The Taste of Time

2017-04-13WangYuanchang,WangYuanchang,Huitu等

The Taste of Time

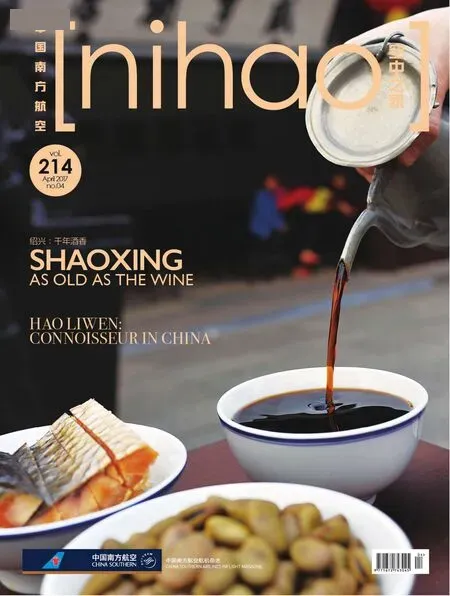

From grain to liquor, a bowl of rich and savory yellow rice wine witnesses the change of time.

Text by Wang Yuanchang Photos by Wang Yuanchang & Huitu Translation by Sonia

一碗黄酒的光阴故事

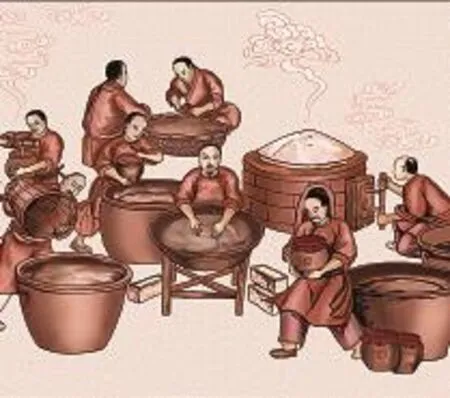

The making of traditional Shaoxing yellow rice wine is complete with over 20 steps. The whole process lasts for a season and only ends in March or April when it comes to sealing and storing the vats.

Soaking: Wine was classifled into three grades based on ingredients back in the Western Han Dynasty (206 BC – 8 AD) and glutinous rice wine was considered the best. Shaoxing yellow rice wine has been made from glutinous rice since ancient times. The key is to select fresh and high-quality white glutinous rice. The criteria of high-quality glutinous rice includes a white color, full grain, nice smell, no foreign substance, and the new harvest of the year. Preparation work is completed after the rice is sieved, washed, and soaked in water for around 40 hours.

Steaming: Drained rice is steamed to 90% done. Ideally the rice is steamed till it is hard on the outside and soft inside, no raw core, loose but not sticky, and evenly done. After turning off the heat, the lid should not be removed until the rice is almost cool. The rice is scooped out of the steamer and spread on bamboo mat to cool gradually before being placed in the vats.

Vatting: Brewing yeast is added to the vats containing glutinous rice in proportion and even stirring is required.

Initial Fermentation (“raking”): Timely raking is essential to control the formation of all elements in the fermentation process. Raking indicates adding malt and the water from Jian Lake, stirring to cool off, adjusting the temperature and supplying oxygen. This is a pivotal technique in the whole brewing craftsmanship and has to be performed by seasoned brewers as it is the most crucial stage to the flnal results of brewing.

Post-fermentation: After the initial fermentation, the wort in the vat is poured into sterilized pottery jars. The jars are sealed with lotus leaves and kept at room temperature until fermentation completes by next spring. The whole fermentation process is as long as 90 days, the longest among all sorts of yellow rice wine.

Pressing and clariflcation: Fermented wort is poured into clean cloth bags and placed on a wooden winepress. Wine liquid flows out after pressing. The liquid will be kept at a low temperature for two to three days to make the wine clear.

Boiling (sterilization by heating): Wine liquid from pressing is steamed until the temperature is increased to 85 degrees Celsius. Heating stops then.

Sealing and storing: The flltered wine liquid is poured into clean jars, covered by lotus leaves and sealed with clay. The jars are kept in cool and airy places for natural ageing.

从谷米到佳酿,一碗浓郁香醇的黄酒记录了一个又一个的冬去春来。

传统的绍兴黄酒,酿酒方式相当复杂,先后有筛米、泡米、蒸饭、摊冷、落缸、密封、发酵等20余道传统工序。整个酿造期持续一个季度左右,直到三四月份入缸密封仓储才算告一段落。

泡米:早在西汉时期,人们根据酿酒原料的不同,将酒分成三级,以糯米酿制的酒为上等。绍兴黄酒自古以来就以糯米为原料,选择新鲜优质的精白糯米,即米粒洁白、颗粒饱满、气味良好、不含杂质的上等优质糯米,同时又要是当年的新米。过筛、淘洗后,用水浸泡40个小时左右,沥干后备用。

蒸饭:将沥干的米上锅蒸至九成熟离火。要求米饭蒸到外硬内软,无夹心、疏松不煳、熟透均匀。熟后不要马上掀锅盖,在锅内把饭放至快凉时再出锅。出锅后打散,再摊放在竹席上自然冷却,然后装入大缸。

落缸:在装有糯米饭的大缸内,按比例加入酒药等,均匀搅拌。

前发酵(俗称开耙): 为了掌握和控制发酵过程中各种成分适时适量的形成,必须适时开耙,即加麦曲、鉴湖水等,进行搅拌冷却、调节温度、补充氧气,这是整个酿酒工艺中较难掌握的一项关键性技术,对酒的最终质量至关重要,必须由酿酒经验丰富的老师傅把关。

后发酵:前发酵结束后,将缸内酒醪灌入经过杀菌的陶制酒坛中,用荷叶封口,空气中自然放置,直至次年立春发酵结束。此工艺前后发酵时间达90天左右,是各类黄酒中酵期最长的。

压榨澄清:将发酵好的醪液装入干净的布袋中,放到木榨上,利用空气压缩原理,榨出酒液。此时将酒液低温放置两至三天,使酒澄清。

煎酒(加热杀菌):把压榨出的酒液放入锅内蒸,当温度升到85度左右,即停止加热。

封存:把滤液装进干净的坛子里,并用荷叶包好,外面再封上泥口,放到阴凉通风处,自然陈化后熟。