Work characteristic analysis of single-rod symmetric cylinders①

2017-09-25ShenWeiHuangHongleiLiYangZhangDijiaJiangJihai

Shen Wei (沈 伟), Huang Honglei, Li Yang, Zhang Dijia, Jiang Jihai

(*Department of Mechatronics Engineering, University of Shanghai for Science and Technology, Shanghai 200093, P.R.China)(**Tianjin Uranus Hydraulic Machinery Co. Ltd, Tianjin 300385, P.R.China)(***School of Mechatronics Engineering, Harbin Institute of Technology, Harbin 150080, P.R.China)

Work characteristic analysis of single-rod symmetric cylinders①

Shen Wei (沈 伟)②*, Huang Honglei*, Li Yang**, Zhang Dijia***, Jiang Jihai***

(*Department of Mechatronics Engineering, University of Shanghai for Science and Technology, Shanghai 200093, P.R.China)(**Tianjin Uranus Hydraulic Machinery Co. Ltd, Tianjin 300385, P.R.China)(***School of Mechatronics Engineering, Harbin Institute of Technology, Harbin 150080, P.R.China)

Hydraulic cylinders are divided into single-rod asymmetric cylinders and double-rod symmetric cylinders. The single-rod asymmetric cylinder has the advantages of small size and simple structure, but its speed characteristic is not symmetric. The double rod symmetric cylinder has the characteristic of symmetric speed, but it cannot be used in some special occasions. In this paper, one special hydraulic cylinder, a single-rod symmetric cylinder, is developed. Firstly, characters of this type of cylinder are introduced. Then, the system model is constructed by using one software which is Simulation X. Moreover, one single rod asymmetric cylinder is designed and the test rig using the symmetric valve to control single-rod symmetric or asymmetric cylinder is constructed. Both of the simulation and experimental results show that the symmetric valve control single-rod symmetric cylinder servo system is of symmetric speed characteristic, which can be used in practical occasion.

single-rod symmetric cylinders, Simulation X, servo system

0 Introduction

Single-rod asymmetric cylinders and double-rod symmetric cylinders are two types of cylinders which are used widely[1-5]in which the single-rod asymmetric cylinder possesses a multitude of advantages, such as small size and simple structure, which can be applied to different working conditions. However, since its speed characteristic is not symmetric because of different working areas of the two chambers[6-9], the complex control system should be investigated in order to obtain high-precision performance. Alternatively, the other method uses the asymmetric servo valve, but the cost would be extremely high because of the complex valve structure. Moreover, although the double-rod symmetric cylinder has the characteristic of symmetric speed, quite a few occasions are limited by the space requirement, for example, the 6-DOF platforms and road simulation systems[10-12]. Therefore, a new type of cylinder combining the advantages of both the space saving and symmetric structure should be a promising choice. The detail is to make the areas of two chambers equal by using a suitable structure design method. Then, there are several positive merits. Firstly, sudden pressure change can be avoided when the direction of motion is changed, and the system dynamic performance can be improved. Secondly, a normal symmetric valve can be used to control symmetric cylinder without complex control algorithm[13,14]. Finally, the flow requirement of hydraulic source is reduced.

There are several famous companies which have released the products of the single-rod symmetric cylinders, such as Haenchen, Rexroth. Especially, Haenchen gains tremendous market share by relying on the cost-effective characteristic of their products, and these products have been applied to a majority of flight simulators, such as the simulator for Airbus A340 and A380, in which the maximum amplitude of the cylinder could reach 6.5m. Moreover, scholars from Delft University of Technology investigated the control performance considering the influence of friction and leakage. Several universities and enterprises in China have presented detailed methods for applying the single-rod symmetric to hydraulic elevator or pumping unit[15-17]. Hence, the single-rod symmetric cylinder is one promising component to meet the high control performance requirement, especially for the space limited condition.

In this paper, a general structure of the single-rod symmetric cylinder is introduced, and then simulations including comparison of single-rod symmetric and asymmetric are conducted. The experimental results show the single-rod symmetric cylinder has better control performance in both directions.

1 Basic principle

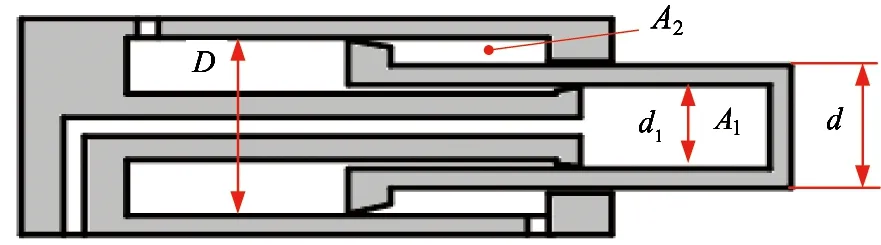

The structure of the single-rod symmetric cylinder is shown as Fig.1, in which the areas of two chambers (A1and A2) are equal. It is worth noting that the rod has two functions, one is to be used as the piston and the other is as the piston barrel. Hence, in order to meet the second requirement, the piston should be hollow, moreover, the high surface accuracy of the hole is supposed to be guaranteed. The piston is divided into two parts and they are processed respectively, and the processing technologies include welding, finish turning and chrome plate.

