CMJY-1500型农田残膜捡拾打包联合作业机设计与试验

2017-06-05陈学庚周敦兴

赵 岩,郑 炫※,陈学庚,牛 琪,纪 超,周敦兴

·综合研究·关键技术·

CMJY-1500型农田残膜捡拾打包联合作业机设计与试验

赵 岩1,郑 炫1※,陈学庚1,牛 琪2,纪 超1,周敦兴3

(1. 新疆农垦科学院机械装备研究所,石河子 832000;2. 中国农业大学工学院,北京 100083;3. 新疆科神农业装备科技开发股份有限公司,石河子 832000)

为降低残膜储运成本,提高机收残膜回收利用率,研究设计了CMJY-1500型农田残膜捡拾打包联合作业机。机具主要由捡拾机构、脱膜机构、打包机构、传动系统、地轮、机架等组成,可同时完成集条残膜的自动捡拾、杂质分离与打包成型作业。根据捡拾机构结构特征与作业原理,建立捡拾机构与物料对象动力学模型,分析获得了核心弹齿最佳空间排布形式与优选安装倾角45°。为降低残膜物料土壤掺杂量,基于残膜与杂质尺寸密度及缠绕特性差异,开发了离心分离与振动分离相结合的多级膜土分离系统,提高了捡拾物料压缩比,减小打包作业压缩阻力。设计了液压驱动式电控打包机构,残膜经打包机构压缩成型,以方包形式卸料,利于装载运输。2015年10月于兵团第六师共青团农场,对残膜捡拾打包机进行了40 hm2实地田间作业性能测试,试验结果表明:机具残膜捡拾净率达92.8%,打包成捆率高于94%,单包成型耗时58 s,残膜捡拾打包联合作业机作业效果良好的、系统稳定,具有较高的应用推广价值。

农业机械;设计;试验;残膜;捡拾;清理;打包;联合作业

0 引 言

地膜覆盖技术因其良好的增产保墒效果被广泛应用于中国粮食、经济作物的种植作业中,现全国覆膜种植面积已达2 000万hm2。在常年覆膜种植的地区,农田土壤中残膜累积量逐年递增,其带来的白色污染已严重影响到作物正常生长,对农业生产的可持续发展构成了极大威胁[1-6]。针对该问题,一是人工捡拾较大片的地表残膜,但效率低、强度大、成本高;二是机械回收。国内研发的残膜回收机械类型诸多,主要有勾耙式、弹齿式、伸缩杆齿式、铲式、卷收式等[7-11]。其中,勾耙式残膜回收机能够实现残膜聚拢,但不能在回收过程中清理残茬、土壤等杂质[12-14];弹齿式在脱膜过程中需为收膜弹齿配置用于控制工作位置的曲线轨迹滑道,加工难度较大,捡拾过程会撕裂膜面产生碎膜,缠绕转动部件[15-19];伸缩杆齿式的捡拾滚筒结构复杂,造价偏高[20-25];铲式起茬收膜部件对土壤的性能有一定要求,且所收残膜与作物根茬混合难分,膜土分离效果较差,给残膜的再生利用带来困难[26-28];苗期回收方式不适宜回收厚度小于0.008 mm的农田残膜[29-32];链耙式残膜回收部件作业效果较好,但工作效率低、故障率高,整机可靠性难以保证[33-37]。上述机具主要以回收残膜作业为主,功能较为单一。为提高农田耕作效率,开发可同时完成收膜、秸秆还田等多种功能的联合作业机逐渐成为残膜回收机具研究的新趋势[38-41]。不论单一作业抑或联合作业,经机械回收后的残膜多以集条或集堆形式置于田间,后续被焚烧或掩埋处理,不仅污染大气环境,而且破坏土壤生态。随着人们对生态环境的日益重视,对回收残膜进行再利用必将成为一种趋势[42]。

目前以新疆生产建设兵团(以下简称兵团)为代表的新疆棉区普遍采用立杆搂膜机进行秋后回残膜回收。在进行立杆搂膜作业前,先用秸秆粉碎还田机沿垂直于棉行方向,间隔50 m开出宽3 m的行道,作为卸膜处和残膜转运通道。该方法作业效率高、产生粉尘少,但回收后的残膜质地松散,占用空间大,易受大风天气影响,人工转运劳动强度大,不利于残膜的回收再利用。为解决该问题,研制了CMJY-1500型农田残膜捡拾打包联合作业机,可同时完成残膜捡拾、清理与压缩打包作业,不仅利于回收残膜的即时储运,并且为开展回收残膜的集中处理与再利用提供有效的装备支撑,故具有很好的应用前景。

1 整机结构与工作原理

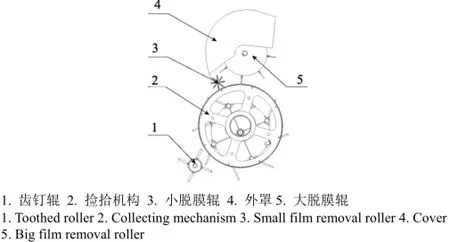

1.1 整机结构

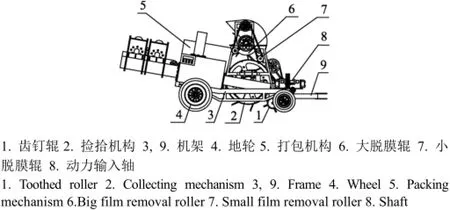

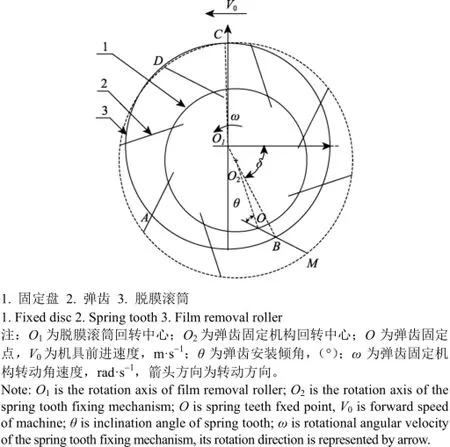

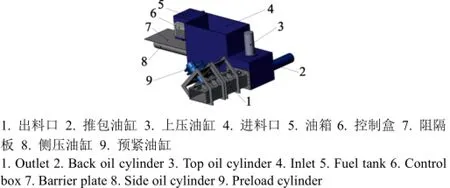

CMJY-1500型农田残膜捡拾打包联合作业机主要由捡拾机构、脱膜机构、打包机构、传动系统、地轮和机架等组成,如图1所示。其中,捡拾机构包括弹齿、弹齿固定机构和脱膜滚筒,弹齿固定机构与脱膜滚筒为偏心配置,弹齿脱膜滚筒下部偏前进方向伸出长度达到最大。脱膜机构由脱膜辊筒、刮板、外罩组成,打包机构包括3个液压油缸、液压系统、控制系统、打包箱体。

图1 整机结构示意图Fig.1 Structural diagram of whole machine

1.2 工作原理

机具作业由拖拉机牵引连接机架的牵引架行进,旋转的齿钉辊将混有土壤、秸秆和残膜的物料抛起,捡拾机构将残膜钩起,向上输送至脱膜辊筒下部,弹齿缩进脱膜滚筒内,小脱膜辊与大脱膜辊将输送的残膜拨送至后部的打包机构的打包箱体内,待残膜储存到一定量的时候,启动液压油缸控制系统进行压缩,最后在油缸推力作用下推出,掉落到地面。整机动力由拖拉机后动力输出轴通过万向节传输给动力输入轴,传动给整机捡拾机构、脱膜机构和液压系统。

