identify those variables that separate the different samples. All of the statistical analyses were performed by using SPSS software, version 20.0 (SPSS Inc.,Chicago, IL, USA) program.

2 Results and Analysis

2.1 Effect of toasting intensity and wood grain on total phenol and tannin in oak heartwood

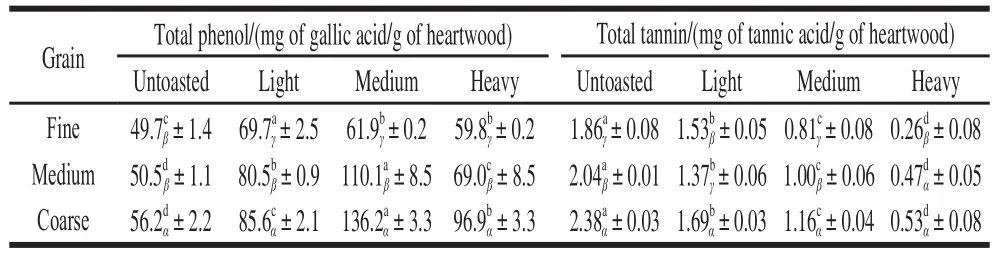

Table 1 lists the total phenolis and tannins in the three different grain classes from the species Q. petreaea. For the untoasted heartwood samples, the extractable total phenols were the highest in the coarse grain, followed by the medium and then the fine-grained samples. The total phenolic extraction was also influenced by the toasting proces. The total phenolis extracted rose to a maximum in the medium toasted oak before decreasing to a lower level in the heavily toasted oak, except for the fine-grained oak turned to the highest value of total phenol at light toasting level.In particular, the medium toasted coarse-grained samples showed a 142% increase in the total extractable phenolic content over the untoasted material, while a 116% increase was observed in the medium-grained counterparts, and a 40% increase was observed in the fi ne-grained oak samples after light toasting. So while greater heat treatment to the medium toast level generated higher quantities of phenolics,intense toasting has been shown to carbonize lignins and hemicelluloses, and degrade other compounds, such as phenolic aldehydes, thereby decreasing the total phenolics[11].This explains the decrease in total extractable phenolics at higher toasting intensity across all grain types.

Table 1 Total phenol and tannin contents of oak heartwood after different toasting regimes

In contrast, the untoasted heartwood was rich in total tannin, which was in accord with Cadahia[15]and Glabasnia[24]et al.’s results which showed a predominance of hydrolyzable tannins (ellagitannins). Similar to the total phenols, total extractable tannins were the highest in coarse grain heartwood, and this trend was observed for all the heat treatments. However, in contrast to total phenols,total extractable tannins were decreased with increasing the heating intensity, independent of grain type. It has been previously reported that tannin accumulation was observed microscopically in parenchyma cell vacuoles, and the production might be related to the depletion of starch reserves. When the tannin accumulation reached a certain level, the vacuole was disrupted, thus mixing the tannins with the cytosol ic constituents. Cell disintegration allowed the tannins to diffuse throughout the woody tissues[25]. Because the deposition of tannins occurred predominantly in large diameter spring growth vessels, the coarse-grained tissue of oak heartwood accumulated more tannin during the entire growth stage, explaining why the coarse-grained oak samples have the highest level of total tannin. Moreover, we found the tannins of coarse-grained sample were extremely sensitiveto heat treatment, and their concentration was decreased by 29% after light toasting, by more than 51% and 78% when the heartwood was subject to medium and heavy toasting,respectively. A similar trend was also observed in the medium-grained samples. In the fine-grained samples, the content was decreased by 18% to 86% with the increase in toasting intensity from light to heavy.

2.2 Effect of toasting intensity and heartwood grain on LMW phenolics in oak heartwood

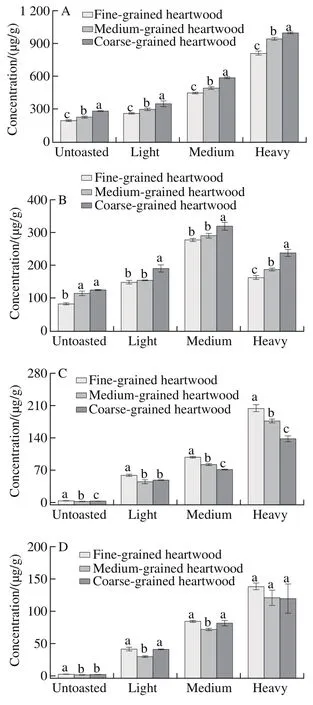

HPLC an alysis of the diethyl ether and ethyl acetate extracts revealed the presence of the following LMW phenolics in the oak heartwood samples∶ ellagic acid, gallic acid, vanillic acid, syringic acid, and ferulic acid. Of these sinapaldehyde, coniferaldehyde, syringaldehyde, and vanillin were identifi ed before and after the toasting as shown in Fig. 1,and all the compounds were higher in concentration in the toasted samples compared with those of the untoasted ones.

Fig. 1 Evolution of concentrations of LMW phenolic compounds in toasted oak heartwoods with different grains

As shown in Fig. 1, ellagic acid and gallic acid were the most abundant phenolic acids in these oak samples, even in the untoasted heartwood. Oak is known to be rich in ellagitannins;so it was not surprising that ellagic acid was found to be present at high concentrations (>190 μg/g) among all sample extracts. It was found to be highest in the heavily toasted oak samples (coarse-grained 996 μg/g, medium-grained 948 μg/g,and fi ne-grained 812 μg/g), followed by medium-toasted oak(584 μg/g for the coarse grain, 492 μg/g for the mediumgrained, and 447 μg/g for the fine-grained) (P<0.05), with the lowest, 192 μg/g, in the untoasted fine-grained sample(Fig. 1A). In all the samples, the ellagic acid content increased with toasting, probably due to the increasing thermolytic degradation of ellagitannin[26]. Moreover, the accumulation of ellagic acid can be also attributed to its high melting point, which prevents its carbonization even at toasting temperatures[15].

Gallic acid is als o important in oak heartwood, because during aging it contributes to astringency and bitterness, and acts as a copigment, enhancing the color of aging wine as well[27]. In our results, the levels of gallic acid were much higher in the coarse-grained samples than in the other grain types (Fig. 1B). An average value of 125 μg/g gallic acid was found in the untoasted coarse-grained heartwoods, whereas 116 and 83 μg/g gallic acid were found in the medium- and fine-grained oak samples, respectively. In addition, similar to ellagic acid, light and medium heat treatment caused drastic increasing changes in gallic acid content. As can be seen from Fig. 1B, the gallic acid content was higher in the medium-toasted heartwood (278 μg/g for the fine-grained,291 μg/g for the medium-grained, and 320 μg/g for the coarse-grained) being 2.3, 1.5 and 1.6 times as much as the original concentration in untoasted heartwood, respectively.This increase of gallic acid concentration agrees well with previous works[6,22], and can be explained by thermolysis of galloyl esters associated with the parietal composites of the cells during the toasting process. However, a decrease in gallic acid content was observed after heavytoasting(decreased by 25% to 41% compared to medium-toasted oak samples). This could be explained by the extreme sensitivity of gallic acid to heat treatment[22]; therefore, the gallic acid content was gradually decreased with increasing toasting.

