Viscosity profile prediction of a heavy crude oil during lifting in two deep artesian wells☆

2017-05-29YiboLiHaoGaoWanfenPuBingWeiYafeiChenDongLiQiangLuo

Yibo Li,Hao Gao ,Wanfen Pu ,*,Bing Wei,*,Yafei Chen ,Dong Li,Qiang Luo

1 State Key Laboratory of Oil and Gas Reservoir Geology and Exploitation,Southwest Petroleum University,Chengdu 610500,China

2 Research Institute of Experiment and Detection,Xinjiang Oil field Company,PetroChina,Karamy 834000,China

1.Introduction

With the ever-increasing demand for energy and depletion of easyto-produced lightoil,heavy oilresources contribute to the crude oilsupplement in the current energy market[1].Heavy oils are characterized by high content of heavy compounds,boiling point,and molecular weightin comparison with conventionallightoils.Heavy oils are generally composed of four fractions including saturate,aromatic,resin,and alphaltene[2,3].As a result of high aromatic fraction as well as heteroatoms(nitrogen,sulfur,oxygen)and trace metals,heavy oils are usually very viscous ranging from 100 to 10000 mPa·s as de fined by the world Petroleum Congress[4-6].In terms of production,heavy oil can be effectively recovered by thermal,chemical and miscible methods with exception of some unsuccessful water flooding as reported[7].Under reservoirconditions,heavy oils are normally flowable in the formations.However,their flowability will be dramatically changed as temperature and pressure drop during lifting in the production wells.Unfortunately,this uncertain issue renders the heavy oils problematic on the transportability and even makes production wells blocked.Therefore,prior to proposing effective solutions,the accurate prediction of the heavy oil rheology during lifting impacted by temperature and pressure is very desirable.

In the last several decades,numerous empirical models have been established to describe the rheological behavior of crude oils[8-13].For example,Barus realized that the viscosity of bitumen samples increased exponentially with pressure and thus presented the Barus equation[14].Martinet al.used free volume theory to correlate temperature,pressure,and viscosity for heavy petroleum fractions[15,16].They observed that under 40 MPa,bitumen still showed noticeable temperature-dependent behavior and the viscosity reduction rate reached up to 95%from 50°C to 165°C.Hasanet al.studied several factors as shear rate,temperature and light oil concentration on the viscous behavior of heavy oil during transportation.It was found that the heavy oil yielded at the shear stress of 0.7 Pa,light oil blending appeared to be the most appropriate way to improve the mobility of heavy oils[17].Mehrotra and Svrcek reported the viscosity data of Athabasca bitumen at the temperature ranging from 43 to 120°C and pressure up to 10 MPa.They found that the compression of bitumen resulted in a considerable increase in the viscosity but only a slight change in density[18].Puttaguntaet al.proposed a three parameter empirical model to study the relationship among pressure,temperature and viscosity of a Canadian bitumen and heavy oil.This modeloffered greataccuracy with an absolute deviation of4.79%[19].

The rheology of crude oils presents various characteristics during lifting in production wells due to the well condition variation.As temperature and pressure drop in the lifting process,the flow ability ofthe crude oils would be significantly in fluenced and thus leads to reduction in the oil flow rate particularly for heavy crude oils.What is worse,the low shear rate generated by the slowed flowing makes the oil more viscous due to the non-Newtonian property of heavy oils.Therefore,considering the combining effectoftemperature,pressure and shear rate results in the difficulty in characterizing the rheological properties of heavy crude oils.The primary objective of this paper was to predict the viscosity profile of a heavy crude oil during lifting in two deep artesian wells.To accomplish the research objective,the rheological properties of the heavy crude oil were comprehensively investigated.Subsequently,the experimental data were theoretically analyzed using several empirical correlations to study the effect of well conditions such as temperature,pressure and shear rate on the rheology of this heavy oil[20].At the end of this paper,the viscosity of the heavy crude oil as a function of well depth was estimated using the oil field producing data.

2.Experimental

2.1.Materials

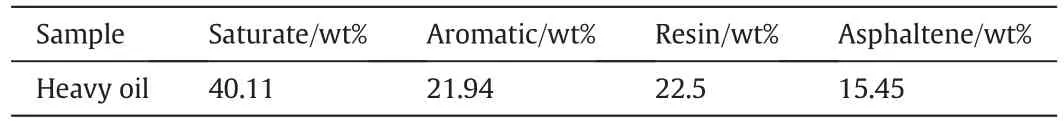

The heavy crude oil was kindly provided by Sinopec Northwest Co.,China.According to ASTM D3279,the SARA(Saturate,Aromatic,Resin and Alphaltene)composition of this heavy oil was listed in Table 1.Before subjected to analysis,the heavy crude oil was degassed,and the sample was vigorously shaken to ensure homogeneity.The homogenous sample was then loaded to a funnel for gravity settling for at least one day,later water and sediment were removed.

