导电聚合物在纤维状能源器件中的应用进展

2017-03-10廖春荣李贤军吴义强罗勇锋

廖春荣 熊 峰 李贤军 吴义强 罗勇锋,*

(1中南林业科技大学理学院,长沙 410018;2复旦大学,聚合物分子工程国家重点实验室和先进材料实验室,上海 200438;3中南林业科技大学材料科学与工程学院,长沙 410018)

导电聚合物在纤维状能源器件中的应用进展

廖春荣1,2熊 峰1,2李贤军3吴义强3罗勇锋1,2,*

(1中南林业科技大学理学院,长沙 410018;2复旦大学,聚合物分子工程国家重点实验室和先进材料实验室,上海 200438;3中南林业科技大学材料科学与工程学院,长沙 410018)

导电聚合物由于成本低、安全环保、比电容高和电化学性能稳定等特点,已经被广泛应用于纤维状能源器件中。导电聚合物具有良好的机械、电学和光学性能,同时具有方便可控的化学和电化学过程,可作为能源器件的电极材料。本文综述了导电聚合物在纤维状能源器件中的最新研究进展,如纤维状超级电容器、纤维状太阳能电池和纤维状集成能源器件。同时根据纤维状能源器件的性能要求,对相关材料、制备技术、纤维结构、电子输运以及机械性能等进行了全面总结。

导电聚合物;纤维;超级电容器;太阳能电池;纤维状能源器件

1 Introduction

Nowadays,energy storage is an important challenge.With the development of modern electronic equipments,it is urgently need to develop wearability and environmentally friendly energy storage devices.Fibrous energy devices possess excellent characteristics of lightweight,flexibility,portability and wearability, which become a hot topic in science and technology.Meanwhile, conductive polymers(CPs)have drawn great attention in the field of energy nanotechnology1-6.Typically,CP nanostructures can improve the electrical conductivity of composite materials and achieve a higher specific capacitance proving to be an alternative material in the development of next generation energy storage devices7-9,which including supercapacitors(SCs)10-12and solar cells13-15.CP nanostructures consist mainly of polyaniline(PANI), polypyrrole(PPy)and poly(3,4-ethylenediox-ythiophene)(PEDOT), which apply to fibrous energy devices that can effectively increasethe conductivity and the specific capacitance to meet requirements of light weight,portability and wearability for modern portable electronic applications10,14,16-20.Extensive effort has been made to develop all kinds of CPs and fabricate novel structures to realize fibrous SCs and solar cells.Mechanical stability is a significant factor for the flexible fibrous SCs and solar cells.In order to enhance the mechanical robustness,various flexible substrates containing stainless wire21,carbon nanofibers22-36have been introduced into fibrous electrodes.Furthermore,to improve the electroconductibility and electrochemical performance of fibrous electrodes,conductive polymers are a key active material to be introduced into the composite materials.Novel CPs applied in fibrous energy devices,preparation and structure design of fibrous electrode are summarized in this paper.

2 Fibrous supercapacitors based on conductive polymers

Electrochemically reactive polymers for SCs mostly consist of PANI,PPy,PEDOT and their derivatives37-39.According to theory of redox reactions,CPs demonstrate a high pseudocapacitance(for example,the theoretical capacitances of PANI,PPy and PEDOT are 1284,480 and 210 F·g-1,respectively).However,the active substance of a given electrode cannot be completely utilized,so these theoretical values are difficult to achieve in practical devices. The fibrous SCs(e.g.electrical double-layer capacitors40,41and pseudocapacitors42,43)can provide energy for portable and wearable electronic devices.Fibrous SCs typically possess two forms,a twisting shape and the more conventional coaxial shape structure. Usually,liquid electrolytes possess a number of security vulnerabilities that can fortunately be overcome by gel electrolytes. Furthermore,gel electrolytes are implemented in these devices and are easily applied to the flexible and wearable electronic devices. Fibrous SCs require a matching fiber electrode,e.g.carbon nanotube(CNT)fibers,graphene fibers,carbon nanomaterials/ conductive polymer composite fibers44-51.

2.1 Polyaniline composite fiber electrodes for the fibrous supercapacitors

Among various CPs,PANI is one of the most commonly implemented electrode materials for fibrous SCs due to its low cost of aniline monomers,light weight,facile synthesis,environmental friendliness and excellent capacity for energy storage52-54.In addition,PANI has a high specific pseudocapacitance and high rates of charge and discharge capacity55,56.To realize the full potential of PANI-based fiber-shape SCs,researchers have taken the following measures:(1)increasing the electrical conductivity of PANI;(2)increasing the capacitance retention of PANI;(3)optimizing the low stability of charge-discharge measurements;and (4)reducing the cost and simplifying the synthesis process.

LIAO Chun-Rong,received her B.S.degree from Lingnan Normal University in 2014. She is now a Master Student in Central South University of Forestry and Technology.Her research interest focuses on the interaction between electromagnetic field and biomass materials.

XIONG Feng,received his B.S.degree from Central South University of Forestry and Technology in 2015.He is now a master student in Central South University of Forestry and Technology.His research interest focuses on the supercapacitor and lithium ion battery of functional nanomaterial.

LI Xian-Jun,received his Ph.D.in wood science and technology from Beijing Forestry University in 2005.He is now a professor at Central South University of Forestry and Technology.His research interests focus on wood drying,wood functional modification, forestry biomass composite material and synthesis of functional nanomaterial.

WU Yi-Qiang,received his Ph.D.in biomass utilization from Ehime University in 2005. He is now a professor at Central South University of Forestry and Technology.In 2015, he was elected as fellow of International Academy of Wood Science and Chang Jiang Scholar.His research interests focus on biomass composites,biomass fictionalization and conversion,and advanced functional materials from biomass for energy storage and catalyst.

LUO Yong-Feng,received his B.S.in physics from Hunan Normal University in 1999. Also,he received his M.S.in condensed matter physics from Nankai University in 2005.In 2012,he received his Ph.D.in materials science from Central South University. Since 1999,he has been at Central South University of Forestry and Technology,where he is currently an associate professor in college of science.His current research and interest areas include the solar cell,supercapacitor,lithium ion battery,and synthesis of functional nanomaterial.

2.1.1 Synthesis of polyaniline composite fiber electrodes

To improve the overall capacitance of fibrous SCs based on the PANI nanostructure,the structure of PANI electrodes require optimization57.Nowadays,the common methods to synthesize PANI electrodes are chemical-based and electrochemical-based methods.Liang et al.58successfully deposited PANI nanowire arrays on various substrates(Pt,Si,Au,C,SiO2)through controlled nucleation via an electrochemical process.Because CNTs and graphene possess a large surface area,excellent conductivity, stable chemical properties and outstanding mechanical properties, these carbon nanomaterials composited with PANI have been investigated as an active current collectors for fibrous SCs and these carbon materials modified by PANI in fibrous devices further achieve improved electrochemical performance.

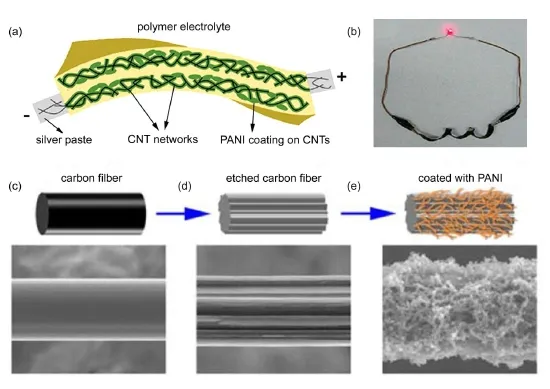

Meng et al.59developed all-solid-state SCs based on two separated PANI/CNT nano-composite fiber electrodes coated by poly (vinyl alcohol)(PVA)/H2SO4gel electrolyte(Fig.1(a)).ALED was lit up very well by this fibrous SC for almost 30 min(Fig.1(b)). Cheng et al.60synthesized a SCs′electrode by depositing PANI nanowires on the surface of an etched carbon fiber(Fig.1(c-e)).

