Microstructure control techniques in primary hot working of titanium alloy bars:A review

2016-11-21GuoLianggangFanXiaoguangYuGaofengYangHe

Guo Lianggang,Fan Xiaoguang,Yu Gaofeng,Yang He

State Key Laboratory of Solidi fication Processing,School of Materials Science and Engineering,Northwestern Polytechnical University,Xi’an 710072,China

1.Introduction

Titanium alloys have been widely applied to aviation,chemical processing,and pharmaceutical due to high speci fic strength,good mesothermal performance,good corrosion resistance,low Young’s modulus,and non-toxicity.Especially,titanium alloys are applied in the aerospace industry largely.They are used in advanced airplanes to 30%–50%weight of the total structure,for instance,41%in F-22 fighters.Titanium alloys have become one of the indispensable structure materials ofairplanes.1–3Forging is the most applicable forming route of titanium alloy parts.Generally,these forgings are fabricated by primary hot working which transforms ingots to semiproducts,followed by secondary hot working which transforms semi-products to final products.Bars are important semi-products,as a large fraction of aerial titanium alloy forgings,such as cartridge receivers manufactured by a ring rolling process,blades,integral blade disks,and bulkheads,are fabricated from bars.The microstructure of bars greatly in fluences the performance of final products.Thus,rigorous control on microstructure is performed in primary hot working.With increasing of the forging projected area,the diameters of bars for fabricating forgings increase from tens of millimeters to hundreds of millimeters.This requires a more advanced microstructure control technique,for the purpose of meeting the microstructural requirements of bars.

Typical primary processing for titanium alloy bars involves forging in both the β phase field(β forging or β working)and the(α + β)phase field((α + β)forging or(α + β)working).Taking the advantages of good workability and low working loads at high temperature4–6,β working is employed to break the coarse as-cast structure so as to obtain fine and homogeneous beta grains.In despite of lower workability and higher working loads,7(α + β)forging is necessary to break the lamellar structure formed in β forging.A more re fined bimodal alpha+beta microstructure is achieved after(α + β)working,of which the various mechanical properties are well matched.In order to achieve a fine and homogeneous bimodal microstructure,β working and(α + β)working should be reasonably matched for titanium alloy bars fabrication.To this end,microstructure evolution and control during β working and(α + β)working are researched actively.

This paper summarizes recent research work on microstructure evolution and microstructure control techniques for fabricating titanium alloy bars.The trends in microstructure control techniques are presented for the fabrication of titanium alloy bars with high ef ficiency,low cost,and high quality by means of β/(α + β)working.For this purpose,the puzzles and challenges in the future are pointed out.The progresses can instruct the fabrication of large-size titanium alloy bars.

2.Microstructure evolution during β working

2.1.Microstructure evolution mechanisms during β working

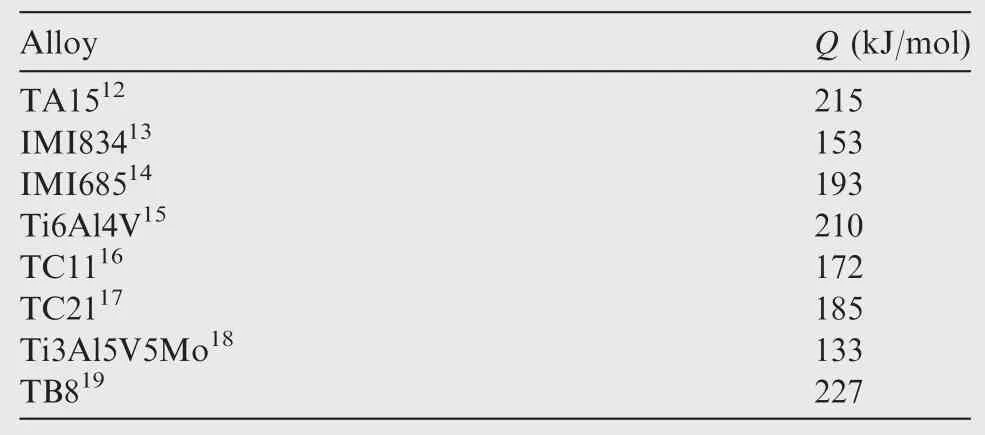

Dynamic recovery(DRV)is an important softening mechanism in high temperature deformation of beta phases.This is often associated with the bcc structure and high stacking fault energy of beta phases,in which dislocation climb and cross-slip are favored.DRV results in a clear substructure within the original beta grains.This has been con firmed by experimental studies in different kinds of titanium alloys.Wang et al.8found that DRV was the dominant microstructure evolution mechanism in β working of the near beta Ti53311S titanium alloy.Han et al.9,10also con firmed that DRV occurred in beta grains during β working of the near alpha Ti600 titanium alloy.The apparent activation energy(Q)ranges from 170 kJ/mol to 220 kJ/mol,which is similar to that of self-diffusion in the beta phase(153 kJ/mol),11as shown in Table 1.12–19The similarity of apparent activation energy to that of self-diffusion in the beta phase indicates that DRV dominates the microstructure evolution during β working.

Besides DRV,some research works also indicate that partial dynamic recrystallization(DRX)occurs.17,18,20Generally,the proportion of DRX to the total microstructure evolution is small.15,21–25Wanjara et al.26reported that an averagerecrystallized fraction was attained to be 2.3%when the IMI834 titanium alloy was deformed at 1050°C with a strain rate of 1 s-1to a true strain of 0.2,which reached to 50%with increasing of a true strain of 1.2.Research by Ding et al.27reported an average recrystallized fraction of less than 30%in deformation of the Ti–6Al–4V titanium alloy at 1050 °C with a strain rate of 0.05 s-1to a true strain of 0.7.These works show that microstructure evolution is mainly DRV for titanium alloys during β working.

Table 1 Apparent activation energy of titanium alloys in the β phase field.12–19

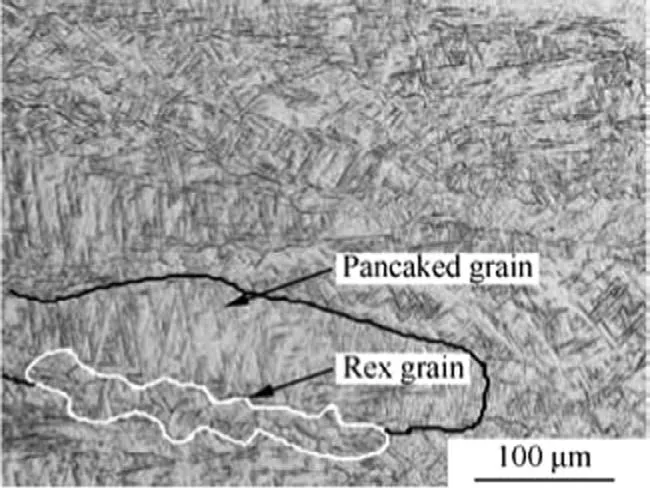

The prior beta grains become elongated in the plane perpendicular to the compress axial direction,and exhibit a tridimensional pancake-shape structure due to the strong DRV in β working.20,28–31Recrystallized beta grains are often observed at the prior beta grain boundaries,where the nucleation of DRX grains is initiated.This gives a necklace-appearance of fine equiaxed beta grains around the deformed and elongated prior beta phase.26,32,33The morphology of beta grains for titanium alloys during β working is illustrated in Fig.1.34

2.2.Effect of process parameters on microstructure evolution during β working

The microstructure of a deformed material is closely related to process parameters,such as temperature,strain rate,strain,and their interactions.Detailed work has been carried out by many researchers on the regulations of microstructure evolution in β working of titanium alloys.