Table 1The SARA fractions of the heavy oil

2.2.Rheological measurements

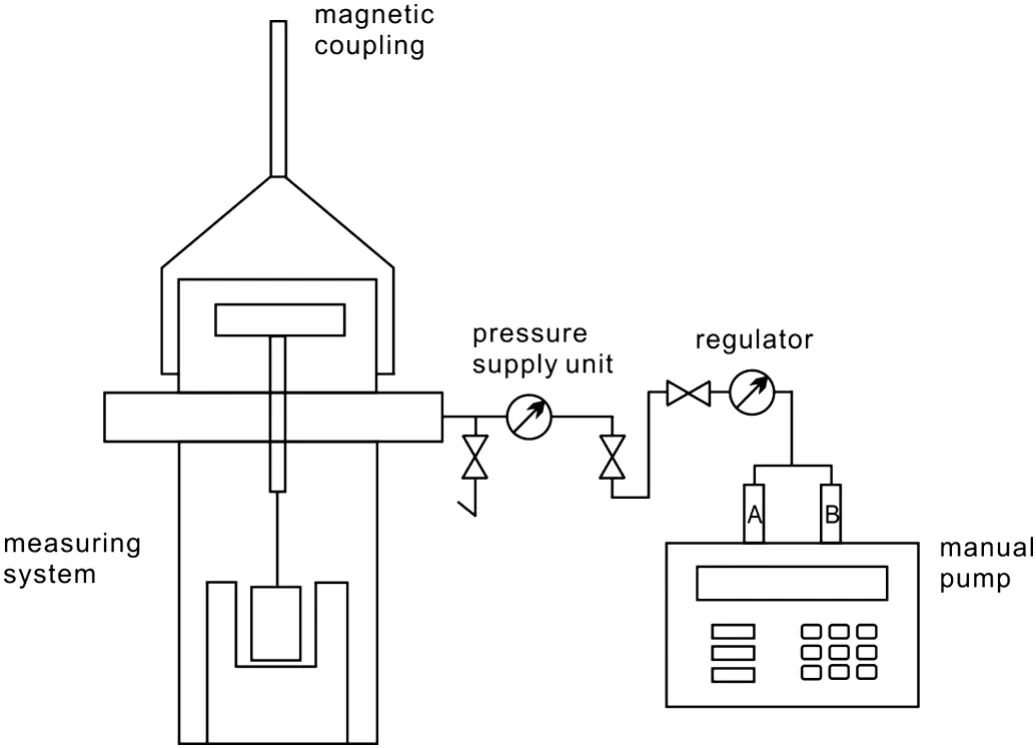

The rheological measurements were carried outusing an Anton Paar MCR 302 Rheometer stress-controlled rheometer shown as Fig.1.A high-pressure cell was equipped with the rheometer.The type of the pressure cell was CC26/PR1000.The material was titanium and measuring system was concentric cylinder.The maximum pressure was 100 MPa.This system was heated by electrical heating system and the temperature range was from room temperature to 300°C.A manual pump was used to pump the oil sample into the pressure cell.Shear test was conducted in a stress-control mode,the tangential stress was imposed and the shear rate was measured to calculate the viscosity.The experimental conditions are as follows,temperature:30-100°C;pressure:0-50 MPa;shear rate:1-1000 s-1.All experiments were performed three times to demonstrate the reproducibility.

Fig.1.The pressure cell rheometer system.

3.Results and Discussion

3.1.Temperature effect

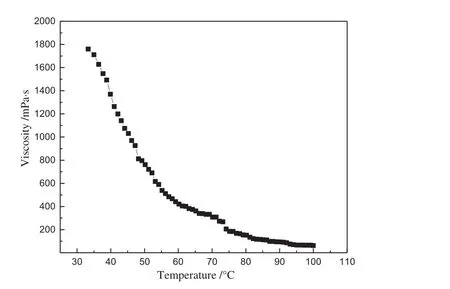

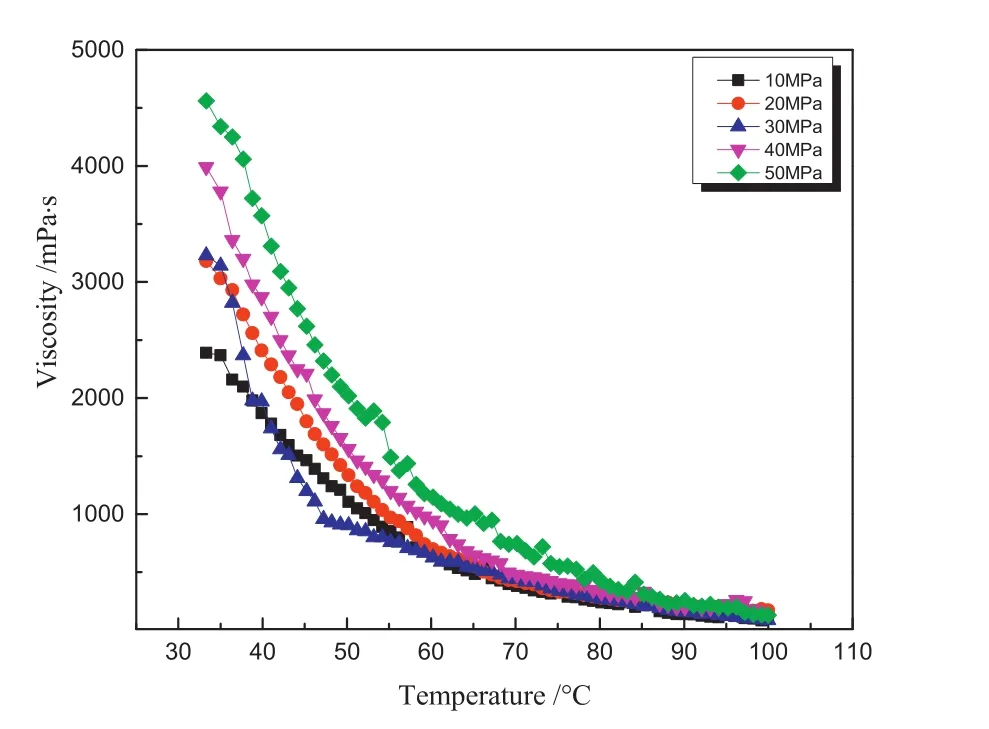

In this section,the effectoftemperature on the rheology ofthe heavy crude oilwas studied.Fig.2 plots the shear viscosity ofthis heavy oilas a function of temperature at atmosphere pressure.Fig.3 plots the shear viscosity of the pressurized heavy oil as a function of temperature.

Fig.2.Viscosity of the heavy oil at atmosphere pressure versus temperature.

Fig.3.Viscosity of the pressurized heavy oil versus temperature.

