Polyhedral octakis (trimenthylsiloxy) silsesquioxane /polyimide composite films: mechanical and hydrophobic properties

2017-07-06PENGYonghongZHANGShuaiYINQiangZHUFanghuaLIWaYIYongDUKai

PENG Yonghong, ZHANG Shuai, YIN Qiang, ZHU Fanghua, LI Wa, YI Yong, DU Kai*

(1. Joint Laboratory for Extreme Conditions Matter Properties, Southwest University of Science and Technology, Mianyang, 621010, Sichuan, China; 2. Research Center of Laser Fusion, China Academy of Engineering Physics, Mianyang, 621900, Sichuan, China)

Polyhedral octakis (trimenthylsiloxy) silsesquioxane /polyimide composite films: mechanical and hydrophobic properties

PENG Yonghong1,2, ZHANG Shuai2, YIN Qiang2, ZHU Fanghua2, LI Wa2, YI Yong1, DU Kai1*

(1.JointLaboratoryforExtremeConditionsMatterProperties,SouthwestUniversityofScienceandTechnology,Mianyang, 621010,Sichuan,China; 2.ResearchCenterofLaserFusion,ChinaAcademyofEngineeringPhysics,Mianyang, 621900,Sichuan,China)

Composite films with excellent mechanical and hydrophobic properties are desired for use in inertial confinement fusion (ICF) physics experiments. In this paper, we use the facile solution blending method to synthesize polyhedral octakis (trimenthyl siloxy) silsesquioxane /polyimide (POSS/PI) composite films. The result suggested that the hydrophobic and mechanical properties were significantly enhanced in the presence of POSS. Mechanical results showed the maximum elastic modulus and hardness reached 29.29 GPa and 1.28 MPa respectively for the composite films containing 10% POSS, compared to the pure PI films 14.9 GPa and 0.64 MPa. The composite films showed the contact angles of 83.59° for 20% POSSS included, which is higher than that of pure PI film (66°). As a consequence, the developed POSS/PI composite film showed a great vitality and an extremely wide application prospect in inertial confinement fusion (ICF) physics experiments than pure PI film.

composite film; polyimide; mechanical properties; hydrophobic

1 Introduction

In inertial confinement fusion physics experiments, ultrathin polymer films are commonly used targets for the National Ignition Facility (NIF), typically as various windows or as tents[1]. PI films are chosen as the membranes for the windows because of their unique mechanical properties[2]. Polyimides (PIs) are a kind of important high-performance polymers with broad application in microelectronics[3], composites[4], automobile[5], aerospace[6]because of their unique physicochemical properties, excellent thermal stability, outstanding mechanical properties and good chemical resistance as well as excellent electrical pro-perties[7]. However, it is known that several drawbacks[8], in the molecule have some hydrophilic group[9], may absorption water and the molecular chain not closely related[10]. For some special applications, such as the cryogenic refrigeration technology and inertial confinement fusion (ICF) physics experiment etc., further improvement the properties of PIs are paramount and worthy[11]. In the experiment of ICF, ice adhesion and accumulation on surfaces of the films can bring about severe problems[12]. The active deicing method is building ice-phobic surfaces via eliminating ice formation or reducing ice adhesion.

Polyhedral octakis silsesquioxane (POSS), which is consisted of an inner inorganic silicon-oxygen framework and external trimenthyl siloxy organic substituents, is a kind of advanced organic/inorganic silica hybrid material[13]. In recent years, various researches have showed that the introduction of POSS cages into polymer system can lead to improve strength, rigidity, modulus, impact resistance, thermal oxidation resis-tance and flame retardancy[14]. Such as, JIANG et al. reported reinforced unsaturated polyester composites by chemically grafting amino-POSS onto carbon fibers with active double spiral structural spiralphosphodicholor[15]. LIU et al. have reviewed the interfacial characterization, control and modification of carbon fiber reinforced polymer composites and demonstrated that the enhancement of interfacial adhesion for POSS grafted carbon fiber composites was attributed to the enhanced mechanical interlocking and the chemical bonding on the interface[16].

In recent years, POSS/PI hybrid nanocomposites have been received a great deal of attention[17], but few studies of the applications of POSS/PI hybrid films at hydrophobic were reported. In this work, adequate POSS is doping in the poly (pyromellitic dianhydride-co-4, 4′-oxydianiline) amic acid solution (PAA) solution via a simple solution blending process. We intend to control the containing of the POSS to improve the films mechanical and hydrophobic properties.

