相变微胶囊悬浮液传热性能的研究进展*

2016-12-03李晓燕李凯娣曲冬琦

李晓燕,李凯娣,曲冬琦

( 哈尔滨商业大学 能源与建筑工程学院, 哈尔滨 150028)

相变微胶囊悬浮液传热性能的研究进展*

李晓燕,李凯娣,曲冬琦

( 哈尔滨商业大学 能源与建筑工程学院, 哈尔滨 150028)

相变微胶囊悬浮液作为一种潜热型功能流体,其独特的性能使其受到科研工作者的关注。在回顾了现有相变微胶囊悬浮液传热性能的研究进展,对相变微胶囊悬浮液的导热性能、对流传热特性分别进行介绍。讨论了悬浮液的体积浓度、雷诺数(Re)、斯蒂芬数(Ste)、努塞尔数(Nu)及无量纲过冷度等因素对相变微胶囊悬浮液换热能力的影响,以及相变微胶囊悬浮液管内换热特性。本文针对相变微胶囊悬浮液中添加纳米粒子(纳米Al2O3, 纳米Fe, 纳米TiO2)和磁性材料对其导热系数和强化传热的提升情况进行了讨论,并指出了目前研究存在的问题和今后研究的发展方向。

相变微胶囊;传热性能;纳米材料;强化换热

0 引 言

相变材料微胶囊悬浮液(microencasulated phase change materials suspension, MPCMS)是一种新型储热介质,由相变材料微胶囊(MPCM)颗粒和单相传热流体构成。MPCMS可以显著提高流体的对流传热性能,而且还可以作为储能介质用于储热储冷系统中,实现储热和强化换热、储热介质与传热介质的统一,从而减少了换热过程[1]。它在太阳能热利用、采暖、空调、热能存储系统、热交换器等领域具有潜在使用价值和广阔的应用前景。因此,相变微胶囊悬浮液传热性能的研究受到广泛关注。

近年来,相变微胶囊悬浮液在应用基础方面已经开展了一系列很有价值的工作,得出了一些有意义的结论[2]。研究发现,MPCMS与相变材料(PCM)和单相流体在热学特性方面都不相同。相变微胶囊悬浮液的强化传热能力主要来源于两个方面:(1) 相变微胶囊颗粒在融化凝固时吸收释放大量潜热增大了有效比热容;(2) 相变微胶囊颗粒附近的“微对流效应”增强了管路壁面的导热性。与普通单相传热流体相比,MPCMS有很大的表观比热,传热能力可增大1.5~4倍。传热能力明显增加,为换热设备小型化开辟了新道路。然而,潜热型相变微胶囊流体的导热系数较低, 且对流换热能力减弱。因此,许多研究学者[3-5]在相变微胶囊悬浮液中添加纳米Al2O3、纳米Fe、纳米TiO2等纳米颗粒增加其热导率。添加纳米颗粒可以提高相变微胶囊悬浮液的导热系数,且对相变微胶囊悬浮液冻结融化行为和相变温度没有明显的影响。相变微胶囊悬浮液换热能力与悬浮液体积浓度、雷诺数(Re)、斯蒂文数(Ste)、相变温度范围和无量纲过冷度等因素密切相关。例如提高MPCMS的体积浓度,增大MPCMS的比热容,都可以增大MPCMS的换热效率。但随着MPCMS的体积浓度增加,使其粘度和压降增加,导致泵的能耗增加,且无法满足长期使用[6-8]。大量已发表的研究结果表明[9-11],斯蒂文数对管内强化换热的有很大的影响,但在有明显的过冷度的情况下,产生影响极微弱,具体原因还不是很清楚,所以,还需对相变微胶囊悬浮液流动传热特性进行更深入的研究。

本文结合国内外相变微胶囊悬浮液的研究工作[12-15],从导热和对流换热两方面入手对相变微胶囊悬浮液的传热做了综述,探究了Ste数、微胶囊颗粒浓度及温度对MPCMS热物性的影响。讨论了纳米粒子和磁性材料对相变微胶囊悬浮液导热系数和强化传热的影响,并探讨了今后相变微胶囊悬浮液传热方面的研究重点并提出了目前存在的问题。

1 相变微胶囊悬浮液导热性能的研究

相变材料导热率低是热能存储系统中存在的问题之一,这将导致热能存储系统的蓄/释冷率降低。因此,在很多文献中[16-17],研究者在改善相变材料的导热率方面做了大量的研究,例如:嵌入高导热率材料的结构[18]、使用带翅片的换热器[19]以及制备相变材料微胶囊[20]等。因为MPCMS中的微胶囊颗粒能够吸收或者放出大量潜热,在相变过程中、微小的MPCM颗粒具有较大的比表面积、悬浮液流动时MPCM颗粒之间的相互作用等因素,使MPCM颗粒能够强化流体的对流传热过程,相变微胶囊悬浮液的有效导热率增大。