As shown in Fig.2,this heavy oil exhibits a linear dependence on temperature,i.e.,as the temperature increases,the viscosity significantly decreases.Compared to 1710 mPa·s at35 °C,the oilviscosity dropped to 62 mPa·s at 100 °C.A similar temperature-dependent behavior was also observed after the heavy oil was pressurized as depicted in Fig.2.In recent years,the free volume theory has achieved highly attention.For macromolecule material,there were two compositions of volume:the volume of molecule and the volume of space.The volume of space was the free volume.The free volume theory was able to describe the viscosity of oil product and thus in this paper,this theory was used to explain the relationship of viscosity and pressure of heavy oil.As can be seen,the rheological properties of the heavy oil were considerably in fluenced by the imposed pressure,which probably resulted from the free volume compressing among oil molecules.Furthermore,after the system temperature was elevated up to 100°C,the viscosities of the pressurized heavy oil almost decreased into same range as indicated in Fig.3.That result can be interpreted as the oil molecules would become more and more active due to the Brownian Motion as a resultof the increasing temperature,therefore,the external forces such as shear stress and/or pressure were offset by the internal forces,which subsequently resulted in a similar viscosity range at high temperature.

The oil viscosity change as a function of temperature can be simply described by the Arrhenius law as given in Eqs.(1)or(2):

where μ is the viscosity,Ais the Arrhenius constant,Eμis the viscosity lf ow activation energy,Ris the gas constantandTis the thermodynamic temperature.

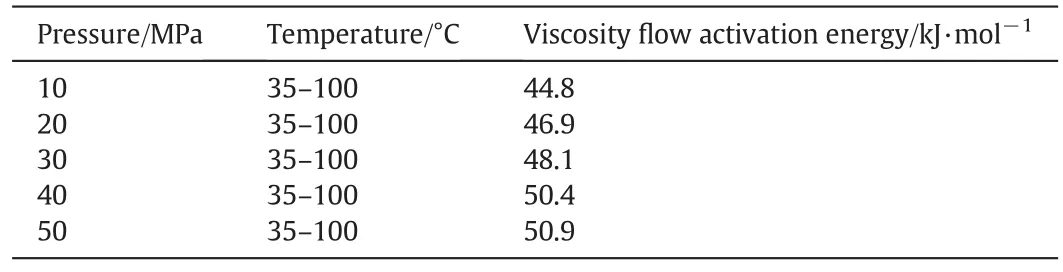

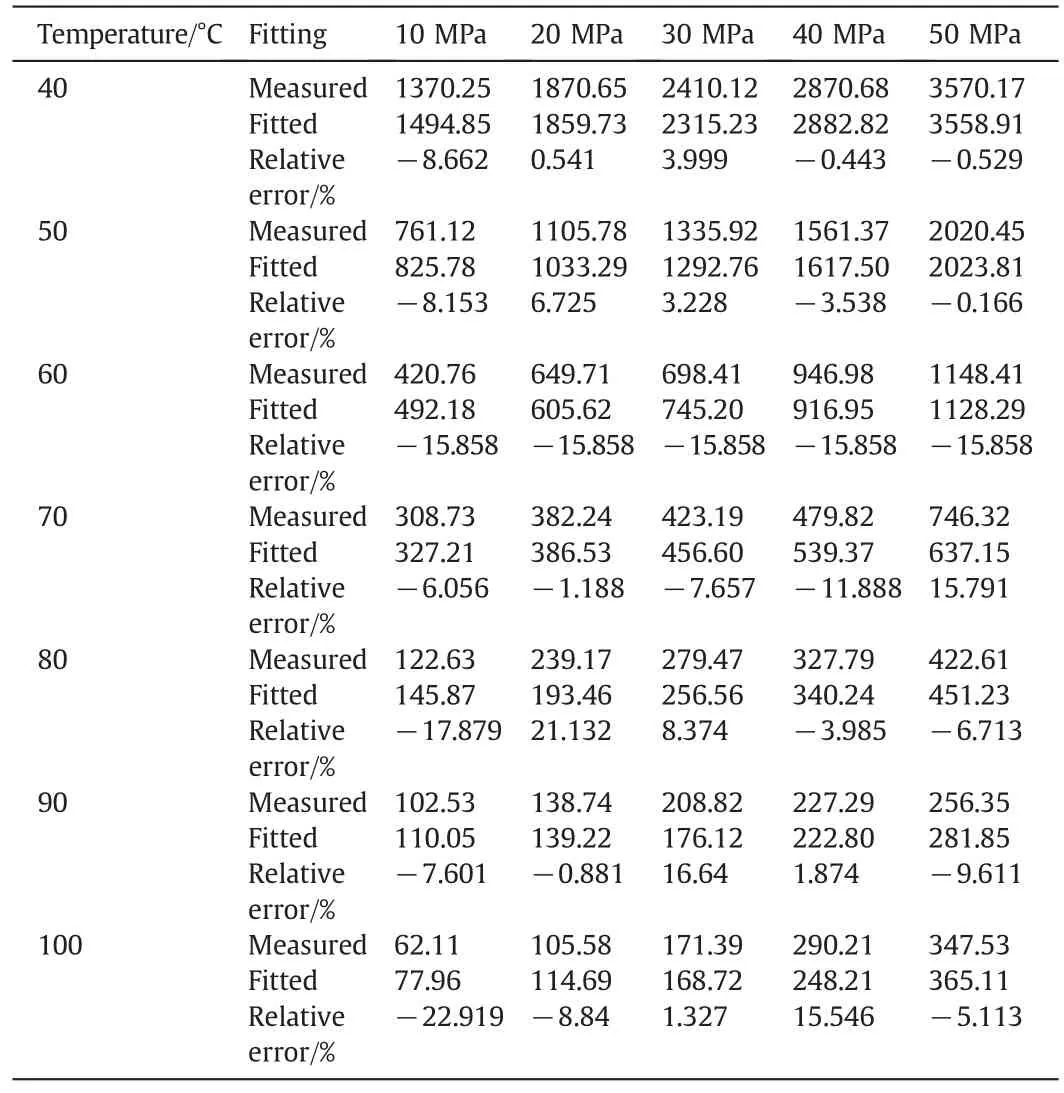

The dependence of viscosity on temperature at the elevating pressure is show in Fig.4 in terms of ln(μ)as a function of inverse temperature.Data present a linear trend and can be fitted with the Arrhenius law at low temperature.Nevertheless,at high temperature,smalldeviations were indeed observed on the fitting curves particularly at high pressures.Based on the Arrhenius law,the viscosity flow activation energy(Eμ)of the heavy oil as a function of pressure was calculated and tabulated in Table 2[21].Within the evaluated temperature range,the flow activation energy of the crude oil increased with the pressure.The compression of the free volume induced by the pressure causes stronger intermolecular forces,which is synonymous with higher viscosity.In this case,more energy is required to overcome the frictional force between the oil molecules.Moreover,as the pressure increases,resin and asphaltene aggregation would take place,which also caused the increasing of the viscosity flow activation energy.