2 Experimental

2.1 Materials

The poly (pyromellitic dianhydride-co-4, 4′-oxydianiline) amic acid solution (PAA) solution was purchased from the SIGMA-ALDRICH CO. (USA), and used without further purification. The 1-Methyl-2-pyrrolidinone (NMP, analytical reagent grade) was obtained from Xiya Chemical Industry Co. Ltd. (Shandong, China) and purified by distillation under reduced pressure over calcium hydride and stored over 0.4 nm molecular sieves. The silicon substrate was purchased from China Electric Technology Company of forty sixth Co. Ltd. (China). The POSS was purchased from Hybrid Plastics, (USA). The chemical structure of POSS (Fig.1) monomer is shown below:

Fig.1 Chemical structure of POSS used in this study

2.2 Preparation of pure polyimide film

The pure polyimide film was prepared by spin coating. The process was contains many steps. First, 2 g poly amic acid solution was added to a 25 mL three necks flask which equipped with nitrogen (N2) inlet and mechanical stirrer. Then, some proper NMP was added to the flask and the solid concentration was kept at about 5.0% and the mixed solution was stirred at room temperature under N2(99.999%) for about 6 h to get a homogeneous and transparent solution. Last, the poly amic acid solution was spin-casted on a silicon slide and heated at 80 ℃ to volatile solvent and at 250 and 350 ℃ for 0.5 h respectively to get the pure PI film.

2.3 Synthesis of POSS/PI composite film

A typical procedure for achieving the POSS/PI hybrid films by the three steps (Fig.2) is as follows: the dissolve of POSS, the blending of POSS and PAA and thermal imidization.

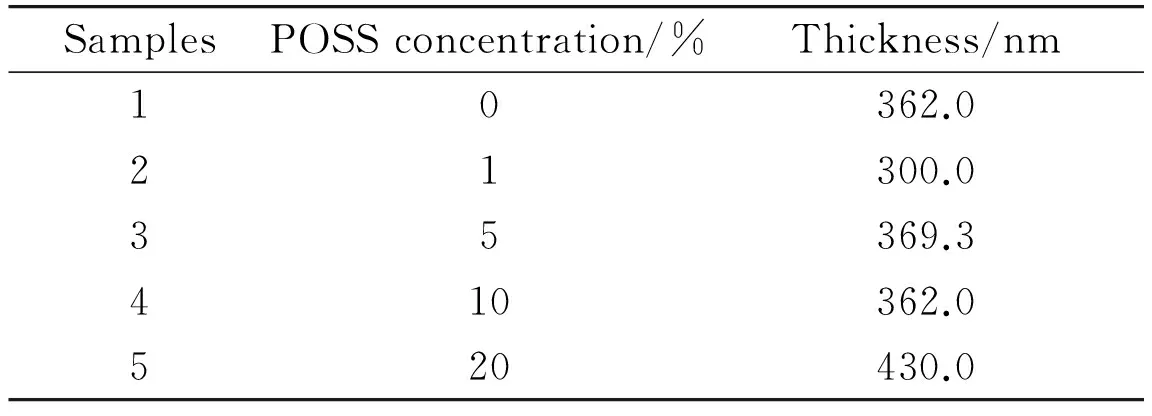

The required quality ratio of POSS and NMP were placed in a 10 mL clean and dried beaker. And then, the beaker was under ultrasonic for 0.5 h at room temperature to gain homogeneous solution. Next, under flowing of N2, the solution was added to the PAA and the system was stirred vigorously for 6 h. Last, the rest steps of preparing the POSS/PI hybrid films were the same as the preparation of pure PI film. The films thickness was shown in the Table 1.

Fig.2 Schematic illustration for the preparation POSS-PI hybrid films

SamplesPOSSconcentration/%Thickness/nm10362.021300.035369.3410362.0520430.0

2.4 Characterization

The microstructures of the samples were charac-terized by diffuse reflectance infrared Fourier transform spectroscopy (FT-IR) (Nicolet Instrument Corporation, USA) and X-ray photoelectron spectroscopy (XPS, PHI-5 400, physical Electronics). The surface morphology of POSS/PI composite films was investigated ZEISS Merlin VP Compact type scanning electron microscope (SEM). 3-D-surface profiles of the composite films were obtained by a vertical scanning WYKO white-light interferometer (WLI) (NT1 100). The mechanical properties of thin POSS/PI films were performed by nanoindentation measurements. All water contact angles were measured at room temperature using a KRÜSS GmbH (Germany) OCA 15pro optical angel measuring system. Water contact angels were measured using 3 μL droplets. Each sample was mea-sure at different 4 positions on the film.