The microstructure evolution during β working is sensitive to strain rate.Excessive high strain rate is disadvantageous to nucleation of DRX.35,36Zhu et al.37studied microstructure morphology with strain rates of 0.01–10 s-1for the TC21 titanium alloy during β working.The results indicated that only DRV was observed at strain rates greater than 1 s-1.A lower strain rate avails to occurrence of DRX as it provides more timefornucleation and growth ofnew recrystallizing grains.38,39Balasubrahmanyam and Prasad40studied the microstructure evolution at strain rates between 0.001 and 100 s-1for the Ti–10V–4.5Fe–1.5Al titanium alloy at hightemperature upset forging and observed DRX at strain rates ranged from 0.001 s-1to 0.1 s-1.Generally,the extent of DRX grows firstly and then decreases with decreasing strain rate.Excessive low strain rate gives enough time for DRV and suppresses DRX.41Wang et al.42studied the microstructure evolution for the Ti–6.5Al–3.5Mo–1.5Zr–0.3Si titanium alloy during β working.Their work indicated that only DRV was observed at 1035–1080 °C at strain rates lower than 0.01 s-1.

Fig.1 Microstructure of IMI834 titanium alloy deformed in the β phase field.34

The deformation temperature also affects the microstructure evolution signi ficantly during β working.It is found that DRX hardly occurs at lower temperature in the β phase field.However,the extent of DRX grows with temperature.19,43,44The work by Ding et al.27showed the proportion of DRX of the Ti–6Al–4V titanium alloy was less than 5%at 1000 °C and all strain rates.However,the DRX percentage grew to about 30%at temperature of 1050°C and a strain rate of 1.0 s-1.Lei et al.45found that the DRX percentage was 30%,42%,and 48%at 1000 °C,1050 °C,and 1100 °C with a strain rate of 0.1 s-1to a true strain of 1.2.

The microstructure evolution is remarkably affected by strain during β working.DRX grains cannot be observed until a certain strain is reached.The fraction of DRX grains grows sharply with strain.46,47Wanjara et al.26reported that the fraction of DRX grew from 2.3%to 50%at a strain rate of 1 s-1and temperature of 1050°C,as the strain increased from 0.2 to 1.2.Chen et al.48reported a similar phenomenon in β working of the TC11 alloy.

2.3.Microstructure prediction and control during β working

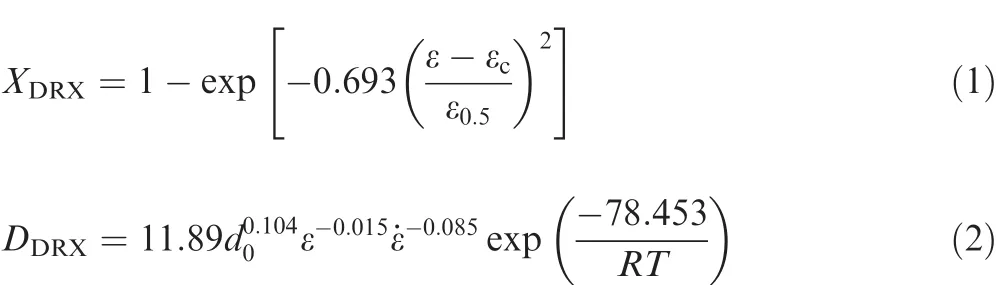

Based on the identi fied microstructure mechanisms,many models have been established for β working of titanium alloys.Generally these models mainly involve the kinetics of DRX and the grains size of DRX.The kinetics models are mainly based on the Avrami equation,for the purpose of prediction volume fraction of DRX.16,36The models for predicting the grains size of recrystallized beta phases are mainly modi fied or improved from the Sellars equation.15,22,26Wang et al.49established the equations of the DRX kinetics and the DRX grains size of the beta phase for the Ti–6.5Al–3.5Mo–1.5Zr–0.3Si titanium alloy deformation in the β phase field,as given in the following equations:

whereXDRXis the volume fraction of DRX,ε is the true strain,εcis the critical strain,ε0.5is the strain of 50%DRX,DDRXis the grain size of DRX,d0is the initial grain size,˙ε is the strain rate,Ris the gas constant,andTis the working temperature.These equations are based on the recrystallized laws of beta phase during β working.Chen et al.16indicated that the DRX grains size of the beta phase was related to theZparameter(Z=˙εexp[Q/(RT)].The recrystallization kinetics and grains size of the beta phase for the TC11 titanium alloy during β working are determined as follows:

whereXSis the modi fied volume fraction of DRX by prior grain size,Bis a material constant,and εpis the peak strain in the flow stress curve.Balasubrahmanyam and Prasad40related the DRX grains size with theZparameter,and established the model of the DRX grains size for the Ti–10V–4.5Fe–1.5Al titanium alloy in upset forging.Ding et al.27modeled the DRX grains size for the Ti–6Al–4V titanium alloy during β working based on the following equation:

where σ is the flow stress,μ is the shear modulus,Dis the mean grain size of DRX,bis Burger’s vector,exponentmis 2/3,andKis a constant in the range of 1–10.

2.4.Further works in β working

Though much work has been carried out on β working,there still exist some problems in the prediction and control of microstructure evolution,which are summarized as follows:

(1)A mechanism map is needed to quantitatively characterize the mechanisms of microstructure evolution under different hot working conditions.The transition from DRV to DRX is sensitive to deformation parameters.Moreover,the recrystallization kinetics is greatly in fluenced by the processing conditions.Though the processing map,which relatesthemain microstructural mechanism with processing parameters,has been used to instruct the deformation of titanium alloys,it may not be accurate enough for quantitative measurement of microstructure evolution.This requires a new method which re flects the detail information on microstructure evolution.

(2)The relationship between grains morphology and process parameters needs to be clari fied.The beta grains become elongated in the plane perpendicular to the compression axial direction and staved in the deformation direction.Deformation texture and substructure are also formed.These affect the precipitation of lamellar alpha during cooling from the deformation temperature.Teixeira et al.50reported that the distributions of sub-grain boundary and misorientation angles were related to the plastic deformation conditions during β working.This affected the occurrences of αGBand αWGB,where subscript GB stands for grain boundary allotriomorph and WGB for Widmansta¨tten plates at the grain boundaries.The morphology of the alpha lamellae will affect the process in the(α + β)phase field.

(3)A model is needed for predicting the morphology of beta grains.The microstructure morphology is determined by the competition between DRV and DRX.The model for characterizing or predicting the morphology of beta grains should be integrated into the traditional DRX model.

3.Microstructure evolution during(α+β)working

3.1.Microstructure evolution mechanisms during(α+β )working

Alpha and beta phases existing in the microstructures of titanium alloys have different morphology when the materials are heated to the(α + β)phase field.It is observed that the lamellar alpha,equiaxed alpha,or a mixture of them is usually distributed in the beta matrix.For the purpose of obtaining an equiaxed microstructure,bimodal microstructure,or tri-modal microstructure,the thermo-mechanical processing in the(α+ β)phase field is adopted.51–58The morphology of the lamellar structure retains the same during heating in the(α + β)phase field,but the thickness of lamella changes at a certain degree(microstructure characteristics of lamellar alpha distributed in the beta matrix is shown in Fig.2).59While complex microstructure appearances are observed when being deformed at the(α + β)phase field.Various microstructure appearances observed in the above mentioned process have signi ficant bearings on the alpha and beta phase evolution laws during(α + β)working.

The morphology of lamellar alpha becomes spheroidized via the occurrence of a high-angle grain boundary during(α+β)working.Meanwhile,DRX and DRV are observed in the beta phase during(α + β)working.Many previous works indicated that the mechanisms of high-angle grain boundary formation could be classi fied into two types:the DRX mechanisms60–62and the non-DRX mechanisms.