1.3 主要技术指标

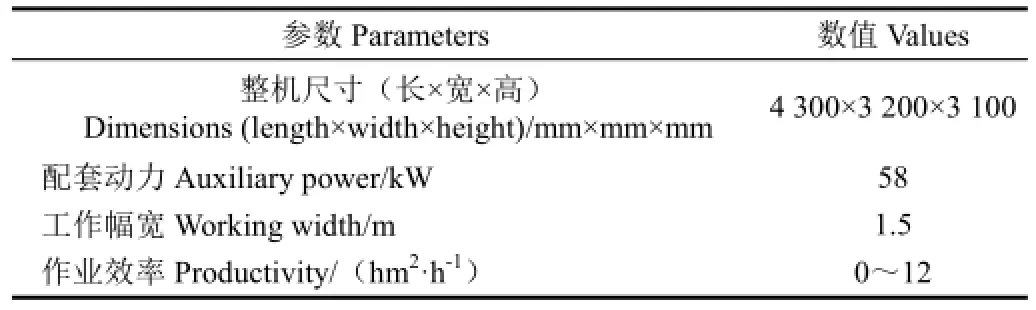

本机具用于采用搂膜作业机具搂膜集条后的农田残膜,一次作业可以实现捡拾、压缩和打包联合作业。其主要技术参数如表1所示。

表1 主要技术指标Table1 Main technical parameters

2 主要部件设计

2.1 捡拾机构

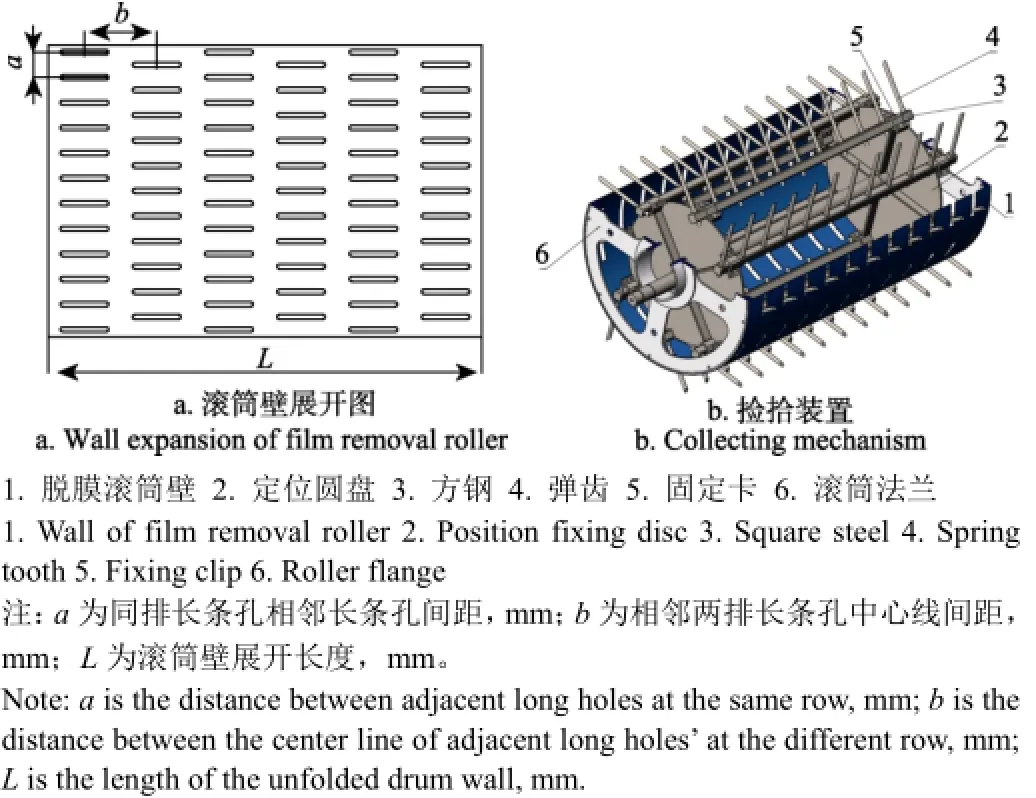

2.1.1 捡拾机构主要结构

直齿型弹齿滚筒机构在残膜回收机中得到了较普遍的应用[43]。如图2所示,捡拾机构主要由脱膜滚筒、定位圆盘、方钢、固定卡和弹齿等部件组成。弹齿安装在弹齿固定机构上,脱膜滚筒均布长条孔。作业时,动力由皮带轮带动弹齿随弹齿固定机构转动,弹齿固定机构通过连杆机构带动脱膜滚筒转动。通过上下调整拖拉机下悬挂臂调节捡拾弹齿与地面间的距离大小。

弹齿固定机构与脱膜滚筒为偏心配置,弹齿设置方向为圆周方向,每组弹齿沿轴向直线均布呈发散状排列,在滚筒上的长条孔内伸缩,在脱膜滚筒下部伸出,在上部缩进其内部,实现残膜捡拾、输送和脱膜的作业过程。设计的弹齿安装有一定倾角,利于弹齿在运动过程中顺利将地面残膜挑起。

图2 捡拾装置示意图Fig.2 Diagram of collecting device

弹齿是材料为65 Mn的圆钢,直径为12 mm,长度为308 mm,顶部处理成45°斜平面,固定端设计有螺纹,通过自锁螺母安装固定在钻孔方钢上。方钢边长30 mm,钻有为直径为15 mm的通孔,中心距为110 mm,每4个方钢一组,分别有11个和12个安装孔。方钢由定位卡固定在定位圆盘上,定位圆盘直径为660 mm,圆周方向均布焊接有8个安装卡槽,通过螺栓与定位卡配合将方钢安装定位。弹齿倾斜角度由定位圆盘上的安装卡槽的焊接角度确定。4组有11个安装孔的方钢一端设计有轴头,通过连杆与滚筒法兰连接。脱膜滚筒壁设计有长条孔,弹齿穿过长条孔。固定盘与滚筒法兰安装到位后呈偏心配置,偏心距为75 mm。

2.1.2 捡拾机构运动分析

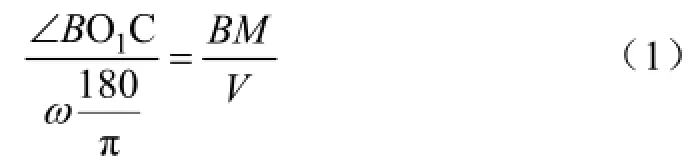

如图3中所示,固定盘和脱膜滚筒简化圆O1和O2的连心线与弹齿尖运动轨迹圆交于D点和M点。分析可知,弹齿在M点伸出距离最长,在D点伸出距离最短。在转动过程中,在偏心装配的作用下,弹齿在脱膜滚筒上的长条孔内产生相对运动。沿转动方向,由D点到B点过程中,弹齿逐渐伸长,A点距离地面理论距离