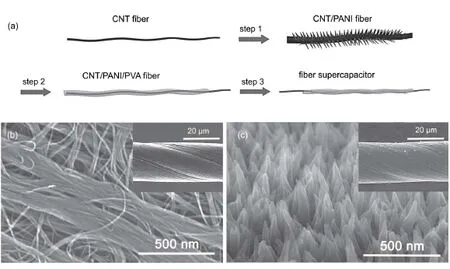

Furthermore,multi-walled CNTs(MWCNTs)are capable of achieving a higher energy density per mass unit than SWCNTs61. Wang et al.38prepared CNT/PANI fiber electrodes with gel PVA/ H2SO4polymer electrolyte through in-situ polymerization shown in Fig.2(a).ACNT fiber could be spun from an aligned MWCNT array,then electrodeposited with conductive PANI nanowire arrays,and subsequently coated with PVA-H2SO4gel electrolyte to form a CNT/PANI/PVA composite fiber.Finally,two composite fibers were twisted together to develop a fibrous SC(Fig.2(a)). The microstructure of the pure CNT and its composite fibers were observed respectively via SEM image(Fig.2(b,c)).After 800 cycles of consecutive charging and discharging,this fibrous SC showed excellent capacitance retention at 91%of its original value.

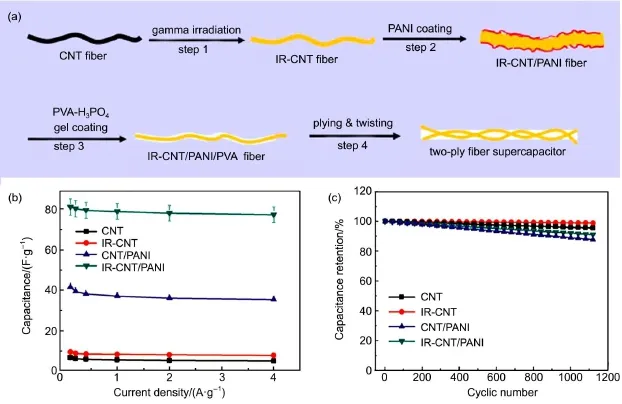

In order to further improve cyclic stability of the PANI-based fiber SCs,Su et al.62prepared CNT/PANI fiber electrodes via chemical polymerization(shown in Fig.3).This SC based on a gamma-irradiated(IR)CNT fiber and aligned-PANI nanowires obtained enhanced cyclic stability of charge-discharge relative to Ref.38,which remained 89%of its original capacitance after 1000 cycles(Fig.3(a,c)),and possessed a high specific capacitance than other fiber materials(Fig.3(b)).

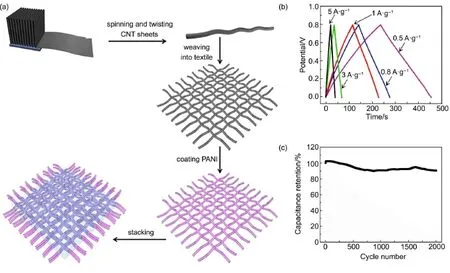

CNT fibers can also be woven into fabric and then coated with PANI to form mesh electrodes61.Then,the gel electrolyte of PVA/ H3PO4was growth on CNT/PANI composite fabric.Finally,two mesh electrodes were stacked to form a planar SC(Fig.4(a)). Owing to the great mechanical strength and prominent electrical performance of CNT fibers and the high electrochemical activity of PANI,the planar SC exhibits a high specific capacitance of 272.7 F·g-1,which demonstrated a capacitance retention of 90% after 2000 cycles(Fig.4(b,c)).

The combination of PANI and aligned CNT fibers in the synthesis of composites is simple,cheap,and effective,which can enhance the specific capacitance of SC.Further researches verify that the electrode of ordered PANI array nanostructure exhibits excellent specific capacitance and capacity retention in comparison with randomly disordered PANI nanowires62,63.

Fig.1 (a)Schematic illustration of the PANI/CNT nanocomposite all-solid-state fibrous SCs device;(b)an optical picture of the above fibrous SCs with lighting a red light-emitting-diode59;(c)diagrammatic sketch and SEM image of a carbon fiber; (d)diagrammatic sketch and SEM of a etched carbon fiber;(e)etched carbon fiber coated with PANI60

2.1.2 Impact of polyaniline content on the performance of SCs

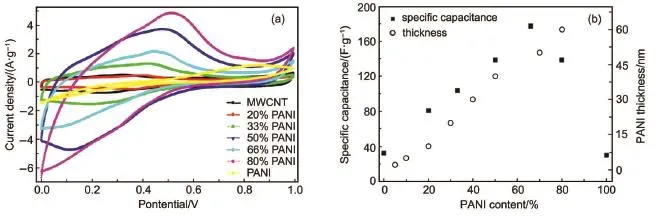

The PANI/MWCNT composite materials have a uniform core-shell structure which are prepared on the MWCNTs templates via in-situ polymerization64.The composite materials possessing 80% (w,mass fraction)PANI content could be obtained on aligned MWCNTs sheet.The impact of PANI contents on the specific capacitance was further studied(Fig.5).The results demonstrate that the highest specific capacitance had been observed when the PANI content was 66%(w).After 700 charging-discharging cycles,the specific capacitance is maintained at 70.9%and further remains stable after more cycles.

Fig.2 (a)Diagrammatic sketch of the preparation for the two-ply yarn SCs;(b)SEM image of a pure CNT fiber and the morphologies of the initial pure CNT fibers;(c)SEM image of a CNT/PANI composite fiber and microstructure of the composite fibers38

Fig.3 (a)Schematic illustration of gamma-IR-CNT/PANI two-ply fiber SC;(b)capacitance at different current densities; (c)stability of charge-discharge cycles62

MWCNT sheets containing varying PANI content are also used as electrodes for flexible SCs and demonstrate the highest specific capacitance of 233 F·g-1.Under identical conditions,the maximum specific capacitance is 36 times greater than a neat MWCNT sheet and 23 times of pure PANI(Fig.6).The SCs also show high cyclic stability.Fig.6(b - f)demonstrate morphologies of the MWCNT/PANI composite films of varying PANI content.Thevoids were essentially filled in aligned CNTs when the PANI content was reached about 70%(w).When the PANI content was less than about 50%(w),specific capacitances increased with increasing PANI content,when the PANI content was more than about 50%(w),the specific capacitance reached a plateau(Fig.6 (g,h)).However,when the PANI content is more than 86%(w), excess PANI leads to weak interaction between the aligned MWCNT fiber and PANI,and poor efficiency of ion diffusion (Fig.6(i)).

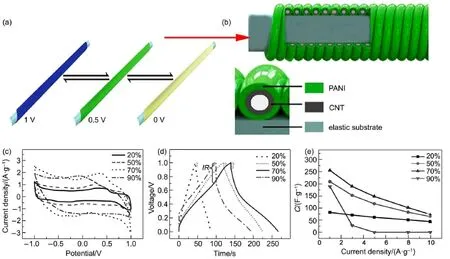

PANI and aligned MWCNTs composite fibrous electrodes were also assembled via chemical polymerization65.The aligned MWCNT/PANI composite films were winded on an elastic fiber as fibrous electrodes,which could realize flexible,stretchable,and electrochromic fibrous SCs62that facilitated quickly and reversible color conversions(Fig.7(a,b)).PANI content has a great influence on the performance of SCs,Fig.7(c)shows cyclic voltammograms with different PANI content in the fibrous SC.When the PANI content increased to 70%,the cyclic voltammagrams′area reached a maximum and when the PANI content was further increased to 90%,the cyclic voltammagram′s area decreased(Fig.7(d)).The previous conclusions were also validated by constant current charge-discharge(Fig.7(e)).