Some researchers believed that the spheroidization in the(α + β)phase field were caused by DRX.According to them,DRX firstly occurred within the lamellar alpha during deformation which led to ‘alpha grains string”,i.e.,multi-alpha grains located in a line,and further resulted in the formation of α–α interface within the lamellar alpha.Secondly,with the aids of interfacial energy controlled diffusion,the grooves caused by perturbations or instability of the alpha–beta interface became deeper and further split the short-bar shaped alpha phases.As a result,lamella with a high aspect ratio split into small segments.Finally,alpha segments underwent a morphological transformation from an irregular shape to a globular shape by the termination migration.Chen et al.63reported that the globularization mechanism with an initial lamellar structure.Their work demonstrated that continuous dynamic recrystallization(CDRX)occurred within the alpha plates in the TC11 titanium alloy during(α + β)working,which included:(1)the formation of a substructure with low-angle boundaries by deformation and recovery within the alpha plates;(2)splitting of the alpha plates by diffusion along the substructure of the beta phase via slipping along grain boundaries;(3)globularization of alpha grains and homogenization of the structure.Zhou64reported that the globularization process of the Ti-17 titanium alloy with an initial lamellar structure deformed in the(α + β)phase field was separated into three steps: firstly,the sub-boundaries formed within the alpha plates by DRX;secondly,the sub-boundaries were split due to the slipping of the α/α grain boundaries; finally,the sub-grains were further globularized.The mechanism of non-DRX mainly contains buckling splitting,boundary splitting,and termination migration.The microstructure evolution is related to the geometrical morphology of the alpha plates.

Lai65offers an example of globularization by buckling splitting.The force imposed generates stress parallel to the compression direction and the effect of material flow assists the alpha plates to rotate to an orientation parallel to the compression axis which results in buckling more easily.The splitting and segregation easily take place in the defect areas due to the beta phase wedging.Li et al.66demonstrated that the evolution of lamellar alpha contained buckling,fragmentation,and spheroidization sequentially.Mironov et al.67studied the microstructure evolution of the Ti–6Al–4V titanium alloy with a colony structure during warm working.The microstructure evolution was found to be driven mainly by the imposed strain and by the kinking of alpha lamellae.For most cases,the lamellar microstructure was considered stable during the conventionalloading process with limited globularization observed only in kinked alpha colonies.

Apart from the buckling splitting mechanism,boundary splitting is another key mechanism comprehensively supported by researchers.Boundary splitting requires an internal boundary through the thickness of one of the lamellar phases.The boundary may originate from a pre-existing grain boundary or a sub-grain boundary/deformation band introduced during cold or hot working.Such a boundary creates an unstable(90°)dihedral angle.To lessen interfacial tension,the dihedral angle is reduced and stabilized by the diffusion of the interlamellar phase into the boundaries.Eventually,the diffusion of the second phase into the boundary(‘thermal grooving”)results in a ‘pinch off” and two new terminations due to the elimination of the intralamellar boundary.The work of Stefansson et al.68indicated that the initial stage consisted of segmentation of the lamellae via boundary splitting.

Shearing of the alpha plate was proposed by Seshacharyulu et al.69The shearing deformation easily takes place in the lamellar alpha phase,which is mainly caused by the force imposed perpendicular to the compression axis.Dislocations are localized on the shear lines(severely sheared regions)within the alpha plates.The dislocations with the opposite signs are annihilated with each other by the recovery.Meanwhile,the interfaces are produced along the shear lines,which are caused by the dislocations with the same sign.To reduce the interfacial energy,the diffusion of the second phase into the interface produces a globularized microstructure.

Fig.2 Lamellar structure of titanium59:(a)before heating;(b)after heating in the(α + β)phase field.

Termination migration consists of the mass transfer from the curved surfaces of the lamellar termination to the flat surfaces of the lamellae.The driving force is provided by the difference in curvature between the lamellar termination and the flat lamellar interface.The lamellar alpha becomes globularized during the course of coarsening.The work of Stefansson et al.68indicated that the second stage of globularization could be attributed to termination migration.

Microstructure evolution mechanisms of the beta phase are mainly DRX or DRV during(α + β)working,unlike the multi-mechanisms controlled lamellar alpha evolution process.70–72The dominant mechanism,DRX or DRV,is determined by the alloy per se and process parameters during deformation.The work of Huang73demonstrated that DRX was observed in the beta phase for the TC11 titanium alloy during deformation in the(α + β)phase field.The work of Jones et al.74indicated that DRV occurred in the beta matrix for the Ti–5Al–5Mo–5V–3Cr–1Fe alloy during(α + β)processing.The work of Warchomicka et al.75showed that DRV mainly occurred in the beta matrix for the Ti–5Al–5M o–5V–3Cr–1Zr alloy during deformation in the(α + β)phase field,albeit CDRX would also occur with the change of strain rate.

3.2.Effects of process parameters on microstructure evolution during(α+β )working

During(α + β)working,globularization usually takes place within the alpha phase with a lamellar structure via the formation of high-angle boundaries and DRX or DRV usually takes place in the beta phase.Many authors have investigated the effects of processing parameters,including the prior beta grain size,thickness of alpha plates,deformation temperature,strain rate,and strain,on globularization.76Complicated precipitation transformations have been corroborated in hot working and subsequent heat treatment or cooling process of bimodal titanium alloys.In the sense of precipitation transformation, αGB, αWGB,and αWI(subscript WI stands for Widmansta¨tten intragranular precipitates)are obtainable during cooling down of the high-temperature beta phase.Moreover,the type,volume fraction,and morphology of these precipitations are determined by processing parameters as well as microstructure parameters.As far as microstructure parameters are concerned,interesting rules have been found that the difference in the size of prior beta grains results in the differences in length and width of the lamellar alpha phase and further in fluences the globularization ef ficiency of alpha grains.Semiatin et al.77studied the globularization kinetics of the lamellar alpha phase in the Ti–6Al–4V alloy with prior beta grain sizes of 100 μm and 400 μm,respectively,during(α+β)working.The result showed that the globularization ratio of the lamellar alpha precipitated from fine beta grains was much higher with the same process parameters.

Poorganji et al.78studied the microstructural evolution of near-alpha titanium alloys with different initial microstructures during(α + β)working.The finer the initial microstructure obtained by quenching and reheating processes was,the more inhomogeneous plastic deformation distribution was gained.This inhomogeneous distribution of plastic deformation increased the driving force for initiation of DRX and the percentage of high-angle grain boundaries.The work indicated that a finer initial microstructure was bene ficial to the globularization of lamellar alpha.Men et al.79studied the microstructure evolution of the TC11 alloy with lamella thicknesses of 3 μm and 0.4 μm,during deformation at a temperature range from 920 °C to 980 °C.They found that the finer the lamellar alpha was,the higher extent of globularization was obtained.This might be attributed to the effect of the alpha lamella thickness,i.e.,the Hall-Petch effect on the globularization mechanisms.Zherebtsov et al.80studied the globularization behavior of the Ti–6Al–4V alloy with a lamellar structure when deformed at 800°C.In their point of view,boundary splitting was a dominant globularization mechanism within the thin plates while CDRX was believed to occur mainly within the thick plates.This lends supports to the assertion thatlamellarthicknessaffectsthe globularization mechanisms.