Fig.1 Structure of the single-rod symmetric cylinder

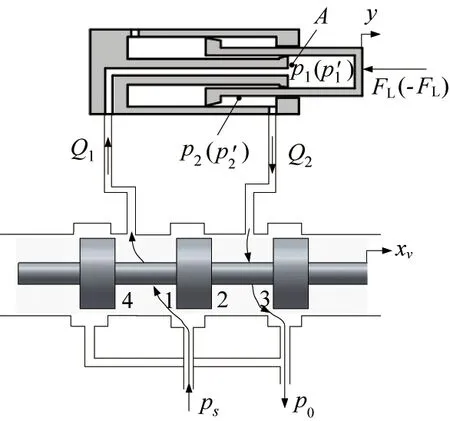

Fig.2 shows the schematic of the single-rod symmetric cylinder controlled by the servo valve. According to fundamental definitions, the parameters are listed in Table 1.

Fig.2 Simplified schematic diagram of single-rod symmetric cylinder controlled by the servo valve

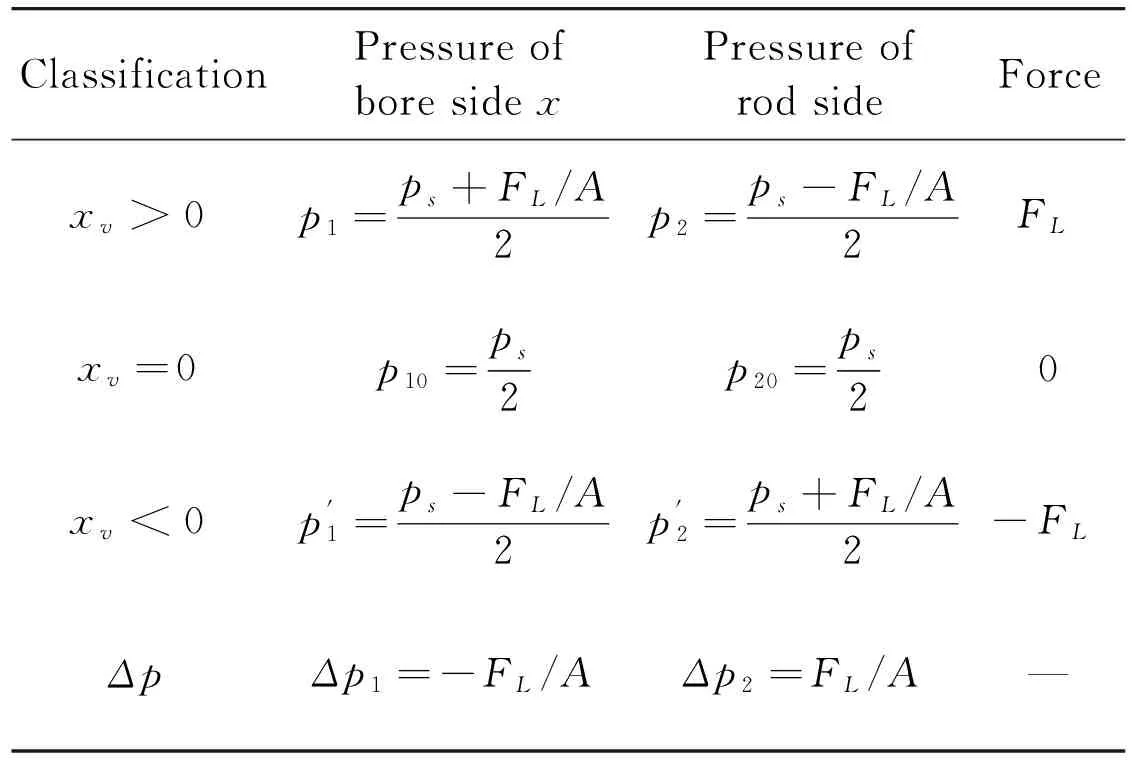

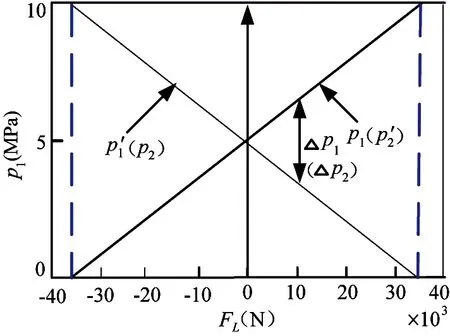

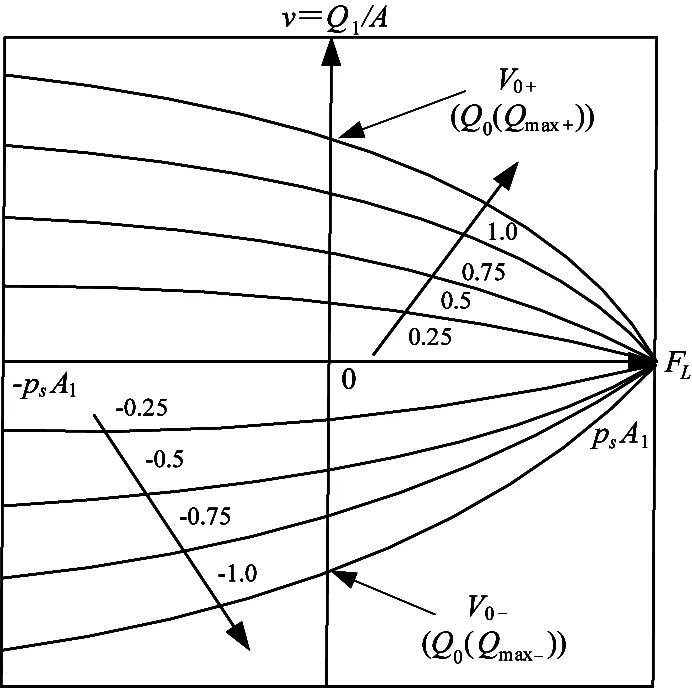

Using the pressure characteristic expressions to describe the two chambers of the hydraulic cylinder in Table 1, the curve of the pressure characteristic is shown in Fig.3. Parameters of the curve are the same as the experiment, ps=10MPa, A=3.1×103m2.