Maxwell[21]研究了静态固液悬浮液的导热率,得到了悬浮液静态时的导热系数的计算式

(1)

在式(1)中,kb为相变微胶囊悬浮液的导热系数,kp为分散相的导热系数,kf为连续相的导热系数,c为分散相的体积浓度。

由于相变微胶囊悬浮液在流动过程中,“微对流效应”存在于微胶囊颗粒与载流体之间,颗粒与载流体之间的对流换热明显增强,从悬浮液角度来说,这种增强与有效导热系数增大是等效的。因此,相变微胶囊悬浮液在流动过程中的有效导热系数要比通过Maxwell关系式计算的静态固液两相悬浮液的导热系数大,有效导热系数的计算式为[21]

(2)

在式(2)中,Pep=e·d2/αf为粒子佩克莱数, ke为有效导热系数,B和m是依赖于佩克莱数的值,e为剪切速率,αf为热扩散率。

一般情况下,相变微粒的热导率的提高幅度不是很大,需进一步改进,Ho等[22]研制了一种新型流体,在质量分数为10%的正二十烷相变微胶囊悬浮液中,分别添加质量分数为2%和10%的纳米Al2O3,与不加纳米Al2O3的正二十烷相变微胶囊悬浮液相比,导热系数分别增加了4%和13%。添加纳米Al2O3材料可以有效改善MPCMS的导热系数。靳健等[23-24]对添加TiO2纳米颗粒的MPCMS的导热系数进行了实验研究。实验结果显示:TiO2纳米颗粒的加入MPCMS的导热系数得到显著提高,当TiO2质量浓度为5%时,MPCMS导热系数约提高7%。Latibari等[25]对纳米相变微胶囊的合成、表征和热性能进行研究。结果表明,纳米相变微胶囊(S1)的导热系数与纯十六酸(PA)相比,提高近3倍,对比结果如表1[25]所示。

表1 相变微胶囊的导热系数[25]

Table 1 Thermal conductivity of encapsulated PCMs[25]

样本代码导热系数/W·m-1·K-1熔化状态/80℃凝固状态/30℃PA0.260.21S10.770.71S20.520.48S30.490.47

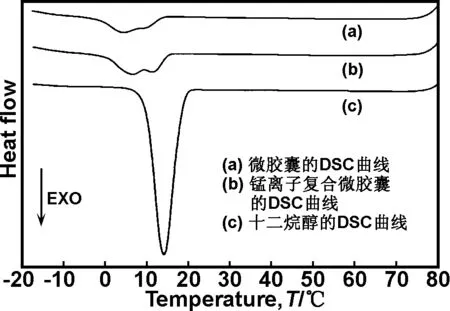

碳纳米管是一种典型的一维纳米材料,Zhang等[26]在相变微胶囊悬浮液中添加多壁碳纳米管研制了一种新型传热流体,研究发现,随着多壁碳纳米管的加入,相变微胶囊悬浮液的导热系数有了显著地提高,相变微胶囊悬浮液的导热系数与多壁碳纳米管的质量分数呈非线性变化。将质量分数为10%的混合石蜡相变微胶囊悬浮液和1%的多壁碳纳米管流体制成的新型流体,具有最佳的热稳定性,导热系数提高了8%。Xuan等[27]用纳米铁粒子为磁性材料、石蜡作为芯材、三聚氰胺-尿素-甲醛树脂作为壳材制备了磁性相变微胶囊,并将磁性相变微胶囊分散在去离子水中制备了磁性相变微胶囊悬浮液。他们研究了磁性相变微胶囊悬浮液的导热系数,研究结果表明,磁性相变微胶囊的质量分数、纳米铁粒子的质量分数和外加磁场是影响磁性相变微胶囊悬浮液的导热系数与去离子水的导热系数之比的主要因素,导热系数比随着磁性相变微胶囊体积浓度的增加呈线性增加。Ma等[28]对装有十二烷醇的微胶囊的结构和形态进行研究,从图1[28]可以清楚的看到微胶囊的结构。通过锰离子络合反应,能够提高微胶囊的导热性能,图2[28]中的DSC曲线表明,锰离子络合的微胶囊相变焓是51.6 J/g高于没有络合的微胶囊,同时在一定程度上抑制了过冷。