Table 2Viscosity flow activation energy of the heavy oil

3.2.Pressure effect

As mentioned above,the free volume of oil molecules would be compressed under the increasing pressure,which would lead oil viscosity to rise.In this part,the oil viscosityversuspressure curves were plotted and theoretically investigated by Barus model as given in Eqs.(3)and(4),which is a typical empirical correlation to quantitatively analyze the pressure-dependent behavior of non-Newtonian fluids:

Fig.4.ln(μ)of the heavy oil at different pressures versus 1/T.

where μ is the viscosity at specific pressure,μois the viscosity at atmosphere pressure,ais the pressure-viscosity coefficient andPis the pressure.

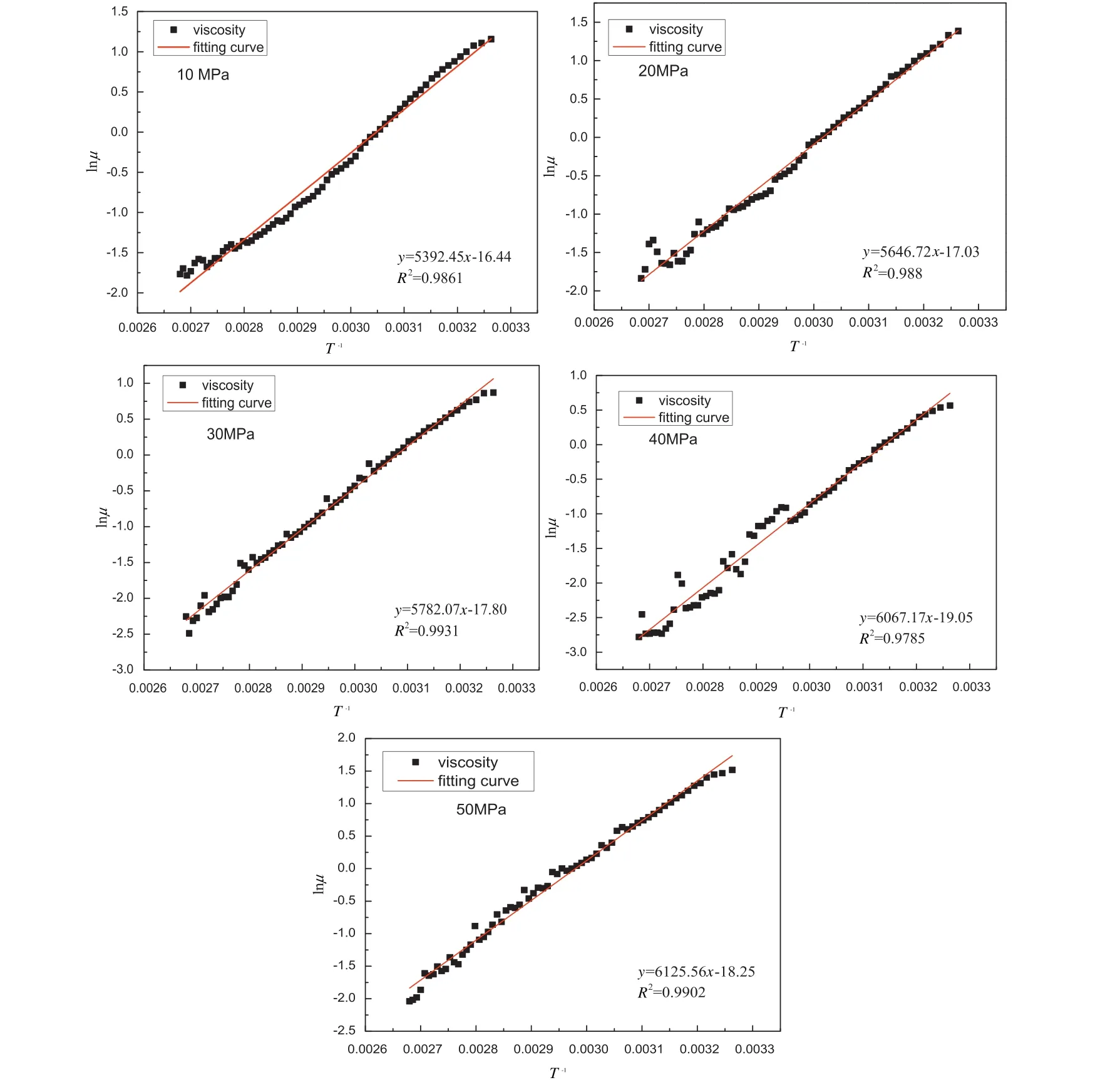

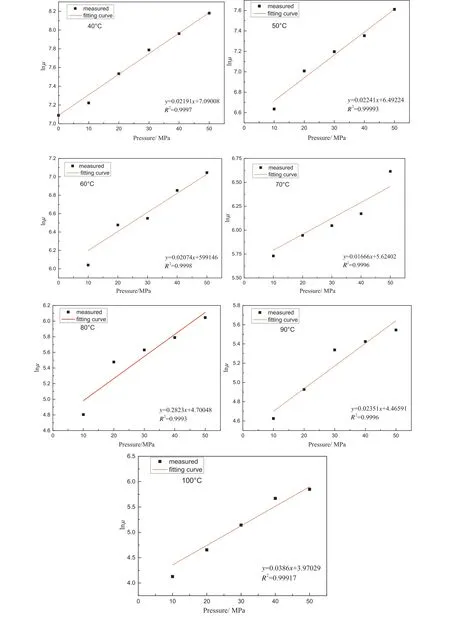

Fig.5 illustrates the performance ofoilviscosity asa function ofpressure at the temperature ranging from 40 to 100°C.As shown in Figs.2 and 3,the samples presented were non-Newtonian characteristic.It was observed that the logarithmic values of the heavy oil viscosity increased almost linearly with pressure as discussed before,and the viscous data were fitted to the Barus model quite well.The summary of the data is listed in Table 3.Due to the accurate fitting,Barus model was used to predict the rheological properties of the heavy oil under high pressure condition.

