Ultrasound assisted solidi fication process of ternary Cu–Sn–Sb alloy

2016-11-21ZhaiWeiHongZhenyuLiuHaimanWeiBingbo

Zhai Wei,Hong Zhenyu,Liu Haiman,Wei Bingbo

Department of Applied Physics,Northwestern Polytechnical University,Xi’an 710072,China

1.Introduction

The microstructures of aerospace materials determine their applied properties.The solidi fication process of light alloys and superalloys for aerospace industries can be improved by ultrasound.1–4Thus the solidi fication of alloys within ultrasonic field has been an important research subject in recent years.The propagation of ultrasonic wave not only transmits acoustic energy into the liquid alloy,but also brings about such nonlinear effects as cavitation and acoustic streaming,which greatly affect the solidi fication process of alloys and ultimately improve their microstructures and mechanical properties.5–8So far,most work is focused on the dendritic growth of Al-based alloys9–12and Mg-based alloys13–17because of their wide applications in the automotive and aerospace industries.18,19

The peri-eutectic transition L+α→β+γ is a typical kind of peritectic transformation in ternary and multicomponent alloys.Like the usual peritectic transition L+α → β,its reactants involve one liquid phase and one solid phase.However,its products are two cooperative solid phases.Since peri-eutectic transformation is an atomic diffusion controlled process which is dif ficultto be completed,the final microstructures are always composed of both primary and peri-eutectic phases.20Therefore,to control phase selection during peri-eutectic solidi fication is of great signi ficance.However,the research of ultrasonic solidi fication of ternary peri-eutectic alloy is rather scarce.It can be speculated that if ultrasound is introduced into the solidi fication process of perieutectic alloy melt,the cavitation effect introduced by intensive ultrasound may alter the competitive nucleation between primary and peri-eutecticphases.Meanwhile,the acoustic streaming accelerates the solute transportation process,which may facilitate the peri-eutectic transformation.

Ternary Cu–Sn–Sb alloy is a complex metallic system whose solidi fication process involves multiple peri-eutectic transitions among various Cu–Sn,Sn–Sb and Cu–Sb intermetallic compounds.This makes it a good candidate of soldering materials without the toxic Pb element,because the formation of various intermetallic compounds could induce a signi ficant composite strengthening effect,and thus has great potential applications in electronic interconnections of packing technology and automotive industry.In this work,the intense ultrasonic field is introduced into the solidi fication process of ternary Cu40Sn45Sb15alloy to investigate the microstructural evolution and mechanical property versus ultrasound power.On the basis of the experimental results,the peri-eutectic solidi fication mechanism is discussed.

2.Materials and method

The experiments were performed with a solidi fication apparatus incorporated with ultrasonic generator.The ternary Cu40-Sn45Sb15alloy sample was∅25 mm×25 mm in size and was prepared from pure Cu(99.99%),Sn(99.99%)and Sb(99.99%)elements by using electrical resistance furnace.During the experiment,the alloy sample was melted by an electrical resistance furnace in the flowing argon atmosphere.The ultrasonic generator consists of two parts:a KNbO3piezoelectric transducer with a resonant frequency of 20 kHz and an ultrasonic horn with an end diameter of∅22 mm.During experiment,the temperature was monitored by positioning a NiCr–NiSi thermocouple at the alloy sample top.When the alloy melting temperature dropped to 100 K above its liquidus temperature,the ultrasonic transducer was turned on and longitudinal ultrasonic wave was introduced from the top of the sample downward into the melted alloy until it solidi fied completely.Different exciting currents were input to the ultrasonic transducer.The corresponding ultrasound powerPWwas estimated to be 250,500,1000 W.After experiments,the alloys samples were vertically sectioned,mounted,polished and etched.The phase constitution and microstructure of solidi fied alloy samples were analyzed by X-ray diffractometer(XRD)and scanning electron microscope(SEM).