图1 微胶囊的显微图和结构图[28]

图2 (a)微胶囊的DSC曲线,(b)锰离子复合微胶囊的DSC曲线,(c)十二烷醇的DSC曲线[28]

Fig 2 DSC curves of (a) microcapsule, (b) Mn ion complexed microcapsule (c) n-dodecanol[28]

2 相变微胶囊悬浮液的对流换热的研究

2.1 MPCM强化对流换热的研究

MPCM是指通过微胶囊制备技术将芯材(PCM)封装在聚合物外壳内的一种新型复合材料[29]。研究人员对MPCM强化悬浮液对流换热进行了深入的研究[30-32]。在恒热流条件下,Zhao等[33]建立了MPCMS管内层流对流换热的数学模型,通过数值模拟研究,结果表明斯蒂芬数和体积浓度是影响微胶囊悬浮的强化传热的重要参数。张寅平等[34-35]提出等效比热容模型,对相变微胶囊悬浮液做了圆管内层流对流换热的研究,考虑微胶囊壳体厚度的影响,得到在影响换热强化的多个因素中,对换热强化的影响最为显著的是Ste数和c,受ML、Mr和dp的影响次之。Ste数越小,c越大,换热越强烈;ML、Mr越小,dp越大,换热越强烈。郝睿等[36]对MPCMS管内层流对流换热进行了模拟计算,分析计算的结果显示微胶囊浓度和Ste数对管内层流传热具有最重要的影响。图3[36]显示不同Ste数强化比η均具有单峰值形状,Ste数较小时强化比显著增大。

图3 Ste数对两种强化比沿管轴向变化的影响以及相应相变区域的变化状况[36]

Fig 3 Effect of ste number on the variation of the two reinforcement ratios along the tube in axial direction and the changes in corresponding phase change area[36]

Charunyakorn等[21]对MPCMS在管内的换热特性进行研究,采用内热源模型进行模拟,他们发现,相变材料微胶囊的颗粒浓度、Ste数、管道与颗粒直径比以及修正的Peclet 数是影响相变材料微胶囊悬浮液流动传热的控制参数。Song等[37]对层流管内MPCMS的传热特性进行数值模拟,对影响MPCMS换热强化的因素进行研究,结果显示,Ste数和微胶囊的质量分数是影响悬浮液换热的主要因素。Delgado等[38]提出一种新的MPCMS的传热现象的分析方法,对质量浓度为10%的石蜡MPCMS进行研究。分析了在不同位置不同功率时MPCMS的对流传热系数,在开始相变后,MPCMS的传热系数比水约改善了25%。王利等[39]对MPCMS的传热特性进行了实验研究,结果表明,当Re数相同,微胶囊体积分数为10%时,MPCMS的Nu数约是水的2.5倍;体积分数为15%时,MPCMS的Nu数约是水的3倍。Alvarado等[40]对以94%正十四烷和6%十四醇为相变材料的微胶囊悬浮液进行了实验研究,发现相变微胶囊悬浮液与水的传热系数之比,在低质量分数时为0.6,在高质量分数时下降到0.4,这是由于相变微胶囊质量分数高时微胶囊悬浮液的粘度高引起的。刘丽等[41]分别制备了以纯水和密度为0.941g/ml的丙醇/水为载流体的MPCMS,对质量浓度为10%~30%,以水、丙醇/水混合溶液的MPCMS 3种流体为传热介质自然对流换热特性的分别进行了实验研究。发现质量浓度范围在10%~30%时,随着质量浓度的不断增大,储热性能和自然对流换热不断提高。

2.2 纳米MPCM强化对流换热的研究

纳米流体是一种在流体中加入纳米数量级的颗粒(金属或金属氧化物颗粒)而制成的悬浮液。它作为一种传热工质,具有热导率高,性能稳定,系统压降增量小等优点[42]。根据MPCMS和纳米流体自身的传热特点,将纳米颗粒加入到相变悬浮液中,得到一种新型纳米MPCM悬浮液,同时拥有较高的热导率和较大的热容。纳米MPCM悬浮液在强化换热领域得到越来越多研究人员的重视[43-44]。Tumuluri等[45]对添加多壁碳纳米管的十八烷相变材料微胶囊悬浮液的传热性能进行了实验研究,在紊流恒定热流密度条件下,测定了该悬浮液的传热系数和压降值。Wang等[46]开发了一种潜热型功能热流体(纳米材料增强型),并对它在管内强制对流换热进行了实验研究,结果显示:添加 0.5% TiO2纳米颗粒的潜热型功能热流体,其对流换热性能有明显改善。Ho等[47]对添加纳米Al2O3颗粒的微胶囊悬浮液进行了强制对流传热效果研究。结果显示,悬浮液强制对流冷却效果与流速、粒子分数和潜显热比有关。