Apart from ellagic acid and gallic acid, phenolic aldehydes were the most abundant LMW phenolics in all of the heartwood extracts, with the fi ne-grained oak heartwoods having the phenolic aldehyde content higher than the other grain types. As shown in Fig. 1C, 1D, 1E and 1F, the untoasted heartwood had low levels of phenolic aldehydes(sinapaldehyde, coniferaldehyde, syringaldehyde and vanillin). According to previous studies, the degradation of lignin by heat affords mono- and di-methoxy hydroxyphenyl aldehydes[28]. Thus, the increase in contents of sinapaldehyde,coniferaldehyde, syringaldehyde, and vanillin in the toasted heartwood samples was to be expected. The data showed that the concentration of sinapaldehyde increased significantly (P<0.05) in the fine-grained samples during the toasting process, and the largest increase was observed after heavy toasting, being some 66 times that of the original concentration and 16% and 50% higher than those in the heavily toasted medium- and coarse-grained oak heartwoods,respectively. This higher value of sinapaldehyde in finegrained toasted samples can be explained by a higher amount of di-methoxy hydroxyphenyl units in the fi ne-grained lignin structure, which could be thermo-depolymerized more easily than the mono-methoxy hydroxyphenyl units[29]. Compared to sinapaldehyde, the concentration of conife raldehyde was lower, but both coniferaldehyde and sinapaldehyde displayed a similar trend in the samples of different grain types and toasting levels. It is well known that t he angiosperm lignin is a three-dimensional heteropolymer formed by sinapyl and coniferyl alcohol copolymerization[30]. Thus, the anatomic tissue conformation of oak heartwood would be different for different grains. It was suggested that the fine-grained oak sample contained more lignin in its cell walls. During the heartwood toasting, the lignin underwent depolymerization reactions, while sinapyl and coniferyl alcohol were depolymerized and oxidisedto the corresponding aldehydes.Therefore, the higher concentrations in fine-grained toasted oak heartwoods can be explained by the difference in the phenolic aldehyde content in different grain types and toasting levels. As the toasting intensity increased, sinapaldehyde and coniferaldehyde were produced by the cleavage of α, β double bonds (C=C) of cinnamic aldehydes, while thermo-oxidation and thermo-decarboxylation reactions produced mainly benzoic aldehydes such as syringaldehyde and vanillin[31].In particular, the concentration of syringaldehyde increased from 14 μg/g (untoasted level) to 92 μg/g (heavy toasting level),accompanied by vanillin rising from 5 μg/g to 75 μg/g. In spite of this increase, the detected levels of these compounds were slightly lower than their sinapaldehyde and coniferaldehyde precursors, in toasted heartwood.

Vanillin has a relatively low fl avor threshold (60 μg/L)and is associated with vanilla and coffee as well as dark chocolate and smoky odors[32]. During the toasting process,the content of vanillin was increased stead ily with toasting intensity, with increases of 12, 15 and 18 folds in the fi ne to coarse grain samples, respectively. In addition the vanillin level in the heavily toasted medium- and coarse-grained oak samples were 17% and 26% lower than that in the fi ne-grained ones at the same toasting level. This trend was also observed for syringaldehyde, which has smoky and spicy aroma descriptors.Previous studies have reported that the syringaldehyde/vanillin rati o is a very important index to evaluate oak heartwood and should be maintained between 1.4 and 2.5[33]. In this study, the fi ne- and medium-grained oak samples at light and medium toasting levels had syringaldehyde/vanillin ratios within these suggested limits, indicating that the products of lignin decomposition were balanced.

Other LMW phenolics in the oak samples extracts,including the derivatives of phenolic aldehyde, were also detected in the HPLC analysis. The vanillic acid and syringic acid (Fig. 1G and Fig. 1H) were produced by the oxidation of vanillin and syringaldehyde, and increased in level with toasting intensity. However, the content of ferulic acid was decreased due to its decarboxylation and degradation at a high temperature during toasting[6], with the lowest levels in the fi ne-grained samples (Fig. 1I).

2.3 Effect of toasting intensity and heartwood grain on volatile compounds in oak heartwood

During heat treatment, the degradation of polysaccharides and polyphenols in oak gives rise to new volatile compounds that increase the amount of odoriferous substances[13].