The compression performance of ternary Cu40Sn45Sb15alloy was tested by CSS44100 universal electronic testing machine.Specimens in a size of∅4.0 mm×4.0 mm were cut from the central part of each alloy sample solidi fied with different ultrasound powers,and the loading speed of mechanical testing machine was set to be 0.3 mm/min downward.To ensure the accuracy of test results,the compression without samples was also conducted to make a baseline correction of machine-stiffness.

3.Results and discussion

3.1.Acoustic field distribution within liquid alloy

The sound distribution within liquid Cu40Sn45Sb15alloy is calculated by COMSOL Multi-physics 5.0 software.The propagation of ultrasound within liquid can be expressed by Helmholtz equation:

in whichpais the sound pressure,ρ0=7746 kg/m3the density of ternary liquid Cu40Sn45Sb15alloy,k=ω/c0the wave number, ω=2πf,c0=3750 m/s the sound velocity,andf=20 kHz the resonant frequency of ultrasound.The acoustic initial and boundary conditions are set as follows:(a)pressure sourcepa=p0cos(ωt)at the ultrasonic probe tip surface and zero normal derivative of the pressure ∂pa/∂n=0,wheretis the time,andS=3.14×10-4m2is the surface area of the ultrasonic probe tip,(b)sound soft boundarypa=0 at the liquid/air interface,and(c)hard boundaries at the lateral and bottom sides of the crucible,which is written as:

Fig.1(a)shows the sound distribution along the wave propagation directionzwithin the liquid alloy att=0 s.It can be seen clearly that the sound pressure increases with the increase of initial ultrasound power at the ultrasonic probe tip.Moreover,as propagation extends,the sound pressure tends to reduce.In Fig.1(b),ΔTLocalis local undercooling.

Fig.1 Calculated sound pressure and local undercooling within liquid Cu40Sn45Sb15alloy.

3.2.Microstructures formed by ultrasonic solidi fication

As previously reported,20the solidus and liquidus temperatures of ternary Cu40Sn45Sb15alloy are determined to be 509 K and 831 K,and five phase transformations occur successively in the cooling process,which initiates with the formation of primary ε(Cu3Sn)phase.After this,η(Cu6Sn5)and β(SnSb)intermetallic compounds successively nucleate and grow.Finally,the solidi fication ends with two peri-eutectic transitionsofL+β(SnSb)→ η(Cu6Sn5)+Sn3Sb2and L+Sn3Sb2→ η(Cu6Sn5)+(Sn).

Fig.2 XRD patterns for ternary Cu40Sn45Sb15alloy solidi fied under static condition and within ultrasonic field.

In order to investigate the effect of ultrasound on the phase constitution of ternary Cu40Sn45Sb15alloy,the XRD analyses are performed on the solidi fied samples with various ultrasound powers.Two typical XRD patterns are presented in Fig.2,which reveal that the solidi fication microstructures obtained under conventional condition and ultrasound power of 1000 W consist of ε(Cu3Sn), η(Cu6Sn5), β(SnSb),Sn3Sb2and(Sn)phases.

Fig.3 shows the microstructures of Cu40Sn45Sb15alloy solidi fied with different ultrasound powers.Under conventional condition(Fig.3(a)),it can be seen clearly that a large amount of primary ε(Cu3Sn)phase exists,which grows in faceted way and develops into long coarse strips.The η(Cu6Sn5)phase grows into thin layers surrounding primary ε phase.Then,an Sn–Sb intermetallic compound layer grows adjacently to η(Cu6Sn5)phase.The EDS analysis indicates that the atomic ratio of Sn:Sb locates between 1 and 1.30.Hence,it is dif ficult to distinguish β(SnSb)from Sn3Sb2and we call this layer Sn–Sb intermetallic compound.Besides,there are also some(Sn)blocks distributed discontinuously on Sn–Sb intermetallic compound matrix.The parallel growth of the inner primary ε(Cu3Sn)phase,the η(Cu6Sn5)phase and the SnSb phase forms a three-layer lamellar structure.

Fig.3 Solidi fication microstructures of ternary Cu40Sn45Sb15alloy under various ultrasound power conditions.