2.3 磁性MPCM强化对流换热的研究

磁性MPCM具有与磁性微粒(如铁、钴、镇及其氧化物等)类似的磁性和相变微胶囊的储热能力,因而磁性MPCM悬浮液是一种集可控、储热、强化换热功能于一身的新颖的功能流体[48-49],。磁性MPCM具有靶向移动、可重复使用、节能环保等优点,在无损探伤、显示、靶向缓释药物等领域有广泛的应用[50]。黄勇[51]对研究了磁性潜热型功能流体的制备及能量传递特性进行了数学模拟和实验研究。利用原位聚合法制备了脲醛-三聚氰胺改性脲醛树脂壳磁性MPCM;同时揭示外磁场对磁性潜热型功能流体对流换热的影响机制。结果表明,磁性MPCM能够增大磁性潜热型功能流体的导热系数,流体的导热系数随着MPCM体积分数增大而增大,且呈线性关系其斜率为0.00542。黄勇,宣益民等[52]建立了磁场作用下水平圆管内磁性MPCMS对流换热的数学物理模型,分析了磁性MPCM的体积分数、磁场强度、流体的质量流量等因素与流体对流换热的关系。研究发现,磁场对磁性MPCMS的对流换热具有显著的强化作用,磁场强度愈大,强化作用愈明显,与不加磁场相比,最大磁场强度为590 kA/m时,表面对流换热系数最大提高了 212%,这是由于磁性MPCM受到磁力作用产生了扰动。

2.4 管道结构强化对流换热的研究

图4 在圆管内插入扭绞带的物理模型[56]

Fig 4 Physical model for twisted tape inserted in a circular tube[56]

Zhang等[57-58]对石蜡-三聚氰胺MPCMS在矩形蓄热槽内自然对流的传热特性进行了实验研究,研究发现,加热温度大约在34 ℃,加热板和冷却板温差在9 ℃时,MPCMS自然对流换热的强化效果最强,传热系数最大。Diaconu等[59]对RT6相变微胶囊悬浮液在槽内的自然对流传热特性进行了研究,发现,在相变阶段,相变微胶囊悬浮液的自然对流传热系数是相同温度条件下水的5倍,但是当温度大于20 ℃时,水的自然对流传热系数却高于相变微胶囊悬浮液。王亮等[60]分别对质量分数为5%,10%和20%的MPCMS在矩形扁管(宽高比为0.14)内的对流换热特性进行了实验研究,发现MPCMS的传热性能与流量有关。流量较小时,MPCMS的传热性能随质量分数增加而提高,且优于水;流量较大时,入口处流体的传热性能弱于水。

3 结 语

到目前为止,国内外研究者对相变微胶囊悬浮液的传热研究,尽管已经取得了很大的进步,但其研究结果还未系统化,无论是传热特性的数值模拟研究还是实验研究方面仍存在一些问题,需要研究学者进一步深入研究。

(1) 相变材料方面:鉴于在实验过程中将相变材料分散在水中,随着浓度的增加流体粘度增加,导致泵耗增加,相变微胶囊在流体中易破碎,管道的堵塞问题不可避免,这个问题亟需解决,因此制备出稳定性好不易破碎,潜热值高的相变微胶囊是我们接下来要研究的方向之一。

(2) 传热方面:进行相变微胶囊悬浮液换热的数值模拟和实验研究时,需要注意影响换热性能的主要参数,以及微胶囊颗粒为了增加传热能力加入的纳米颗粒与流体之间的相分离等问题,是我们今后需要解决的问题之一。

(3) 经验准则方面:对于相变微胶囊悬浮液传热相关的关系式,还没有系统的提出,这就导致模拟结果与实验结果偏差增大,此外换热模型的建立还不够完善,要想将相变微胶囊悬浮液推广使用,必须完善相关关系式和物理模型。

[1] Giro-Paloma J, Martínez M, Cabeza L F, et al. Types, methods, techniques, and applications for microencapsulated phase change materials (MPCM): a review[J]. Renewable & Sustainable Energy Reviews, 2016, 53:1059-1075.

[2] Wang X D, An B, et al. Inverse geometric optimization for geometry of nanofluid cooled microchannel heat sink[J]. Applied Thermal Engineering, 2013, 55(1-2): 87-94.