The effect of strain on globularization of a lamellar structure is more signi ficant compared with those of strain rate and temperature during(α + β)working.The initiation of globularization occurs as the strain reaches a critical value.The fraction of globularization increases with an increasing strain and is able to achieve a suf ficiently high level as the strain reaches to an enough extent.81The initiation strain and completion strain for globularization relate to the thickness of the alpha plates and as a result bound up with the composition of the alloy as the interrelation between the alloy composition and the lamella thickness is concerned.Taking the near beta titanium alloy as an example,the initiation strain and completion strain will be lower when the beta stabilized element is higher.Wu et al.82studied the behavior of globularization of the TA15 titanium alloy with a lamellar structure during(α + β)working.The results showed that the effect of strain on globularization was notable.Initiation strain and completion strain for globularization of the lamellar structure were 0.34–0.59 and 3.4–6.8,respectively,with a strain rate of 0.01–1 s-1and temperature ranging from 860 °C to 970 °C.The work of Wang et al.83demonstrated that the initiation strain and completion strain for globularization of the Ti-17 titanium alloy with a lamellar structure were 0.4 and 1.0,respectively.

Strain rate also has an important effect on the globularization of titanium alloys with lamellar structures during(α + β)working.84,85A higher strain rate leads to more inhomogeneous plastic deformation which will introduce severe deformation at the local region.Li39studied the microstructure evolution of the TC11 alloy with a lamellar structure during(α + β)working at a strain rate of 10.0 s-1.Their observation showed that the adiabatic shear band which was arranged at a 45°orientation from the loading axis was generated due to the local high strain rate shearing and this microstructure pattern attenuated when the strain rate decreased in two to three orders of magnitude.Meanwhile,plastic deformation became more and more homogeneous.In the light of above discussed investigation,a lower strain rate can effectively improve the deformation homogeneity and supply enough time for globularization of lamellar structures and is thus favorable to globularization control.A study86on the microstructure evolution of TC21 in high-temperature deformation regimes done by Zhao indicated that the strain rate is a key factor for DRX.Microstructure characteristics of DRX were not found at high strain rates(1–10 s-1),while a cooperative phenomenon of DRX and alpha lamella globularization was observed at 900°C and 0.01 s-1.

The volume fraction and thickness of lamellar alpha are sensitive to deformation temperature.In detail,with the increase of temperature,the volume fraction of the alpha phase decreases.Moreover,heating temperature exerts effect on the alpha lamella thickness.In other words, fine lamella such as martensite lamella becomes thicker with the increase of temperature within the(α + β)-phase region,while coarse lamella represented by the furnace cooling microstructure changes in an opposite way.59It is explicable because the diffusion of solute elements is much easier at higher temperature which results in the acceleration of interface migration and termination migration.With all these phenomena observed and the clues of the temperature related globularization found,many researchers have been making their efforts to illuminate the in fluence rules of temperature on globularization and the related mechanisms of bi-modal titanium alloys with lamellar structures.87,88Zherebtsov et al.80studied the globularization of the Ti–6Al–4V alloy with a lamellar structure during warm working.They found that CDRX took place at 600°C while boundary splitting took place at 800°C.However,Zhan89found that DRX took place within alpha plates during deformation with a strain rate of 0.001 s-1at 800°C while DRV occurred within alpha plates with the same strain rate at 925°C.

The effect of temperature not only embodies during the working process but also in the subsequent heat treatment process.The lamellar alpha structure transforms into a short-bar shape or a band-like shape after deformation in the two-phase region and alpha grains with these shapes further split or spheroidize via holding or heat treatment.As a consequence,hot working+holding/heat treatment with an appropriate time interval and temperature adjustment is a promising strategy for microstructure modi fication.This kind of strategy was employed by Stefansson et al.90in their work on microstructure evolution of the Ti–6Al–4V titanium alloy during postdeformation annealing at 900 °C and 950 °C.Conclusions were drawn that kinetics of static globularization depended on the pre-imposed strain and the annealing temperature.

3.3.Microstructure prediction and control during(α+ β )working

Lamellar structures of titanium alloys globularize by means of generating intra-lamellae high-angle grain boundaries after deformation in the(α + β)-phase region.Based on previous investigations on microstructure evolution behavior and in fluence rules of lamellar structures during(α + β)working,various kinetics models have been proposed by researchers for the sake of precisely predicting this process.These models were mainly utilized for predicting globularized kinetics of alpha phases,average grains size,and the kinetics during static annealing.The volume fraction and grain size of alpha grains are predicted by the means of empirical models,neural network models,internal variables based models,etc.91–93

Empirical models,in which the microstructure-related variables are expressed as functions of strain,strain rate,and deformation temperature based on experiment results,are one of the most frequently used models to predict microstructure evolution of titanium alloys with lamellar structures in virtue of the fact that they are characterized by simpli fied formation and high prediction precision.Among empirical models,the modi fied Avrami equation gained comprehensive use to predict the kinetics of lamellar structure in titanium during(α + β)working.94,95Chen et al.96founded the modi fied Avrami equation which was established to describe the kinetics of globularization of the TC11 titanium alloy with a lamellar structure as determined by Eq.(6).The prediction result tallied well with the experiment results to some extent.Wu et al.97established another Avrami-type equation,Eq.(7),to predict the dynamic globularization kinetics of the TA15 alloy with a lamellar structure in which better precision was achievable.

wherefdgis the volume fraction of dynamic globularized α,F(Z)is a modi fied function of the Avrami kinetics model,kis the kinetic constant and temperature-dependent factor,andnis the Avrami exponent.

Thearti ficialneuralnetwork method which extracts microstructure evolution laws based on vast laboratory findings and predicts microstructure evolution behaviors accurately is another favorable scheme to predict microstructure evolution of titanium alloys during(α + β)hot working.Based on vast experiment data,Wang et al.98proposed a neural network model to predict microstructure evolution of the Ti-17 titanium alloy with a lamellar structure during(α + β)working.The model successfully predicted the globularization of different locations in a sample with a weight as heavy as 22 kg.

Static globularization behaviors of titanium alloys and model predictions of globularized volume fraction and globularized grain size of prior alpha phases have attracted the attentions of researchers in consideration of improved globularization ef ficiency and effectivenessbroughtby postdeformation holding/heat treatment.99The kinetics models of the TA15 titanium alloy were comparatively established by Fan et al.100based on sigmoidal equation and parabolic equation.The volume fraction of alpha phases during static annealing waspredicted and closeto theexperimentresult.Stefansson et al.90studied the static globularization of the Ti–6Al–4V alloy with a lamellar structure,and precisely predicted the grains size of alpha phases during the static annealing process with the aid of the classical coarsening theory.

3.4.Further works in(α+ β )working

Although a lot of researchers have investigated the in fluence rules and mechanisms of process parameters on microstructure evolution behavior,model prediction and further intended control of the microstructure evolution process,and ultimate performance of bi-modal titanium alloys,some problems still exist in this field,which are summarized as follows:

(1)Limited studies on the effect of beta phase morphology on the microstructure evolution during(α + β)working have been reported.Titanium alloys with lamellar structures investigated recently are mostly obtained by quenching of high temperature heat treated beta phases.The thickness and direction of lamellar alpha are homogeneously distributed and disordered because of the homogeneous nature of precipitation transformation in undeformed beta grains.However,the morphology of beta phases during β working is inhomogeneous which leads to complex microstructure patterns including equiaxed beta grains of DRX,elongated beta grains,and undeformed beta grains.This inhomogeneity of beta grain morphology and distribution affects the morphology of alpha precipitation,and globularization inhomogeneity occurs due to the inheriting effect.As a result,morphology and distribution of beta grains play a key role in microstructure evolution behavior during(α + β)working.This kind of inherited microstructure inhomogeneity could be detrimental in an actual manufacturing process,especially in processing large-size titanium alloy bars.To this end,the research on the effects of beta morphology on microstructure evolution during(α + β)working could be conducive in fabrication of large-size titanium alloy bars.