Fig.4 (a)Preparation of a planar SC based on the CNT/PANI composite fabric;(b)constant current charge-discharge curves of the planar SC;(c)specific capacitance with different cycle numbers at 1A·g-161

Fig.5 (a)Cyclic voltammograms of SCs based on MWCNT,pure PANI,and various PANI contents(scan rate,5 mV·s-1); (b)specific capacitances and PANI thickness affected by the PANI content in the SCs64

2.2 Polypyrrole composite fiber electrodes for the fibrous supercapacitors

PPy is another CP that has been utilized for its energy storage applications owing to its excellent physical and chemical properties66,67.

2.2.1 Synthesis of polypyrrole composite fiber electrodes

In comparison with PANI,the electrochemistry performance of

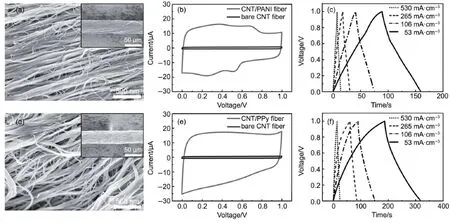

the composite electrode based on PPy also relies on its synthesis method and active surface area.Wang et al.68designed composite fiber electrodes of CNT/PANI and CNT/PPy by electrochemical polymerization(Fig.8).It has been found that PPy is another kind of an active material(identical to PANI)to synthesize composite fibrous electrodes.The CNT and PPy composite fibers not only exhibit a high specific capacitance but also high stability and a wide temperature range69.

Fig.6 MWCNT sheets with different mass fractions of PANI observed by SEM(a-f)and their performance in SCs(g-i)65

Fig.7 (a)Electrochromic and(b)structure of the wearable fibrous SC;(c)cyclic voltammetry curves with different PANI content at 10 mV·s-1;(d)constant current charge-discharge curves for different weight percentages of PANI at 1A·g-1, (e)the relation between of specific capacitance and current density62

Furthermore,Guo et al.69prepared CNT-PPy fibers by diamond wire-drawing dies which can used for electrodes of fibrous SCs. APPy nanolayer was deposited on carbon fibers by using an insitu polymerization technique70.Poly-2,5-dimercapto-1,3,4-thiadiazole(poly(DMcT))can also be deposited on outside of carbon fiber textile by electrochemical method71,producing flexible and huge surface area composite materials that behave as SCs′electrodes(Fig.9).The specific capacitance of this SC affected by the scan rate is shown in Fig.9(c);when the scan rate decreases,the specific capacitance increases.The maximum specific capacitance values can be obtained at 1 mV·s-1for PPy composite fibers.

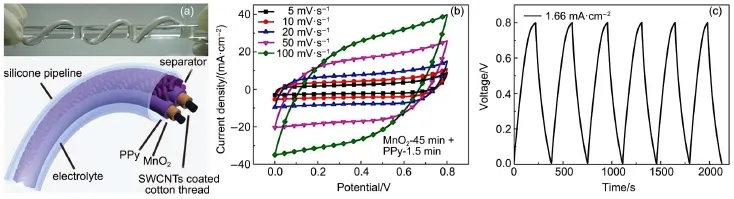

MnO2has a large theoretical specific capacitance of 1370 F·g-1and exhibits environmental friendliness,cost effectiveness and a natural abundance for pseudocapactive materials.Nonetheless,the poor electric conductivity of MnO2limits its application in capacitor72.Meanwhile,PPy with high conductivity and specific capacitance can solve the above shortcomings73.Hence,A thin PPy film deposited on the surface of MnO2nanostructures39(Fig.10(a)) and single-walled CNTs could improve the electrical conductivity and electrochemical performance(Fig.10(b,c)).

Fig.8 (a)SEM image of a single CNT/PANI fiber and the morphologies of the aligned composite fibers,(b)cyclic voltammogram(CV)and (c)constant current charging-discharging curves of SC based on aligned CNT/PANI composite fiber;(d)SEM image of a single CNT/PPy composite fiber and the morphologies of the aligned composite fibers,(e)cyclic voltammograms of bare CNT fiber and CNT/PPY fiber, (f)constant current charge-discharge curves based on CNT/PPy composite fiber for SC68

Fig.9 (a)SEM image of the PPy and the transversal surface of the CF/PPy composite fibers,(b)SEM image of the poly(DMcT)/PPy and the transversal surface of the CF/poly(DMcT)/PPy composite fibers,(c)scanning rate as a function of specific capacitance71

2.2.2 Performance of polypyrrole composite fiber electrodes

Flexible fibrous SCs is easy to be integrated into textiles. However,mass production of fibrous SCs is still a challenge by using manufacturing processes.Meanwhile,helical CNT fibrous SCs can work under many extreme deformation conditions suchas super-elongation(tensile strain up to 150%)(see Fig.11),arbitrary shape change(entangling),and high frequency stretching74, which offer opportunities for portable electronic device applications.

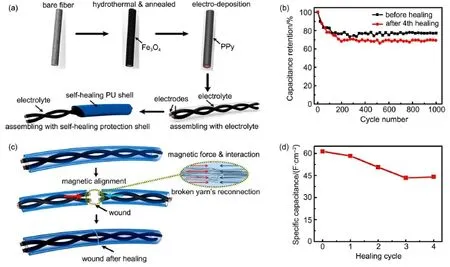

However,mechanical damage of fibrous SCs seriously affects the reliability and lifespan of the device during practical applications.It is well known that Fe3O4exhibits permanent magnetism and provides self-healing properties,while the Fe3O4magnetic layer guarantees restoration of electrical conductivity via magnetic alignment75.Therefore,a fiber-based SC endowed with mechanically and electrically self-healing was fabricated based on magnetic Fe3O4and PPy(see Fig.12).These electrodes exhibit excellent performance of mechanical strength and self-healing behavior.

PPy nanorods are also capable of being deposited on cotton fabrics via in-situ polymerization in the fibrillar complex of FeCl377.The fabrics could be directly implemented as SC electrodes.The capacitance remained higher than 200 F·g-1after 500 cycles.

Wang et al.76synthesized densely packed PPy-nanocellulose composite electrodes via surface modified nanocellulose fibers (NCFs)as substrates for PPy-nanocellulose deposition(Fig.13). The composite with the highest bulk density(PPy/c-NCFs)exhibited the highest volumetric capacitances value(173 F·cm-3)at 1 mA · cm-2.The PPy/c-NCF-based symmetric supercapacitor showed excellent cycling stability,which retained 93%of its initial value after 5000 cycles(Fig.13(c)).More recently,PPy/TiN/ PANI coaxial nanotube composite materials were prepared by electroless plating78.