200 mm,弹齿开始接触并钩挂物料,在脱膜滚筒下部B点处弹齿伸出长度最大。由B点向D点运动过程中,弹齿钩挂物料沿脱膜滚筒壁向上输送,弹齿伸出长度逐渐变小,从C点开始完全缩进滚筒内部。圆心角BO2M对应的弧为的弹齿与脱膜滚筒接触的轨迹,该弧长为75 mm,为避免作业过程中弹齿与脱膜滚筒壁发生剐蹭,滚筒壁上所开长条孔长度应大于该弧长,宽度应大于弹齿直径。考虑到弹齿安装间隙、作业中受力变形等因素,设计长条孔宽25 mm,长300 mm。

分析可知,当O1和O2的偏心坐标以及弹齿安装位置点O确定时,安装倾角θ越大,BO2与水平线的夹角δ和弹齿尖轨迹圆O2半径就越小,根据经验,θ应满足0°≤θ≤90°。分析可知,弹齿上B点物料的运动可为沿机具前进速度V0、沿弹齿运动的速度V和绕O2圆周方向转动等3个运动叠加的复合运动。如图3所示,以O2为原点建立平面直角坐标系,分析弹齿与脱膜滚筒壁相交处的物料由B点到C点的运动过程。V1为弹齿上B点物料绕O2作匀速圆周运动瞬时线速度,方向与O2B垂直。若以机架为参考,物料在绕O2点做圆周运动的同时,在脱膜滚筒壁的作用下,由B点运动到弹齿尖M点运动。弹齿由B点转到C点的同时,物料沿弹齿由B点移动到M点,二者运动时间相等:

图3 捡拾机构运动分析Fig.3 Dynamic analysis of collecting mechanism

已知捡拾机构转速为60 r/s,可知脱膜滚筒转动角速度ω为6.28 rad/s。用作图法测定∠BO1C为154°,线段BM长度为165 mm。将数据代入式(1),计算得出物料沿弹齿运动时间为0.43 s,速度V为0.38 m/s。这说明,在捡拾机构转动过程中,弹齿缩进脱膜滚筒壁,该机构的设计具有将弹齿上的物料脱下的功能。

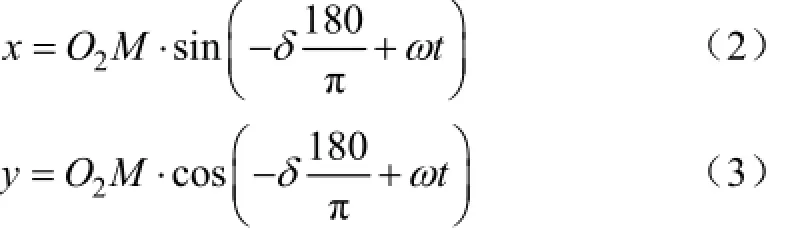

若以机架为参考系,则弹齿尖处M点物料运动轨迹为图中虚线圆。以O2为原点建立直角坐标系,t为机具作业时间,s,建立M点物料的坐标方程为:

上式中,已知O2M设计长度为475 mm,ω为6.28 rad/s测定δ为62°,对应弧度为1.08 rad代入(2)、(3),得到如下方程:

已知机具前进速度V0为0.18 m/s,则B点相对于地面的运动轨迹方程为:

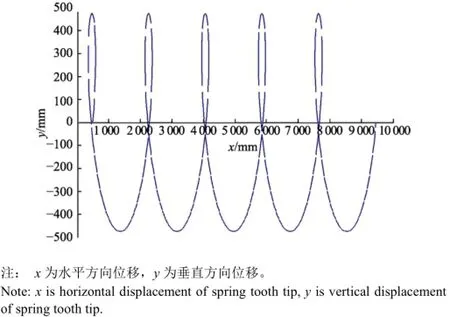

利用Matlab软件绘制弹齿尖部M点物料5 s内运动轨迹,结果如图4。

图4 弹齿尖运动轨迹Fig.4 Movement track of spring tooth tip

弹齿尖运动轨迹坐标系中,x为运动轨迹横坐标,y为运动轨迹纵坐标。仿真结果表明,弹齿尖运动轨迹为余摆线,弹齿尖轨迹最低点间距为180 mm。捡拾机构设计为圆周均布2种4组弹齿,说明在实际作业过程中,在180 mm范围内弹齿可以完成捡拾残膜作业4次,能够保证较高的拾净率。

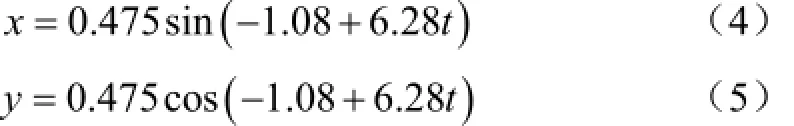

2.1.3 弹齿上物料受力分析

如图所示,以弹齿尖M点为原点,在垂面上沿水平竖直方向建立直角坐标系,在捡拾机构作业过程中,弹齿尖点G处的物料受力情况如图5所示。

图5 物料受力分析图Fig.5 Force diagram of materials

物料随弹齿运动条件为:

式中F为物料所受摩擦力,N;FV为物料所受离心力,N。

其中,离心力FV由下式计算:

式中ϕ为滚筒角速度,rad/s;m为物料质量,kg;r为物料运动轨迹圆半径,m。

摩擦力F由下式计算:

式中G为物料所受重力,N;μ为物料在弹齿的摩擦系数;N为物料所受弹齿支反力,N。

物料所受支反力N可由下式计算:

式中β为弹齿与垂线的夹角,(°)。

分析可知,在同等条件下,当α一定时,弹齿安装倾角θ与β正相关,θ越大,物料所受摩擦力F越大。但过大会影响从脱膜滚筒长条孔的伸缩通过性能,过小会影响弹齿挑膜的效果。田间试验证明,当θ大于55°时,物料在输送出现弹齿勾扯残膜从滚筒长条孔进入滚筒内部的现象,物料中土壤和秸秆比例增加,脱膜效果明显下降,出现卡滞现象,甚至导致弹齿或长条孔周边滚筒外壁变形;当θ小于30°时,弹齿的捡拾功能降低,地膜残膜残留量增加,拾净率降至70%以下。综合考虑,取弹齿安装倾角θ=45°。

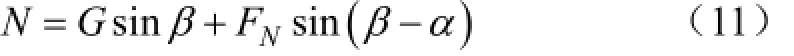

2.2 多级膜土分离机构

搂膜耙集条后的物料中混有约占总质量40%的土壤,影响捡拾打包作业,给后期残膜处理和加工带来困难。为此,研究设计多级膜土分离机构。如图6所示,膜土分离系统由齿钉辊、捡拾机构、小脱膜辊、大脱膜辊和外罩构成。