[3] HungT C, Yan W M. Enhancement of thermal performance in double-layered microchannel heat sink with nanofluids[J]. Heat Mass Transfer, 2012, 55(11-12): 3225-3238.

[4] Hung T C, Yan W M, Wang X D, et al. Heat transfer enhancement in microchannel heat sinks using nanofluids[J]. Heat Mass Transfer, 2012, 55(9-10): 2559-2570.

[5] Hwang Y J, Ahn Y C, et al. Investigation on characteristics of thermal conductivity enhancement of nanofluids[J]. Current Applied Physics, 2006, 6(6):1068-1071.

[6] Fang Y T, Yu H M, Wan W J, et al. Preparation and thermal performance of polystyrene/n-tetradecane composite nanoencapsulated cold energy storage phase change materials[J]. Energy Conversion and Management, 2013, 76: 430-436.

[7] Fang Y T, Kuang S Y, Gao X N, et al. Preparation and characterization of novel nanoencapsulated phase change materials[J]. Energy Conversion and Management, 2008, 49(12): 3704-3707.

[8] Lin C, Wang T, Yan Z, et al. Characterization of thermal and hydrodynamic properties for microencapsulated phase change slurry (MPCS)[J]. Energy Conversion & Management, 2014, 79(3): 317-333.

[9] Zeng R, Wang X, Chen B J, Zhang Y P, et al. Heat transfer characteristics of microencapsulated phase change material slurry in laminar flow under constant heat flux[J]. Applied Energy, 2009, 86(12): 2661-2670.

[10] Xu H, Yang R, Zhang Y P, et al. Emulsions thermal properties and phase transition key influencing factors[J]. Science Bulletin, 2005, 50(1): 92-96.

徐 慧, 杨 睿, 张寅平,等. 相变乳状液热物性及关键影响因素研究[J]. 科学通报, 2005, 50(1):92-96.

[11] Ho C J, Huang J B, Chen C P, et al. Forced convection performance of a MEPCM suspension through an iso-flux heated circular tube: an experimental study[J]. Heat and Mass Transfer, 2012, 48(3): 487-496.

[12] Jessica Giro-Paloma, Mònica Martínez, et al. Types, methods, techniques, and applications for microencapsulated phase change materials (MPCM): a review[J]. Renewable and Sustainable Energy Reviews, 2016, 53: 1059-1075.

[13] Guo X, Cao J Z, et al. Incorporation of microencapsulated dodecanol into wood flour/high-density polyethylene composite as a phase change material for thermal energy storage[J]. Materials and Design,2016, 89: 1325-1334.

[14] Chai L, Wang X, Wu D. Development of bifunctional microencapsulated phase change materialswith crystalline titanium dioxide shell for latent-heat storage and photocatalytic effectiveness[J]. Applied Energy, 2015, 138: 661-674.

[15] Zheng X H, Xi Q L, Zhu J, et al. Thermal conductivity measurement of phase change microcapsules[J]. Journal of Engineering Thermophysics, 2012, 33(3): 454-456.

郑兴华, 夕邱琳, 祝捷,等. 相变微胶囊的热导率测量[J]. 工程热物理学报,2012,33(3):454-456.

[16] Li X Y, Zhao Q Q, Qu D Q. Investigation on the dynamic characteristics of a direct contact thermal energy storage charging process for use in conventional air-conditioning systems[J]. Applied Thermal Engineering, 2015, 91: 172-180.

[17] Li K N, Guo N N, Wang H. Review of study on improving conductivity of phase change material[J]. Journal of Refrigeration, 2008, 29(6): 46-50.

李夔宁, 郭宁宁, 王 贺. 改善相变材料导热性能研究综述[J]. 制冷学报, 2008, 29(6):46-50.

[18] Karaipekli A, Sari A, Kaygusuz K, et al. Thermal conductivity improvement of stearic acid using expanded graphite and carbon fiber for energy storage applications[J]. Renewable Energy, 2007, 32(13): 2201-2210.

[19] Liu Z L, Sun X, Ma C F. Experimental investigations on the characteristics of melting processes on stearic acid in an annulus and its thermal conductivity enhancement by fins[J]. Energy Conversion and Management, 2005, 46(6): 959-969.

[20] Yang X B, Yuan W X, Jiang J. The research of development of application and preparation of phase change microcapsule in different temperature ranges[J]. Refrigeration, 2009, 28(4): 49-57.

杨骁博, 袁卫星, 姜 军.不同温区相变微胶囊的制备及研究进展[J]. 制冷, 2009, 28(4): 49-57.