When ultrasound power of 250 W is applied,as presented in Fig.3(b),remarkable re finement effect takes place to the primary ε(Cu3Sn)phase within the whole alloy sample.Meanwhile,as compared with that during conventional solidi fication,the thickness of η(Cu6Sn5)phase increases.The solidi fication microstructure formed under ultrasound power 500 W is similar to that under 250 W but seems to be more re fined.It also needs to be mentioned that homogeneous microstructure is observed within the alloy samples solidi fied under ultrasound power of both 250 W and 500 W.However,If the ultrasound power further increases toPW=1000 W,as shown in Fig.3(c),the structure becomes inhomogeneous,and a lot of spherical equiaxed grains appear at the top of the alloy sample.Whereas the similar structure as that in Fig.3(b)formed in the remaining lower part.This is because the intensive cavitation effect occurs at the sample top when the ultrasound power is suf ficiently high.The cavitation leads to the sharply attenuation of the ultrasonic wave at the remaining bottom part of the alloy sample.As seen in the enlarged view of zone C in Fig.3(d),a large proportion of these equiaxed grains are only made up of η(Cu6Sn5)phase,whereas the others are composed of a little amount of primary ε(Cu3Sn)phase in the core,and the η(Cu6Sn5)phase is also the major phase.This is further con firmed by the solute distribution scanning with EDS analysis.As seen in Fig.4(a)which shows the solute contentC,this equiaxed grain is uniform with respect to Cu,Sn and Sb elements distribution,and the atomic ratio of Cu to Sn element is close to 6:5 while about 10 at.%Sb dissolved in the η(Cu6Sn5)phase.This demonstrates that such a grain is only composed of η(Cu6Sn5)phase without any traces of primary ε(Cu3Sn)phase.By contrast,as illustrated in Fig.4(b),there is a little amount of primary ε(Cu3Sn)phase remaining in the center of the equiaxed grain shown in Fig.4(b),whose Sb content is very limited.

3.3.Solidi fication mechanism within ultrasonic field

On the above mentioned microstructural characteristics,it can be seen clearly that the effect of power ultrasound on the solidi fication mechanism of ternary Cu40Sn45Sb15alloy lies in the following two aspects.Firstly,it brings about remarkable re finement to the primary ε(Cu3Sn)phase.Fig.5 illustrates the relationship between the average size for primary ε(Cu3Sn)phase versus ultrasound power.As ultrasound power rises,both the lengthLεand widthWεdecrease,and especially for the length,it is decreased from 1135 μm to that of 11 μm under the ultrasound power of 1000 W,which is reduced by two orders of magnitudes.Meanwhile,the width also declines from 25 μm to that of 6 μm under the highest ultrasound power.

Fig.5 Average width and length for primary ε(Cu3Sn)phase.

Secondly,the ultrasound may alter the solidi fication path for ternary Cu40Sn45Sb15alloy.As shown in Fig.3(c),when the ultrasound is suf ficiently intensive,the η(Cu6Sn5)phase may directly nucleate and grow from the liquid alloy to form an equiaxed grain in some regions of the alloy melt due to the local intensive cavitation effect.In fact,cavitation effect generates a huge local transient pressure of up to GPa magnitude and affects the nucleation process by elevating the local melting temperature.The change of liquidus temperatureTPwith pressurePLis given by the Clausius–Clapeyron equation as

whereTLis the liquidus temperature at the atmospheric pressureP0. ΔVand ΔHmare the volume change and enthalpy change during liquid–solid transformation,respectively.Assuming that the high pressurePLin the liquid alloy produced by cavitation effect is up to 1–10 GPa,(Fig.1(b)),the local undercooling ΔTLocalis calculated to be elevated by 30–307 K.The undercooling is suf ficient to cool the local alloy melt to a point much lower than the liquidus temperature.In this case,the per-eutectic η(Cu6Sn5)phase can nucleate preferentially by preventing the formation of primary ε(Cu3Sn)phase.

Fig.4 Solute distribution pro files of peri-eutectic structures after high power ultrasonic solidi fication.