3 Results and discussion

3.1 Structure of the PI and POSS/PI composite films

The chemical structure of PI was measured by FT-IR spectroscopy as given in Fig.3. The peaks at 716, 1 371, 1 716 and 1 774 cm-1are observed in Fig.3, correspond to C=O bending, C-N stretching and C-O stretching, respectively, confirming the formation of imide in the synthesis process[4]. There is no great difference between pure PI, 1% POSS/PI and 20% POSS/PI, it is because POSS particle no reaction with PAA and only as the dopant.

Fig.3 FT-IR curves of (a) Pure PI, (b) 1% POSS/PI and (c) 20% POSS/PIcomposite films

The XPS survey spectra of pure PI and 20% POSS/PI films are shown in Fig.4. As shown in Fig.4, the peaks of C1s, N1s and O1s can be clearly observed on the spectra of PI and POSS/PI composite films. In the Fig.4b can observed week Si2p peak, which confirms the existence of Si element in the POSS/PI composite film. Fig.5a shows the detailed C1s XPS spectra of PI and composite films. As shown in Fig.5b The component peaks of 1, 2, 3 are assigned to the C-C, C-N and C-O bonds,respectively[4].

Fig.4 XPS curves of (a) Pure PI and (b) 10% POSS/PI composite films

Fig.5 (a)C1 s XPS spectra of PI and 10% POSS/PI. (b)peak separation of pure PI curves

3.2 Surface roughness and surface morphologies

The WLI technique can characterization the surface topography features accurate quantitative[18]. The root-mean-square roughness (Rq) is one of the important parameters to evaluate the film surface morphology, and can indirectly reflect the structure characteristics of the films. The results of the WLI are presented in Fig.6(a)-(e). The surface roughness evolution with different contents of POSS is shown in Fig.6(f). The pure PI Rq only have 2.76 nm, this is because through spin-coating can get equably thickness surface[19]. But with the increases of POSS, the Rq of the films increases rapid. This is because the POSS dispersed and increased the roughness of the films. As shown in Fig.6d, the Rq of 10% POSS up to 159.54 nm. But when the POSS increase to the 20%, the particle can fanning in the films surface and the Rq only have 125.18 nm.

Fig.6 Surface image WLI interferometer:(a) pure PI, (b) 1% POSS/PI, (c) 5% POSS/PI, (d) 10% POSS/PI, (e) 20% POSS/PI. (f) The root-mean-square roughness (Rq) of the composite films at different contents of POSS

Fig.7 SEM images of the surface morphologies of (a) neat PI film, (b) 20% POSS film, (c) POSS; the fracture morphologies of (d) neat PI film, (e) 20% POSS film

SEM is usually used to observe the failure and surface structures of specimens. In order to make specimens electrically conductive, the PI composite films were coated with gold by vacuum sputtering in advance. Fig.6 shows the SEM surface and failure micrographs of the pristine PI and 20% POSS/PI composite films. The pure PI surface (Fig.7a) is smooth, only several bright dots, which are attributed to the dirt, can be observed. In the surface of 20% POSS/PI composite films (Fig.7d), we can clearly observe POSS aggradation. This can improve the roughness of the film as shown in Fig.6e. On the fracture surface of pure PI (Fig.6b), we can clearly observe some plastic deformed veins which correspond to shrinkage deformation of the film as a homogenous material[20]. But the 20% POSS/PI composite films (Fig.7e) fracture surface plastic deformed veins decline. This is because POSS have rigidity loop, the POSS mix in the films, the rigidity improve and shrinkage decrease and we also can clearly observe the POSS concentration in the PI films. The surface of POSS particle is shown in Fig.7c.

3.3 Water contact angle measurements

The combination of appropriate surface roughness and surface chemistry is crucial to the preparation of hydrophobic surfaces. Vogler defined hydrophobic surfaces (CA higher than 65°) and hydrophilic surfaces (CA less than 65°) based on the observation that there are two distinct kinds of water structure and reactivity, which was revealed by using a surface force apparatus and ancillary techniques[21]. The water contact angle measurements on pure PI and POSS/PI composite films were carried out to evaluate the hydrophobic performance of each surface and the results are plotted in Fig.8. The contact angle of pure PI is 65°, with the increase of POSS content, the contact angles of POSS/PI films are slightly higher than pure film. This is due to units of POSS structures migrating to the external surface during the film formation and the POSS have low surface tension[22]. The contact angles of the POSS/PI films are 66.2°±1.4° (1%), 72.8°±1.2° (5%), 79.33°±0.75° (10%) and 83.59°±1.65° (20%), respectively. This phenomenon as confirmed by WLI and SEM.