图6 膜土分离系统Fig.6 Separating system of plastic film and soil

机具作业时,高速逆时针旋转的齿钉辊将物料捡拾、抛起,在离心力作用下,残膜和土壤实现一次分离;捡拾滚筒逆时针旋转,捡拾弹齿将残膜捡拾勾扯住沿滚筒壁输送,泥土在机具运转产生振动和自身重力作用下掉落,实现膜土第2次分离;脱膜滚筒顺时针旋转,将输送到滚筒上部的物料沿外罩内壁向上输送,脱膜机构的外罩轮廓线采用渐开线设计,脱膜辊转动过程中,在离心力的作用下,残膜中含有的的泥土杂质和其他大密度颗粒脱离,甩出通孔或撞到外罩内壁掉落,实现膜土第3次分离。捡拾弹齿轨迹圆直径为1 090 mm,捡拾滚筒外壁直径为1 000 mm。齿钉辊轨迹圆直径为400 mm,与捡拾弹齿轨迹圆的圆心距为1 300 mm。

脱膜滚筒的半径越大,物料输送距离越长,在机具作业过程中,部件运转和地表高低起伏变化等作用会产生振动,由于密度的差异,在重力作用下实现捡拾残膜中夹杂的尘土、石块等物料的清理,减少杂质含量,提高捡拾物料压缩比,减少打包作业的压缩阻力。但如果直径太大将会影响整机部件的布局,造成动力损耗增加。综合分析机具结构空间布局和动力匹配的合理性,通过试验验证,设计捡拾机构转速为60 r/min,齿钉辊转速为90 r/min。

大脱膜辊设有多个刮板,刮板运动轨迹圆与捡拾机构的脱膜滚筒外壁圆连心线约等于两圆半径之和,作业时刮板与脱膜滚筒接触,能将脱膜滚筒外壁上捡拾的残膜顺利剥脱,随后输送到后部打包机构喂料口。大脱膜辊设计转速为300 r/min,运动轨迹圆直径为650 mm。小脱膜辊设计转速为900 r/min,轨迹圆直径为120 mm。弧形外罩轮廓线为渐开线设计,向后方向为敞口,后壁均布直径为20 mm的通孔,残膜中含的尘土杂质可以从中甩出。

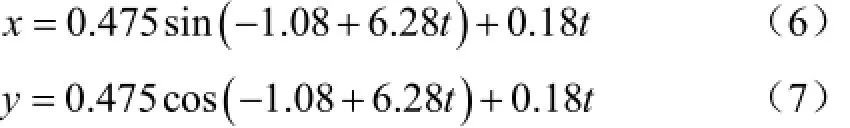

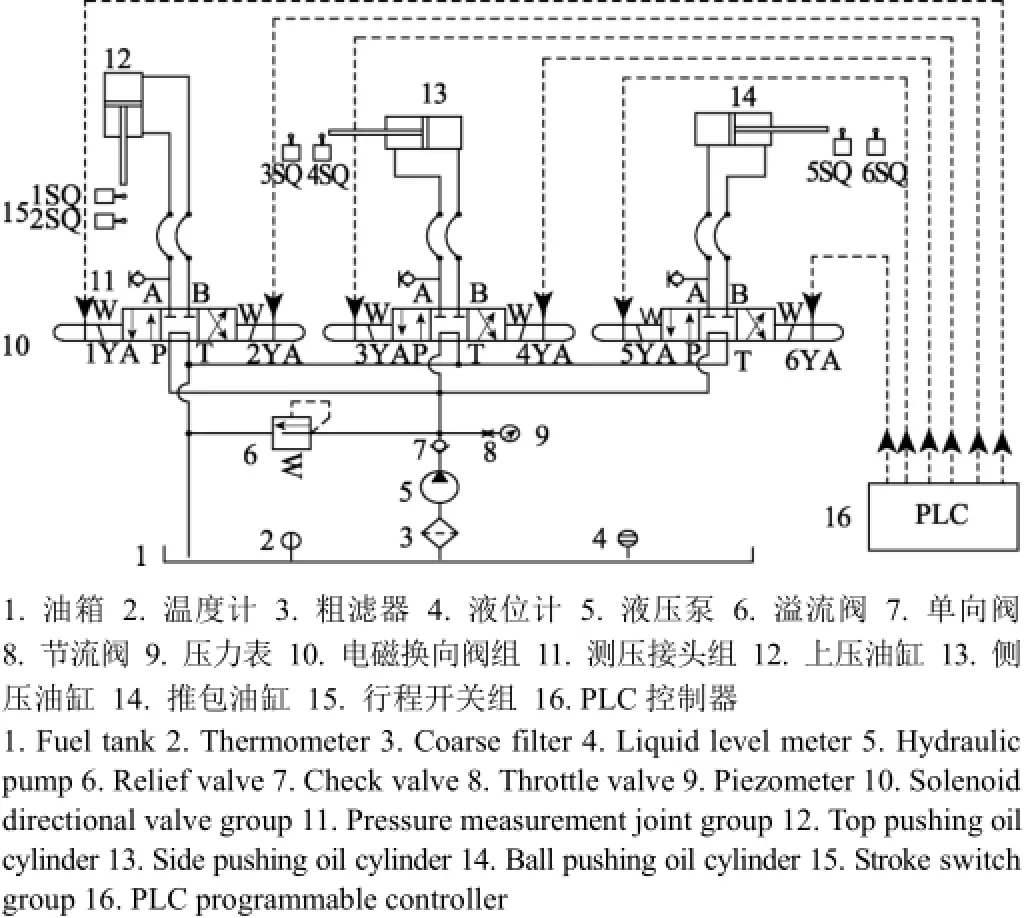

2.3 打包机构

打包机构位于脱膜机构的后方,其结构包含进料口、侧压油缸、上压液压油缸、推包油缸,预紧油缸等部分组成,在打包箱体上方设有进料口,后部设有出料口。通过PLC程序控制电磁阀的开关状态,控制3个液压油缸依次作业。打包作业的控制模式有自动、半自动和手动3种。自动模式下,打包程序不间断循环作业;半自动模式下,触发1次开关完成1个作业循环;手动模式下,点触开关控制3个油缸进退。

图7 打包机构结构图Fig.7 Structural diagram of balling mechanism

打包作业时,残膜由进料口进入打包箱体,侧压油缸首先启动,将打包箱体内残膜压缩至近出料口一端,压缩到位后触发行程开关,上压油缸启动,将打包箱体内压缩后残膜向箱底方向压缩,二次压缩到位后触动行程开关,推包油缸启动,将二次压缩后的残膜由残膜包出口推出,完成打包作业。推包油缸到位后,触发行程开关,推包油缸、上压油缸和侧压油缸依次退回,退到位后触发行程开关,停止运行,完成打包作业的一个循环。

打包作业单次循环时间为58 s,通过系统设置,2次作业间隔时间在0~300 s范围内可调。箱体内物料的质量与间隔时间成正比关系。通过田间试验测试,循环间隔时间设定为9 s时,残膜捡拾较为干净,打包作业过程顺畅,打包成型后膜包松紧度适中且不会散开。

图8 打包机构液压控制系统Fig.8 Hydraulic control system of balling mechanism

3 田间试验

3.1 田间准备

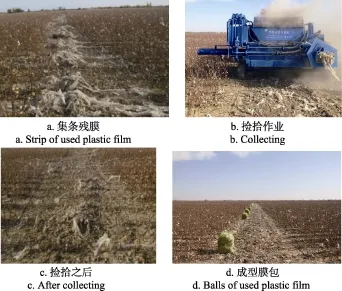

2015年4月在新疆玛纳斯县六户地进行了春播前棉田残膜捡拾打包试验,试验面积为10 hm2。2015年10月,在兵团第六师共青团进行秋收后田间试验,试验面积40 hm2。试验田前茬种植作物为棉花,滴灌管带和滴灌设备已清理,栽培模式行距为宽窄行配置(660 mm+ 100 mm),棉杆高度750~850 mm,株距95 mm。