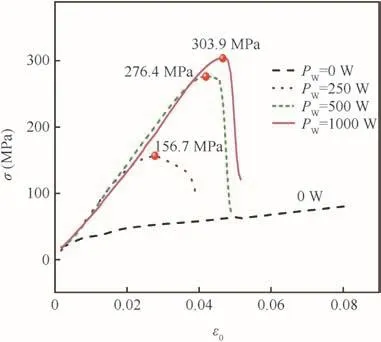

Fig.6 Stress–strain curve for ternary Cu40Sn45Sb15alloy samples solidi fied with different ultrasound powers.

3.4.Mechanical property of ultrasonically solidi fied alloy

Fig.6 shows the compressive stress–strain curves for ternary Cu40Sn45Sb15alloy samples solidi fied with different ultrasound powers,in which σ stands for stress and ε0denotes strain.Clearly,under conventional condition,the alloy sample sustains a long life without rupture strain,and the corresponding elasticity modulus is 2478 MPa.At a low power ultrasound of 250 W,the compressive strength of the solidi fied alloy sample is about 156.7 MPa with a fracture strain of 2.7%.As ultrasound power rises,both the compressive strength and fracture strain show an increasing tendency.As seen in Fig.6,when the ultrasound power reaches the maximum value of 1000 W,the compressive strength rises to 303.9 MPa with a fracture stain of 4.7%,which are 1.94 and 1.74 times higher than those under ultrasound of 250 W,respectively.It also needs to be mentioned that the elasticity modulus also elevates sharply to about 6107 MPa for the ternary Cu40Sn45Sb15alloy samples solidi fied within ultrasonic field,which is increased by a factor of 2.46 as compared with that during conventional solidi fication.These results indicate that the introduction of ultrasound during solidi fication promotes the compressive strength as well as elasticity modulus and decreases the ductility of ternary Cu40Sn45Sb15alloy.The re finement effect on the primary ε(Cu3Sn)phase and the increase in volume fraction of the η(Cu6Sn5)phase take responsibility for the variation in mechanical properties.

4.Conclusions

The effect of power ultrasound on the solidi fication of ternary Cu40Sn45Sb15peri-eutectic alloy is investigated,which proves that the introduction of power ultrasound is an effective way to control the microstructure formation and promotes the mechanical property for ternary peri-eutectic type alloys.The main conclusions are as follows:

(1)Both of the Cu40Sn45Sb15alloy samples solidi fied during the conventional condition and within ultrasonic field,are composed of ε(Cu3Sn),η(Cu6Sn5),β(SnSb),Sn3Sb2and(Sn)phases.The introduction of ultrasonic field does not change the phase constitution of this ternary alloy.

(2)The ultrasonic field has a prominent re finement effect on the primary ε(Cu3Sn)phase,whose size is reduced by nearly two orders of magnitudes as compared with that during conventional solidi fication.

(3)Under the highest ultrasound power of 1000 W,the intensive cavitation effect at the sample top prevents the formation of primary ε(Cu3Sn)phase and the η(Cu6Sn5)phase nucleates and grows directly from the liquid alloy melt.

(4)The introduction of ultrasound during solidi fication promotes the compressive strength as well as elasticity modulus and decreases the ductility of ternary Cu40Sn45Sb15alloy.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China(Nos.51327901,51271150 51571164 and 51471134),the Fundamental Research Fund of Northwestern Polytechnical University(No.JCQ01091)of China and the NPU Excellent Personnel Supporting Project of AoXiang New Star of China.

1.Chinnama RK,Fauteux C,Neuenschwander J.Evolution of the microstructure of Sn–Ag–Cu solder joints exposed to ultrasonic waves during solidi fication.Acta Mater2011;59(4):1474–8.

2.Zhai W,Hong ZY,Wen XL,Geng DL,Wei B.Microstructural characteristics and mechanical properties of peritectic Cu–Sn alloy within ultrasonic field.Mater Des2015;72:43–50.

3.Zhai W,Hong ZY,Mei CX,Wang WL,Wei B.Dynamic solidi fication mechanism of ternary Ag–Cu–Ge eutectic alloy under ultrasonic condition.Sci China Ser G-Phys Mech Astron2013;56(2):462–73.