Table 1 Pressure characteristics of symmetric valve control single-rod symmetric cylinder

Two conclusions can be drawn from Fig.3:

Pressure characteristics of the single-rod symmetric cylinder’s two chambers are the same, with no phenomenon of cavitation and overpressure.

When the cylinder motion reverses, the pressure suddenly changes, whose value is only related to the load force FLwhen the area of the cavity is determinate.

Fig.3 Pressure characteristics of the single-rod symmetric cylinder controlled by the symmetric valve

1.1 Output characteristics

xv>0, the stretch-out speed of the rod

(1)

xv<0, the retraction speed of the rod

(2)

Output characteristics of symmetric valve control single-rod symmetric cylinder are shown in Fig.4.

Fig.4 Output characteristics of symmetric valve control single-rod symmetric cylinder

Equation can be obtained from comparing the force ranges which is

-psA≤FL≤psA

(3)

Hence, the load force transformation range of a single-rod symmetric cylinder controlled with a symmetric valve system is larger than that of a single-rod asymmetric cylinder controlled with a symmetric valve system.

1.2 Modeling

In order to test the control performance of the cylinder which is designed and compared with traditional cylinders, a single-rod symmetric cylinder prototype is constructed. However, some simulations by using Simulation X, a multidisciplinary simulation software, are operated before it is manufactured. The model is assembled using the elements predefined in Simulation X. According to the simulation, such as friction descriptions, end stops and leakage models can be adjusted easily. Moreover, a simulation model of the cylinder servo system controlled by the symmetric valve is constructed in order to prove the single-rod symmetric cylinder’s advantages mentioned above.

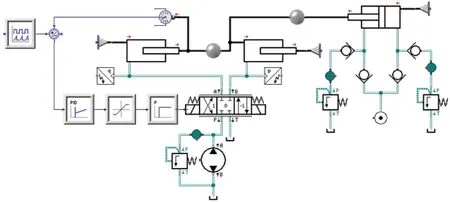

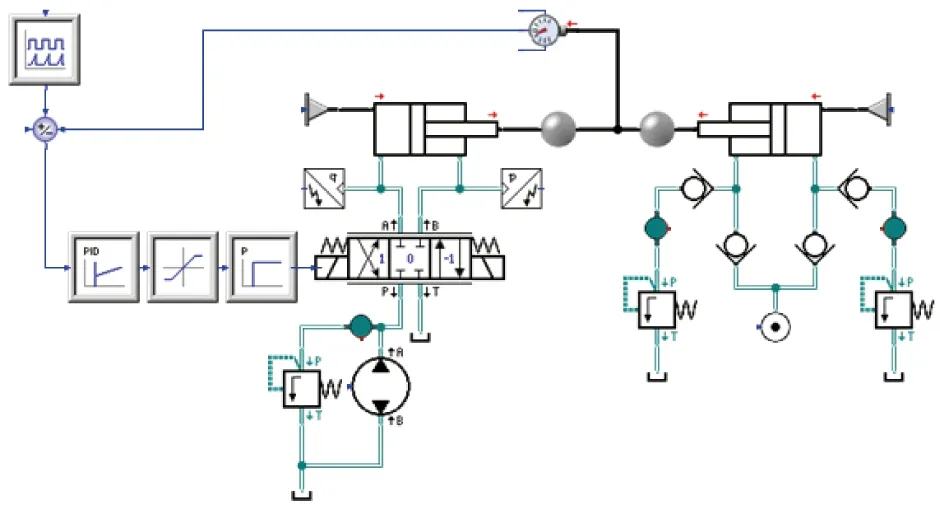

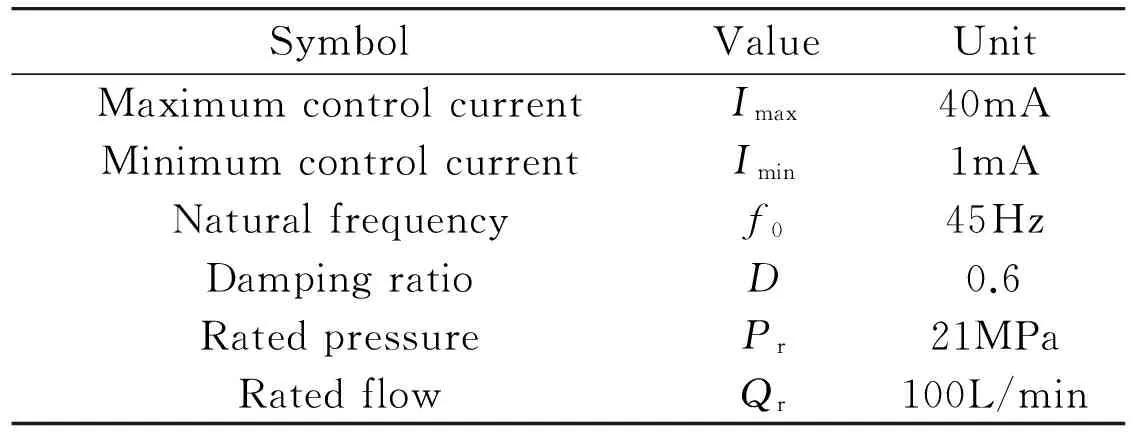

Fig.5 shows a single-rod symmetric hydraulic cylinder electro-hydraulic servo system model. Furthermore,for comparing and analyzing, a single-rod asymmetric cylinder electro-hydraulic servo system model is also made, as shown in Fig.6, and the main simulation parameters are listed in Table 2.