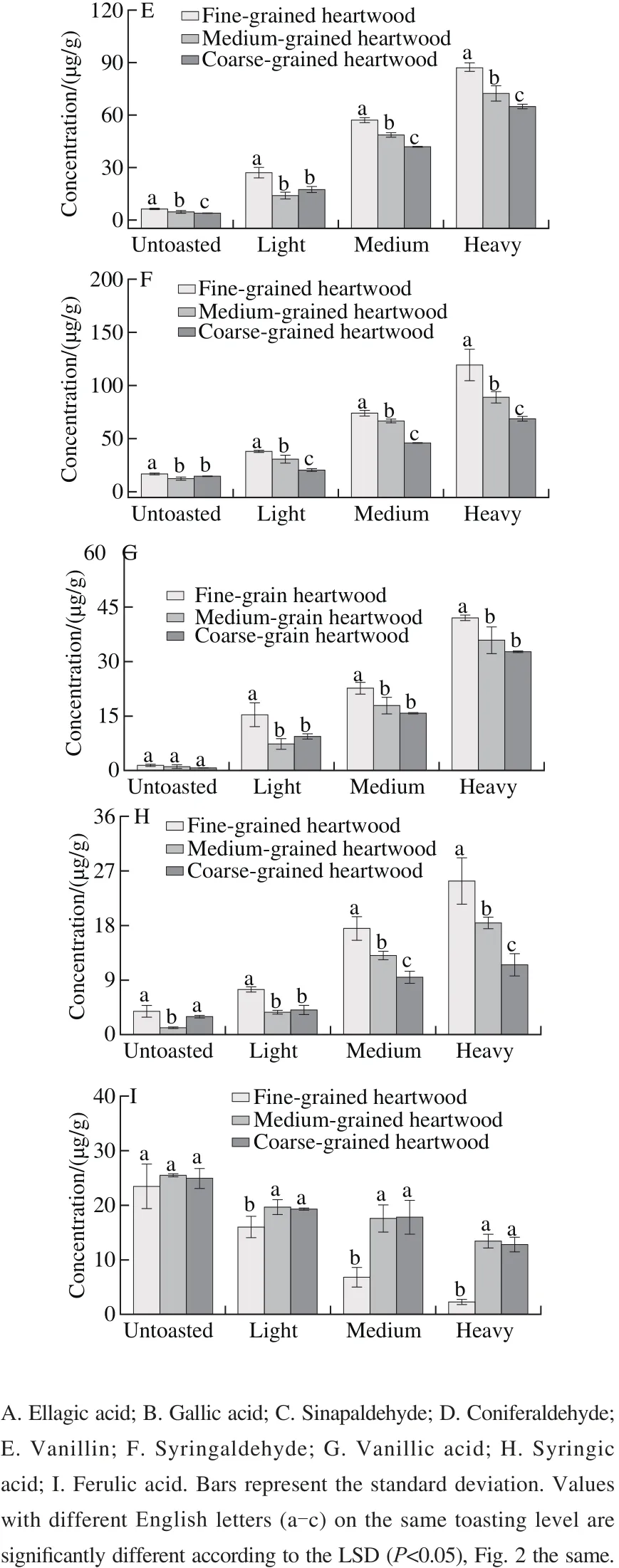

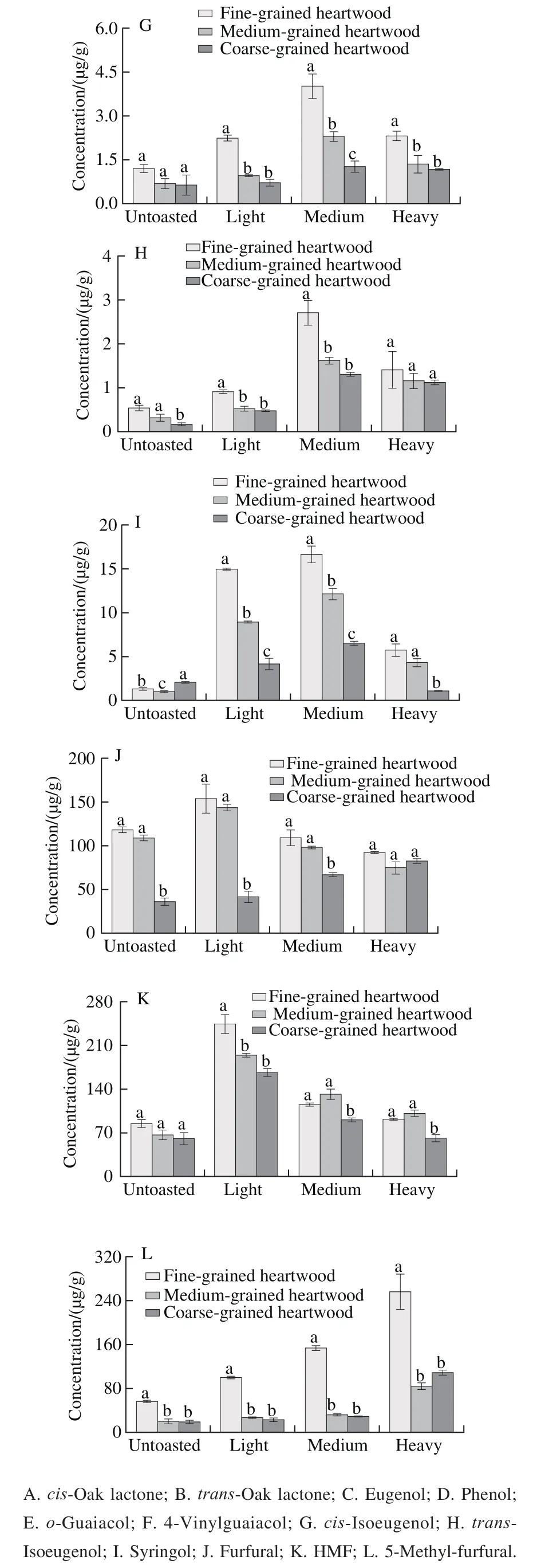

In this study (Fig. 2), two oak lactone isomers (cis- an d trans-β-methyl-γ-octalactone) were identifi ed in the oak and their amounts were signifi cantly inc reased with medium heat treatment. For example, their average contents in the finegrained oak samples ranged from 15 μg/g in the untoasted heartwood to 73 μg/g in the medium-toasted heartwood,but then decreased with heavy toasting (30 μg/g). Many studies have reported that toasting increases the levels of the oak lactones by releasing their precursor, the 6’-O-gallate derivative of β-D-glucopyranosyloxy-3-methyloctanoic acid[34-35]. However, we extracted more oak lactones in the light- and medium-toasted samples than in the heavy-toasted,possibly through the thermo-degradation of these heatsensitive compounds or their loss by volatilization when the oak heartwood was subjected to very high temperatures[36].On the other hand, the amount of oak lactones was also influenced by heartwood grain. The average concentration of oak lactone was significantly decreased (P<0.05) from 162 μg/g in fine-grained heartwoods to 40 μg/g in coarse samples. As is known, the oak lactones have aromas described as oaky, coconut, or vanilla at a low concentration[37]. Moreover, it has also been reported that the cis-oak lactone has a more powerful aroma than the transisomer with reported threshold values being 74 and 320 μg/L for cis- and trans-isomers, respectively[34]. In general, the oak la ctone isomer ratio range between 1 and 5 in French oak[38-39].In our samples, the cis-oak lactone was detected at a higher concentration than the trans-counterpart (31.0–125.8 μg/L of cis-isomer and 8.7–35.7 μg/L of trans-isomer from coarse to fine-grained oak samples, respectively), which were similar to those showed in early papers in wines aged in oak barrels or with other oak products[38-39]. This suggested that it is possible to di stinguish oaks of different grain types on the basis of their content and ratio of cis- and trans-oak lactones.

Fig. 2 Evolution of concentrations of volatile compounds in toasted oak heartwoods with different grains

Phenol, o-guaiacol, 4-vinylguaiacol, and syringol as well as eugenol and isoeugenol are the main volatile phenols with smoky and clove aroma characteristics. These compounds originate from the thermo-degradation of lignins[40]and, except for phenol and eugenol, showed the highest concentration in the medium toasted samples for all the three grain types.Fig. 2C shows the change in eugenol concentration in the different grained oaks with light, medium, and heavy toasting.For all toasting treatments, the fi ne-grained oak had the highest levels of eugenol and the levels were steadily decreased as the toasting increased. This decrease with severity of heat treatment is similar to previous reports[41]. This indicates that the rearrangement effects may lead to the formation of isoeugenol in the isomerization reaction during toasting. Phenol normally has a pungent aroma when its concentration is above 6 000 μg/L[42-43].The phenol levels for all grain types were increase with increasing levels of toasting (Fig. 2D), showing significantly higher concentrations in the heavy-toasted oak heartwoods.The o-guaiacol content of all grain types was increased with the initial light toasting but thereafter all was decreased with increasing toasting. The fine-grained oak samples decreased signifi cantly from the light to the heavy toasting intensity, with the average concentration being decreased by about 32% in the medium toast and 44% in the heavy toast. However these were still higher than in the untoasted sample (Fig. 2E). In a similar manner, the toasted of medium- and coarse-grained samples also lost 25% and 38%, and 22% and 41%, for the medium and heavy toasting regimes respectively. Both light and medium toasting of the heartwood increased the concentration of 4-vinylguaiacol. Its concentration ranged from 0.5 μg/g(coarse-grained untoasted heartwood) to 8.3 μg/g(medium-toasted fine-grained heartwood) (Fig. 2F). However,further toasting resulted in a decrease in all three grain types.The presence of the two isomers of isoeugenol was also important because the odor characteristics of isoeugenols are usually described as floral and clove[44]. As shown in Fig. 2G and Fig. 2H, the heartwood samples exhibited a similar profi le with heating for the two isoeugenol isomers. The isoeugenol concentration was higher in the fi ne-grained heartwood than in the other heartwoods (P<0.05). Syringol, an important oak heartwood sensory compound, was present in the untoasted heartwoods, but its levels changed with the heat treatment.Similar to isoeugenol, all three grain types showed a maximum with medium toasting but then was dropped with further toasting.