(2)An appropriate model is required by which the prediction of microstructure evolution during β/(α + β)working is obtainable.In view of the present situation that existing models predict the microstructure evolution independently,i.e.,they predict the microstructure evolutions during β working and(α + β)working separately rather than providing a scheme of through-process prediction to effectively demonstrate microstructure evolution behavior concerning both β working and(α + β)working.A mathematical method should be proposed to quantify and characterize the microstructure evolution features based on the present models,which can overall consider the in fluences of both β working and(α + β)working on globularization in the(α + β)phase field.By this way,accurate,thorough,and systematical prediction and control of the target microstructure of titanium alloys during hot working should be expected.

4.Microstructure control methods in forming titanium alloy bars

Titanium alloy ingots melted by double or three VAR processes are forged in the beta phase field and the two phase field to obtain titanium alloy bars with required shape and microstructure.101–105

β forging can break up the coarse cast structure and re fine beta grains.In a β forging process,we pay attention to the degree of total deformation,which is determined by the degree of deformation in a single heat and heating times.Wang et al.106studied the forging process for TC11 titanium alloy bars with a diameter of 320 mm during β forging.Two types of forging processes were employed:(1)the total deformation degree was greater than 50%within 1–2 times of heat;(2)the total deformation degree was greater than 70%within 1–2 times of heat.An acceptable bar was fabricated using the second processing route.In most cases,the processing parameters are selected based on experience or the trial-and-error method.These methods are time and cost consuming,and the obtained processing routes are not always the best.Ref.107indicated that the grains size of beta phases was sensitive to heating temperature above the beta transus.The grains size and morphology of beta phases are determined by heating temperature and the degrees of deformation in the last heat.The grain size and morphology of beta phases will affect the subsequent working in the two-phase region.Therefore,it is a key factor for fabrication of titanium alloy bars.

(α + β)forging deformed below the beta transus can break up the lamellar structure cooled from the beta phase field and obtain the microstructure of globularized alpha distributed in the beta matrix.The heating temperature,heating times,and degree of deformation for single heat are the most important parameters for obtaining a fine and homogeneous microstructure.Wu et al.108studied the forging process for TC11 titanium alloy bars with a diameter of 130–160 mm via a radial forging process during(α + β)forging.Two types of forging processes were employed:(1)the total deformation degree was 50%;(2)the total deformation degree was 80%.A bar with an equiaxed and homogeneous microstructure was fabric isa tu endu b suy a t lhl ye 1s e0 c–o7 n0 d° Cp r b oecleosws in tgh e r ob uett ea. tTr ahnes hu es a.1t0i9n–g11t2em Thp e e rsap teucriefic temperature is in fluenced by the workability of the material and the required volume fraction of primary alpha.The heating times and degree of deformation are often determined by experience,and examined by a simple experiment.Similar to β working,further work is needed on optimizing the processing parameters.

As mentioned above,the processing route of titanium alloy bars contains both β working and(α + β)working.β working affects the globularization of the lamellar structure of titanium alloy during (α + β)working,and thusin fluencesthe microstructure of the final product.The process of β/(α + β)working should be considered as a whole one,in which β working and(α + β)working match each other.Huang et al.113studied the optimization working process for the Ti-1023 titanium alloy.They matched β forging with(α + β)forging by the means of alternating one or two times,and the final processing was accomplished in the(α + β)phase field.A bar with a fine and homogeneous microstructure was fabricated successfully.The method for selecting the alternated frequency is dependent on experience or the trial-and-error method.This method is helpful for obtaining a fine and homogenous microstructure,but is time and cost consuming.

However,β working and(α + β)working are considered as two separate processes in most cases.The absence of an integrated design of β/(α + β)working increases the total deformation degree required,which increases production cycle and cost.Especially,for large-size titanium alloy bars(diameter≥ 350 mm),the matching between β working and(α + β)working is more important.This is because the deformation inhomogeneity increases with the size of the bar.To obtain a homogeneous microstructure, multi-heat and multidirectional deformation is necessary.114The total deformation degree may increase sharply if β working and(α + β)working do not match,which lowers the production ef ficiency,so this requires an advanced processing technic for titanium alloy bas.Further works are needed on the effect of interaction between β working and(α + β)working on the globularization of lamellar structure.

5.Trends in microstructure control techniques for titanium alloy bars

Microstructure control is important to the fabrication of titanium alloy bars.With the increasing demands of largesize titanium alloy bars,it is necessary to optimize the primary hot working process so as to obtain high-quality bars with low cost.The trends in microstructure control techniques for titanium alloy bars are as follows:

(1)Quantifying the relationship between beta grain morphology and processparametersisnecessary for microstructure control in β working.

(2)The effect of β working on the microstructure evolution in subsequent(α + β)working needs further investigation so as to control the globularization process in primary working.

(3)Integrated design of β working and(α + β)working is necessarysothatproductioncostandtimecanbereduced.

(4)The through-process modeling and prediction of microstructure evolution can be used to optimize the primary hotworking process.Modelsrelating the microstructure parameters with the complex thermomechanical processing route based on the underlying mechanisms need further investigation.

6.Remarks

Howto fabricatehigh-quality titanium alloybars is veryimportant to the fabrication of titanium alloy components in the aviation industry.To fabricate titanium alloy bars with high ef ficiency,low cost,and high quality,it is necessary to develop advanced microstructure control techniques.With the increasing demands of large-scale bars,how to control the microstructurehasbecomeachallenge.Integrateddesignofβworkingand(α + β)working is a feasible way to develop microstructure control techniques.Through-process modeling and simulation are important tools for integrated process design.

The authors would like to thank the National Natural Science Foundation of China(51175427,51275415),Open Fund of State Key Laboratory of Materials Processing and Die&Mould Technology of China(P2014-005),the EU Marie Curie Actions–MatProFuture Project of China(FP7-PEOPLE-2012-IRSES-318968),and the ‘111” ProjectofChina(B08040)for their supports to this research.

Appendix A.Supplementary data

Supplementary data associated with this article can be found,in the online version,at http://dx.doi.org/10.1016/j.cja.2015.07.011.

1.Peng YP,Zeng FC,Wang JJ,Zhang YN,Xia SY.Development,application and feature of titanium alloys in foreign aviation industry.J Mater Eng1997;10:3–6[Chinese].

2.Zhang HS.The status and trend in developing aeronautical structural materials in foreign countries.Aviat Eng Maintenance1997;11:3–6[Chinese].

3.Gao J,Yao L.The domestic and overseas research development in titanium alloys.World Nonferrous Metal2001;2:4–7[Chinese].

4.Flower HM.Microstructural development in relation to hot working oftitanium alloys.MaterSciTechnol1990;6(11):1082–92.

5.Kuhlman GW.Critical appraisal of thermomechanical processing of structural titanium alloys.Proceedings of the symposium on microstructure/property relationships in titanium aluminides and alloys presented at the 1990 TMS fall meeting.Warrendale,PA:Minerals,Metals&Materials Society;1991.p.465–91.

6.Semiatin SL,Seetharaman V,Weiss I.Thermomechanical processing of alpha/beta titanium alloys.JOM-US1997;49(6):33–9.

7.MalcorJG,MontheilletF,ChampinB.Mechanicaland microstructural behavior of Ti–6%Al–4%V alloy in hot working range.In:Lu¨tjering G,Zwicker U,Bunk W,editors.Proceedings of the fifth international conference on titanium;1984 Sep 10–14;Munich,German.Oberursel:Deutsche Gesellschaft fur Metallkunde E.V;1985.p.1495–502.