Fig.5 A single-rod symmetric hydraulic cylinder electro-hydraulic servo system model

Fig.6 A single-rod asymmetric hydraulic cylinder electro-hydraulic servo system model

SymbolValueUnitMaximumcontrolcurrentImax40mAMinimumcontrolcurrentImin1mANaturalfrequencyf045HzDampingratioD0.6RatedpressurePr21MPaRatedflowQr100L/min

2 Simulation analysis

2.1 Frequency domain analysis

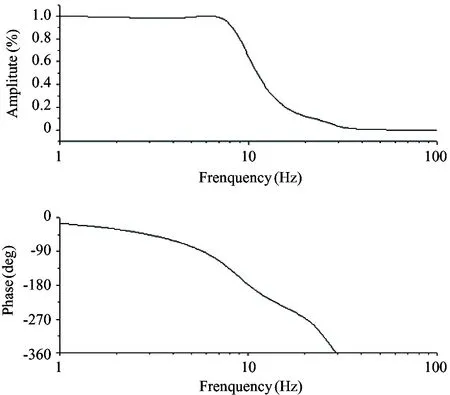

To obtain the frequency domain analysis result of the single-rod asymmetric hydraulic cylinder electrohydraulic servo system, a closed-loop Bode diagram is obtained by using the Simulation X software after analyzing the input-output process. Fig.7 shows that the result obtained from the condition of the load is 10kN and supplying pressure is 10MPa. It can be concluded from the closed-loop Bode diagram that the width of the system band at -3dB is 9Hz.

Fig.7 A closed-loop Bode diagram of a single-rod symmetric hydraulic cylinder electro-hydraulic servo system

2.2 Time domain analysis

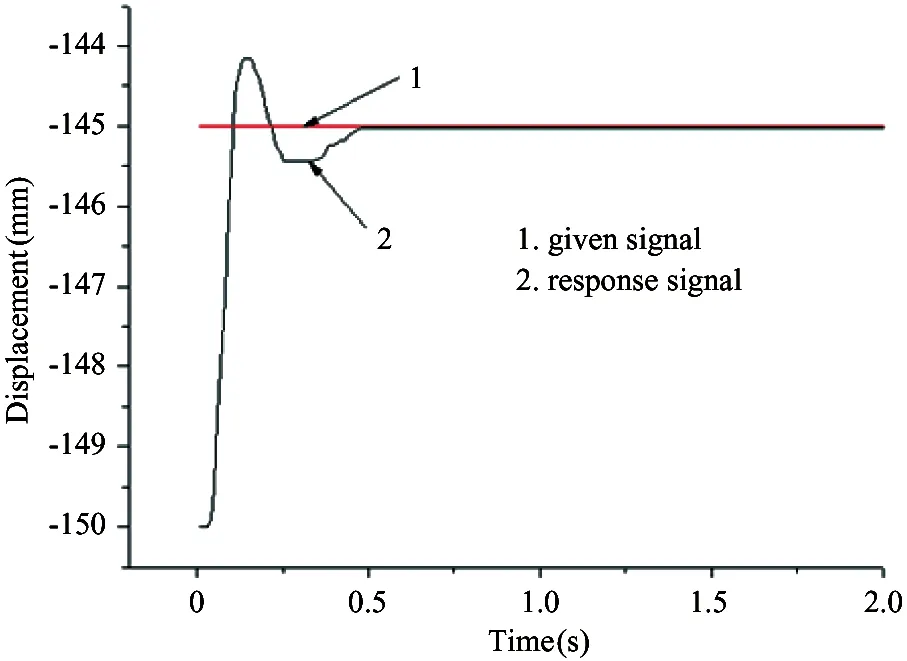

In this paper, the step, ramp and sinusoidal signal are used to investigate the response of the electro-hydraulic servo system. In order to make a fair comparison, the response during retracting process of the single-rod asymmetric cylinder is chosen. The following part is the response curve of each group (1 is the given signal, 2 is the response signal). It can be found from Fig.8 that the rising time is basically identical, both of them are about 0.5s.