秸秆粉碎还田机沿垂直棉行方向,开出一条3 m宽卸膜道,相邻卸膜道间距50 m。利用立杆式残膜回收机顺棉行方向搂膜,将搂好的残膜以集条形式卸于卸膜道内(图9a),集条宽度标准为1 500 mm,供残膜捡拾打包联合作业机进行作业试验。

图9 田间试验Fig.9 Field experiment

3.2 结果与分析

试验机具在拖拉机牵引下沿卸膜道行走,同时完成残膜捡拾、打捆出包等动作。行走速度为3.7 km/h,作业幅宽1 500 mm,捡拾物料宽度1 300~1 800 mm,物料主要成分为土壤、秸秆和残膜,铺放厚度50~150 mm,单次连续行走距离85 m。

试验证明,机具各部件运转良好,动作执行顺畅,残膜捡拾干净、残余量少(图9b),成型方包紧实、不易松散,且能够长时间保持固定形状(图9c),单次打包作业循环平均耗时58 s。

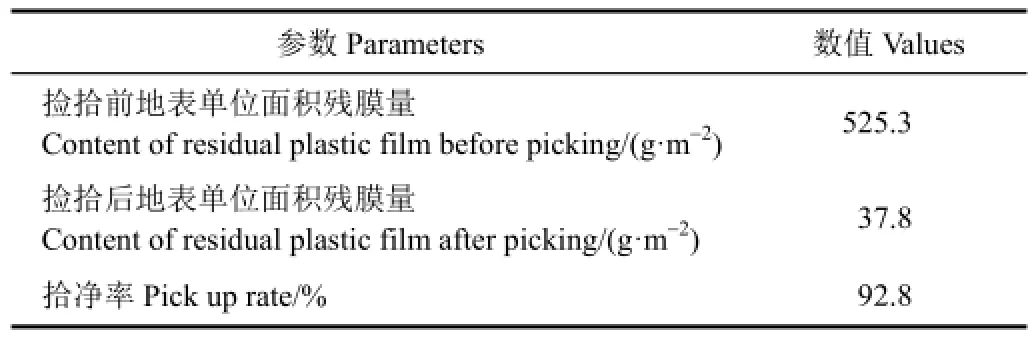

3.2.1 拾净率

参考《GB/T 25412-2010 残地膜回收机》,制定试验测试方案。机具在长度不小于50 m的作业区内往返测试10个行程,每个行程内随机选取2段长度为10 m的试验区进行试验样本采集,5次重复试验。残膜取样清洗晾干后称质量,仪器为JAS5003A电子精密天平秤(精度0.000 1 g),各参数取平均值。

残膜拾净率计算公式如下:

式中C为残膜拾净率,%;W为机具回收残膜质量,g;W0为地表地膜总质量,g。试验结果表2所示。

表2 残膜捡拾试验结果Table2 Result of collecting plastic film residue

测试结果表明,机具具有较好的捡拾效果,地表集条残膜捡拾率约为92.8%。产生残膜捡拾遗漏的主要原因,一是捡拾弹齿设计间距略宽,部分长度小于60 mm的残膜在随弹齿提升过程中从弹齿缝隙中掉落;二是拖拉机行走路线偏出铺放中心线,导致某一侧边100~200 mm范围内残膜漏捡。

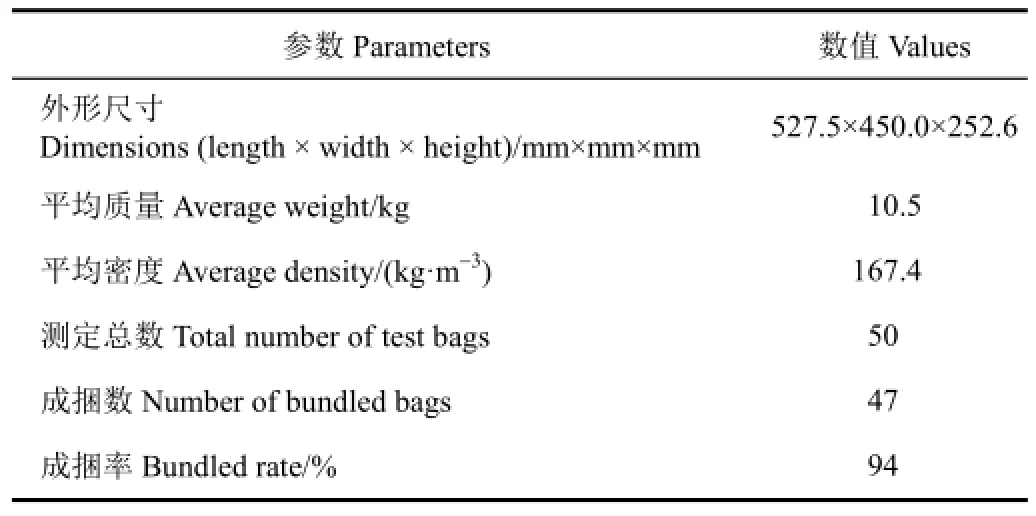

3.2.2 成捆率

参考《GBT14290-1993 圆草捆打捆机试验方法》试验标准,选择机具持续作业面积不低于5 hm2的测试区5个,每个测试区选取连续卸料的10个残膜包作为检测对象,计算数据采用各测试区测试值的总和[23]。

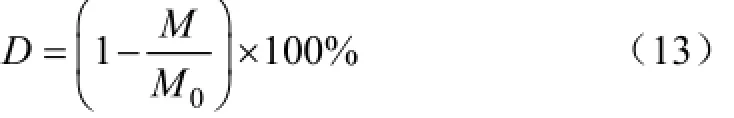

成捆率计算公式如下:

式中D为成捆率,%;M为成型包总数;M0为打包总数。

试验结果表明,整机运转过程中未出现打捆系统卡滞现象,成型方包紧实、不易松散,所收成捆率达94%,表3所示。造成残膜未能打包成捆的原因主要有:一是部分地段集条残膜量少,导致喂入量不足,成型方包密度不达标;二是所掺尘土等杂质过多,降低残膜压缩后的相互吸附力,使成型方包易松散。试验中还发现:长度大于50 mm的残膜打捆成形的效果较差;掺杂有适量长度小于50 mm的秸秆时,成形的物料捆紧实度较大,且形状保持时间较长。

表3 残膜打包试验结果Table3 Result of balling plastic film residue

3.3 田间使用情况

CMJY-1500型农田残膜捡拾打包联合作业机进行了生产试验,2014年10月在兵团第八师145团7连和149团7连,兵团第七师130团6连,2015年4月和10月,在兵团第八师145团北泉镇农场,第六师共青团农场等地,累计作业面积约为150 hm2。田间生产实践表明,研制的CMJY-1 500型农田残膜捡拾打包联合作业机可以实现捡拾和打包功能,将农田残膜捡拾作业与打包作业相结合的农艺措施可行,可以提升残膜回收作业效率,能有效压缩残膜存储体积,便于田间转运,减少污染。