The degradation of polysaccharides produced furanicaldehydes, mainly being furfural, 5-methylfurfural, and 5-hydroxymethylfurfural (HMF). It is known that degradation of glucose in c ellulose releases 5-methylfurfural and HMF, whereas t he degradation of pentoses, the principal constituents of hemicelluloses, produces furfural[4]. As with previous reports[45], untoasted heartwood was found to contain furfural, 5-methylfurfural, and HMF. It is readily apparent that heat treatment resulted in signifi cant differences in furanic aldehydes (Fig. 2J). The average concentrations of furfural was first increased significantly with light toasting, particularly in the fine-grained oak samples, and then decreased at a higher temperature. This is due to the higher instability of hemicelluloses with temperature. A similar trend was also observed for HMF. The concentration of HMF was incre ased rapidly with light heat treatment and reached a maximum level at the light toasting level (244 μg/g,194 μg/g and 166 μg/g from the fine to coarse grains,respectively), as shown in Fig. 2K. In contrast to HMF, the level of 5-methylfurfural was higher for all fine-grained samples than for the medium- and coarse-grained counterparts with corresponding heat treatments (Fig. 2L).

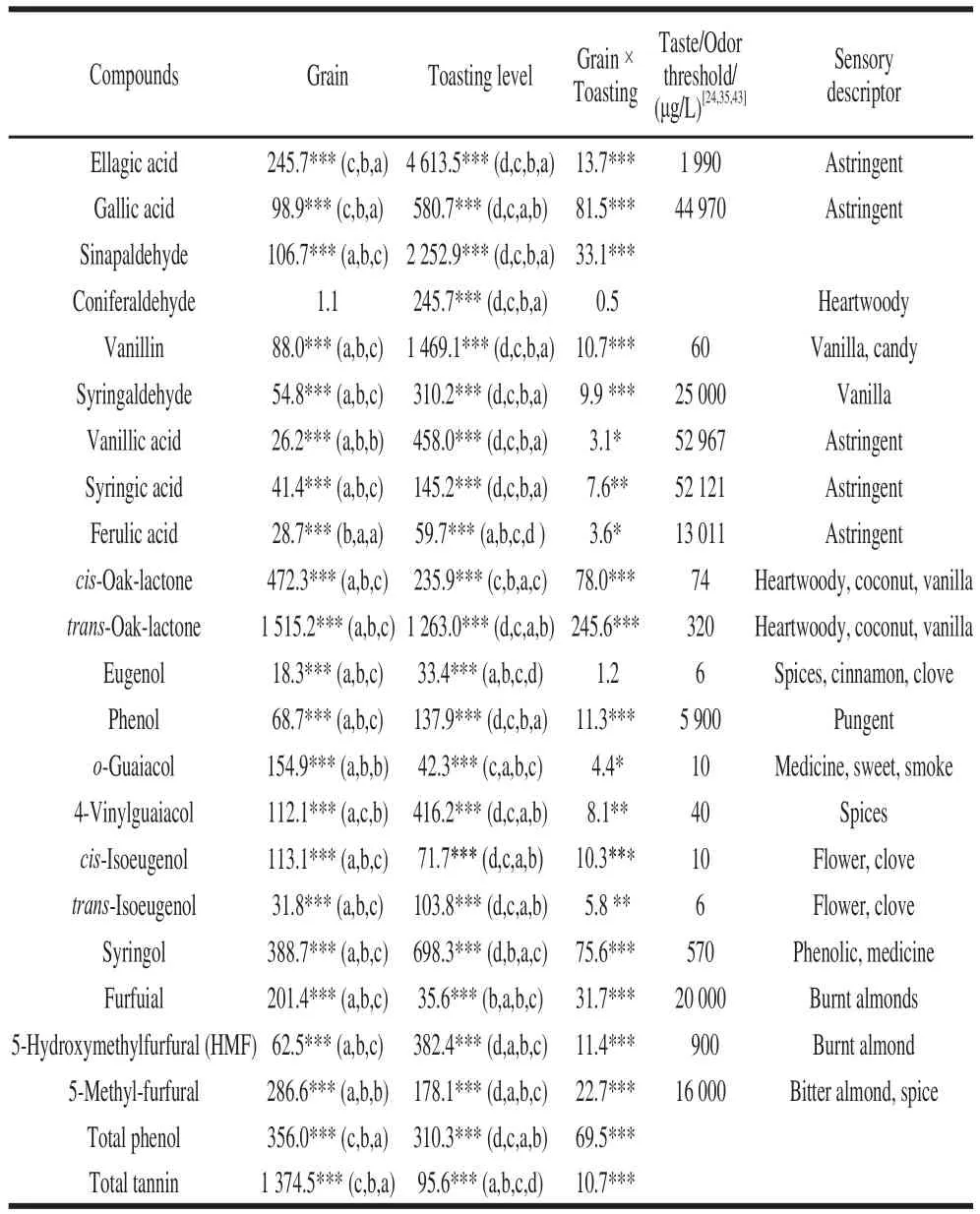

2.4 Analysis of variance

A summary of the analysis of variance (ANOVA) is given in Table 2. The data obtained for the heartwood grain, toasting level, and heartwood grain × to asting level were evaluated by ANOVA. Comparing toasting level, regardless heartwood grain, all the studied compounds showed statistically signifi cant differences related to toasting conditions. It had highlighted the F-values of most of LMW phenolics, eugenol, phenol,4-vinylguaiacol, trans-isoeugenol and syringol, all of them are related to polyphenolic characteristics of heartwoods. For example, the oak samples at the heavy toasting level released the highest concentrations of ellagic acid, sinapaldehyde,coniferaldehyde, vanillin, syringaldehyde, vanillic acid, syringic acid and phenol, while the medium toasting level released the highest concentrations of trans-isoeugenol, 4-vinylguaiacol and syringol, allowed us to differentiate the samples according to toasting level. These fi ndings agreed with previous studies that had been suggested that the toasted oak heartwoods contained the highest concentration of the oak-derived volatile aroma compounds[46]. And the results also indicated that the effect of toasting regimes used might be more important for the oak compounds than for the grain type, because toasting changed the chemical compositions of the heartwood and increased the amounts of several key soluble and volatile compounds as a result of various heat-related reactions. However, ANOVA also revealed that heartwood grain was significant for certain compounds such as oak lactones, furanic aldehydes, and several volatile compounds, indicating that heartwood grain type affects the formation of these compounds. Moreover, when ANOVA was applied to these data the following two factors need to be taken into account∶ heartwood grain and toasting level,the higher F-values were obtained for cis/trans-oak-lactone, cisisoeugenol, furfuial, 5-methyl-furfural, total phenol and tannin all related to heartwood grain, followed by ellagic acid, gallic acid,sinapaldehyde, vanillin, phenol, syringol and HMF, related to toasting level. It therefore appeared that there were two factors that would cause differences in the phenolic and aroma compositions of wines∶ the different amounts of certain compounds provided by each heartwood to wine during ageing could help in the classifi cation of wines according to heartwood grain and toasting condition.