(a) Single-rod symmetric cylinder

(b) Single-rod asymmetric cylinder

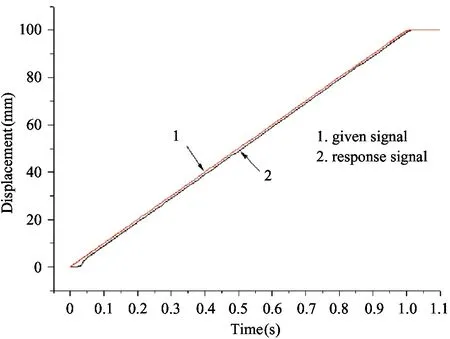

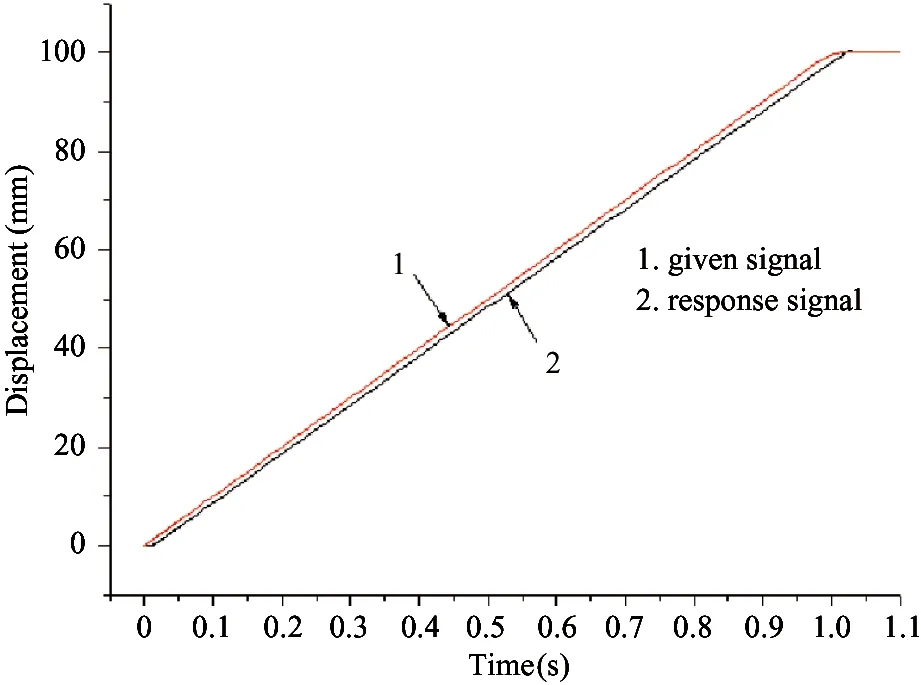

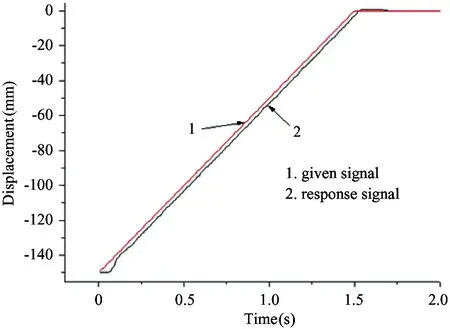

Fig.9 shows the ramp signal response of tracking 100mm/s signal. Conclusion drawn from Fig.9(a) and (b) is that delay time of the single-rod symmetric cylinder electro-hydraulic servo system is 0.010s and 0.014s respectively which means the constant speed tracking ability of the two systems is basically the same. However, the steady error of the single-rod symmetric cylinder is smaller.

(a) Single-rod symmetric cylinder k=100mm/s

(b) Single-rod asymmetric cylinder k=100mm/s

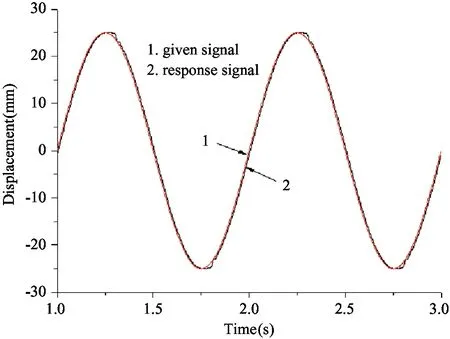

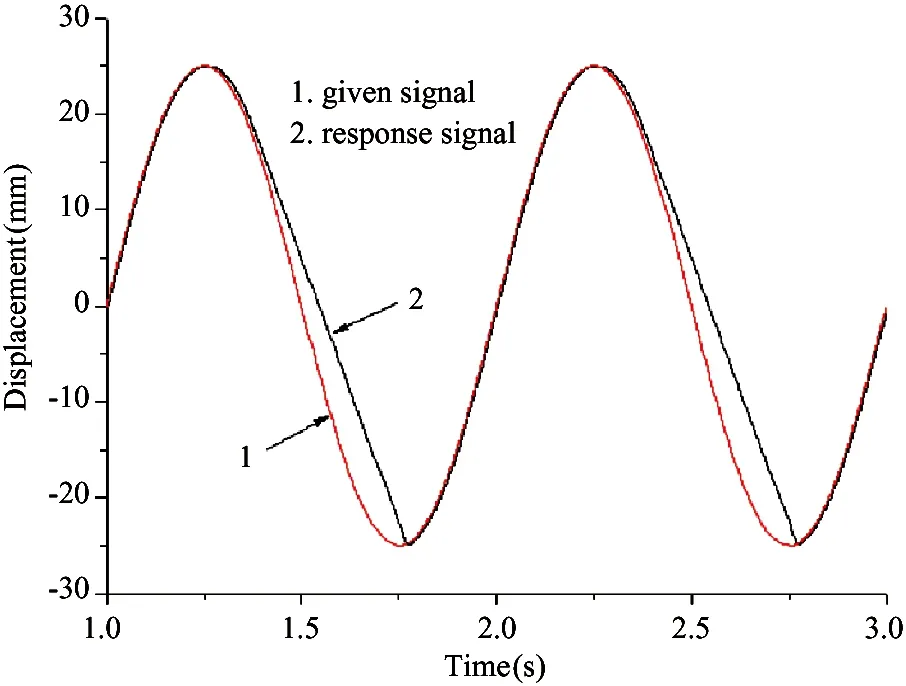

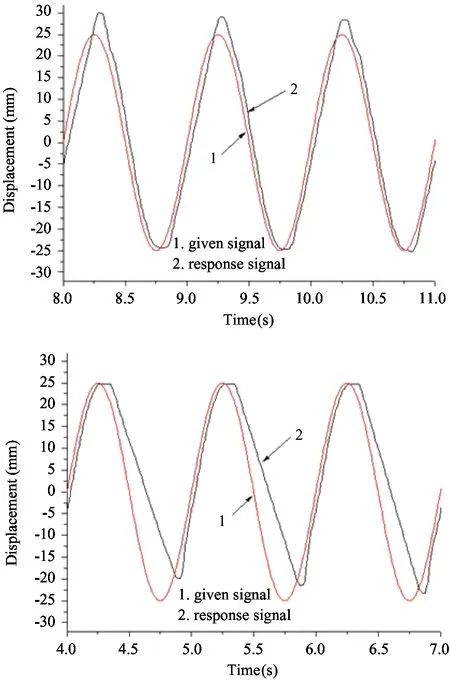

The sinusoidal response is shown in Fig.10. It can be found that the single-rod symmetric cylinder has symmetric speed characteristic. However, the asymmetric cylinder performs different speed responses during the extending and retracting.