Fig.5.ln(μ)of the heavy oil at different temperatures versus pressure.

Table 3Comparison of measured and fitted viscosity using Barus model

3.3.Shear rate effect

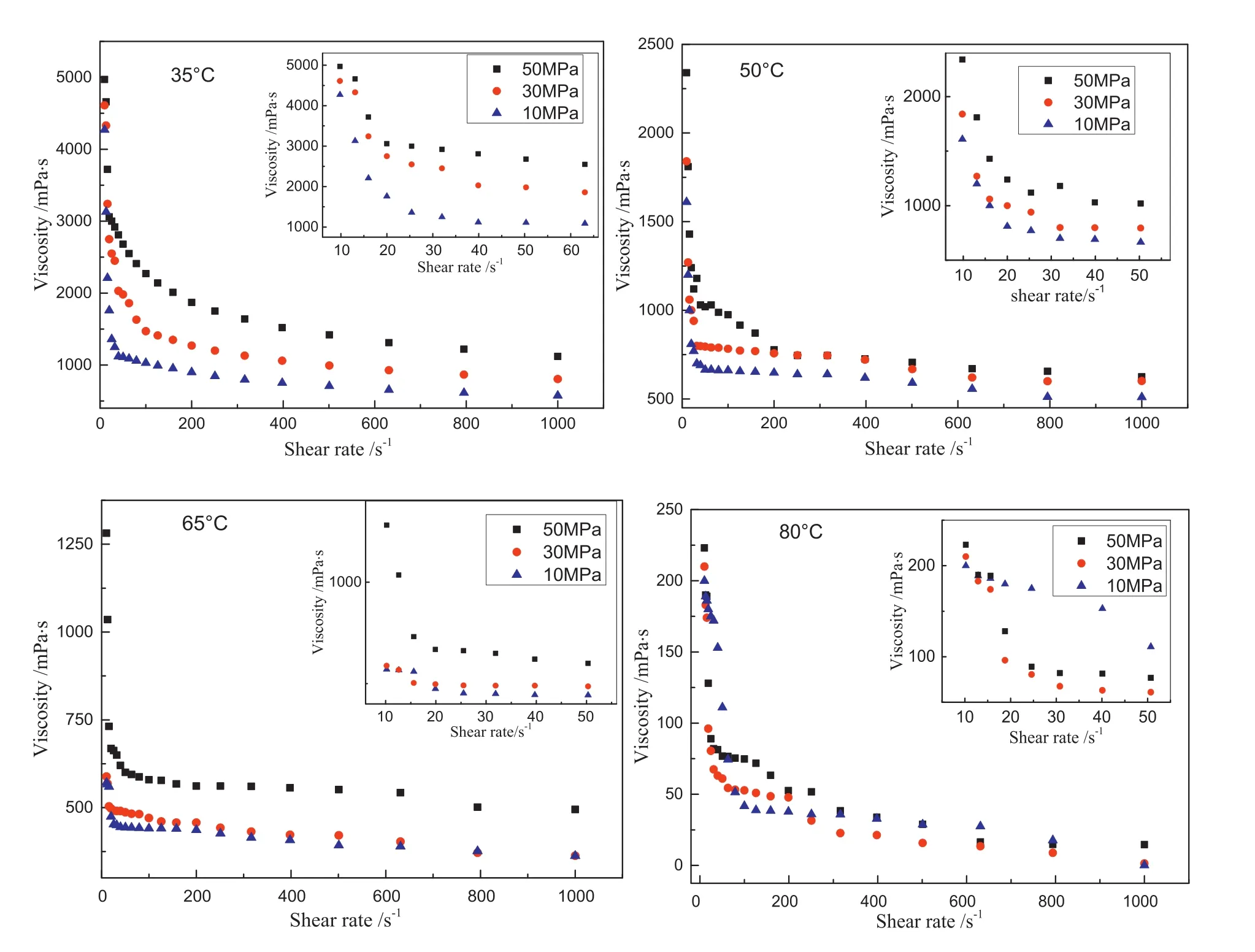

The shear-thinning behavior,which is a typical character of non-Newtonian fluids,refers to the fluid viscosity reduction with the shear rate increasing[22,23].When heavy oils are transported in production wells,this unique property may lead frequent viscosity variation result from the instable flow rate.Therefore,itis extremely importantto study the shearrate-dependentbehaviorofthe oilviscosity underthe effectof temperature and pressure.In this section,the oil viscosity was determined at the shear rate ranging from 1 to 1000 s-1with the temperature varying from 35 to 80°C and pressure from 10 to 50 MPa.The results are shown in Fig.6.

As depicted in Fig.6,the shear-thinning behavior of the heavy oil was very pronouncing at 35°C.As the shear rate increased to 200 s-1,the shear viscosity of the heavy oil was reduced up to 79%,72%and 62%at 10 MPa,30 MPa and 50 MPa,respectively.Nevertheless,it appears that this behavior is prone to be less significant with temperature increasing evidenced by two indexes,shear-thinning range and viscosity reduction rate.For instance,at 50°C,the shear-thinning behavior was only observed below the shear rate of 80 s-1,and accordingly the oil viscosity was reduced 59%,57%and 56%at 10 MPa,30 MPa and 50 MPa.With the temperature further increasing up to 65 and 80°C,the shear-thinning behavior of the heavy oil only noticed with in quite narrow shear rate range,suggesting the insensitivity of oil viscosity to shear.

Fig.6.Viscosity of the heavy oil versus shear rate.