Table 22 F-values aanndd P from the analysis of variance (ANOVA) of quantitative evaluation of LMW phenolic and volatile compounds in oak heartwood, and odor threshold and sensory descriptor for each compound

2.5 Principal component analysis

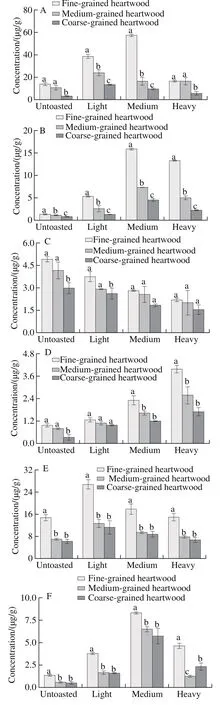

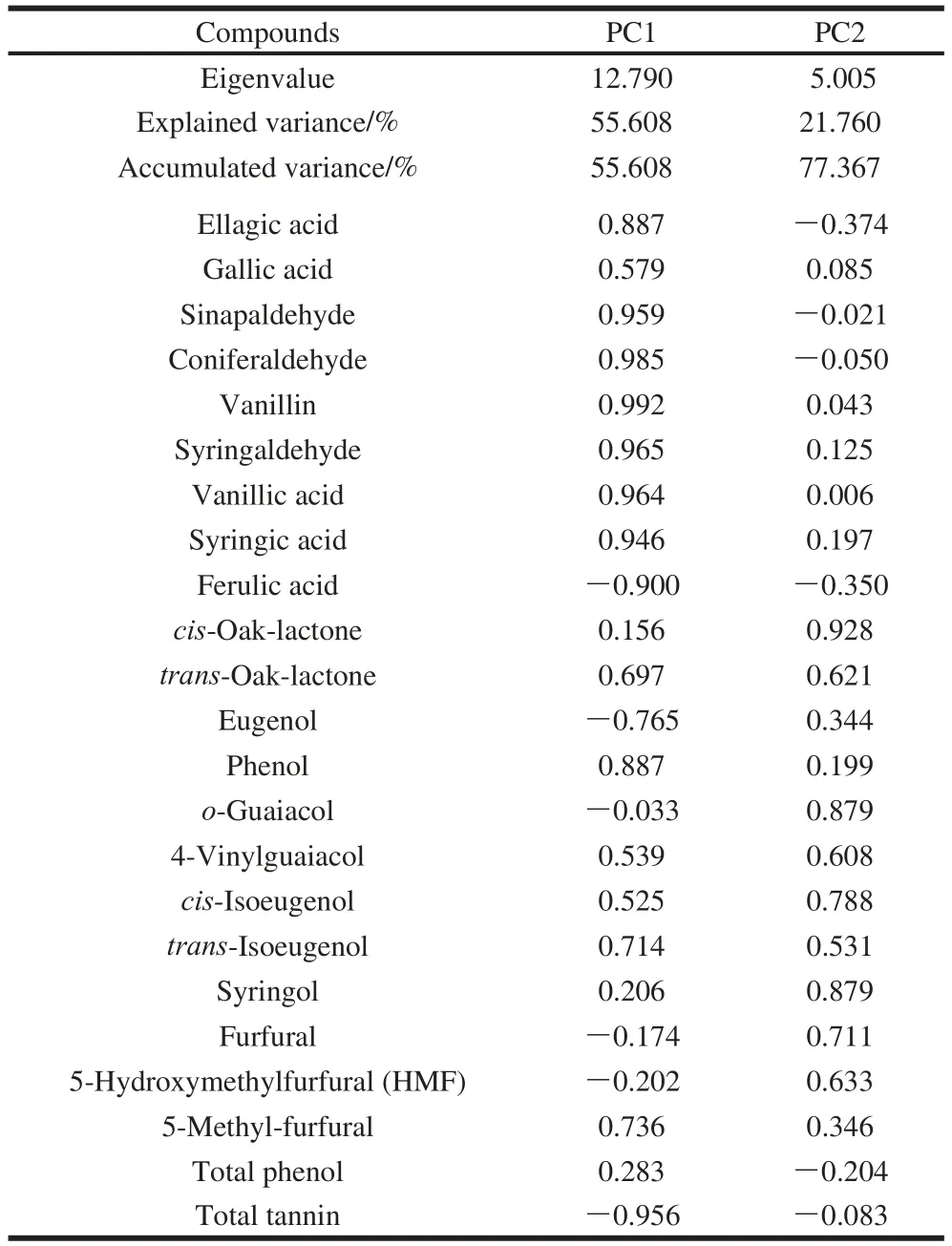

Principal component analysis ( PCA) was performed onthe data listed in Table 3. The fi rst two principal components(PCs) accounted for 77.37% of the total variance, and they were considered worthy of further discussion.

Table 3 Eigenvalues, percentage of explained and accumulated variance and coeffi cients of the fi rst two PCs in PCA

Fig. 3A shows the loading plot of PC1 and PC2 derived from the PCA analysis. The variables of the fi rst component(PC1), which accounted for 55.61% of the total variance.The more correlated variables were vanillin, coniferaldehyde,syringaldehyde, vanillic acid, sinapaldehyde, total tannin,syringic acid, and ferulic acid, and to a minor extent, ellagic acid, phenol, eugenol, 5-methylfurfural, and trans-isoeugenol.For the second principal component (PC2, 21.76% of the total variance), the strongly correlated attributes were cis-oak-lactone,o-guaiacol, and syringol, all showing high positive values.