[21] Charunyakorn P, Sengupta S, Roy S K. Forced convection heat transfer in microencapsulated phase change material slurries: flow in circularducts[J]. International Journal of Heat and Mass Transfer, 1991, 34(3): 819-833.

[22] Ho C J, Huang J B, Tsai P S, et al. Preparation and properties of hybrid water-based suspension of Al2O3nanoparticles and MEPCM particles as functional forced convection fluid[J]. International Communications in Heat and Mass Transfer, 2010, 37(5): 490-494.

[23] Jin J, Liu P Q, Lin G P, et al. Research on TiO2nanoparticles influence on phase transformation suspension rheology and thermal conductivity properties[J]. Journal of Engineering for Thermal Energy and Power, 2010, 25(2): 172-176.

靳 健, 刘沛清, 林贵平, 等. TiO2纳米颗粒对相变悬浮液流变和导热系数特性影响研究[J]. 热能动力工程, 2010, 25(2): 172-176.

[24] Jin J, Liu P Q, Lin G P, et al. Viscosity and thermal conductivity characteristics of microencapsulated phase change material suspensions added with nano-particles[J]. Acta Aeronautica et Astronautica Sinica, 2010, 31(2): 244-248.

靳 健, 刘沛清, 林贵平, 等. 加入纳米颗粒的相变悬浮液黏性和热导率特性[J]. 航空学报, 2010, 31(2): 244-248.

[25] Latibari S T, Mehrali M, Mehrali M,et al. Synthesis, characterization and thermal properties of nanoencapsulated phase change materials via sol-gel method[J]. Energy, 2013, 61: 664-672.

[26] Zhang G H, Zhao C Y. Thermal property investigation of aqueous suspensions of microencapsulated phase change material and carbon nanotubes as a novel heat transfer fluid[J]. Renewable Energy, 2013, 60: 433-438.

[27] Xuan Y, Huang Y, Li Q. Experimental investigation on thermal conductivity and specific heat capacity of magnetic microencapsulated phase change material suspension[J]. Chemical Physics Letters, 2009, 479(4): 264-269.

[28] Ma Y J, Zong J W, Wei L, et al. Synthesis and characterization of thermal energy storage microencapsulated n-dodecanol with acrylic polymer shell[J]. Energy, 2015, 87: 86-94.

[29] Li W, Zhang X X, Wang J P,et al. Synthesis and purification of microcapsules containing phase change materials[J]. Polymer Materials Science & Engieering, 2008, 24(4): 143-146.

李 伟, 张兴祥, 王建平, 等.相变材料微胶囊的制备及提纯[J]. 高分子材料科学与工程,2008, 24(4):143-146.

[30] Allouche Y,Varga S, et al. Experimental determination of the heat transfer and cold storage characteristics of a microencapsulated phase change material in a horizontal tank[J]. Energy Conversion and Management, 2015, 94: 275-285.

[31] Zhang Y P, Hu X X, et al. Within-tube heat latent functionally thermal fluid laminar flow within the heat exchanger model and its application[J]. Science in China: Series E, 2003, 33(3): 237-244.

张寅平, 胡先旭,等. 热流圆管内潜热型功能热流体层流换热的内热源模型及应用[J]. 中国科学: E 辑, 2003, 33(3):237-244.

[32] Fang Y T, Wang W J. Review on latent functionally thermal fluid[J]. Materials Review,2009, 23(15): 108-111.

方玉堂, 万伟军.潜热型功能热流体的研究进展[J]. 材料导报, 2009, 23(15):108-111.

[33] Zhao Z N, Hao R, Shi Y Q. Parametric analysis of enhanced heat transfer for laminar flow of microencapsulated phase change suspension in a circular tube with constant wall temperature[J]. Heat Transfer Engineering, 2008, 29(1): 97-106.

[34] Hu X, Zhang Y P. Novel insight and numerical analysis of convective heat transfer enhancement with microencapsulated phase change material slurries: laminar flow in a circular tube with constant heat flux[J]. International Journal of Heat and Mass Transfer, 2002, 45(15): 3163-3172.

[35] Hu X X, Zhang Y P. Theoretical analysis of the convective heat transfer enhancement of latent functionally thermal fluid withisothermal wall[J]. Acta Energiae Solaris Sinica, 2002, 25(5): 626-633.

胡先旭, 张寅平. 等壁温条件下潜热型功能热流体换热强化机理的理论研究[J]. 太阳能学报, 2002, 25(5):626-633.

[36] Hao R, Zhao Z N. Parameters analysis on heat transfer enhancement for Microencapsulated phase change layer suspension in tube flow[J]. Journal of Engineering Thermophysics, 2006, 27(2): 1-4.