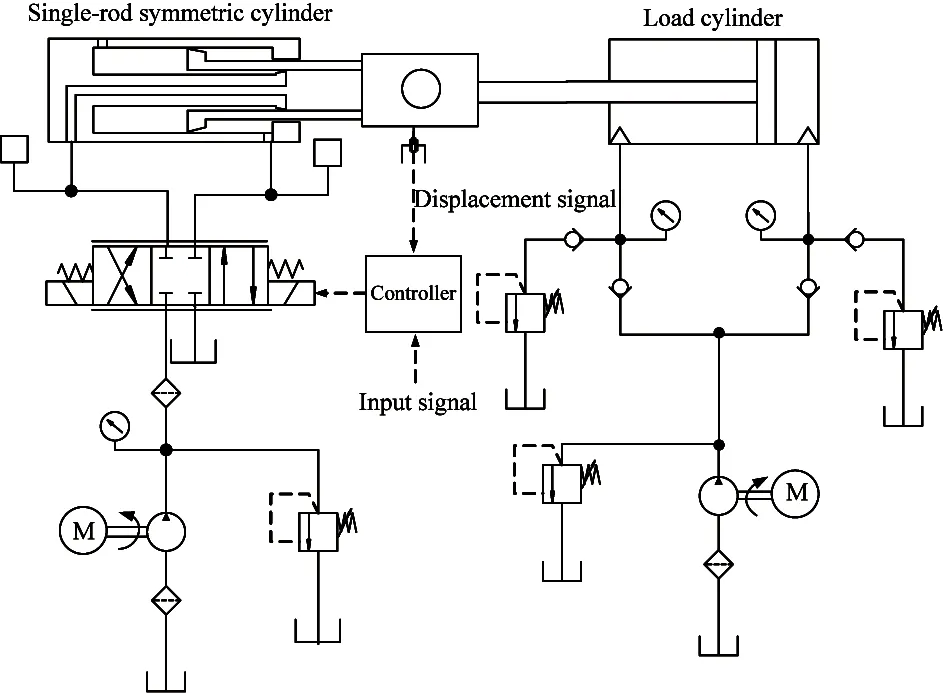

3 Experimental analysis

In order to test the effectiveness of the proposed cylinder, a test rig is designed which is shown in Fig.11(a) and Fig.11(b), moreover, the schematic is shown in Fig.12. Then, the contrastive experiments were done by changing the single-rod symmetric hydraulic cylinder and the single-rod asymmetric hydraulic cylinder.