Fig. 3B shows the corresponding scores scatter plot used to establish the relative importance of each component to relate the compounds to each other and with the oak samples.Four well-defined groups could easily be discriminated according to their toasting degrees (untoasted, light, medium,and heavy) along PC1. Toasting effects were well explained by differences in chemical composition of compounds correlated to PC1, namely LMW phenolics, volatiles and other related chemical compounds, which separated the medium- and heavy-toasted samples on the right hand side of the score plot from the untoasted and light-toasted ones on the left hand side. Consequently samples 8, 9, and 12 (medium toasted medium- and fi ne-grained samples, and heavy toasted fine-grained ones, respectively) were easily distinguished along PC1 and PC2, which were related mainly to the volatile compounds (cis/trans-oak-lactone, syringol, cis/transisoeugenol, 5-methylfurfural, vanillin, and syringaldehyde).In general, the oak heartwood contains a high level of volatile compounds that would have a great impact on heartwoodmatured wine aroma. For example, vanillin concentration in white wines was positively correlated with ‘smoky’and ‘cinnamon’ descriptors, and in red wines, vanillin was associated with ‘vanilla’, as well as with ‘dark chocolate’aromas[36]. Thus, it indicated that these samples might cause modifi cations in the fi nal aromatic composition of the wine.While, the heavy toasted medium-grained oak sample (sample number 11) was grouped with medium and heavy toasted coarse-grained oak samples (sample numbers 7 and 10). They were scattered on the positive side of PC1 and negative side of PC2, demonstrating a positive correlation with ellagic acid and total phenol. This may affect the organoleptic characteristics of samples because these compounds are associated with a puckering astringent mouth feel[47], possibly because of the increased depolymerized tannins produced by this toasting regime. On the other side, oak sample numbers 5 (lightly toasted medium-grained) and 6 (lightly toasted fine-grained) had a similar chemical composition and were located in the top left quadrant of the PCA plot, showing a positive correlation with the furanic aldehydes (furfural and HMF) and volatile phenols (eugenol, o-guaiacol, and 4-vinylguaiacol). The sensory impact of these components would play an important role in developing the “toasted”,“burnt”, or “caramel” aromas in samples 5 and 6 barrelaged wines. Finally, the remaining samples (numbers 1–4 represent untoasted coarse-, medium- and fine-grained oak samples, and light toasted coarse grain oak samples,respectively) were located at the negative side of PC1 and PC2, showing a negative correlation with volatiles, and highest levels of total tannin and ferulic acid, particular in sample 1. And because the samples 1– 4 demonstrated a good affinity with the total tannin, which probably affected the organoleptic characteristics since it has been shown to be related to bitterness and astringency produced by wine at taste thresholds lower than the concentrations detected in some beverages after it contact with oak heartwood. In additionto this study, further studies on organoleptic characteristics,including sensory evaluation and GC-olfactometry, should be carried out for a better understanding of the infl uence that the oak heartwoods can have on the quality of aged wines.

Fig. 3 PCA results

3 Conclusions

This study aimed to reveal the differences in the LMW phenolics and volatiles of cooperage oak heartwood of different grain types and the influence of different toasting treatments on the chemical constituents of such heartwoods.According to the our results, the greater the increase in the toasting was, the greater the change in chemical composition of the heartwood extracts was. In particular a higher temperature and time combination during the toasting process increased the degradation of compounds. For example, the oak samples at the heavy toasting level released the highest concentrations of ellagic acid, sinapaldehyde,coniferaldehyde, vanillin, syringaldehyde, vanillic acid,syringic acid and phenol, while the medium toasting level released the highest concentrations of trans-isoeugenol,4-vinylguaiacol and syringol, allowed us to differentiate the samples according to toasting level. Independent of toasting, fine-grained heartwood samples were found to be higher in volatile compound concentrations, e.g.,cis/trans-oak-lactone, syringol, cis/trans-isoeugenol, furanic aldehydes, and LMW phenolic aldehydes, particularly sinapaldehyde, coniferaldehyde, vanillin, and syringaldehyde.However, medium- and coarse-grained heartwoods were higher in the total tannin, ellagic acid, and gallic acid of LMW phenolic acids. Using principal component analysis, it was possible to discriminate the various heartwood samples studied, and in particular, medium toasted medium- and fi negrained and heavy-toasted oak samples could be distinguished based on the content of volatile compounds (cis/trans-oaklactone, syringol, cis/trans-isoeugenol, 5-methylfurfural,vanillin, and syringaldehyde), indicating that these samples may cause modifi cations in the fi nal aromatic composition of the wine. The heavy toasted medium-grained, and medium and heavy toasted coarse-grained oak samples were related mainly to the ellagic acid and total phenol. These high correlations of ellagic and total phenol could have an effect on the organoleptic characteristics. The lightly toasted fi neand medium-grained oak samples demonstrated a good affinity with the furanic aldehydes (furfural and HMF) and volatile phenols (eugenol, o-guaiacol, and 4-vinylguaiacol),which would play an important role in developing the“toasted”, “burnt”, or “caramel” aromas. Moreover, the untoasted and lightly toasted coarse-grained samples were probably related to bitterness and astringency characteristics since they have been shown to be high tannins derived from the heartwood. Of course, further research, including sensory evaluation and GC-olfactometry, should be carried out.

The study should be extended by using a large number of Q. petraea oak samples as well as different species and geographical origins of oak; different sizes of oak heartwoods and more detailed toasting process should be investigated.Moreover, the effect of toasting regimes on different species such as chestnut (Castanea sativa), ash (Fraxinus excelsior and F. vulgaris), false acacia (Robinia pseudoacacia), and cherry (Prunus avium), which have been used for wine barrels, should also be investigated. Thus, the next study will compare the differences in the LMW phenolics and volatile compounds of oak heartwoods of different grain types and in different regions and oak/alternative species during the toasting process.

[1] ZHANG B, CAI J, DUAN C Q, et al. A review of polyphenolics in oak woods[J]. International Journal of Molecular Sciences, 2015,16(4)∶ 6978-7014. DOI∶10.3390/ijms16046978.

[2] ESPITIA-LOPEZ J, ESCALONA-BUENDIA H B, LUNA H, et al. Multivariate study of the evolution of phenolic composition and sensory profile on mouth of Mexican red Merlot wine aged in barrels vs wood chips[J]. CYTA-Journal of Food, 2015, 13(1)∶ 26-31.DOI∶10.1080/19476337.2014.907826.

[3] OBERHOLSTER A, ELMENDORF B L, LERNO L A, et al. Barrel maturation, oak alternatives and micro-oxygenation∶ infl uence on red wine aging and quality[J]. Food Chemistry, 2015, 173∶ 1250-1258.DOI∶10.1016/j.foodchem.2014.10.043.

[4] DE SIMON B F, MARTINEZ J, SANZ M, et al. Volatile compounds and sensorial characterisation of red wine aged in cherry, chestnut,false acacia, ash and oak wood barrels[J]. Food Chemistry, 2014,147(6)∶ 346-356. DOI∶10.1016/j.foodchem.2013.09.158.

[5] JACKSON R S. Wine science∶ principles and applications[M]. 3rd ed.California∶ Academic Press, 2008.

[6] CADAHIA E, MUNOZ L, DE SIMON B F, et al. Changes in low molecular weight phenolic compounds in Spanish, French, and American oak woods during natural seasoning and toasting[J].Journal of Agricultural and Food Chemistry, 2001, 49(4)∶ 1790-1798.DOI∶10.1021/jf0006168.

[7] GARCIA R, SOARES B, DIAS C B, et al. Phenolic and furanic compounds of Portuguese chestnut and French, American and Portuguese oak wood chips[J]. European Food Research and Technology, 2012,235(3)∶ 457-467. DOI∶10.1007/s00217-012-1771-2.

[8] ALANON M E, CASTRO-VAZQUEZ L, DIAZ-MAROTO M C, et al. Antioxidant capacity and phenolic composition of different woods used in cooperage[J]. Food Chemistry, 2011, 129(4)∶ 1584-1590.DOI∶10.1016/j.foodchem.2011.06.013.

[9] KANAKAKI E, SIDERAKOU D, KALLITHRAKA S, et al. Effect of the degree of toasting on the extraction pattern and profile of antioxidant polyphenols leached from oak chips in model wine systems[J]. European Food Research and Technology, 2015, 240(5)∶1065-1074. DOI∶10.1007/s00217-014-2410-x.