Fig.10 (a)a cable-type supercapacitor and a twisting cable-type supercapacitor; (b)CV curves of SCs based on a PPy-MnO2-CNT-cotton thread electrodes;(c)galvanostatic charging and discharging curves of the SCs39

Fig.11 (a)Illustration of the process of a helical CNT fiber(with or without PPy on the surface)coated by gel electrolyte,while two of such fibers twisted into a double-helix SC;(b)CV curves of the SC with different testing conditions including static(without stretching, f=0 Hz)and during dynamic test;(c)photographs of a double helix CNT fiber SC and its tensile strain(ε)up to 150%; (d)capacitance retention of the SC when stretched by different frequencies74

2.3 Poly(3,4-ethylenedioxythiophene)composite fiber electrodes for the fibrous supercapacitors

Apart from PANI and PPy,PEDOT was also utilized to fabricate composite fibrous SCs due to its high environmental stability79,80.Furthermore,PEDOT electropolymerized in ionic liquidsfor energy storage applications has been studied in recent publications81,82.

Fig.12 (a)Preparation process of the magnetic-assisted self-healable SC;(b)the self-healing process of SC; (c)capacitance retention at 4.4 mA·cm-2;(d)before and after healing specific capacitance as a function of cycles75

Fig.13 (a)Schematic of NCFs paper and molecular structure of NCFs;(b)volumetric capacitances as a function of varying charging/discharging current densities;(c)cycling performance in terms of capacitance retention at 30 mA·cm-2for a PPy/c-NCFs based device(the capacitance from the first cycle is set to 100%)76

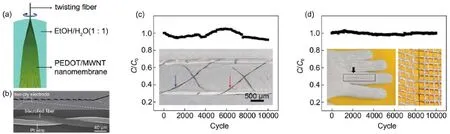

PEDOT nanostructures containing a large surface area were synthesized via vapor phase polymerization83and exhibited a specific capacitance of 175 F·g-1due to a highly conducting and efficient nanofibrillar electrode.CNT fibers can be used as an effective current collector in fibrous SCs(Fig.14).PEDOT was potentiostatically grown on CNT fibers84to yield a specific capacitance of 126.23 F·g-1.Meanwhile,wearable,knottable and viewable fibers were also implemented as high performance electrodes for pseudocapacitive SCs82.The SCs utilized a MWCNT/PEDOT nano-composite fiber and a Pt wire as two-fiber electrodes with a H2SO4/PVA gel polymer electrolyte.The fibrous SCs were twisted,helically wound or woven into textile and displayed capacitance reduction of only 2%after 2000 cycles and 8%after 10000 cycles,respectively,indicating excellent cycling performance under different flexible states.

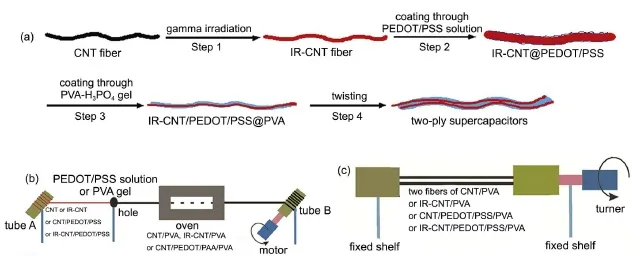

Su et al.85developed a facile synthesis route to yield highperformance,flexible,fibrous SCs based on PEDOT/poly(styrenesulfonate)(PSS)(Fig.15).The aligned CNT fiber was treated by gamma-irradiation(IR)and then coated with PEDOT/PSS and gel electrolyte in order to enhance capacitance.Finally,two coated fibers twisted around to form an electrode for SCs.The results verify that gamma-IR greatly increases the electrical conductivityand improves the gram capacitance of the fibrous SC.These flexible fibrous SCs with fine diameters can be easily applied in wearable electronics.

PEDOT and its metal oxide composites have been synthesized in a porous alumina membrane by a simple electrochemical method86,87.Conventional metal oxides,such as MnO2and RuO2, possess poor conductivity,yet can be applied to pseudocapacitors and other electrochemical applications.In order to solve the problem of low electrical conductivity,Mirvakili et al.88deposited high performing pseudocapacitive materials(i.e.conductive polymers)or niobium nanowires on the electrode to realize high power,energy density and capacitance in fibrous SCs.Yuan et al.80prepared meter-long PEDOT:PSS fibers through a coagulation bath,in which the fibers could be used as electrodes of SC exhibiting an excellent areal capacitance and adequate mechanical stability.

It is a challenge to further increase the electrical conductivity and stability of charge and discharge performance of the conductive polymers.However,compared with the traditional plane SCs,fibrous SCs have unique one-dimensional structure,that can meet the requirements of miniaturization,integration portable and wearable.In the future,fibrous SCs based on CPs and carbon composite materials can achieve greater advantages of high power

density,fast charge-discharge and long cycle life.

Fig.14 (a)Preparation of a biscrolled PEDOT/MWNT fiber;(b)SEM image of the PEDOT/MWNT biscrolled fiber; (c)capacitive performance of fibrous SC winding on a glass tube;(d)capacitive performance of fibrous SC woven into a glove82,83

Fig.15 (a)Schematic of the preparation route for two-ply fiber SCs;methods used for(b)coating fibers with PEDOT/PSS and PVA-H3PO4gel and(c)preparing two-ply fiber SCs85

3 Conductive polymers in fibrous solar cells

With the recent advancement of portable devices,miniaturization of energy harvesting and storage devices is highly desired to meet their demands.Fibrous solar cells utilized as energy harvesting devices show unigue and promising advantages89. Materials and their structural designs are prominent for these fibrous solar cells.TiO2particles and CP are used as two opposite electrode materials,which were grown on the surface of a round steel to form a coaxial structure.The polymer solar cell(PSC)was triumphantly made into fiber format as the same of organic solar cell,which acquired a transfer efficiency of 0.6%higher than the latter of 0.5%90,91.

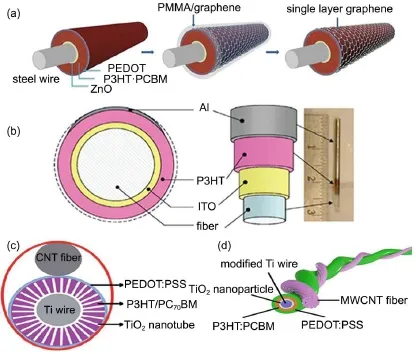

The first fibrous PSC based on two metal wires was created in 2009.The PSC was composed of three parts,the electron transport layer(TiOx),hole transport layer(PEDOT:PSS),and photoactive layers were synthesized on a steel wire23.Twisted structure can improved electric contact between the two electrodes,in which experimental results showed that PSC had an average efficiency of 2.99%.However,the illuminated field of primary electrode would be shadowed by the superficially wrapped secondary electrode.The highest power conversion efficiency(PCE)is3.81%from the fibrous PSC,in which the shadowing effect of the secondary electrode was eliminated by placing it beneath the primary electrode.

Two twisted metal fibrous electrodes with internal stress can be easily displaced because the metal electrode is not mechanically stable.However,as a more flexible fiber electrode,CNT fibers are chosen as the counter electrode of PSCs.A CNT fiber was wrapped around a metal wire deposited with ZnO nanoparticles, the corresponding PSC demonstrated an efficiency of 2.11%92.In addition,two-dimensional materials,such as graphene,are applied to counter electrode because of their flexibility,excellent electrical conductivity and enhanced surface area(see Fig.16(a))93.The graphene sheet modified by gold nanocrystal layer could improve electroconductivity which is then twisted with a primary electrode (see Fig.16(a)).Meanwhile,single-layer graphene has an optical transmission of 95%,which assists in obtaining insolation.The flexible single-layer graphene enhances a conformal contact with the electrode.Moreover,even though PSC is exposed to air for a few days,the PCE was still maintained by more than 95%.Because the charge generation and segregation only appear on the primary electrode,and the counter electrode acts as a significant factor of transfer electrons.