The power law model was the most extensively used correlation applied to describe the shear-thinning behavior for non-Newtonian fluids from intermediate to high shear rate[24].The expression is shown as follows:

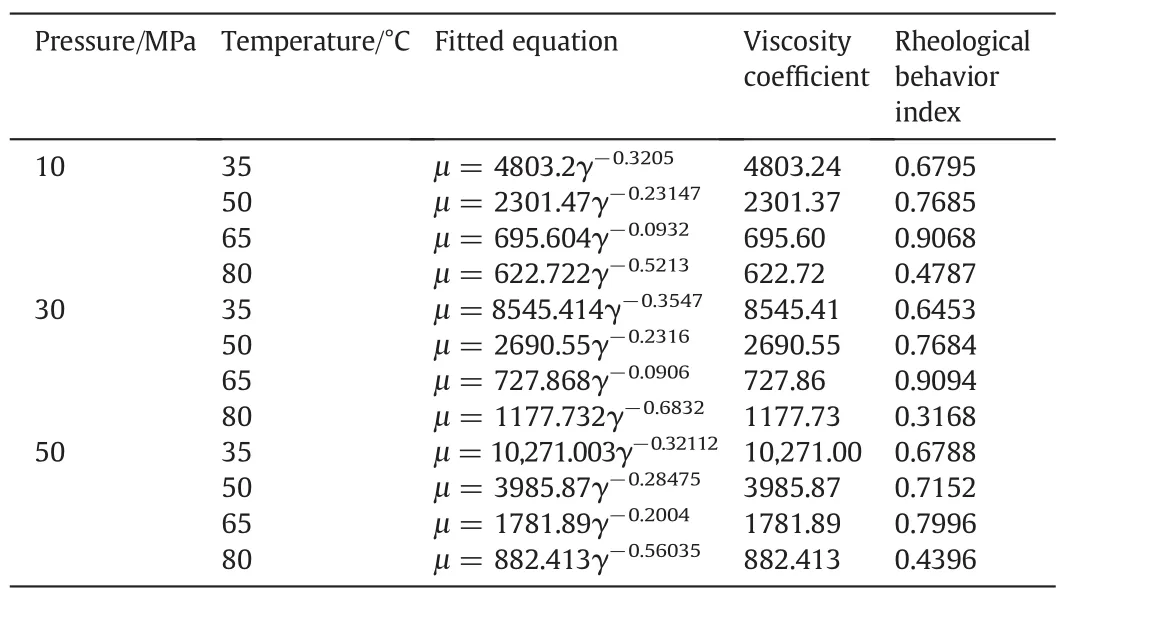

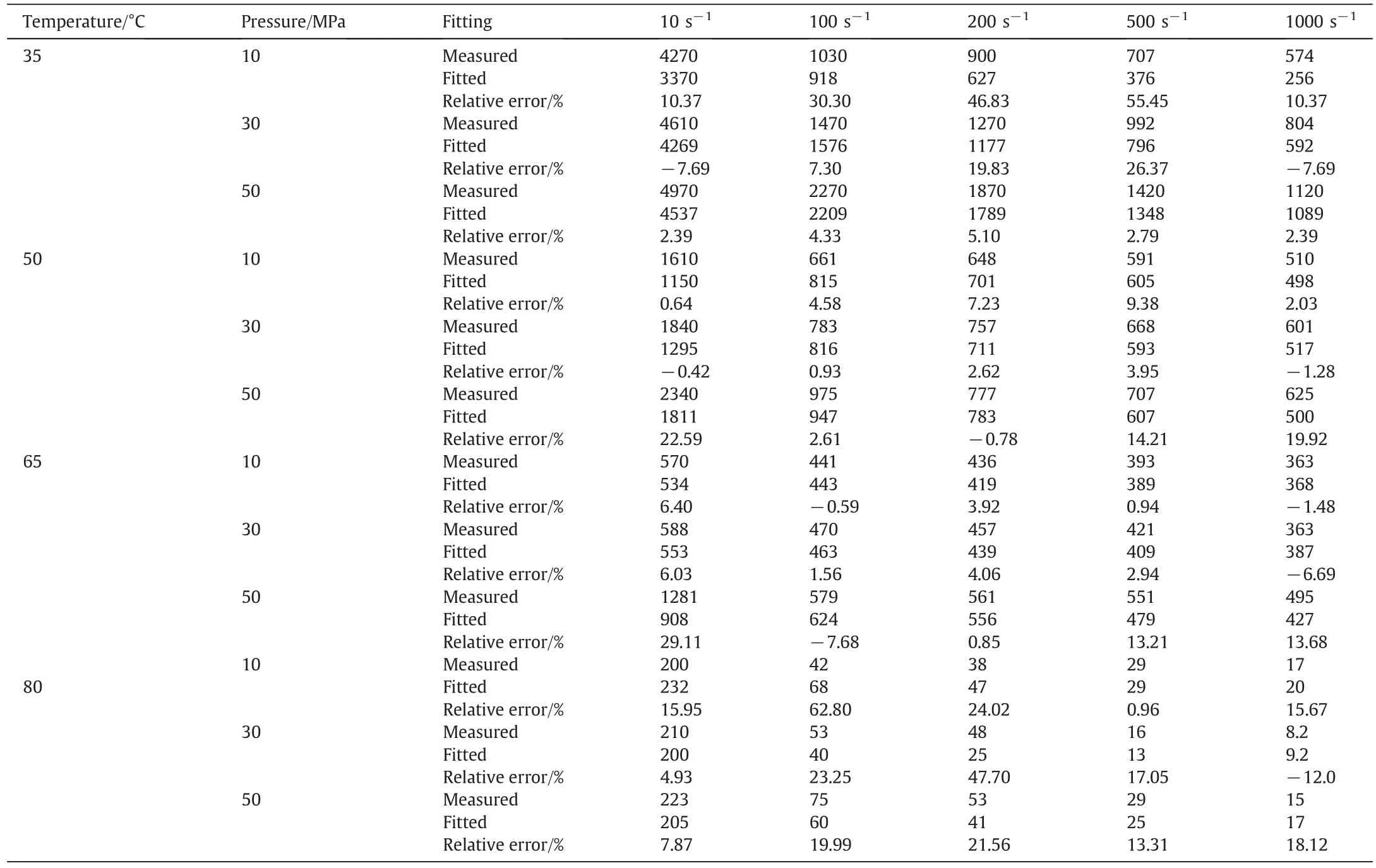

where μ is the viscosity,kis the viscosity coefficient,γ is the shear rate andnis the rheological behavior index.Tables 4 and 5 were presented to list the fitting parameters using power law model.The data prove that the rheology of the heavy oil was remarked impacted by temperature.As listed in Table 4,the relative error of the fitted and measured value of the oil viscosity was quite small at 35 °C and 50 °C,revealing the non-Newtonian characteristics of the heavy oil at low temperature.On the contrary,as the temperature rising up,the resin and precipitated asphaltene are prone to disperse forming a kind of dispersed colloidal system,which corresponds to the Newtonian behavior.