8.Wang RN,Xi ZP,Zhao YQ,Qi YL.Hot deformation microstructure and mechanism of Ti53311S titanium alloy.Rare Metal Mater Eng2008;37(8):1356–9.

9.Han YF,Zeng WD,Qi YL,Zhao YQ.The in fluence of thermomechanical processing on microstructural evolution of Ti600 titanium alloy.Mater Sci Eng A2011;528(29):8410–6.

10.Han YF,Zeng WD,Qi YL,Zhao YQ.Optimization of forging process parameters of Ti600 alloy by using processing map.Mater Sci Eng A2011;529:393–400.

11.Weiss I,Semiatin SL.Thermomechanical processing of alpha titanium alloys–an overview.Mater Sci Eng A1999;263(2):243–56.

12.Tang Z,Yang H,Sun ZC,Li ZY,Duan H.TA15 microstructure evolution and numerical simulation of TA15 titanium alloy during hot compressive deformation.Chin J Nonferrous Metal2008;18(4):722–7[Chinese].

13.Wanjara P,Jahazi M,Monajati H,Yue S,Immarigeon JP.Hot working behavior of near-α alloy IMI834.Mater Sci Eng A2005;396(1):50–60.

14.Liu Y,Baker TN.Deformation characteristics of IMI685 titanium alloy under β isothermal forging conditions.Mater Sci Eng A1995;197(2):125–31.

15.Seshacharyulu T,Medeiros SC,Frazier WG,Prasad YVRK.Hot working of commercial Ti–6Al–4V with an equiaxed α-β microstructure:materials modeling considerations.Mater Sci Eng A2000;284(1):184–94[Chinese].

16.Chen HQ,Cao CX,Guo L,Lin H.Dynamic recrystallization processes during hot deformation of TC11 titanium alloy in β field.J Mater Eng2009;5:43–8.

17.Zhu YC,Zeng WD,Feng F,Sun Y,Han YF,Zhou YG.Characterization of hot deformation behavior of as-cast TC21 titanium alloy using processing map.Mater Sci Eng A2011;528(3):1757–63.

18.Li LX,Lou Y,Yang LB,Peng DS,Rao KP.Flow stress behavior and deformation characteristics of Ti–3Al–5V–5Mo.Mater Des2002;23(5):451–7.

19.Duan YP,Li P,Xue KM,Zhang Q,Wang XX.Flow behavior and microstructure evolution of TB8 alloy during hot deformation process.Trans Nonferrous Metal Soc2007;17(6):1199–204.

20.Sun ZC,Yang H,Tang Z.Microstructural evolution model of TA15 titanium alloy based on BP neural network method and application in isothermal deformation.Comput Mater Sci2010;50(2):308–18.

21.Qiu W,Lu SQ,Ouyang DL,Huang X,Lei LM.Investigation on hot deformation behavior of as-casted TB6 titanium alloy in β phase field.ForgingStampingTechnol2010;35(6):119–23[Chinese].

22.Qu W.Research on hot deformation microstructure evolution of titanium alloy TB6[dissertation].Nanchang:Nanchang Hangkong University;2010[Chinese].

23.Yu LL,Mao XN,Zhao YQ,Zhang PX,Yuan SC.Isothermal behavior and microstructure evolution of BT22 titanium alloy.Rare Metal Mater Eng2007;36(3):505–8[Chinese].

24.Yu XQ.The processing map and the forging process optimization of casting TB6 titanium alloy[dissertation].Nanchang:Nanchang Hangkong University;2009[Chinese].

25.Zhao JG.The deformation behavior and microstructure evolution TC21 alloy during hot working[dissertation].Dalian:Dalian University of Technology;2008[Chinese].

26.Wanjara P,Jahazi M,Monajati H,Yue S.In fluence of thermomechanical processing on microstructural evolution in near-α alloy IMI834.Mater Sci Eng A2006;416(1):300–11.

27.Ding R,Guo ZX,Wilson A.Microstructural evolution of a Ti–6Al–4V alloy during thermomechanical processing.Mater Sci Eng A2002;327(2):233–45.

28.Shan DB,Shi K,Xu WC,Lv Y.Hot deformation mechanism and processing map of TC11 alloy.Rare Metal Mater Eng2009;38(4):632–6.

29.Shi K.The isothermal forming law and numerical simulation of TC11 alloy impeller component with complex shape[dissertation].Harbin:Harbin Institute of Technology;2008.

30.Qu YD,Wang MM,Lei LM,Huang X,Wang LQ,Qin JN,et al.Behavior and modeling of high temperature deformation of an α+ β titanium alloy.Mater Sci Eng A2012;555:99–105.

31.Qu HL,Zhao YQ,Feng L,Xi ZP,Li H,Xia YM.Study on microstructures of TC21 alloy under different deformation conditions.J Mater Eng2006(S1);274–7[Chinese].

32.Chen HQ,Lin HZ,Guo L,Lin H.Hot deformation behavior and microstructure evolution of TC11 alloy.J Aeronaut Mater2007;27(3):1–5[Chinese].

33.Zhang HR.Deformation behavior,microstructure and texture evolution of TC11 alloys by hot compression[dissertation].Guangzhou:South China University of Technology;2011[Chinese].

34.Vo P,Jahazi M,Yue S,Bocher P.Flow stress prediction during hot working of near-α titanium alloys.Mater Sci Eng A2007;447(1–2):99–110.

35.Wu C.Study on the dynamic recrystallization behavior and prediction model of TA15 titanium alloy in the β hot process[dissertation].Nanchang:Nanchang Hangkong University;2009[Chinese].

36.Ouyang DL,Lu SQ,Cui X,Wu C,Dong XJ.Dynamic recrystallization of TA15 alloy during β hot process at different strain rates.Rare Metal Mater Eng2011;40(2):325–30[Chinese].

37.Zhu ZS,Wang XN,Gu W,Chen MH.A study on high temperature deformation behaviors of new type TC21 titanium alloy.Mater China2009;28(2):51–5[Chinese].

38.Zeng WD,Zhou YG,Shu Y,Zhao YQ,Yang J,Zhang XM.A study on hot deformation mechanisms in Ti-40 burn resistant titanium alloy using forming maps.Rare Metal Mater Eng2007;36(1):1–6[Chinese].

39.Li X.Research on hot deformation behavior and optimization of forging process of titanium alloy TC11[dissertation].Nanjing:Nanjing University of Aeronautics and Astronautics;2008[Chinese].

40.Balasubrahmanyam VV,Prasad YVRK.Deformation behavior of beta titanium alloy Ti–10V–4.5Fe–1.5Al in hot upset forging.Mater Sci Eng A2002;336(1):150–8.

41.Wang KL,Lu SQ,Li X,Yang HJ,Dong XJ.Dynamic recrystallization of β phase of Ti–6.5Al–3.5Mo–1.5Zr–0.3Si alloy.Rare Metal Mater Eng2009;38(2):219–23[Chinese].

42.Wang KL,Lu SQ,Fu MW,Li X,Dong XJ.Optimization of β/near-β forging process parameters of Ti–6.5Al–3.5Mo–1.5Zr–0.3Si by using processing maps.Mater Charact2009;60(6):492–8.

43.Zhu YC,Zeng WD,Liu JL,Zhao YQ,Zhou YG,Yu HQ.Effect of processing parameters on the hot deformation behavior of ascast TC21 titanium alloy.Mater Des2012;33:264–72.

44.Jia WJ,Zeng WD,Liu JR,Zhou YG,Wang QJ.On the in fluence of processing parameters on microstructural evolution of a near alpha titanium alloy.Mater Sci Eng A2011;530:135–43.