郝 睿, 赵镇南. 微胶囊化相变悬浮液层流传热强化的参数分析[J]. 工程热物理学报,2006, 27(2):1-4.

[37] Song S, Liao Q, Shen W, et al. Numerical study on laminar convective heat transfer enhancement of microencapsulated phase change material slurry using liquid metal with low melting point as carrying fluid[J]. International Journal of Heat and Mass Transfer, 2013, 62: 286-294.

[38] Delgado M, Lázaro A, Mazo J, et al. Experimental analysis of a microencapsulated PCM slurry as thermal storage system and as heat transfer fluid in laminar flow[J]. Applied Thermal Engineering, 2012, 36: 370-377.

[39] Wang L, Zhao B Q, Zhao Z N. Experimental research of heat transfer characteristics in micro-encapsulated phase change material suspensions[J]. Gas & Heat, 2006, 26(12): 66-70.

王 利, 赵兵全, 赵镇南. 微胶囊相变悬浮液传热特性的实验研究[J]. 煤气与热力, 2006, 26(12):66-70.

[40] Alvarado J L, Marsh C, Sohn C, et al. Thermal performance of microencapsulated phase change material slurry in turbulent flow under constant heat flux[J]. International Journal of Heat and Mass Transfer, 2007, 50(9): 1938-1952.

[41] Liu L, Wang L, WangY F, et al. Test and analysis on the thermal properties of microcapsulated phase change materials suspension using propanol/water solution as base fluid[J]. Journal of Functional Materials,2014, 45(1): 109-113.

刘 丽, 王 亮, 王艺斐, 等. 基液为丙醇/水的相变微胶囊悬浮液的制备、稳定性及热物性[J]. 功能材料, 2014, 45(1): 109-113.

[42] Jin J, Liu P Q, Lin G P, et al. Rheological characteristics of suspensions of microencapsulated phase change materials in presence of nanoparticles[J]. Mechanics in Engineering, 2009, 31(6): 17-20.

靳 健, 刘沛清, 林贵平, 等. 加入纳米颗粒的相变悬浮液流变特性[J]. 力学与实践, 2009, 31(6):17-20.

[43] Yu F, Chen Z H, Zeng X R. Preparation and Properties of phase change thermal energy storage microcapsules modified with nano-SiO2[J]. New Chemical Materials, 2009, 37(3): 44-46.

余 飞, 陈中华, 曾幸荣. 纳米 SiO2改性相变储热微胶囊的制备及性能研究[J]. 化工新型材料, 2009, 37(3): 44-46.

[44] He Y, Jin Y, Chen H, et al. Heat transfer and flow behaviour of aqueous suspensions of TiO2nanoparticles (nanofluids) flowing upward through a vertical pipe[J]. International Journal of Heat and Mass Transfer, 2007, 50(11): 2272-2281.

[45] Tumuluri K, Alvarado J L, Taherian H, et al. Thermal performance of a novel heat transfer fluid containing multiwalled carbon nanotubes and microencapsulated phase change materials[J]. International Journal of Heat and Mass Transfer, 2011, 54(25): 5554-5567.

[46] Wang L, Lin G P, Chen H S, et al. Convective heat transfer characters of nanoparticle enhanced latent functionally thermal fluid[J]. Science in China Series E: Technological Sciences, 2009, 52(6): 1744-1750.

[47] Ho C J, Chen W C, Yan W M. Experiment on thermal performance of water-based suspensions of Al2O3nanoparticles and MEPCM particles in a minichannel heat sink[J]. International Journal of Heat and Mass Transfer, 2014, 69: 276-284.

[48] Zhou J L. Preparation and property of magnetic microcapsule[D].Shanghai: Donghua University, 2012. 15-20.

周建林. 磁性微胶囊的制备及其性能研究[D]. 上海:东华大学, 2012. 15-20.

[49] Philip J, Shima P D, Raj B. Enhancement of thermal conductivity in magnetite based nanofluid due to chainlike structures[J]. Applied Physics Letters, 2007, 91(20): 203108.

[50] Zhou J L, Luo Y, Zhong Y. Preparation and magnetic response property of magnetic microcapsule by complex coacervation[J]. Materials Review, 2012, 26(10): 54-57.

周建林, 罗 艳, 钟 毅.复凝聚法制备磁性微胶囊及其磁响应特性[J]. 材料导报, 2012, 26(10): 54-57.

[51] Huang Y. Preparation and energy transfer features of magnetic latent functionally thermal fluid[D]. Nanjing:Nanjing University of Science &Technology, 2012.20-25.