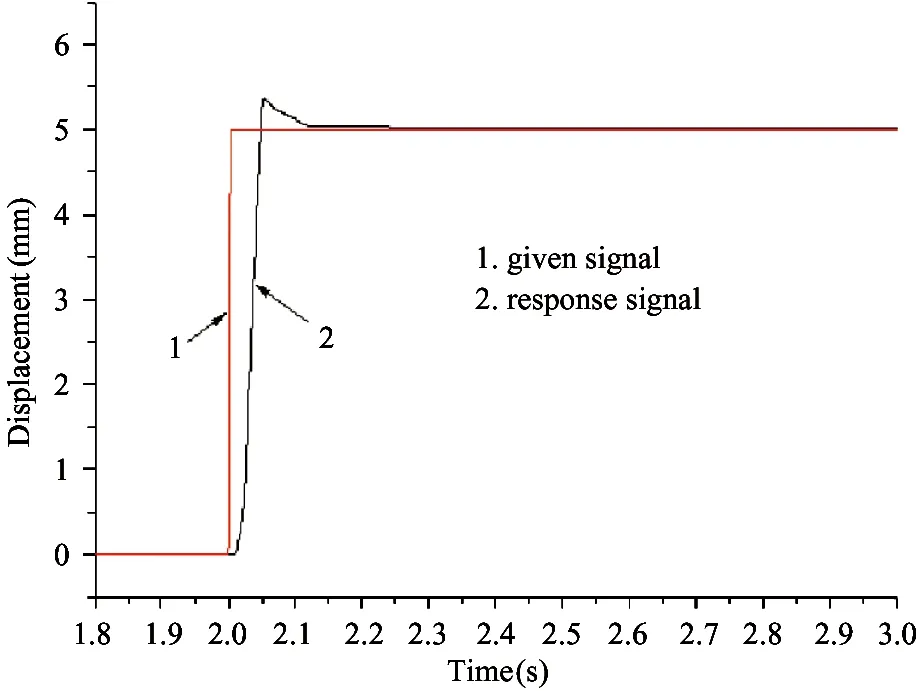

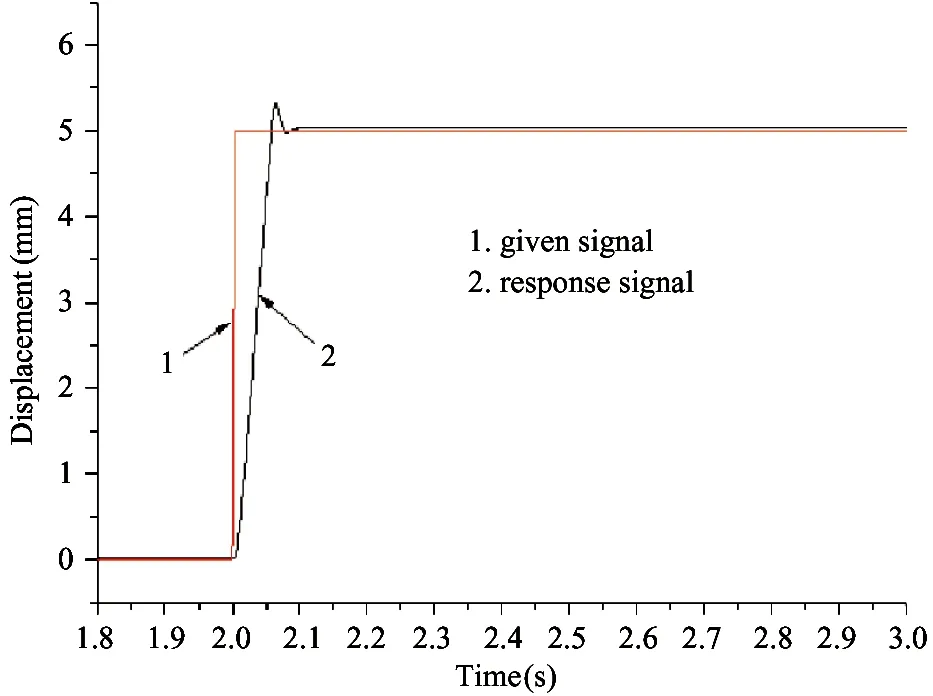

Two kinds of step response experiments are compared in this paper. The single-rod step response experiment of asymmetric hydraulic cylinder is done when the piston is back. Fig.13 shows the load step response curve for the two kinds of system.

(a) Single-rod symmetric cylinder at y=25sin(2πt)

(b) Single-rod asymmetric cylinder at y=25sin(2πt)

Fig.11 The single-rod symmetric cylinder test rig

Fig.12 Schematic of the single-rod symmetric cylinder test rig

Step response curves of single-rod symmetric cylinder and single-rod asymmetric cylinder electro-hydraulic servo system are shown in Fig.13(a) and (b), in which the amplitude is 5mm. It can be found from Fig.13(a) that rising time of the single-rod symmetric cylinder electro-hydraulic servo system is 0.11s and the steady state error is 0.02m. The conclusion drawn from Fig.13(b) is that rising time of the single-rod asymmetric cylinder electro-hydraulic servo system is 0.10s and the steady state error is 0.1. Hence, rise time of the two systems is basically the same.

(a) Single-rod symmetric cylinder

(2) Ramp response experiments

Then, ramp response experiments are finished. In order to be comparable, the single-rod step response experiment of asymmetric hydraulic cylinder is done when the piston is retracting. For the load case, neither of the two kinds of systems can track the ramp signal for 200 mm/s slope. But they can track the ramp signal for 100 mm/s slope well. Ramp response curve of single-rod symmetric cylinder and single-rod asymmetric cylinder electro-hydraulic servo system is shown in Fig.14(a) and (b), in which the slope is 100mm/s. Conclusion drawn from Fig.14(a) is that delay time of the single-rod symmetric cylinder electro-hydraulic servo system is 0.030s. Conclusion drawn from Fig.14(b) is that the delay time of the single-rod asymmetric cylinder electro-hydraulic servo system is 0.033s. So the constant speed tracking ability of the two systems is basically the same.

(b) Single-rod asymmetric cylinder k=100mm/s

(3) Sinusoidal response experiments

Finally, sinusoidal response experiments are conducted. Fig.15 shows the load sinusoidal response curve for the two kinds of systems.

Sinusoidal response curves of single-rod symmetric cylinder and single-rod asymmetric cylinder electro-hydraulic servo system are shown in Fig.15(a) and (b) where the amplitude is 25mm and frequency is 1Hz. Conclusion drawn from comparison is that for single-rod asymmetric cylinder, the extending speed is bigger than the retracting speed obviously. But for the single-rod symmetric cylinder, they are almost the same.

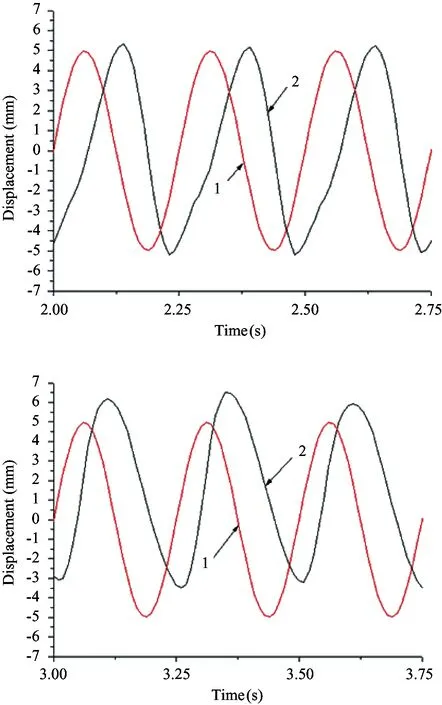

Moreover, the different working condition experiments of sinusoidal signal response are shown by Fig.15(c) and (d), where the amplitude is 5mm and frequency is 4Hz. Forward and reverse phase lag of the single-rod symmetric cylinder is almost -90°. Forward phase lag of the single-rod asymmetric cylinder is smaller than the reverse phase lag. Forward overshoot, reverse attenuate, reverse phase lag reaches -90°; forward overshoot reaches 10%. Experimental results show that both of two systems are unable to track the signal which possesses the characteristics of high frequency and low amplitude. According to different signal responses, two kinds of systems have the similar performance, however, the single-rod symmetric cylinder possesses the symmetric characteristic.