45.Lei LM,Hung X,Wang MM,Wang LQ,Qin JN,Lu SQ.Effect of temperature on deformation behavior and microstructures of TC11 titanium alloy.Mater Sci Eng A2011;528(28):8236–43.

46.Li YT.Microstructure evolution of TC11 alloy during hot compressive deformation[dissertation].Harbin:Harbin Institute of Technology;2006[Chinese].

47.Ma FC,Lu WJ,Qin JN,Di Z.Microstructure evolution of nearαtitanium alloys during thermomechanical processing.Mater Sci Eng A2006;416(1):59–65.

48.Chen HQ,Cao CX,Guo L,Lin H.Hot deformation mechanism and microstructure evolution of TC11 titanium alloy in β field.Trans Nonferrous Metal Soc2008;18(5):1021–7.

49.Wang KL,Fu MW,Lu SQ,Li X.Study of the dynamic recrystallization of Ti–6.5Al–3.5Mo–1.5Zr–0.3Si alloy in β-forging process via finite element method modeling and microstructure characterization.Mater Des2011;32(3):1283–91.

50.Teixeira JDC,Appolaire B,Aeby-Gautier E,Denis S,Bruneseaux F.Modeling of the effect of the β phase deformation on the β phase precipitation in near-β titanium alloys.Acta Mater2006;54(1):4261–71.

51.He D,Zhu JC,Lai ZH,Liu Y,Yang XW.An experimental study of deformation mechanism and microstructure evolution during hot deformation of Ti–6Al–2Zr–1Mo–1V alloy.Mater Des2013;46:38–48.

52.Huang LG,Kong FT,Chen YY,Xiao SL.Microstructure and tensile properties of Ti–6Al–4V–0.1B alloys of direct rolling in the near β phase region.Mater Sci Eng A2013;560:140–7.

53.Roy S,Suwas S.The in fluence of temperature and strain rate on the deformation response and microstructural evolution during hot compression of a titanium alloy Ti–6Al–4V–0.1B.J Alloy Compd2013;548:110–25.

54.Seshacharyulu T,Mederios SC,Frazier WG,Prasad YVRK.Microstructural mechanisms during hot working of commercial grade Ti–6Al–4V with lamellar starting structure.Mater Sci Eng A2002;325(1):112–25.

55.Wang T,Guo HZ,Zhao Y,Yao ZK,Guo YG,Dou ZL.Effect of isothermal deformation amount on microstructure and properties of 600°C high temperature titanium alloy TG6.Rare Metal Mater Eng2010;39(9):1540–4[Chinese].

56.Xiong AM,Chen SH,Huang WC,Lin H,Li MQ.Thermal deformation behavior and microstructure evolution of TC6 titanium alloy.RareMetalMaterEng2003;32(6):447–50[Chinese].

57.Bruschi S,Poggio S,Quadrini F,Tata ME.Workability of Ti–6Al–4V alloy at high temperatures and strain rates.Mater Lett2004;58(27):3622–9.

58.Kim JH,Semiatin SL,Lee CS.High-temperature deformation and grain-boundary characteristics of titanium alloys with an equiaxed microstructure.Mater Sci Eng A2008;485(1):601–12.

59.Semiatin SL,Bieler TR.The effect of alpha platelet thickness on plastic flow during hot working of Ti–6Al–4V with a transformed microstructure.Acta Mater2001;49(17):3565–73.

60.Gopala KV,Prasad YVRK,Birla NC,Sambasiva RG.Processing map for the hot working of near-α titanium alloy 685.J Mater Process Technol1997;71(3):377–83.

61.Tan MJ,Chen GW,Thiruvarudchelvan S.High temperature deformation in Ti–5Al–2.5Sn alloy.J Mater Process Technol2007;192:434–8.

62.Zong YY,Shan DB,Xu M,Lv Y.Flow softening and microstructural evolution of TC11 titanium alloy during hot deformation.J Mater Process Technol2009;209(4):1988–94.

63.Chen HQ,Cao CX,Guo L,Lin H.Globularization mechanisms during hot deformation processes of TC11 alloy with lamellar structure.Rare Metal Mater Eng2009;38(3):421–5[Chinese].

64.Zhou J.A study on globularization mechanism of lamellar microstructure in Ti-17 titanium alloy[dissertation].Xi’an:Northwestern Polytechnical University;2005[Chinese].

65.Lai YJ.Study on microstructural evolution of lamellar structure and globularization kinetics of titanium alloy[dissertation].Xi’an:Northwestern Polytechnical University;2007[Chinese].

66.Li C,Zhang XY,Zhou KC,Peng CQ.Relationship between lamellar αevolution and flow behavior during isothermal deformation of Ti–5Al–5Mo–5V–1Cr–1Fe near β titanium alloy.Mater Sci Eng A2012;558:668–74.

67.Mironov S,Murzinova M,Zherebsov S,Salishchev GA,Semiatin SL.Microstructure evolution during warm working of Ti–6Al–4V with a colony-α microstructure.Acta Mater2009;57(8):2470–81.

68.Stefansson N,Semiatin SL.Mechanisms of globularization of Ti–6Al–4V during static heat treatment.Metall Mater Trans A2003;34(3):691–8.

69.Seshacharyulu T,Mederios SC,Morgan JT,Malas JC,Frazier YVRK,PrasadYVRK.Hotdeformationmechanismsin ELIGrade Ti–6Al–4V.Scr Mater1999;41(3):283–8.

70.Zhou J,Zeng WD,Shu Y,Zhou YG.Study on globularization of lamellar α structure in TC17 titanium alloy during hot deformation using processing map.Rare Metal Mater Eng2006;35(2):265–9[Chinese].

71.Song HG,Zhang SH,Cheng M.Subtransus deformation mechanisms of TC11 titanium alloy with lamellar structure.Trans Nonferrous Metal Soc2010;20(11):2168–73.

72.Prasad YVRK,Seshacharyulu T.Processing map for hot working of titanium alloy.Mater Sci Eng A1998;243(1):82–8.

73.Huang LJ.Equiaxed treatment and hot deformation of TC11 titanium alloy[dissertation].Harbin:Harbin Institute of Technology;2007[Chinese].

74.Jones NG,Dashwood RJ,Dye D,Jackson M.Thermomechanical processing of Ti–5Al–5Mo–5V–3Cr.Mater Sci Eng A2008;490(1–2):369–77.

75.Warchomicka F,Poletti C,Stockinger M.Study of the hot deformation behavior in Ti–5Al–5Mo–5V–3Cr–1Zr.Mater Sci Eng A2011;528(28):8277–85.

76.Song HW,Cheng M,Zhang SH,Men F,Wang ZT.Microstructure mechanism and processing optimization during sub-transus deformation of TC11 alloy with martensite microstructure.Chin J Rare Metal2008;32(6):698–703[Chinese].

77.Semiatin SL,Seetharaman V,Weiss I.Flow behavior and globularization kinetics during hot working of Ti–6Al–4V with a colonyalphamicrostructure.MaterSciEngA1999;263(2):257–71.

78.Poorganji B,Yamaguchi M,Itsumi Y,Matsumoto K,Tanaka T,Asa Y,et al.Microstructure evolution during deformation of a near-α titanium alloy with different initial structures in the twophase region.Scr Mater2009;61(4):419–22.

79.Men F,Wang ZT,Song HW.A study on globularization mechanism of lamellar microstructure in TC11 alloy.Mech Eng Automat2008;2:113–6[Chinese].

80.Zherebtsov S,Murzinova M,Salishchev G,Semiatin SL.Spheroidization of the lamellar microstructure in Ti–6Al–4V alloy during warm deformation and annealing.Acta Mater2011;59(10):4138–50.