Additionally,coaxial fibrous PSC based on optical fibers have been prepared(see Fig.16(b))94.Optical fibers modified by indium tin oxide(ITO)are utilized as substrates in the coaxial structure. Modified plastic fibers,like polypropylene fiber and polyimidebased silica fiber,could replace the optical fiber as a substrate in PSC.However,the thickness of the deposited metal layers was under 20 nm to ensure the propagation of incident ray96.A vast variety of fibrous PSCs based on aligned CNT fibers were studied in the recent years23,95.Because of their enhanced flexibility,light weight,high electrical conductivity(102-103S·cm-1),mechanical strength(~500 MPa),and electro-catalytic ability,aligned CNT fibers have been studied for their use as fibrous electrodes in PSCs.A titanium wire modified by TiO2nanotube acted as electron-transporting layer and electrode23.Subsequently,the titanium wire with TiO2nanotube was placed into a P3HT:PC70BM solution, and was then coated with PEDOT:PSS by dip-coating method, which acted as the primary electrode.Finally,the aligned CNT fiber was wrapped around the primary electrode(Fig.16(c)).The TiO2nanotube was used as electronic receiver,because the conduction band(4.2 eV)of TiO2was less than the P3HT′s lowest unoccupied molecular orbital level.The electrons drifted across PC70BM or TiO2,and then transferred to the Ti wire.Meanwhile, the holes drifted across PEDOT:PSS,and then converged on CNT fiber.This PSC gave a PCE of 0.15,while the values of the other parameters of PSC were Voc=0.42V,Jsc=0.98 mA·cm-2,and FF= 36%.The weak connection between the electrode and photosensitive layer led to low PCE(Fig.16(d))95.TiO2nanoparticles assist in increasing the contact surface area and display advantages for dye-sensitized solar cells.Sequentially,the PCE of PSC with TiO2nanoparticles was increased by 36%.If the outer surface of the Ti wire was destroyed via coating TiO2nanotubes,TiO2nanoparticles could remedy the defects.

Fibrous solar cell with unique one-dimensional(1D)configurations can be woven into an energy textile,but the challenges in fabricating fibrous solar cell still remain.Such as uniform thin electrode layers are difficultly coated on the fiber substrate for the core sheath structure and two fiber electrode cannot closely and stably intertwined for the twisting structure.In addition the low efficiency of fibrous solar cell badly limits the commercialized development.However,we can further optimize the structure, material,and technique to fabricate better fibrous solar cell in the future.

Fig.16 Preparation of a coaxial fibrous PSC based on(a)graphene93,(b)optical fiber94, (c)Ti wire amended by TiO2nanotubes23and(d)TiO2nanoparticles95

4 Integration of supercapacitors and solar cells

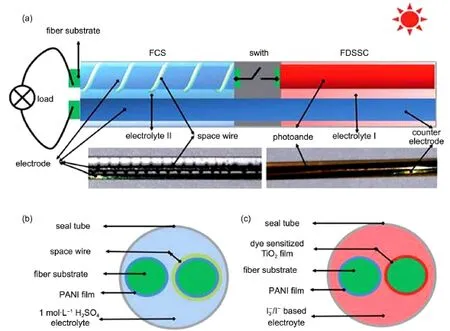

Integrated devices have been extensively researched for many years,while the first fibrous integrated devices were successfully realized in 201197.These results have attracted more and more efforts to investigate the viability of fibrous integrated energy devices.Planar integrated energy devices have been realized on the basis of PSC and then created a variety of integrated power conversion and storage devices97-101.

Fig.17 (a)Schematic illustration of the all-solid-state,coaxial fibrous integrated energy device; (b)charging-discharging process of the integrated device;(c)charging-discharging curve at 0.1 μA19

Fig.18 (a)Diagram of the integrated energy fiber based on fiber DSSC and fiber SC; (b)cross-sectional diagram of the fiber SC and(c)fiber DSSC98

An all-solid-state,flexible fibrous integrated device incorporating photovoltaic conversion and energy storage has been developed by Zhang et al.19in 2014(see Fig.17).The coaxial structure of the fibrous integrated device was conducive to elucidating the preponderances for both components(see Fig.17(a)). This integrated fibrous energy device has been realized on the basis of Ti wire modified by TiO2nanotubes and aligned CNT sheets.For the photovoltaic conversion component,vertically arranged TiO2nanotubes are deposited Ti wire,followed by growing of P3HT:PCBM as the active materials and PEDOT:PSS as the hole transport materials,the aligned CNT sheet was finally twisted around the Ti wire to form the photovoltaic conversion component.For the energy storage component,the PVA/H3PO4gel electrolyte was coated outside of a modified Ti wire and then the aligned CNT sheets were wrapped on it to form the energy storage part.In this device,the electrons are transferred to the Ti wire by TiO2nanotubes.In the meantime,the holes are collected by CNT sheets via a hole transfer layer of PEDOT:PSS.The charge-discharge process is shown in Fig.17(b)while a charge-discharge curve is shown in Fig.17(c).The PCE of the photovoltaic conversion part can reach 1.01%and the specific length capacitance of the energy storage part is about 0.08 mF·cm-1.The total energy conversion efficiency is 0.82%for the fibrous integrated energydevice.All-solid-state status can allow for integrated devices to achieve high stability during the process of deformation.

Another fibrous integrated device of a dye-sensitive solar cell (DSSC)and a SC has been reported by Fuet al.98.It also can be utilized for power conversion and storage.The PANI was coated on a metal wire by electrochemical deposition to form electrodes for the DSSC and SC.The total energy conversion efficiency of the fibrous integrated energy device was 2.1%.The structural schematic of the fibrous integrated device is shown in Fig.18(a).

In more recent years,effective measures are underway to further improve the integration of energy devices.The total energy transformation efficiency act as a significant role that determines the overall performance of fibrous integrated device.In order to improve fibrous integrated devices,it is imperative to exploit solar cells exhibiting a higher PCE102,103.

5 Conclusions

In this review,recent work on CPs in fibrous energy devices has been summarized in detail.CPs,such as PANI,PPy and PEDOT, possess significant potential and outstanding performance in fibrous energy devices.Various CPs exhibit high pseudo-capacitance as active materials of fibrous electrodes.In the meantime, CPs,acting as active materials in the counter electrode behave comparable to platinum electrodes in solar cells.

(1)Li,C.;Bai,H.;Shi,G.Chem.Soc.Rev.2009,38(8),2397. doi:10.1039/B816681C

(2)Lu,X.;Zhang,W.;Wang,C.;Wen,T.C.;Wei,Y.Prog.Polym. Sci.2011,36(5),671.doi:10.1016/j. progpolymsci.2010.07.010

(3)Tran,H.D.;Li,D.;Kaner,R.B.Adv.Mater.2009,21(14-15),1487.doi:10.1002/adma.200802289

(4)Wang,L.L.;Xing,R.G.;Zhang,B.W.;Hou,Y.Acta Phys.-Chim.Sin.2014,30(9),1659.[汪丽丽,邢瑞光,张邦文,侯渊 .物理化学学报,2014,30(9),1659.]doi:10.3866/PKU. WHXB201406162

(5)Yang,S.;Xu,G.Y.;Han,J.P.;Bing,H.;Dou,H.;Zhang,X.G.Acta Phys.-Chim.Sin.2015,31(4),685.[杨 硕,徐桂银,韩金鹏,邴 欢,窦 辉,张校刚.物理化学学报,2015,31(4), 685.]doi:10.3866/PKU.WHXB201502022