4 结 论

1)从便于回收残膜再利用的角度出发,将残膜回收与打包技术结合,研制了CMJY-1 500型农田残膜捡拾打包联合作业机。能够一次完成搂后集条残膜的捡拾、清理、打包作业。

2)在偏心弹齿式残膜捡拾滚筒转动作业过程中,残膜被弹齿挑起,在离心力作用下实现膜土分离,经脱膜辊剥离后送入打包箱体。通过残膜捡拾清理机构作业,残膜拾净率达92.8%。

3)残膜打包机构通过液压油缸驱动,可实现自动行程控制,残膜进入打包箱体后,被压缩成型并以方捆形式卸料,单包成型仅耗时58 s,成捆率可达94%。

残膜捡拾打包联合作业机田间试验证明,机具各部件运转良好,动作执行顺畅,残膜捡拾干净、残余量少,成型方包外形规整,物料包紧实不易松散,成捆质量满足设计要求。

[1] 毕继业,王秀芬,朱道林. 地膜覆盖对农作物产量的影响[J]. 农业工程学报,2008,24(11):172-175.

Bi Jiye, Wang Xiufen, Zhu Daolin. Effect of plastic-film mulch on crop yield[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(11): 172-175. (in Chinese with English abstract)

[2] 严昌荣,梅旭荣,何文清,等. 用地膜残留污染的现状与防治[J]. 农业工程学报,2006,22(11):269-272.

Yan Changrong, Mei Xurong, He Wenqing, et al. Present situation of residue pollution of mulching plastic film and controlling measures[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2006, 22(11): 269-272. (in Chinese with English abstract)

[3] 何文清,严昌荣,赵彩霞,等. 我国地膜应用污染现状及其防治途径研究[J]. 农业环境科学学报,2009,28(3):533-538.

He Wenqing, Yan Changrong, Zhao Caixia, et al. Study on the pollution by plastic mulch film and its countermeasures in china[J]. Journal of Agro-Environment Science, 2009, 28(3): 533-538. (in Chinese with English abstract)

[4] 杜晓明,徐刚,许端平,等. 中国北方典型地区农用地膜污染现状调查及其防治对策[J]. 农业工程学报,2005,21(增刊1):225-227.

Du Xiaoming, Xu Gang, Xu Duanping, et al. Mulch film residue contamination in typical areas of north China and countermeasures[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2005, 21(Supp.1): 225-227. (in Chinese with English abstract)

[5] 何文清,严昌荣,刘爽,等. 典型棉区地膜应用及污染现状的研究[J]. 农业环境科学学报,2009,28(8):1618-1622.

He Wenqing, Yan Changrong, Liu Shuang, et al. The use of plastic mulch film in typical cotton planting regions and the associated environmental pollution[J]. Journal of Agro-Environment Science, 2009, 28(8): 1618-1622. (in Chinese with English abstract)

[6] 严昌荣,梅旭荣,何文清,等. 农用地膜残留污染的现状与防治[J]. 农业工程学报,2006,22(11):269-272.

Yan Changrong, Mei Xurong, He Wenqing, et al. Present situation of residue pollution of mulching plastic film and controlling measures[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2006, 22(11): 269-272. (in Chinese with English abstract)

[7] 侯书林,胡三媛,孔建铭,等. 国内残膜回收机研究的现状[J]. 农业工程学报,2002,18(3):186-190.

Hou Shulin, Hu Sanyuan, Kong Jianming, et al. Present situation of research on plastic film residue collector in China[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2002, 18(3): 186-190. (in Chinese with English abstract)

[8] 马少辉,张学军. 废膜收获机的研究现状和发展趋势[J].农机化研究,2006(5):37-38.

Ma Shaohui, Zhang Xuejun. The rudimental plastic harvestingmachinery’s present condition and developing trend[J]. Journal of Agricultural Mechanization Research, 2006(5): 37-38. (in Chinese with English abstract)

[9] 张惠友,侯书林,那明君,等. 收膜整地多功能作业机的研究[J]. 农业工程学报,2007,23(8):130-134.

Zhang Huiyou, Hou Shulin, Na Mingjun, et al. Multifunctional machine for retrieving the used plastic film after harvesting and soi preparation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2007, 23(8): 130-134. (in Chinese with English abstract)

[10] 杨希晨,刘炳,龚军. 残膜回收机的研究现状及存在问题[J]. 新疆农机化,2006(5):15-17.

Yang Xichen, Liu Bin, Gong Jun. Ontology research and existing problems in plastic film collector[J]. XinjiangAgricultural Mechanization, 2006(5): 15-17. (in Chinese with English abstract)

[11] 戚江涛,张涛,蒋德莉,等. 残膜回收机械化技术综述[J].安徽农学通报,2013(9):153-155.

Qi Jiangtao, Zhang Tao, Jiang Deli, et al. Study on the plastic film recovery machine technology[J]. Anhui Agricultural Science Bulletin, 2013(9): 153-155. (in Chinese with English abstract)

[12] 张学军,吴成武,马少辉,等. 残膜回收机搂膜连杆机构模糊优化设计[J]. 农业机械学报,2007,38(9):55-58.

Zhang Xuejun, Wu Chengwu, Ma Shaohui, et al. Fuzzy optimization design of the links mechanism with film rake of remnant plastic film collector[J]. Transactions of the Chinese Society of Agricultural Machinery, 2007, 38(9): 55-58. (in Chinese with English abstract)

[13] 张佳. 驱动耙残膜回收联合作业机的设计及试验研究[D].乌鲁木齐:新疆农业大学,2013.

Zhang Jia. Design and Experimental Study on Driving Target and Plastic Film Collecting Combined Operation Machine[D]. Urumqi: Xinjiang Agricultural University, 2013. (in Chinese with English abstract)

[14] 王学农,史建新,郭俊先,等. 悬挂式棉秆粉碎还田搂膜机搂膜机构的设计与试验研究[J]. 农业工程学报,2008,24(1):135-140.

Wang Xuenong, Shi Jianxin, Guo Junxian, et a1. Experimental study and design on film raking mechanism of hanging film raker with cotton stalk crushing and returning to field[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(1): 135-140. (in Chinese with English abstract)

[15] 侯书林,张淑敏,孔建铭,等. 弹齿式收膜机主要机构设计[J]. 中国农业大学学报,2004,9(2):18-22.

Hou Shulin, Zhang Shumin, Kong Jianming, et al. Development of spring-tooth plastic film collecting machine[J]. Journal of China Agricultural University, 2004, 9(2): 18-22. (in Chinese with English abstract)

[16] 卢博友,杨青,薛少平,等. 圆弧形弹齿滚筒式残膜捡拾机构设计及捡膜性能分析[J]. 农业工程学报,2000,16(6):68-71.

Lu Boyou, Yang Qing, Xue Shaoping, et al. Design of arc spring tooth type collector for collecting mulching plastic film the collecting property analysis[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2000, 16(6): 68-71. (in Chinese with English abstract)

[17] 杨树森,沈美容,林素元. 弹齿式收膜机工作部件的研究[J]. 农业工程学报,1988,4(2):17-25.