黄 勇. 磁性潜热型功能流体的制备与能量传递特性研究[D]. 南京:南京理工大学, 2012. 20-25.

[52] Huang Y,Xuan Y M,Li Q. Simulation of convection heat transfer in magnetic microencapsulated phase change material slurries in a circular tube[J]. Chinese Journal of Computational Physics,2012, 29(1): 87-94.

黄 勇, 宣益民, 李 强. 水平圆管内磁性潜热型功能流体对流换热特性的数值模拟[J]. 计算物理, 2012, 29(1): 87-94.

[53] Zeng R L, Wang X, et al. Heat transfer characteristics of microencapsulated phase change material slurry in laminar flow under constant heat flux[J]. Applied Energy, 2009, 86(12): 2661-2670.

[54] Cheng B J, Wang X, Zeng R L, et al. Experimental research of laminar forced convection heat transfer characteristics of microencapsulated phase change material suspension[J]. Acta Energiae Solaris Sinica, 2009, 30(8): 1018-1022.

陈斌娇, 王 馨, 曾若浪, 等. 相变微胶囊悬浮液层流强迫对流换热实验研究[J]. 太阳能学报, 2009, 30(8):1018-1022.

[55] Jin J, Liu P Q, Lin G P. The heat transfer characteristics of a cylindrical tube embedded in the numerical simulation of heat and fluid laminar dive analysis capabilities[J]. Science in China: Series E, 2009, 39(5): 897-903.

靳 健, 刘沛清, 林贵平. 层流下潜热型功能流体在内嵌圆柱圆管中的传热特性数值模拟分析[J]. 中国科学: E 辑, 2009, 39(5): 897-903.

[56] Song S, Liao Q, Shen W. Laminar heat transfer and friction characteristics of microencapsulated phase change material slurry in a circular tube with twisted tape inserts[J]. Applied Thermal Engineering, 2013, 50(1): 791-798.

[57] Zhang Y L, Rao Z H, Wang S F, et al. Experimental evaluation on natural convection heat transfer of microencapsulated phase change materials slurry in a rectangular heat storage tank[J]. Energy Conversion and Management, 2012, 59: 33-39.

[58] Zhang Y L, Rao Z H, Li F H, et al. Influence on heat storage phase change material microcapsule during phase change process[J]. Journal of Engineering Thermophysics, 2014, 35(1): 140-144.

张艳来, 饶中浩, 李复活, 等. 相变材料微胶囊流体相变过程对储热蓄热影响[J]. 工程热物理学报, 2014, 35(1): 140-144.

[59] Diaconu B M, Varga S, Oliveira A C. Experimental study of natural convection heat transfer in a microencapsulated phase change material slurry[J]. Energy, 2010, 35(6): 2688-2693.

[60] Wang L, Lin G P,Wang T, et al. Convective heat transfer characteristics of latent functionally thermal fluid in a flat tube[J]. Acta Aeronautica et Astronautica Sinica,2011, 32 (11): 2124-2130.

王 亮, 林贵平, 王 涛, 等. 潜热型功能热流体在扁管内的对流换热实验[J]. 航空学报,2011, 32 (11): 2124-2130.

Progress in research on heat transfer properties of microencapsulated phase change material suspensions

LI Xiaoyan, LI Kaidi, QU Dongqi

(Energy and architectural engineering institute, Harbin University of Commerce,Harbin 150028, China)

As a new type of a latent functional thermal fluid, microencapsulated phase change material suspension (MPCMS) has attracted much attention of researchers due to its unique properties. This paper reviews previous studies and developments with regard to the heat transfer properties of a MPCMS. We analyzed the relationship between several key parameters and heat transfer ability of MPCMS. These key parameters include the volume concentration of the suspension, the Reynolds number (Re), the Stefan number (Ste), the Nusselt number (Nu). We characterized both thermal conductivity and convection heat transfer, and we discuss how these properties can be significantly improved by adding nanoparticles (nano-Al2O3, nano-Fe, nano-TiO2) or magnetic materials. Furthermore, the key issues related to the heat transfer of MPCMS which needed to be solved in future were further pointed out.

microencapsulated phase change material; heat transfer;nanomaterials; heat transfer enhancement

1001-9731(2016)04-04033-07

国家自然科学基金资助项目(51476049)

2015-09-10

2015-11-20 通讯作者:李晓燕,E-mail: mylxy6168@sina.com

李晓燕 (1962-),女,哈尔滨人,教授,博士,主要从事相变蓄冷材料研究。

TB34

A

10.3969/j.issn.1001-9731.2016.04.007