81.Xu B,Wang XY,Zhou JH,Wang KX,Zeng WD.Research on the microstructure evolution of TC17 titanium alloy during hot deformation.ChinJNonferrousMetal2010;20(S1):167–72[Chinese].

82.Wu CB,Yang H,Sun ZC,Fan XG.Hot deformation behavior and microstructure globularization of TA15 with lamellar structure.Chin J Nonferrous Metal2010;20(S1):94–9[Chinese].

83.Wang KX,Zeng WD,Zhao YQ,Shao YT,Zhou JH,Wang XY,et al.Quantitative analysis on microstructural evolution of lamellar α phase in titanium alloy during hot working.Rare Metal Mater Eng2010;39(4):565–9.

84.Zhao YL,Li BL,Zhu ZS,Nie ZR.In fluence of high temperature deformation parameters on microstructure and properties of TC21 titanium alloy.Chin J Nonferrous Metal2010;20(S1):132–7[Chinese].

85.Zhou J,Zeng WD,Shu Y,Zhou YG.In fluence of hot processing parameters on globularization of lamellar α in Ti-17 alloy.Hot Working Technol2005;1:16–9[Chinese].

86.Zhao YL,Li BL,Zhu ZS,Nie ZR.The high temperature deformation behavior and microstructure of TC21 titanium alloy.Mater Sci Eng A2010;527(21):5360–7.

87.Chen HQ,Guo L,Cao CX.Hot deformation behavior and microstructure evolution of TC11 alloy with lamellar structure.J Aeronaut Mater2008;28(1):18–22[Chinese].

88.Ma X,Zeng WD,Tian F,Zhou YG,Sun Y.Optimization of hot processparametersofTi–6.7Al–2Sn–2.2Zr–2.1Mo–1W–0.2Si alloy with lamellar starting microstructure based on the processing map.Mater Sci Eng A2012;545:132–8.

89.Zhan JJ.Thermoplastic deformation behavior and microstructure evolution of TA15 alloy[dissertation].Harbin:Harbin Institute of Technology;2006[Chinese].

90.Stefansson N,Semiatin SL,Eylon D.The kinetics of static globularization of Ti–6Al–4V.Metall Mater Trans A2002;33(11):3526–34.

91.Deng WB.Hot deformation microstructure evolution model and the development and application of finite element software of TC11[dissertation].Taiyuan:Taiyuan University of Science and Technology;2009[Chinese].

92.Luo J.Deformation behavior and models at the high temperature deformation of Ti–6.62Al–5.14Sn–1.82Zr titanium alloy[dissertation].Xi’an:Northwestern Polytechnical University;2007[Chinese].

93.Ma X,Zeng WD,Tian F,Zhou YG.The kinetics of dynamic globularization during hot working of a two phase titanium alloy with starting lamellarmicrostructure.MaterSciEngA2012;548:6–11.

94.Song HW,Zhang SH,Cheng M.Dynamic globularization kinetics during hot working of a two phase titanium alloy with a colony alpha microstructure.J Alloy Compd2009;480(2):922–7.

95.Wang KX,Zeng WD,Zhao YQ,Lai YJ,Zhou YG.Dynamic globularization kinetics during hot working of Ti-17 alloy with initial lamellar microstructure.Mater Sci Eng A2010;527(10):2559–66.

96.Chen HQ,Cao CX,Guo L,Lin H.Hot deformation globularization kinetic processes of TC11 titanium alloy with lamellar structure.J Aeronaut Mater2009;29(1):37–42[Chinese].

97.Wu CB,Yang H,Fan XG,Sun ZC.Dynamic globularization kinetics during hot working of TA15 titanium alloy with colony microstructure.Trans Nonferrous Metal Soc2011;21(9):1963–9.

98.Wang KX,Zeng WD,Zhao YQ,Shao YT,Zhou YG.Prediction of dynamic globularization of Ti-17 titanium alloy with initial lamellar microstructure during hot compression.Mater Sci Eng A2010;527(23):6193–9.

99.Chen HQ,Cao CX.Static globularization of TC11 alloy during hot working process.Rare Metal Mater Eng2011;40(6),0946–50.

100.Fan XG,Yang H,Yan SL,Gao PF,Zhou JH.Mechanism and kinetics of static globularization in TA15 titanium alloy with transformed structure.J Alloy Compd2012;533:1–8.

101.Dong CS,Li WQ,Cai JM.Effect of finish forge and heattreatment on microstructure of TC11 alloy bars.Chin J Rare Metal2004;28(1):286–8[Chinese].

102.He JY,Li DF,Chen HS,Shen J,Zhao YH.Microstructure and mechanical properties of TB2 forgings.Rare Metal Mater Eng2006;35(S2):152–5[Chinese].

103.Yang HL,Li XW,Yang YL,Ma EH,Li DM.Forging process of BTi62 titanium alloy.Chin J Nonferrous Metal2010;20(S1):815–8[Chinese].

104.Wu XD,Ge P,Xi ZP,Mao XN,Yang GJ,Zhou W.Microstructure evolution during solution treatment cooling process of BT22 alloy large-sized forged rods.Rare Metal Mater Eng2010;39(9):1555–60[Chinese].

105.Yang HL.The correlations between the structures and properties of TC21 titanium alloys Φ350 mm bars.China Titanium Ind2011;3:19–21[Chinese].

106.Wang XL,Dong J,Quan YP,Bai YH.Research on forging processes of Φ320 mm TC11 titanium alloy bars.China Titanium Ind2011;3:22–5[Chinese].

107.Peng XN,Guo HZ,Wang T,Yao ZK.Effects of β treatments on microstructures and mechanical properties of TC4-DT titanium alloy.Mater Sci Eng A2012;533:55–63.

108.Wu YY,Wang WB,Ji B.Final wrought deformation of TC11 titanium alloy in(α + β)phase.Chin J Nonferrous Metal2010;20(S1):811–4[Chinese].

109.He PZ,Liu HF,Wei SY,Zhou SC.Effect of processing technique on structural properties of titanium alloy TC8.Titanium Ind Process2009;26(5):18–21[Chinese].

110.Mao ZY,Ji SL,Geng J,Jia WJ,Zeng WD,Wang QJ.Research on the isothermal forging processing of Ti60 alloy.Titanium Ind Process2012;29(4):16–9[Chinese].

111.Zhu BH,Zhao HZ,Shen LH,Ren LP,Liu ST,Wang PJ,et al.Study on TC19 alloy bars.Titanium Ind Process2012;29(3):26–8.

112.Zhang Z,Ju JH,Qi YL,Du Y.Forging technology of titanium alloy and application of forgings.Hot Working Technol2010;39(23):34–7[Chinese].

113.Huang LJ,Qi LC,Huang X.Deformation process optimization of Ti-1023 titanium alloy.Chin J Nonferrous Metal2010;20(S1):726–9[Chinese].

114.Chen GC,Yang WJ,Chao L,Chen S.Study on production technology and its structure and properties for TC9 alloy.Titanium Ind Process2010;27(2):28–30[Chinese].

杂志排行

CHINESE JOURNAL OF AERONAUTICS的其它文章

- Plastic wrinkling prediction in thin-walled part forming process:A review

- Progress of continuously rotating detonation engines

- A hybrid original approach for prediction of the aerodynamic coefficients of an ATR-42 scaled wing model

- Dynamic modeling and analysis of vortex filament motion using a novel curve- fitting method

- Boundary-layer transition prediction using a simpli fied correlation-based model

- Aeroelastic scaling laws for gust load alleviation control system