Yang Shusen, Shen Meirong, Lin Suyuan. A study on the working parts of the spring-tooth type mulching plastic film collector[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 1988, 4(2): 17-25. (in Chinese with English abstract)

[18] 陈发,史建新,王学农,等. 弧型齿残膜捡拾滚筒捡膜的机理,农业机械学报[J]. 2006,37(6):36-41.

Chen Fa, Shi Jianxin, Wang Xuenong, et al. Study oncollecting principle of arc-type tooth roller for collecting plastic residue[J]. Transactions of the Chinese Society of Agricultural Machinery, 2006, 37(6): 36-41. (in Chinese with English abstract)

[19] 李斌,王吉奎,蒋蓓. 残膜回收机顺向脱膜机理分析与试验[J]. 农业工程学报,2012,28(21):23-28.

Li Bin, Wang Jikui, Jiang Bei. Analysis and test of forward film removing mechanism forpolythene film collector[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(21): 23-28. (in Chinese with English abstract)

[20] 王春耀,陈发,郭小军,等. 弧形挑膜齿残膜清理滚筒运动分析[J]. 农业机械学报,2005,36(8):38-40,44.

Wang Chunyao, Chen Fa, Guo Xiaojun, et al. Analysis on the movement of arc spring-finger type plastic film residue pickup cylinder[J]. Transactions of the Chinese Society of Agricultural Machinery, 2005, 36(8): 38-40, 44. (in Chinese with English abstract)

[21] 陈发,史建新,赵海军,等.固定凸轮残膜捡拾机构的优化设计[J]. 农业机械学报,2005,36(12):43-46.

Chen Fa, Shi Jianxin, Zhao Haijun, et al. Optimum design of fixing cam combination mechanism for collecting plastic residue[J]. Transactions of the Chinese Society of Agricultural Machinery, 2005, 36(12): 43-46. (in Chinese with English abstract)

[22] 康建明,王士国,颜利民,等. 残膜回收机起膜铲设计与试验[J]. 农业机械学报,2016,47(增刊1):143-148.

Kang Jianming, Wang Shiguo, Yan Limin, et al. Optimum design of fixing cam combination mechanism for collecting plastic residue[J]. Transactions of the Chinese Society of Agricultural Machinery, 2016, 47(Supp.1): 143-148. (in Chinese with English abstract)

[23] 王春耀,陈发,王学农,等.弧形挑膜齿残膜清理滚筒主要部件的强度分析[J]. 农业机械学报,2007,38(2):76-78. Wang Chunyao, Cheng Fa, Wang Xuenong, et al. Analytical research on intensity of the arc spring-finger type plastic film residue pickup cylinder[J]. Transactions of the Chinese Society of Agricultural Machinery, 2007, 38(2): 76-78. (in Chinese with English abstract)

[24] 谢建华,侯书林,付宇,等.残膜回收机弹齿式拾膜机构运动分析与试验[J]. 农业机械学报,2013,44(增刊1):94-99.

Xie Jianhua, Hou Shulin, Fu yu, et al. Motion Analysis and experiment on spring-tooth mulching plastic film collector[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(Supp.1): 94-99. (in Chinese with English abstract)

[25] 李刚,张林海,付宇,等. 曲柄摇杆式残地膜捡拾机构研究[J]. 农业机械学报,2014,45(增刊1):63-67.

Li Gang, Zhang Linhai, Fu Yu, et al. Crank-rocker mechanism for collecting plastic film[J]. Transactions of the Chinese Society of Agricultural Machinery, 2014, 45(Supp.1): 63-67. (in Chinese with English abstract)

[26] 刘伟峰,田海清,赵满全,等. 1MC-70 型地膜回收起茬机铲刀结构和参数确定及试验研究[J]. 中国农机化,2004(1):35-38.

Liu Weifeng, Tian Haiqing, Zhao Manquan, et al.An experimental study on the structure and parameters of the knives of the 1MC-70 model plastic film residue and stubble collecting machine[J]. Chinese Agricultural Mechanization, 2004(1): 35-38. (in Chinese with English abstract)

[27] 娄秀华,张东兴,耿端阳,等. 残膜回收机起膜器的设计与试验研究[J]. 农业工程学报,2002,18(6):88-90.

Lou Xiuhu, Zhang Dongxing, Gen Duanyang, et al. Research and design on loosening shovel of polythene film collector[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2002, 18(6): 88-90. (in Chinese with English abstract)

[28] 娄秀华,张东兴,张淑敏,等. 1MS-Ⅱ型地膜回收机起膜铲动力性能试验分析[J]. 农业机械学报,2004,35(5):67-69.

Lou Xiuhua, Zhang Dongxing, Zhang Shumin, et al. Experimental investigation on performance of loosening shovel of 1MS-Ⅱ polythene film collector[J]. Transactions of the Chinese Society of Agricultural Machinery, 2004, 35(5): 67-69. (in Chinese with English abstract)

[29] 张佳喜,王学农,张丽,等. 农田地膜拉伸性能变化对缠绕式回收的影响[J]. 农业工程学报,2015,31(20):41-47.

Zhang Jiaxi, Wang Xuenong, Zhang Li, et al. Effects of mechanical tensile properties of plastic film on plastic recycling method[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(20): 41-47. (in Chinese with English abstract)

[30] 张秋芳,张东兴. 苗期地膜回收机的起膜轮的设计[J]. 农机化研究,2007(9):84-86.

Zhang Qiufang, Zhang Dongxing. Design of film removing wheel for a polythene film collector during seedling period[J]. Journal of Agricultural Mechanization Research, 2007(9): 84-86. (in Chinese with English abstract)

[31] 杨丽,刘佳,张东兴,等. 棉花苗期地膜回收机设计与试验[J]. 农业机械学报,2010,41(增刊1):73-77.

Yang Li, Liu Jia, Zhang Dongxing, et al. Design and experiment of plastic film collector for cotton fields during seedling period[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(Supp.1): 73 - 77. (in Chinese with English abstract)

[32] 杨丽,张东兴,侯书林,等. 玉米苗期地膜回收机结构参数分析与试验[J]. 农业机械学报,2010,41(12):29-34. Yang Li, Zhang Dongxing, Hou Shulin. et al. Analysis of structural parameters and experiment of plastic film collector for corn fields during seedling period[J]. Transactions of the Chinese Society of Agricultural Machinery, 2010, 41(12): 29-34. (in Chinese with English abstract)

[33] 那明君,董欣,侯书林,等. 残膜回收机主要工作部件的研究[J]. 农业工程学报,1999,15(2):112-115.

Na Mingjun, Dong Xin, Hou Shulin, et al. Research on main components of the machine for retrieving the used plastic film after harvesting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 1999, 15(2): 112-115. (in Chinese with English abstract)

[34] 王吉亮,王敏,营雨琨,等. 链耙式残膜回收与茎秆粉碎联合作业机设计[J]. 广东农业科学,2013,40(5):189-190,194.

Wang Jiliang, Wang Min, Ying Yukun, et al. Design of chain harrow type film remnant recycle and stem crushing combined machine[J]. Guangdong Agricultural. Sciences, 2013, 40(5): 189-190, 194. (in Chinese with English abstract)

[35] 崔方方,吕钊钦,李法德,等. 链条式烟田地膜回收机设计研究[J]. 农机化研究,2010(5):78-80.