Fig.8 Effect of POSS content on the water contact angles of POSS/PI composite films

3.4 Mechanical properties of POSS/PI composite films

The mechanical properties of composite films were measured by nanoindentation measurements (TRIBOIN DENTER) using the continuous stiffness measurement technique. This technique is the most reliable method which has been widely used for evaluating the mechanical properties of thin films from the load-displacement curves of the indenter[23]. Fig.8 indicates load and unload curves at maximum indentation load of 200 μN for composite films. It is observed that the pure PI (Fig.9d) has broader hysteresis curve and lower recovery during unloading. On the other hand, the composite films reveal lower hysteresis and higher recovery during loading-unloading curves. Furthermore, the hysteresis decreases and recovery enhances with increasing of POSS. The observed hysteresis decrease and recovery enhancement may be attributed to the Young’s modulus of POSS is higher than that of PI matrix epoxy groups. The load-displacement curves are also used to determine the hardness and elastic modulus. In order to avoid substrate effects in the nanoindentation measurements, the indenter penetration depth for our samples did not exceed about 35% of the total film thickness[24]. The elastic modulus and hardness increases with the increase content of POSS. As we know, the hardness is determined by the structure of the film. The values of elastic modulus and hardness for samples are found in Table 2. The maximum of elastic modulus and hardness is 29.29 GPa, 1.28 MPa respectively.

Table 2 Elastic modulus and hardness of the composite films

4 Conclusions

Different quality ratios of POSS cage mixture are introduced to the PAA solution and obtained 5 composite films. We investigate the relationship of the additive amounts of POSS with the mechanical and hydrophobic properties of hybrid systems. It is observed that the existence of POSS increased the mechanical and hydrophobic properties of the systems. Mechanical results showed the maximum elastic modulus and hardness reached 29.29 GPa and 1.28 MPa for the composite films containing 10% POSS, compared to those of pure PI films. The composites show the contact angles of 83.59° for 20% POSSS included film, which is higher than that of pure PI film (66°). This method is very simple, and the resultant with excellent mechanical performance and increase the hydrophobic of the composite film, holding great potential in a wide range of applications, especially at ICF experiment.

[1] SU B, TIAN Y, JIANG L. Bioinspired interfaces with superwettability: From materials to chemistry [J]. Journal of the American Chemical Society, 2016, 138(6): 1727-1748.

[3] YEO H, GOH M, KU B C, et al. Synthesis and characterization of highly-fluorinated colorless polyimides derived from 4,4′-((perfluoro-[1,1′-biphenyl]-4,4′-diyl)bis(oxy))bis(2,6-dimethylaniline) and aromatic dianhydrides [J]. Polymer, 2015, 76: 280-286.

[4] ZHANG P P, ZHAO J P, ZHANG K, et al. Fluorographene/polyimide composite films: Mechanical, electrical, hydrophobic, thermal and low dielectric properties [J]. Composites Part A: Applied Science and Manufacturing, 2016, 84: 428-434.

[5] LIAW D J, WANG K L, HUANG Y C, et al. Advanced polyimide materials: Syntheses, physical properties and applications [J]. Progress in Polymer Science, 2012, 37(7): 907-974.

[6] WOZNIAK A I, YEGOROV A S, IVANOV V S, et al. Recent progress in synthesis of fluorine containing monomers for polyimides [J]. Journal of Fluorine Chemistry, 2015, 180: 45-54.

[7] ZhANG Y H, LUO P, YAO H Y, et al. Synthesis and characterization of fluorinated polyimide oligomers terminated with a phenylethynyl group [J]. Reactive and Functional Polymers, 2012, 72(9): 621-626.

[8] WANG C Y, ZHAO X Y, LI G C, et al. High optical transparency and low dielectric constant of novel soluble poly-imides containing fluorine and trifluoromethyl groups [J]. Colloid and Polymer Science, 2011, 289(14): 1617-1624.

[9] HUANG J Y, ZHENG Y X, LUO L B, et al. Facile preparation of highly hydrophilic, recyclable high-performance polyimide adsorbents for the removal of heavy metal ions [J]. Journal of Hazardous Materials, 2016, 306: 210-219.

[10] CHUANG M J. Carbon tetrafluoride plasma modification of polyimide: A method of in-situ formed hydrophilic and hydrophobic surfaces [J]. Surface and Coatings Technology, 2009, 203(23): 3527-3532.