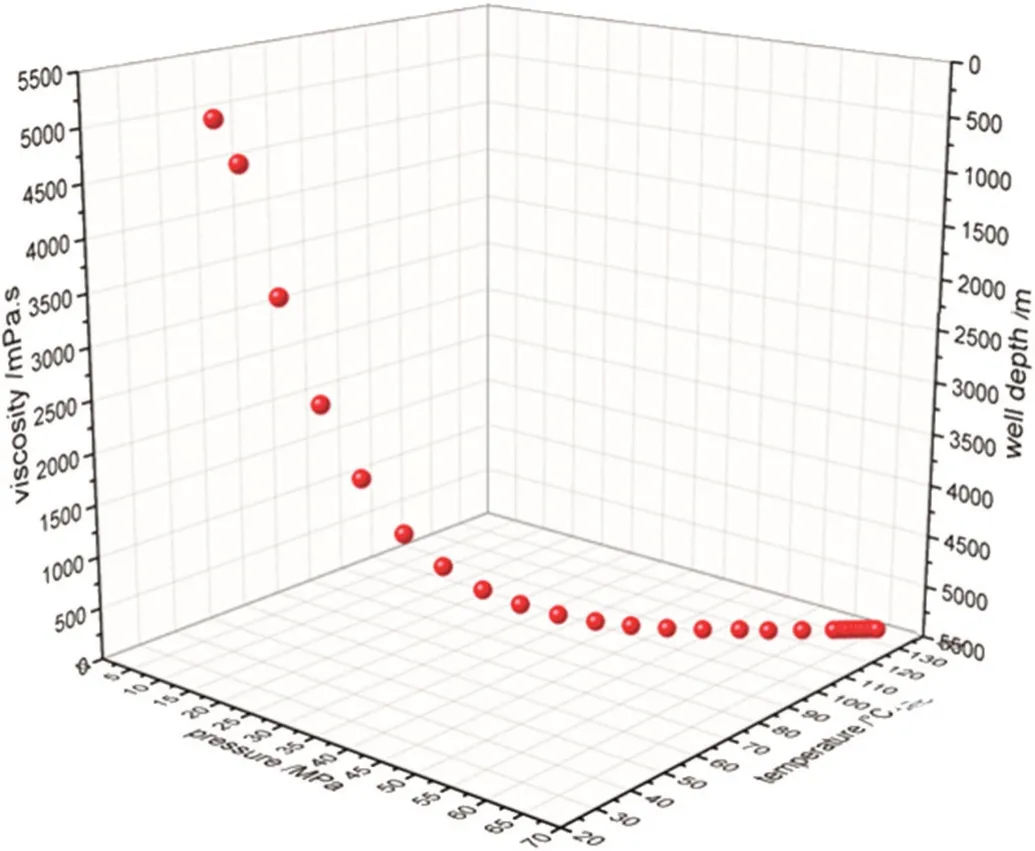

3.4.Viscosity prediction in the production wells

Based on the above investigations,the viscosity of the heavy oil in the artesian wells as a function of well depth was tentatively estimated using oil field producing data.Two representative production wells,Q5 and Q3-1 in the oil field,were selected for the estimation under the real well conditions.Since the insufficient data in production history,the shear rate variation with well depth is not able to be determined so far.Therefore,the variables of pressure and temperature were only considered in the current estimation.The viscosity profile of the heavy oil produced in Q5 well as a function of well depth was presented in Table S1.During oil lifting in the well,the oil viscosity has considerable increased as a result of pressure and temperature changes.The initial viscosity of the heavy oil at the well bottom is only 100 mPa·s although the pressure is as high as 49.59 MPa.However,as the well depth decreases,the pressure and temperature steadily dropped to 3.73 MPa and 29.86°C,respectively,and correspondingly the oil viscosity increased up to 2127.78 mPa·s as illustrated in Fig.7.Table S2 is presented to list the viscosity change in Q3-1 well.Due to the higher bottom pressure,the initial oil viscosity at well bottom is larger than that of Q5.Moreover,at the surface,the oil viscosity remained as high as 5261.42 mPa·s as shown in Fig.8 induced by the high pressure(20.26 MPa).

Table 5The fitting parameters at different pressures and temperatures

Table 4Comparison of measured and fitted viscosity at different shear rates

Fig.7.Oil viscosity of Q5 well as a function of well depth.

Fig.8.Oil viscosity of Q3-1 well as a function of well depth.

4.Conclusions

The rheologicalproperties ofa heavy crude oilwere comprehensively studies in this paper.The measured viscosity data were theoretically analyzed using severalempiricalcorrelations to understand the effectof three variables on oil viscosity.The viscosity of the heavy oil was sensitive to temperature within the evaluated temperature range,30-100°C.Pressure imposed a significant effect on the rheological behavior of the heavy oil.As the pressure elevates,the oil viscosity also increases due to the compression ofthe free volume.Moreover,the viscosity flow activation energy of the heavy oil increases with the pressure.The power law model was suitable for describing the shear rate-dependent properties of the heavy oil at the temperature below 65°C,after which the whole system was transited to Newtonian fluid.The viscosity profile of the heavy oil in the artesian wells was predicted through combining the above correlations.During lifting,the heavy oil viscosity was found to dramatically change with well depth induced by temperature and pressure changes.