Cui Fangfang, Lü Zhaoqin, Li Fade, et al. Study on the machine for retrieving the used plastic film in tobacco seedlings[J]. Journal of Agricultural Mechanization Research, 2010(5): 78-80. (in Chinese with English abstract)

[36] 李斌. 后置链齿耙式残膜回收机工作机理研究[D]. 石河子:石河子大学,2013.

Li Bin. Research on Residual Film Recycling Mechanism of Rear Chain Harrow Machine[D]. Shihezi: Shihezi University, 2013. (in Chinese with English abstract)

[37] 王能勇. 4CM-150 型齿链式悬挂收膜机[J]. 新疆农机化,1997(5):15-16.

Wang Nengyong. 4CM-150 model chain type suspension plastic film collector[J]. Xinjiang Agricultural Mechanization, 1997(5): 15-16. (in Chinese with English abstract)

[38] 于云海,陈学庚,温浩军. 秸秆粉碎与残膜集条联合作业机的研制与试验[J]. 农业工程学报,2016,32(24):1-8.

Yu Yunhai, Cen Xuegeng, Wen Haojun. Development and experiment of straw chopping and plastic film strip-collection combined machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(24): 1-8. (in Chinese with English abstract)

[39] 胡凯,王吉奎,李斌,等. 棉秆粉碎还田与残膜回收联合作业机研制与试验[J]. 农业工程学报,2013,29(19):24-32.

Hu Kai, Wang Jikui, Li Bin, et al. Development and experiment of combined operation machine for cotton straw chopping and plastic film collecting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(19): 24-32. (in Chinese with English abstract)

[40] 王吉奎,付威,王卫兵,等. SMS-1500型秸秆粉碎与残膜回收机的设计[J]. 农业工程学报,2011,27(7):168-172.

Wang Jikui, Fu Wei, Wang Weibing, et al. Design of SMS-1500 type straw chopping and plastic film residue collecting machine. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(7): 168-172. (in Chinese with English abstract)

[41] 王学农,冯斌,陈发,等. 棉秸秆切碎及残膜回收联合作业关键技术研究[J]. 新疆农业大学学报,2005,28(3):49-52.

Wang Xuenong, Feng Bin, Chen Fa, et al. Research on key technic of cotton stalk shredding and used polythene film collecting combined machine[J]. Journal of Xinjiang Agricultural University, 2005, 28(3): 49-52. (in Chinese with English abstract)

[42] 赵胜利,黄宁生,朱照宇. 塑料废弃物污染的综合治理研究进展[J] .生态环境,2008(6):2473-2481.

Zhao Shengli, Huang Ningsheng, Zhu Zhaoyu. Development of comprehensive treatment of the waste plastics pollution[J]. Ecology and Environment, 2008(6): 2473-2481. (in Chinese with English abstract)

[43] 卢博友,杨青,薛少平,等. 圆弧形弹齿滚筒式残膜捡拾机构设计及捡膜性能分析[J]. 农业工程学报,2000,16(6):68-71.

Lu Boyou, Yang Qing, Xue Shaoping, et al. Design of arc spring-tooth type collector for collecting mulching plastic film the collecting property analysis[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2000, 16(6): 68-71. (in Chinese with English abstract)

Design and test of CMJY-1500 type plastic film residue collecting and balling machine

Zhao Yan1, Zheng Xuan1※, Chen Xuegeng1, Niu Qi2, Ji Chao1, Zhou Dunxing3

(1. Mechanical Equipment Research Institute, Xinjiang Academy of Agriculture And Reclamation Science, Shihezi, 832000, China; 2. College of Mechanical Engineering, China Agricultural University , Beijing, 100083, China; 3. Xinjiang KeShen Agriculture Equipment Technology Development Co., Ltd, Shihezi, 832000, China)

Plastic film cultivation technology has been used around the world, and it is widely recognized that plastic film cultivation technology can make a valuable contribution to agriculture. Under the principle of maximizing the interests of farmers and factories, plastic film mulch used in field is too thin to be collected completely. Year after year, more and more residual plastic film has been left in the field, which damages the physical and chemical structure of soil and even causes farmland to become uncultivable. Lots of residual plastic film collectors have been designed to address “how to collect” in recent years, however, the problem of “after collecting” is often overlooked. Usually, collected residual film is separated and gathered by manual work, and transported by the simplest container pulled by tractors. It would be buried or burned somewhere. If accumulated residual film is not well handled, it will cause new environmental pollution. So far, there is little study on the transfer facility of collected residual plastic film. In order to reduce the storage and transportation cost, and increase the recovery utilization rate of plastic film collected by machine, the CMJY-1500 type combine machine was developed. It has a mechanical structure composed of film collecting device, film removing device, film balling device, driving system, ground wheel, frame, and so on. According to the structural characteristics and main working principle of the film collection mechanism, the dynamic models of collecting device and film object were established. After model analysis, the optimal space aligning was confined and the best installation inclination was set as 45°. With the aim to reduce the content of soil doping of residual membrane material, based on the difference of density, size and twisting characteristic between the residual plastic film and the impurity, multi-stage membrane separation system with the combination of centrifugal and vibration separation was developed. This system consists of toothed roller, film collection mechanism, film removal rollers, and cover whose contour line adopts an involute design, and it can increase the compression ratio of collecting material and reduce the packaging compression resistance. The hydraulic drive type electronic packaging mechanism was designed, and therefore the plastic film was compressed as square package to upload by 3 sets of cylinders, which was beneficial to load and transport. The field performance test of this plastic film residue baller was carried out in the Gongqingtuan Farm of Xinjiang Corps in October, 2015, and the test area was about 40 hm2. The results showed that the residual film collection rate was 92.8%, the successful rate of packaging was higher than 94%, and the average cycle time of single packing operation was 58 s. The operation effect is good and the system is stable, and this plastic film residue baller has the high application promotion value. This research result has both economic and social benefit.

agricultural machinery; design; experiments; plastic films; collection; cleaning; balling; combined operation

10.11975/j.issn.1002-6819.2017.05.001

S223.5

A

1002-6819(2017)-05-0001-09

赵 岩,郑 炫,陈学庚,牛 琪,纪 超,周敦兴. CMJY-1500型农田残膜捡拾打包联合作业机设计与试验[J]. 农业工程学报,2017,33(5):1-9.

10.11975/j.issn.1002-6819.2017.05.001 http://www.tcsae.org

Zhao Yan, Zheng Xuan, Chen Xuegeng, Niu Qi, Ji Chao, Zhou Dunxing. Design and test of CMJY-1500 type plastic film residue collecting and balling machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(5): 1-9. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.05.001 http://www.tcsae.org

2016-10-30

2017-02-13

公益性行业(农业)科研专项(201503105);国家自然科学基金资助项目(31560336);中国博士后科学基金资助项目(2015M572666XB);兵团重点领域创新团队(2015BD002)

赵 岩,男,河南永城人,副研究员,主要从事农业机械化工程研究。石河子 新疆农垦科学院机械装备研究所,832000。

Email:xjnkkxy_zy@126.com

※通信作者:郑 炫,女,江苏徐州人,研究员,主要从事农业机械化工程研究。石河子 新疆农垦科学院机械装备研究所,832000。

Email:jiazhengxuan@sohu.com