(6)Lin,Y.C.;Zhong,X.X.;Huang,H.X.;Wang,H.Q.;Feng,Q. P.;Li,Q.Y.Acta Phys.-Chim.Sin.2016,32(2),474.[林有铖,钟新仙,黄寒星,王红强,冯崎鹏,李庆余.物理化学学报,2016,32(2),474.]doi:10.3866/PKU.WHXB201511104

(7)Huang,M.H.;Mao,S.;Feick,H.;Yan,H.;Wu,Y.;Kind,H.; Weber,E.;Russo,R.;Yang,P.Science2001,292(5523),1897. doi:10.1126/science.1060367

(8)Li,F.S.;Wu,Y.S.;Chou,J.;Winter,M.;Wu,N.L.Adv. Mater.2015,27(1),130.doi:10.1002/adma.201403880

(9)Long,Y.Z.;Li,M.M.;Gu,C.;Wan,M.;Duvail,J.L.;Liu,Z.; Fan,Z.Prog.Polym.Sci.2011,36(10),1415.doi:10.1016/j. progpolymsci.2011.04.001

(10)Lang,X.;Hirata,A.;Fujita,T.;Chen,M.Nat.Nanotech.2011,6(4),232.doi:10.1038/nnano.2011.13

(11)Snook,G.A.;Kao,P.;Best,A.S.J.Power Sources2011,196(1),1.doi:10.1016/j.jpowsour.2010.06.084

(12)Yu,X.;Su,X.;Yan,K.;Hu,H.;Peng,M.;Cai,X.;Zou,D.Adv.Mater.Technol.2016,doi:10.1002/admt.201600009

(13)Alemu,D.;Wei,H.Y.;Ho,K.C.;Chu,C.W.Energy Environ. Sci.2012,5(11),9662.doi:10.1039/C2EE22595F

(14)Chen,T.;Qiu,L.;Yang,Z.;Peng,H.Chem.Soc.Rev.2013,42(12),5031.doi:10.1039/C3CS35465B

(15)Qiu,L.;He,S.;Yang,J.;Deng,J.;Peng,H.Small2016,doi:10.1002/smll.201600326

(16)Cai,Z.;Li,L.;Ren,J.;Qiu,L.;Lin,H.;Peng,H.J.Mater. Chem.A2012,1(2),258.doi:10.1039/C2TA00274D

(17)Chen,T.;Qiu,L.;Cai,Z.;Gong,F.;Yang,Z.;Wang,Z.;Peng, H.Nano Lett.2012,12(5),2568.doi:10.1021/nl300799d

(18)Ren,J.;Bai,W.;Guan,G.;Zhang,Y.;Peng,H.Adv.Mater.2013,25(41),5965.doi:10.1002/adma.201302498

(19)Lin,H.;Weng,W.;Ren,J.;Qiu,L.;Zhang,Z.;Chen,P.;Chen, X.;Deng,J.;Wang,Y.;Peng,H.Adv.Mater.2014,26(8), 1217.doi:10.1002/adma.201304319

(20)Xia,K.L.;Jian,M.Q.;Zhang,Y.Y.Acta Phys.-Chim.Sin.2016,32(10),2427.[夏凯伦,蹇木强,张莹莹.物理化学学报,2016,32(10),2427.]doi:10.3866/PKU.WHXB201607261

(21)Fan,X.;Chu,Z.;Wang,F.;Zhang,C.;Chen,L.;Tang,Y.;Zou, D.Adv.Mater.2008,20(3),592.doi:10.1002/adma.200701249

(22)Guo,W.;Liu,C.;Sun,X.;Yang,Z.;Kia,H.G.;Peng,H.J. Mater.Chem.2012,22(3),903.doi:10.1039/C1JM13769G

(23)Chen,T.;Qiu,L.;Li,H.;Peng,H.J.Mater.Chem.2012,22(44),23655.doi:10.1039/C2JM35158G

(24)Ren,J.;Li,L.;Chen,C.;Chen,X.;Cai,Z.;Qiu,L.;Wang,Y.; Zhu,X.;Peng,H.Adv.Mater.2013,25(8),1155.doi:10.1002/ adma.201203445

(25)Cai,Z.;Li,L.;Ren,J.;Qiu,L.;Lin,H.;Peng,H.J.Mater. Chem.A2013,1(2),258.doi:10.1039/C2TA00274D

(26)Yang,Z.;Sun,H.;Chen,T.;Qiu,L.;Luo,Y.;Peng,H.Angew. Chem.Int.Ed.2013,52(29),7545.doi:10.1002/ ange.201301776

(27)Chen,X.;Qiu,L.;Ren,J.;Guan,G.;Lin,H.;Zhang,Z.;Chen, P.;Wang,Y.;Peng,H.Adv.Mater.2013,25(44),6436. doi:10.1002/adma.201301519

(28)Luo,Y.;Zhang,Y.;Zhao,Y.;Fang,X.;Ren,J.;Weng,W.; Jiang,Y.;Sun,H.;Wang,B.;Cheng,X;Peng,H.J.Mater. Chem.A2015,3(34),17553.doi:10.1039/C5TA04457J

(29)Li,Z.;Mi,Y.;Liu,X.;Liu,S.;Yang,S.;Wang,J.J.Mater. Chem.2011,21(38),14706.doi:10.1039/C1JM11941A

(30)Naoi,K.;Ishimoto,S.;Miyamoto,J.I.;Naoi,W.Energy Environ.Sci.2012,5(11),9363.doi:10.1039/C2EE21675B

(31)Jiang,H.;Lee,P.S.;Li,C.Energy Environ.Sci.2013,6(1), 41.doi:10.1039/C2EE23284G

(32)Dai,L.;Chang,D.W.;Baek,J.B.;Lu,W.Small2012,8(8), 1130.doi:10.1002/smll.201101594

(33)Chen,W.;Rakhi,R.;Hedhili,M.N.;Alshareef,H.N.J.Mater. Chem.A2014,2(15),5236.doi:10.1039/C3TA15245F.

(34)Dong,Z.;Jiang,C.;Cheng,H.;Zhao,Y.;Shi,G.;Jiang,L.; Qu,L.Adv.Mater.2012,24(14),1856.doi:10.1002/ adma.201200170

(35)Cong,H.P.;Ren,X.C.;Wang,P.;Yu,S.H.Sci.Rep.-UK2012,2,613.doi:10.1038/srep00613

(36)Xin,G.;Yao,T.;Sun,H.;Scott,S.M.;Shao,D.;Wang,G.; Lian,J.Science2015,349(6252),1083.doi:10.1126/science. aaa6502

(37)Lota,K.;Khomenko,V.;Frackowiak,E.J.Phys.Chem.Solids2004,65(2),295.doi:10.1016/j.jpcs.2003.10.051

(38)Wang,K.;Meng,Q.;Zhang,Y.;Wei,Z.;Miao,M.Adv.Mater.2013,25(10),1494.doi:10.1002/adma.201204598

(39)Liu,N.;Ma,W.;Tao,J.;Zhang,X.;Su,J.;Li,L.;Yang,C.; Gao,Y.;Golberg,D.;Bando,Y.Adv.Mater.2013,25(35), 4925.doi:10.1002/adma.201301311

(40)Frackowiak,E.Phys.Chem.Chem.Phys.2007,9(15),1774. doi:10.1039/B618139M

(41)Stoller,M.D.;Park,S.;Zhu,Y.;An,J.;Ruoff,R.S.Nano Lett.2008,8(10),3498.doi:10.1021/nl802558y.