4 Conclusions

In this paper, a single-rod symmetric cylinder is designed and the test rig for the performance experiment is conducted. The step signal tracking results show that both of the two kinds of systems possess almost the same response. Then, by importing the sinusoidal signal into the simulation model, it can be concluded that the symmetric valve controling symmetric cylinder servo system has symmetric speed characteristic, however, the symmetric valve controling asymmetric cylinder servo system does not have the performance. Finally, experiment results verify that the single-rod symmetric cylinder system can obtain the same performance compared with the asymmetric one, it also possesses the identical merit during extending and retracting. Hence, it can be used in practical working condition.

(a) Single-rod symmetric cylinder at y=25sin(2πt)

(b) Single-rod symmetric cylinder at y=5sin(0.5πt)

[ 1] Yang J, Quan L, Yang Y. Excavator energy-saving efficiency based on diesel engine cylinder deactivation technology. Chinese Journal of Mechanical Engineering. 2012, 25(5):897-904

[ 2] Ai C, Kong X. Research on hydraulic wind turbine semi-physical simulation platform. High Technology Letters, 2015, (3): 269-275

[ 3] Liu J, Li B, Yang B, et al. FEM modeling and dynamic performance analysis of electric spindle system of high speed cylinder grinding machine. Journal of Donghua University (English Edition), 2012, 38(5): 14-19

[ 4] Shen W, Jiang J, Su X, et al. Control strategy analysis of the hydraulic hybrid excavator. Journal of the Franklin Institute, 2015, 352(2): 541-561

[ 5] Sochacki W. Modelling and analysis of damped vibration in hydraulic cylinder. Mathematical and Computer Modelling of Dynamical Systems, 2015, 21(1): 23-37

[ 6] Finzel R, Helduser S, Jang D. Electro-hydraulic control systems for mobile machinery with low energy consumption. In: Proceedings of the 7th International Conference on Fluid Power Transmission and Control, Hangzhou, China, 2009. 214-219

[ 7] Shen W, Mai Y, Su X, et al. A new electric hydraulic actuator adopted the variable displacement pump. Asian Journal of Control, 2016, 18(1): 178-191

[ 8] Wang C, Ding F, Li Q. The research on dynamic performance of asymmetric cylinder hydraulic servo system controlled by symmetric valve. Chinese Machine Engineering. 2004, 15(6): 471-474. (In Chinese)

[ 9] Zhao X, Hu Z, Li R, et al. Internal leakage fault feature extraction of hydraulic cylinder using wavelet packet energy. In: Proceedings of the International on Parallel Computational Fluid Dynamics. Springer Berlin Heidelberg, 2014. 363-375. doi: 10.1007/978-3-642-53962-6-32

[10] Shih M C, Tseng S I. Identification and position control of a servo pneumatic cylinder. Control Engineering Practice, 1995, 3(9): 1285-1290[11] Wang X, Liu Q, Wu S. Synchronization control of the oppositely driven system with dual asymmetric cylinders. Journal of Harbin Institute of Technology, 1995, 2(2): 53-55

[12] Zhang W, Wang X, Wang Z. Structural optimization of cylinder-crown integrated hydraulic press with hemispherical hydraulic cylinder.Procedia Engineering,2014,81:1663-1668

[13] Wu Z. Adaptive Control Theory and Its Application. Harbin: Harbin Institute of Technology Press, 2005 (In Chinese)

[14] Hisseine D. Robust tracking control for a hydraulic actuation system. In: Proceedings of the IEEE Conference on Control Applications, Toronto, Canada, 2005. 422-427

[15] Li Y, Huang Y, Yan X. Performance analysis of irreversible reciprocating brayton cycle with variable specific heat of working fluid. Journal of Donghua University (English Edition), 2012, 38(3): 327-331

[16] Wang X, Yu A, Chen W. Optimal matching on driving system of hydraulic hybrid vehicle. Procedia Engineering. 2011, 15: 5294-5298

[17] Liu Z, Gao W, Li J. The research of hydraulic cylinder controlled by digital valve. Indonesian Journal of Electrical Engineering, 2014, 12(5): 3873-3886

Shen Wei, born in 1984. He is a lecture at University of Shanghai for Science and Technology. He graduated from Harbin Institute of Technology from 2014 and got the Ph.D degree. His research area is about the energy saving and control research of the hydraulic system.

10.3772/j.issn.1006-6748.2017.03.009

Supported by the National Natural Science Foundation of China (No. 51505289).

To whom correspondence should be addressed. E-mail: shenwei@usst.edu.cn

on Apr. 28, 2016

杂志排行

High Technology Letters的其它文章

- Quantitative analysis of the performance of vector tracking algorithms①

- Application of linear active disturbance rejection control for photoelectric tracking system①

- Structure design of gradient hard coatings on YG8 and their residual stress analysis by ANSYS①

- ZnO whiskers growth on the surface of Sn9Zn/Cu solder joints in concentrator silicon solar cells solder layer①

- Characterizing big data analytics workloads on POWER8 SMT processors①

- A leveling mechanism for the platform based on booms-constraint control of aerial vehicle①