4.Luque de Castro MD,Priego-Capote F.Ultrasound-assisted crystallization(sonocrystallization).Ultrason Sonochem2007;14(6):717–24.

5.Liao Q,Li WP,Liu HC,Zhu LQ.Fabrication of nanostructured electroforming copper layer by means of an ultrasonic-assisted mechanical treatment.Chin J Aeronaut2010;23(5):599–603.

6.Ramirez A,Qian M,Davies B,Wilks T,StJohn DH.Potency of high-intensity ultrasonic treatment for grain re finement of magnesium alloys.Scripta Mater2008;59(1):19–22.

7.Puga H,Teixeira JC,Barbosa J.The combined effect of melt stirring and ultrasonic agitation on the degassing ef ficiency of AlSi9Cu3alloy.Mater Lett2009;63(24–25):2089–92.

8.Khashaba UA,Aljinaidi AA,Hamed MA.Nano fillers modi fication of Epocast 50–A1/946 epoxy for bonded joints.Chin J Aeronaut2014;27(5):1288–300.

9.Zhong G,Wu S,Jiang H,An P.Effects of ultrasonic vibration on the iron-containing intermetallic compounds of high silicon aluminum alloy with 2%Fe.J Alloys Compd2010;492(1–2):482–7.

10.Kandemir S,Helen VA,Lawes SDA.Effect of ultrasonic treatment on the microstructure of A201 aluminium alloy for thixoforming.AIP Conf Proc2011;1353:1063–8.

11.Li YL,Feng HK,Cao FR,Chen YB,Gong LY.Effect of high density ultrasonic on the microstructure and re fining property of Al–5Ti–0.25C grain re finer alloy.Mater Sci Eng,A2008;487(1–2):518–23.

12.Wannasin J,Martinez RA,Flemings MC.Grain re finement of an aluminum alloy by introducing gas bubbles during solidi fication.Scripta Mater2006;55(2):115–8.

13.Liu X,Osawa Y,Takamori S,Mukai T.Microstructure and mechanical properties of AZ91 alloy produced with ultrasonic vibration.Mater Sci Eng,A2008;487(1–2):120–3.

14.Qian M,Ramirez A,Das A,StJohn DH.The effect of solute on ultrasonic grain re finement of magnesium alloys.J Cryst Growth2010;312(15):2267–72.

15.Bantibhai P,Chaudhari GP,Bhingole PP.Microstructural evolution in ultrasonicated AS41 magnesium alloy.Mater Lett2012;66(1):335–8.

16.Gao D,Li Z,Han Q,Zhai Q.Effect of ultrasonic power on microstructure and mechanical properties of AZ91 alloy.Mater Sci Eng,A2009;502(1–2):2–5.

17.Aghayani MK,Niroumand B.Effects of ultrasonic treatment on microstructure and tensile strength of AZ91 magnesium alloy.J Alloys Compd2011;509(1):114–22.

18.Tolnai D,Townsend P,Requena G,Salvo L,Lendvai J,Degischer HP.In situ synchrotron tomographic investigation of the solidi fication of an AlMg4.7Si8 alloy.ActaMater2012;60(6–7):2568–77.

19.Amberger D,Eisenlohr P,Goken M.On the importance of a connected hard-phase skeleton for the creep resistance of Mg alloys.Acta Mater2012;60(5):2277–89.

20.Zhai W,Wang BJ,Lu XY.Rapid solidi fication mechanism of highly undercooled ternary Cu40Sn45Sb15alloy.Appl Phys A2015;121(1):273–81.

杂志排行

CHINESE JOURNAL OF AERONAUTICS的其它文章

- Plastic wrinkling prediction in thin-walled part forming process:A review

- Progress of continuously rotating detonation engines

- Microstructure control techniques in primary hot working of titanium alloy bars:A review

- A hybrid original approach for prediction of the aerodynamic coefficients of an ATR-42 scaled wing model

- Dynamic modeling and analysis of vortex filament motion using a novel curve- fitting method

- Boundary-layer transition prediction using a simpli fied correlation-based model