(42)Peng,C.;Zhang,S.;Jewell,D.;Chen,G.Z.Prog.Nat.Sci.2008,18(7),777.doi:10.1016/j.pnsc.2008.03.002

(43)Wei,W.;Cui,X.;Chen,W.;Ivey,D.G.Chem.Soc.Rev.2011,40(3),1697.doi:10.1039/C0CS00127A

(44)Chang,K.W.;Lim,Z.Y.;Du,F.Y.;Yang,Y.L.;Chang,C.H.; Hu,C.C.;Lin,H.P.Diam.Relat.Mater.2009,18(2),448. doi:10.1016/j.diamond.2008.10.003

(45)Hussain,A.;Kumar,A.J.Power Sources2006,161(2),1486. doi:10.1016/j.jpowsour.2006.05.051

(46)Huang,H.S.;Chang,K.H.;Suzuki,N.;Yamauchi,Y.;Hu,C. C.;Wu,K.C.W.Small2013,9(15),2520.doi:10.1002/ smll.201202786

(47)Li,S.M.;Wang,Y.S.;Yang,S.Y.;Liu,C.H.;Chang,K.H.; Tien,H.W.;Wen,N.T.;Ma,C.C.M.;Hu,C.C.J.Power Sources2013,225,347.doi 10.1016/j.jpowsour.2012.10.037

(48)Hu,C.C.;Wang,C.W.;Wu,T.H.;Chang,K.H.Electrochim. Acta2012,85,90.doi:10.1016/j.electacta.2012.07.123

(49)Hsu,C.T.;Hu,C.C.J.Power Sources2013,242,662. doi:10.1016/j.jpowsour.2013.05.130

(50)Chen,Y.C.;Hsu,Y.K.;Lin,Y.G.;Lin,Y.K.;Horng,Y.Y.; Chen,L.C.;Chen,K.H.Electrochim.Acta2011,56(20), 7124.doi:10.1016/j.electacta.2011.05.090

(51)Wang,S.;Pei,B.;Zhao,X.;Dryfe,R.A.Nano Energy2013,2(4),530.doi:10.1016/j.nanoen.2012.12.005

(52)Zhang,Y.;Feng,H.;Wu,X.;Wang,L.;Zhang,A.;Xia,T.; Dong,H.;Li,X.;Zhang,L.Int.J.Hydrog.Energy2009,34(11),4889.doi:10.1016/j.ijhydene.2009.04.005

(53)Rahy,A.;Yang,D.J.Mater.Lett.2008,62(28),4311. doi:10.1016/j.matlet.2008.06.057.

(54)Yang,J.E.;Jang,I.;Kim,M.;Baeck,S.H.;Hwang,S.;Shim, S.E.Electrochim.Acta2013,111,136.doi:10.1016/j. electacta.2013.07.183

(55)Ryu,K.S.;Lee,Y.G.;Kim,K.M.;Park,Y.J.;Hong,Y.S.; Wu,X.;Kang,M.G.;Park,N.G.;Song,R.Y.;Ko,J.M.Synth.Met.2005,153(1),89.doi:10.1016/j. synthmet.2005.07.167

(56)Jang,J.;Bae,J.;Choi,M.;Yoon,S.H.Carbon2005,43(13), 2730.doi:10.1016/j.carbon.2005.05.039

(57)Peng,C.;Hu,D.;Chen,G.Z.Chem.Commun.2011,47(14), 4105.doi:10.1039/C1CC10675A

(58)Liu,J.;Lin,Y.;Liang,L.;Voigt,J.A.;Huber,D.L.;Tian,Z. R.;Coker,E.;Mckenzie,B.;Mcdermott,M.J.Chem.-Eur.J.2003,9(3),604.doi:10.1002/chem.200390064

(59)Meng,C.;Liu,C.;Chen,L.;Hu,C.;Fan,S.Nano Lett.2010,10(10),4025.doi:10.1021/nl1019672

(60)Cheng,Q.;Tang,J.;Ma,J.;Zhang,H.;Shinya,N.;Qin,L.C.J.Phys.Chem.C2011,115(47),23584.doi:10.1021/ jp203852p

(61)Pan,S.;Lin,H.;Deng,J.;Chen,P.;Chen,X.;Yang,Z.;Peng, H.Adv.Energy Mater.2015,5(4),1401438.doi:10.1002/ aenm.201401438

(62)Su,F.;Miao,M.;Niu,H.;Wei,Z.ACS Appl.Mater.Interfaces2014,6(4),2553.doi:10.1021/am404967x

(63)Wang,K.;Wu,H.;Meng,Y.;Wei,Z.Small2014,10(1),14. doi:10.1002/smll.201301991

(64)Zhou,Y.;Qin,Z.Y.;Li,L.;Zhang,Y.;Wei,Y.L.;Wang,L.F.; Zhu,M.F.Electrochim.Acta2010,55(12),3904.doi:10.1016/ j.electacta.2010.02.022

(65)Lin,H.;Li,L.;Ren,J.;Cai,Z.;Qiu,L.;Yang,Z.;Peng,H.Sci. Rep.-UK2013,3,1353.doi:10.1038/srep01353

(66)Sultana,I.;Rahman,M.;Li,S.;Wang,J.;Wang,C.;Wallace, G.G.;Liu,H.K.Electrochim.Acta2012,60,201. doi:10.1016/j.electacta.2011.11.037

(67)Wang,J.;Xu,Y.;Wang,J.;Du,X.Synth.Met.2011,161(11), 1141.doi:10.1016/j.synthmet.2011.01.011

(68)Wang,B.;Fang,X.;Sun,H.;He,S.;Ren,J.;Zhang,Y.;Peng, H.Adv.Mater.2015,27(47),7854.doi:10.1002/ adma.201503441

(69)Guo,F.;Xu,R.;Cui,X.;Zhang,L.;Wang,K.;Yao,Y.;Wei,J.J.Mater.Chem.A2016,4(23),9311.doi:10.1039/ C6TA02437H

(70)Kim,J.H.;Sharma,A.K.;Lee,Y.S.Mater.Lett.2006,60(13),1697.doi:10.1016/j.matlet.2005.12.002

(71)Davoglio,R.A.;Biaggio,S.R.;Bocchi,N.;Rocha-Filho,R. C.Electrochim.Acta2013,93,93.doi:10.1016/j. electacta.2013.01.062

(72)Yu,G.;Hu,L.;Liu,N.;Wang,H.;Vosgueritchian,M.;Yang, Y.;Cui,Y.;Bao,Z.Nano Lett.2011,11(10),4438. doi:10.1021/nl2026635

(73)Zhao,Y.;Liu,J.;Hu,Y.;Cheng,H.;Hu,C.;Jiang,C.;Jiang, L.;Cao,A.;Qu,L.Adv.Mater.2013,25(4),591.doi:0.1002/ adma.201203578

(74)Shang,Y.;Wang,C.;He,X.;Li,J.;Peng,Q.;Shi,E.;Wang, R.;Du,S.;Cao,A.;Li,Y.Nano Energy2015,12,401. doi:10.1016/j.nanoen.2014.11.048

(75)Huang,Y.;Huang,Y.;Zhu,M.;Meng,W.;Pei,Z.;Liu,C.;Hu, H.;Zhi,C.ACS Nano2015,9(6),6242.doi:10.1021/ acsnano.5b01602

(76)Wang,Z.;Carlsson,D.O.;Tammela,P.;Hua,K.;Zhang,P.; Nyholm,L.;Stromme,M.ACS Nano2015,9(7),7563. doi:10.1021/acsnano.5b02846

(77)Xu,J.;Wang,D.;Fan,L.;Yuan,Y.;Wei,W.;Liu,R.;Gu,S.; Xu,W.Org.Electron.2015,26,292.doi:10.1016/j. orgel.2015.07.054

(78)Xie,Y.;Wang,D.J.Alloy.Compd.2016,665,323. doi:10.1016/j.jallcom.2016.01.089.