Nomenclature

AArrhenius constant

aPressure-viscosity coefficient

EμViscosity flow activation energy,kJ·mol-1

kViscosity coefficient

PPressure,Pa

RGas constant(8.314 J·mol-1·K-1)

TThermodynamic temperature,K

TTemperature,K

γ Shear rate,s-1

μ Viscosity,Pa·s

Appendix A.Supplementary data

Supplementary data to this article can be found online at http://dx.doi.org/10.1016/j.cjche.2016.11.014.

[1]Z.J.Chen,Heavy oils,part II,SIAM News39(2006)1-4.

[2]D.Whiteoak,U.Shell Bitumen,The Shell Bitumen Handbook,in:R.N.Hunter,A.Self,J.Read(Eds.),6 edition,ICE Publishing,UK,2015.

[3]X.Yang,W.Li,A novel theoretical approach to the temperature-viscosity relation for fluidic fuels,Fuel153(2015)85-89.

[4]M.Dusseault,Comparing Venezuelan and Canadian heavy oil and tar sands,Canadian InternationalPetroleum Conference,Petroleum Society ofCanada,Calgary,Canada,2001.

[5]J.Seccombe,R.Akkurt,M.Smith,R.Akkurt,Ranking oil viscosity in heavy oil reservoirs,SPE SPE International Thermal Operations and Heavy Oil Symposium,Calgary,Canada,2005.

[6]J.F.Argillier,C.Coustet,I.Henaut,Heavy oil rheology as a function of asphaltene and resin content and temperature,SPE International Thermal Operations and Heavy Oil Symposium and International Horizontal Well Technology Conference,Calgary,Canada,2002.

[7]A.Shah,R.Fishwick,J.Wood,G.Leeke,S.Rigby,M.Greaves,A review of novel techniques for heavy oil and bitumen extraction and upgrading,Energy Environ.Sci.3(2010)700-714.

[8]T.Fan,J.S.Buckley,Rapid and accurate SARA analysis of medium gravity crude oils,Energy Fuel16(2002)1571-1575.

[9]S.R.Ferreira,A.P.Oliveira,N.Pucciarelli,C.A.B.Tooge,R.Souza,Green products for reducing the viscosity of heavy oil,SPE Heavy and Extra Heavy Oil Conference:Latin America,Medellin,Colombia,2014.

[10]Y.Gao,K.Li,New models for calculating the viscosity of mixed oil,Fuel95(2012)431-437.

[11]I.Henaut,L.Barre,J.F.Argillier,F.Brucy,R.Bouchard,Rheological and structural properties of heavy crude oils in relation with their asphaltenes content,SPE International Symposium on Oil field Chemistry,Houston,Texas,2001.

[12]O.Alomair,A.Elsharkawy,H.Alkandari,A viscosity prediction model for Kuwaiti heavy crude oils at elevated temperatures,J.Pet.Sci.Eng.120(2014)102-110.

[13]M.Taghizadeh,M.Eftekhari,Improved correlations for prediction of viscosity of Iranian crude oils,Chin.J.Chem.Eng.22(2014)346-354.

[14]C.Barus,Isothermals,isopiestics and isometrics relative to viscosity,Am.J.Sci.1(1893)87-96.

[15]M.J.Martín-Alfonso,F.J.Martínez-Boza,F.J.Navarro,M.Fernández,C.Gallegos,Pressure-temperature-viscosity relationship for heavy petroleum fractions,Fuel86(2007)227-233.

[16]M.J.Martín-Alfonso,F.Martínez-Boza,P.Partal,C.Gallegos,In fluence of pressure and temperature on the flow behaviour of heavy fuel oils,Rheol.Acta45(2006)357-365.

[17]S.W.Hasan,M.T.Ghannam,N.Esmail,Heavy crude oil viscosity reduction and rheology for pipeline transportation,Fuel89(2010)1095-1100.

[18]A.K.Mehrotra,W.Y.Svrcek,Viscosity of compressed Athabasca bitumen,Can.J.Chem.Eng.64(1986)844-847.

[19]V.Puttagunata,B.Singh,A.Miadonye,Correlation of bitumen viscosity with temperature and pressure,Can.J.Chem.Eng.71(1993)447-450.

[20]J.F.Argillier,I.Henaut,P.Gateau,J.P.Heraud,P.Glenat,Heavy oil dilution,SPE International Thermal Operations and Heavy Oil Symposium,Calgary,Canada,2005.

[21]L.Quinchia,M.Delgado,J.Franco,H.Spikes,C.Gallegos,Low-temperature flow behaviour of vegetable oil-based lubricants,Ind.Crop.Prod.37(2012)383-388.

[22]M.T.Ghannam,S.W.Hasan,B.Abu-Jdayil,N.Esmail,Rheological properties of heavy&light crude oil mixtures for improving flowability,J.Pet.Sci.Eng.81(2012)122-128.

[23]H.P.Rønningsen,Rheological behaviour of gelled,waxy North Sea crude oils,J.Pet.Sci.Eng.7(1992)177-213.

[24]J.Hermoso,F.Martinez-Boza,C.Gallegos,In fluence of aqueous phase volume fraction,organoclay concentration and pressure on invert-emulsion oil muds rheology,J.Ind.Eng.Chem.22(2015)341-349.

杂志排行

Chinese Journal of Chemical Engineering的其它文章

- Suppression of gold nanoparticle agglomeration and its separation via nylon membranes☆

- Effects of solubility parameter differences among PEG,PVP and CA on the preparation of ultra filtration membranes:Impacts of solvents and additives on morphology,permeability and fouling performances

- Experimental detection of bubble-wall interactions in a vertical gas-liquid flow☆

- Horizontal gas mixing in rectangular fluidized bed:A novel method for gas dispersion coefficients in various conditions and distributor designs

- Synthesis of clay-supported nanoscale zero-valent iron using green tea extract for the removal of phosphorus from aqueous solutions

- Hydrodynamic dispersion ofreactive solute in a Hagen-Poiseuille flow of a layered liquid