[10] FRANGIPANE M T, SANTIS D D, CECCARELLI A. I nfl uence of oak woods of different geographical origins on quality of wines aged in barriques and using oak chips[J]. Food Chemistry, 2007, 103(1)∶ 46-54.DOI∶10.1016/j.foodchem.2006.07.070.

[11] ACUNA L, GONZALEZ D, DE LA FUENTE J, et al. Influence of toasting treatment on permeability of six wood species for enological use[J]. Holzforschung, 2014, 68(4)∶ 447-454. DOI∶10.1515/hf-2013-0044.

[12] DE SIMON B F, CADAHIA E, DEL ALAMO M, et al. Effect of size,seasoning and toasting in the volatile compounds in toasted oak wood and in a red wine treated with them[J]. Analytica Chimica Acta, 2010,660(1/2)∶ 211-220. DOI∶10.1016/j.aca.2009.09.031.

[13] CADAHIA E, DE SIMON B F, JALOCHA J. Volatile compounds in Spanish, French, and American oak woods after natural seasoning and toasting[J]. Journal of Agricultural and Food Chemistry, 2003, 51(20)∶5923-5932. DOI∶10.1021/jf0302456.

[14] DE SIMON B F, CADAHIA E, CONDE, E, et al. Low molecular weight phenolic compounds in Spanish oak woods[J]. Journal of Agricultural and Food Chemistry, 1996, 44(6)∶ 1507-1511. DOI∶10.1021/jf9502461.

[15] CADAHIA E, VAREA S, MUNOZ L, et al. Evolution of ellagitannins in Spanish, French, and American oak woods during natural seasoning and toasting[J]. Journal of Agricultural and Food Chemistry, 2001,49(8)∶ 3677-3684. DOI∶10.1021/jf010288r.

[16] DEDRIE M, JACQUET N, BOMBECK P L, et al. Oak barks as raw materials for the extraction of polyphenols for the chemical and pharmaceutical sectors∶ a regional case study[J]. Industrial Crops and Products, 2015, 70(1)∶ 316-321. DOI∶10.1016/j.indcrop.2015.03.071.

[17] DOUSSOT F, DE JÉSO B, QUIDEAU S, et al. Extractives content in cooperage oak wood during natural seasoning and toasting; infl uence of tree species, geographic location, and single-tree effects[J]. Journal of Agricultural and Food Chemistry, 2002, 50(21)∶ 5955-5961.DOI∶10.1021/jf020494e.

[18] COLLINS T S, MILES J L, BOULTON R B, et al. Targeted volatile composition of oak wood samples taken during toasting at a commercial cooperage[J]. Tetrahedron, 2015, 71(20)∶ 2971-2982.DOI∶10.1016/j.tet.2015.02.079.

[19] PÉREZ-JUAN P M, CASTRO M D L D. Chapter 57-Use of oak wood to enrich wine with volatile compounds[J]. Processing and Impact on Active Components in Food, 2015∶ 471-481.

[20] CALDEIRA I, CLIMACO M C, DE SOUSA R B, et al.Volatile composition of oak and chestnut woods used in brandy ageing∶ modification induced by heat treatment[J]. Journal of Food Engineering, 2006, 76(2)∶ 202-211. DOI∶10.1016/j.jfoodeng.2005.05.008.

[21] RIBEREAU-GAYON P, GLORIES Y, MAUJEAN A, et al. Handbook of enology[M]. Chichester∶ UK John Wiley & Sons Ltd, 2000.

[22] SANZ M, DE SIMON B F , ESTERUELAS E, et al. Effect of toasting intensity at cooperage on phenolic compounds in Acacia (Robinia pseudoacacia) heartwood[J]. Journal of Agricultural and Food Chemistry, 2011, 59(7)∶ 3135-3145. DOI∶10.1021/jf1042932.

[23] 质量监督检疫总局, 国家标准化管理委员会. 葡萄酒、果酒通用分析方法∶ GB/T 15038—2006[S]. 北京∶ 中国标准出版社, 2006∶ 2-14.

[24] GLABASNIA A, HOFMANN T. Sensory-directed identification of taste-active ellagitannins in American (Quercus alba L.) and European oak wood (Quercus robur L.) and quantitative analysis in bourbon whiskey and oak-matured red wines[J]. Journal of Agricultural and Food Chemistry, 2006, 54(9)∶ 3380-3390. DOI∶10.1021/jf052617b.

[25] HELM R F, RANATUNGA T D, CHANDRA M. Lignin-hydrolyzable tannin interactions in wood[J]. Journal of Agricultural and Food Chemistry, 1997, 45(8)∶ 3100-3106. DOI∶10.1021/jf970083b.

[26] CHIRA K, TEISSEDRE P-L. Relation between volatile composition,ellagitannin content and sensory perception of oak wood chips representing different toasting processe[J]. European Food Research and Technology, 2013, 236(4)∶ 735-746. DOI∶10.1007/s00217-013-1930-0.

[27] DOS ANJOS J P, CARDOSO M D G, SACZK A A, et al. Evolution of the concentration of phenolic compounds in cachaca during aging in an oak (Quercus sp.) barrel[J]. Journal of the Brazilian Chemical Society,2011, 22(7)∶ 1307-1314. DOI∶10.1590/S0103-50532011000700016.

[28] BOZALONGO R, CARRILLO J D, TORROBA M A, et al. Analysis of French and American oak chips with different toasting degrees by headspace solid-phase microextraction-gas chromatography-mass spectrometr[J]. Journal of Chromatography A, 2007, 1173(1/2)∶ 10-17.DOI∶10.1016/j.chroma.2007.09.079.

[29] SANZ M, DE SIMON B F, CADAHIA E, et al. LC-DAD/ESI-MS/MS study of phenolic compounds in ash (Fraxinus excelsior L. and F. americana L.) heartwood. Effect of toasting intensity at cooperage[J].Journal of Mass Spectrometry, 2012, 47(7)∶ 905-918. DOI∶10.1002/jms.3040.

[30] BOERJAN W, RALPH J, BAUCHER M. Lignin biosynthesis[J].Annual Review of Plant Biology, 2003, 54(1)∶ 519-546. DOI∶10.1146/annurev.arplant.54.031902.134938.

[31] ALANON E M, DIAZ-MAROTO M C, PEREZ-COELLO M S. Analysis of volatile composition of toasted and non-toasted commercial chips by GC-MS after an accelerated solvent extraction method[J]. International Journal of Food Science and Technology,2012, 47(4)∶ 816-826. DOI∶10.1111/j.1365-2621.2011.02914.x.

[32] SCHUMACHER R, ALANON M E, CASTRO-VAZQUEZ L, et al.Evaluation of oak chips treatment on volatile composition and sensory characteristics of Merlot wine[J]. Journal of Food Quality, 2013, 36(1)∶1-9. DOI∶10.1111/jfq.12012.

[33] MARTÍNEZ R G, MIR M V, ALARCÓN M N, et al. Study of vanillin,syringaldehyde and gallic acid content in oak wood and wine spirit mixtures∶ infl uence of heat treatment and chip size[J]. Journal of Wine Research, 2001, 12(3)∶ 175-182. DOI∶10.1080/09571260120106811.