(79)Li,W.;Chen,J.;Zhao,J.;Zhang,J.;Zhu,J.Mater.Lett.2005,59(7),800.doi:10.1016/j.matlet.2004.11.024

(80)Yuan,D.;Li,B.;Cheng,J.;Guan,Q.;Wang,Z.;Ni,W.;Li,C.; Liu,H.;Wang,B.J.Mater.Chem.A2016,4(30),11616. doi:10.1039/C6TA04081K

(81)Liu,K.;Hu,Z.;Xue,R.;Zhang,J.;Zhu,J.J.Power Sources2008,179(2),858.doi:10.1016/j.jpowsour.2008.01.024

(82)Lee,J.A.;Shin,M.K.;Kim,S.H.;Cho,H.U.;Spinks,G.M.; Wallace,G.G.;Lima,M.D.;Lepró,X.;Kozlov,M.E.; Baughman,R.H.Nat.Commun.2013,4(3),1970. doi:10.1038/ncomms2970

(83)D′Arcy,J.M.;El-Kady,M.F.;Khine,P.P.;Zhang,L.;Lee,S. H.;Davis,N.R.;Liu,D.S.;Yeung,M.T.;Kim,S.Y.;Turner, C.L.ACS Nano.2014,8(2),1500.doi:10.1021/nn405595r.

(84)Chu,C.Y.;Tsai,J.T.;Sun,C.L.Int.J.Hydrog.Energy2012,37(18),13880.doi:10.1016/j.ijhydene.2012.05.017

(85)Su,F.;Miao,M.Electrochim.Acta2014,127,433. doi:10.1016/j.electacta.2014.02.064.

(86)Duay,J.;Gillette,E.;Liu,R.;Lee,S.B.Phys.Chem.Chem. Phys.2012,14(10),3329.doi:10.1039/C2CP00019A

(87)Cheng,X.L.;Zhang,J.;Ren,J.;Liu,N.;Chen,P.;Zhang,Y.; Deng,J.;Wang,Y.G.;Peng,H.J.Phys.Chem.C2016,120(18),9685.doi:10.1021/acs.jpcc.6b02794

(88)Mirvakili,S.M.;Mirvakili,M.N.;Englezos,P.;Madden,J. D.;Hunter,I.W.ACS Appl.Mater.Interfaces2015,7(25), 13882.doi:10.1021/acsami.5b02327

(89)Baps,B.;Eberkoyuncu,M.;Koyuncu,M.Key Engineering Mater.2001,206-213,937.doi:10.4028/www.scientific.net/ KEM.206-213.937

(90)Liu,J.;Namboothiry,M.A.;Carroll,D.L.Appl.Phys.Lett.2007,90(6),063501.doi:10.1063/1.2435988

(91)O′Connor,B.;Pipe,K.P.;Shtein,M.Appl.Phys.Lett.2008,92(19),193306.doi:10.1063/1.2927533

(92)Liu,D.;Zhao,M.;Li,Y.;Bian,Z.;Zhang,L.;Shang,Y.;Xia, X.;Zhang,S.;Yun,D.;Liu,Z.ACS Nano2012,6(12),11027. doi:10.1021/nn304638z

(93)Liu,D.;Li,Y.;Zhao,S.;Cao,A.;Zhang,C.;Liu,Z.;Bian,Z.; Liu,Z.;Huang,C.RSC Adv.2013,3(33),13720.doi:10.1039/ C3RA40710A

(94)Liu,J.;Namboothiry,M.A.;Carroll,D.L.Appl.Phys.Lett.2007,90(13),133515.doi:10.1063/1.2716864

(95)Chen,X.;Sun,H.;Yang,Z.;Guan,G.;Zhang,Z.;Qiu,L.; Peng,H.J.Mater.Chem.A2014,2(6),1897.doi:10.1039/ C3TA13712K

(96)Bedeloglu,A.C.;Demir,A.;Bozkurt,Y.;Sariciftci,N.S.Text Res.J.2010,80(11),1065.doi:10.1177/0040517509352520

(97)Bae,J.;Park,Y.J.;Lee,M.;Cha,S.N.;Choi,Y.J.;Lee,C.S.; Kim,J.M.;Wang,Z.L.Adv.Mater.2011,23(30),3446. doi:10.1002/adma.201101345

(98)Fu,Y.;Wu,H.;Ye,S.;Cai,X.;Yu,X.;Hou,S.;Kafafy,H.; Zou,D.Energy Environ.Sci.2013,6(3),805.doi:10.1039/ C3EE23970E

(99)Guo,W.;Xue,X.;Wang,S.;Lin,C.;Wang,Z.L.Nano Lett.2012,12(5),2520.doi:10.1021/nl3007159

(100)Yang,Z.;Deng,J.;Sun,H.;Ren,J.;Pan,S.;Peng,H.Adv. Mater.2014,26(41),7038.doi:10.1002/adma.201401972

(101)Sun,H.;Jiang,Y.;Xie,S.;Zhang,Y.;Ren,J.;Ali,A.;Doo,S. G.;Son,I.H.;Huang,X.;Peng,H.J.Mater.Chem.A2016,4, 7601.doi:10.1039/C6TA01514J

(102)Liu,Y.;Che,R.;Chen,G.;Fan,J.;Sun,Z.;Wu,Z.;Wang,M.; Li,B.;Wei,J.;Wei,Y.;Wang,G.;Guan,G.;Elzatahry,A.A.; Abdulaziz,A.B.;Abdullah M.A.;Deng,Y.;Peng,H.;Zhao, D.Sci.Adv.2015,1(4),e1500166.doi:10.1126/ sciadv.1500166

(103)Liu,Y.;Luo,Y.;Elzatahry,A.A.;Luo,W.;Che,R.;Fan,J.; Lan,K.;Al-Enizi,A.M.;Sun,Z.;Li,B.ACS Cent.Sci.2015,1(7),400.doi:10.1021/acscentsci.5b00256

Progress in Conductive Polymers in Fibrous Energy Devices

LIAO Chun-Rong1,2XIONG Feng1,2LI Xian-Jun3WU Yi-Qiang3LUO Yong-Feng1,2,*

(1College of Science,Central South University of Forestry and Technology,Changsha 410018,P.R.China;2State Key Laboratory of Molecular Engineering of Polymers and Laboratory of Advanced Materials,Fudan University,Shanghai 200438,P.R.China;3College of Material Science and Engineering,Central South University of Forestry and Technology,Changsha 410018,P.R.China)

Conductive polymers implemented in fibrous energy devices have drawn considerable attention because of their economic importance,good environmental stability,and electrical conductivity.Conductive polymers demonstrate interesting mechanical,electronic,and optical properties,controllable chemical and electrochemical behavior,and facile processability.This review elaborates on the latest research in conductive polymers in fibrous energy devices,such as fibrous supercapacitors,fibrous solar cells,and fibrous integrated energy devices.The performance requirements of these fibrous energy devices,with specific reference to related materials,fabrication techniques,fiber structure,and electronic transport as well as mechanical functionality, are also reviewed in this paper.

Conductive polymer;Fiber;Supercapacitor;Solar cell;Fibrous energy device

.Email:yfluo@csuft.edu.cn;Tel:+86-731-85623352.

The project was supported by the National Natural Science Foundation of China(31530009).

国家自然科学基金(31530009)资助项目© Editorial office of Acta Physico-Chimica Sinica

O646

10.3866/PKU.WHXB201611072

Received:September 29,2016;Revised:November 7,2016;Published online:November 7,2016.*