[11] GHOLAM A K. Synthesis and characterization of new disperse-red functionalized polyimide for use as nonlinear optical material [J]. Designed Monomers & Polymers, 2012, 15(3): 275-288.

[12] ZHANG K Q, LI X H, ZHAO Y H, et al. UV-curable POSS-fluorinated methacrylate diblock copolymers for icephobic coatings [J]. Progress in Organic Coatings, 2016, 93: 87-96.

[13] LI Z Q, LI D H,YANG R J. Synthesis, characterization, and properties of a novel polyhedral oligomeric octamethyldiphenylsulfonylsilsesquioxane [J]. Journal of Materials Science, 2014, 50(2): 697-703.

[14] GAO B, ZHANG R L, HE M S, et al. Interfacial microstructure and mechanical properties of carbon fiber composites by fiber surface modification with poly(amido-amine)/polyhedral oligomeric silsesquioxane [J]. Composites Part A: Applied Science and Manufacturing, 2016, 90: 653-661.

[15] JIANG D W, LIU L, LONG J, et al. Reinforced unsaturated polyester composites by chemically grafting amino-POSS onto carbon fibers with active double spiral structu-ral spiralphosphodicholor [J]. Composites Science and Technology, 2014, 100: 158-165.

[16] LIU L, JIAC Y, HE J M, et al. Interfacial characterization, control and modification of carbon fiber reinforced polymer composites [J]. Composites Science and Technology, 2015, 121: 56-72.

[17] ATA S, BANERJEE S L, SINGHA N K, et al. Polymer nano-hybrid material based on graphene oxide/POSS via surface initiated atom transfer radical polymerization (SI-ATRP): Its application in specialty hydrogel system [J]. Polymer, 2016, 103: 46-56.

[18] BARSHEV S V, ZINOVEV A V, TRIPA C E, et al. White light interferometry for quantitative surface characterization in ion sputtering experiments [J]. Applied Surface Science, 2012, 258(18): 6963-6968.

[19] WANG D, LIU H, HE J H, et al. Progress in preparation of functional films by spin-coating [J]. Imaging Science and Photochemistry, 2012, 30(2): 91-101.

[20] WEI S H, WU X J, DU K, et al. Preparation, thermal and mechanical properties of POSS/PI hybrid films for cryogenic applications [J]. Chemical Research, 2016, 27(6): 771-778.

[21] VOGLER E A. Structure and reactivity of water at biomaterial surfaces [J]. Advances in Colloid and Interface Science, 1998, 74: 69-117.

[22] LI B, LI X H, ZHANG K Q, et al. Synthesis of POSS-containing fluorosilicone block copolymers via RAFT polymerization for application as non-wetting coating materials [J]. Progress in Organic Coatings, 2015, 78: 188-199.

[23] OLIVER W C, PHARR G M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments [J]. Journal of Materials Research, 1992, 7(6): 1564-1583.

[24] ISHPAL, KUMAR S, DWIVEDI N, et al. Investigation of radio frequency plasma for the growth of diamond like carbon films [J]. Physics of Plasmas, 2012, 19(3): 033515.

[责任编辑:张普玉]

低聚倍半硅氧烷/聚酰亚胺复合薄膜的力学性能和疏水性能

彭永虹1,2,张 帅2,尹 强2,朱方华2,李 娃2,易 勇1,杜 凯1*

(1.西南科技大学 极端条件物质特性联合实验室,四川 绵阳 621010;2.中国工程物理研究院 激光聚变研究中心,四川 绵阳 621900)

具有优良的力学和疏水性能的复合薄膜在惯性约束物理实验中具有重要作用. 在本文中,我们使用简单的溶液混合的方法合成了低聚倍半硅氧烷/聚酰亚胺(POSS/PI)复合薄膜. 结果表明由于POSS的引入,力学性能和疏水性能显著增强. 力学测试结果显示,当POSS质量分数为 10% 时,弹性模量和硬度分别达到29.29 GPa和29.29 MPa,相比纯的PI薄膜为14.9 GPa和0.64 MPa. 同时,当POSS质量分数为20%,复合薄膜的接触角为83.59°,明显高于纯的PI薄膜(66°). 因此,POSS/PI复合膜比纯PI薄膜显示了强大的生命力和极其广阔的应用前景在惯性约束聚变(ICF)物理实验中.

复合薄膜;聚酰亚胺;力学性能;疏水性

, E-mail:qyin89@sina.com.cn.

O633 Document code: A Article ID: 1008-1011(2017)03-0378-08

Received date: 2017-01-03.

Biography: PENG Yonghong(1992-), female, majoring in the materials research.*