[34] PÉREZ-COELLO M S, DÍAZ-MAROTO M C. Volatile compounds and wine aging[M]//Wine Chemistry and Biochemistry. New York,Springer, 2009∶ 295-311.

[35] GARCIA-CARPINTERO E G, SANCHEZ-PALOMO E, GONZALEZ VINAS M A. Volatile composition of Bobal red wines subjected to alcoholic/malolactic fermentation with oak chips[J]. LWTFood Science and Technology 2014, 55(2)∶ 586-594. DOI∶10.1016/j.lwt.2013.10.024.

[36] CHIRA K, TEISSEDRE P L. Extraction of oak volatiles and ellagitannins compounds and sensory profi le of wine aged with French wine woods subjected to different toasting methods∶ behaviour during storage[J]. Food Chemistry, 2013, 140(1/2)∶ 168-177. DOI∶10.1016/j.foodchem.2013.02.049.

[37] PÉREZ-PRIETO L J, LÓPEZ-ROCA J M, MARTÍNEZ-CUTILLAS A, et al. Maturing wines in oak barrels. Effects of origin, volume,and age of the barrel on the wine volatile composition[J]. Journal of Agricultural and Food Chemistry, 2002, 50(11)∶ 3272-3276.DOI∶10.1021/jf011505r.

[38] PEREZCOELLO M S, GONZALEZVINAS M A, GARCIAROMERO E, et al. Chemical and sensory changes in white wines fermented in the presence of oak chips[J]. International Journal of Food Science and Technology, 2000, 35(1)∶ 23-32. DOI∶10.1046/j.1365-2621.2000.00337.x.

[39] WATERHOUSE A L, TOWEY J P. Oak lactone isomer ratio distinguishes between wines fermented in American and French oak barrels[J]. Journal of Agricultural and Food Chemistry, 1994, 42(9)∶1971-1974. DOI∶10.1021/jf00045a026.

[40] HERNANDEZ-ORTE P, FRANCO E, GONZALEZ H C, et al.Criteria to discriminate between wines aged in oak barrels and macerated with oak fragments[J]. Food Research International, 2014,57(1)∶ 234-241. DOI∶10.1016/j.foodres.2014.01.044.

[41] CHATONNET P, CUTZACH I, PONS M, et al. Monitoring toasting intensity of barrels by chromatographic analysis of volatile compounds from toasted oak wood[J]. Journal of Agricultural and Food Chemistry,1999, 47(10)∶ 4310-4318. DOI∶10.1021/jf981234t.

[42] LARCHER R, NICOLINI G, PUECHER C, et al. Determination of volatile phenols in wine using high-performance liquid chromatography with a coulometric array detector[J]. Analytica Chimica Acta, 2007, 582(1)∶ 55-60. DOI∶10.1016/j.aca.2006.08.056.

[43] RODRIGUEZ-BENCOMO J J, ORTEGA-HERAS M, PEREZMAGARINO S, et al. Volatile compounds of red wines macerated with Spa nish, American, and French oak chips[J]. Journal of Agricultural and Food Chemistry, 2009, 57(14)∶ 6383-6391. DOI∶10.1021/jf900739k.

[44] DÍAZ-MAROTO M C, GUCHU E, CASTRO-VÁZQUEZ L, et al. Aroma-active compounds of American, French, Hungarian and Russian oak woods, studied by GC-MS and GC-O[J]. Flavour and Fragrance Journal, 2008, 23(2)∶ 93-98. DOI∶10.1002/ffj.1859.

[45] DE SIMON B F, ESTERUELAS E, MUNOZ A M, et al. Volatile compounds in acacia, chestnut, cherry, ash, and oak woods, with a view to their use in cooperage[J]. Journal of Agricultural and Food Chemistry, 2009, 57(8)∶ 3217-3227. DOI∶10.1021/jf803463h.

[46] FAN W, XU Y, YU A. Influence of oak chips geographical origin,toast level, dosage and aging time on volatile compounds of apple cider[J]. Journal of the Institute of Brewing, 2006, 112(3)∶ 255-263.DOI∶10.1002/j.2050-0416.2006.tb00721.x.

[47] ARAPITSAS P. Hydrolyzable tannin analysis in food[J]. Food Chemistry,2012, 135(3)∶ 1708-1717. DOI∶10.10 16/j.foodchem.2012.05.096.

烘烤强度和木纹理对橡木(Quercus petraea)心材多酚和香气的影响

张 波1,2,何 非2,蔡 建2,王云鹤2,段长青2,韩舜愈1,*

(1.甘肃农业大学食品科学与工程学院,甘肃省葡萄与葡萄酒工程学重点实验室,甘肃 兰州 730070;2.中国农业大学食品科学与营养工程学院,葡萄与葡萄酒研究中心,北京 100083)

考察不同烘烤程度对不同纹理橡木心材试样中低分子质量酚酸和挥发性物质含量的影响,结果表明烘烤过程将会改变橡木心材的物质组成,并通过相应的化学反应增加挥发性物质的含量。同时,在不考虑烘烤强度条件下,供试的细纹理橡木心材试样含有较高的挥发性物质含量,例如顺/反橡木内脂、顺/反异丁子香酚、呋喃醛、紫丁香醇,以及芥子醛、松柏醛、香草醛和丁香醛等低分子质量酚类化合物,而中纹理和粗纹理的样品则表现出较高的总酚、总单宁水平,以及较高的鞣花酸和没食子酸含量。此外,主成分分析显示,中纹理和细纹理样品的中度和重度烘烤处理与橡木心材试样的挥发性物质含量有较大的正相关性,而粗纹理的未烘烤和轻度烘烤样品则与试样中总单宁和阿魏酸含量呈正相关。

橡木;纹理;烘烤度;酚类物质;挥发性物质

TS26

A

1002-6630(2017)20-0070-13

nces:

2016-12-07

国家自然科学基金地区科学基金项目(31560451);国家自然科学基金面上项目(31271926);

张波(1983—),男,讲师,博士,研究方向为葡萄酒化学与酿造。E-mail:zb692002@163.com

ZHANG Bo, HE Fei, CAI Jian, et al. Effect of toasting intensity and wood grain on polyphenolic compounds and aroma components in oak (Quercus petraea) heartwood[J]. 食品科学, 2017, 38(20): 70-82.

10.7506/spkx1002-6630-201720011. http://www.spkx.net.cn

ZHANG Bo, HE Fei, CAI Jian, et al. Effect of toasting intensity and wood grain on polyphenoli c compounds and aroma components in oak (Quercus petraea) heartwood[J]. Food Science, 2017, 38(20)∶ 70-82. DOI∶10.7506/spkx1002-6630-201720011. http∶//www.spkx.net.cn

甘肃农业大学“伏羲人才”项目(Gaufx-02Y06)

*通信作者:韩舜愈(1963—),男,教授,博士,研究方向为果蔬加工及葡萄酒风味化学。E-mail:gsndhsy@163.com

DOI∶10.7506/spkx1002-6630-201720011