炭纤维和废弃聚乙烯在沥青中的分散行为及其性能

2016-11-01张茂荣方长青周世生程有亮胡京博

张茂荣, 方长青, 周世生, 程有亮, 胡京博

(1.西安理工大学 机械与精密仪器工程学院,陕西 西安710048;2.西安理工大学 印刷包装与数字媒体学院,陕西 西安710048)

炭纤维和废弃聚乙烯在沥青中的分散行为及其性能

张茂荣1,2,方长青1,2,周世生1,2,程有亮2,胡京博1,2

(1.西安理工大学 机械与精密仪器工程学院,陕西 西安710048;2.西安理工大学 印刷包装与数字媒体学院,陕西 西安710048)

聚丙烯腈基炭纤维和废弃聚乙烯作为改性剂,采用热熔共混、絮凝处理、熔融共挤3种工艺对道路沥青进行改性,并研究了炭纤维分散性对沥青性能的影响。研究表明:炭纤维和废弃聚乙烯对沥青的改性为物理改性,随着炭纤维含量的增加,改性沥青的软化点和延度上升,针入度降低,改性沥青高温性能得到改善。过高的炭纤维含量将不利于分散而发生纤维团聚,当炭纤维含量超过0.1%,将造成改性沥青性能降低。微观观察发现,熔融共挤工艺较其他工艺,炭纤维与聚乙烯能较好的分散和结合,使得聚乙烯与炭纤维形成良好的类荆棘状吸附,在沥青中分散最佳,改性沥青的高温性和抗车辙性能得到较大提高。

包装废PE; 炭纤维; 复合改性; 沥青

1 Introduction

The domestic ordinary asphalt is unable to meet the demands of modern high-speed motorway due to its disadvantages, such as high wax,bad cohesive force, low ductility and large temperature-sensitivity. In order to deal with these problems, many polymers were used to modify the asphalt, such as styrene-butadiene-styrene triblock copolymer (SBS), rubber and polyethylene(PE). At present, the asphalt modified by SBS are broadly used. The properties of the asphalt modified by any single polymer could not be improved comprehensively to meet the demands of modern paving[1-4]. There are different materials that have been employed to reinforce asphalt. Fibers and polymers are two important examples used for this purpose[5,6]. Carbon fibers have many advantages, such as high axial force, high modulus, low density, high temperature resistance in non oxidizing environment, high fatigue resistance, good corrosion resistance and good thermal conductivity[7,8]. Carbon fibers are one class of the important materials used to make composites,owing to their good tensile property and softness. Nowadays, environmental protection, as a social responsibility, has become an important task in all countries. Therefore, the recycled waste packaging polymers and carbon fibers appear to be the attractive modifiers.

Based on the above background, recycled waste packaging polyethylene (WPE) and polyacrylonitrile (PAN) -based carbon fibers (PANCFs) were selected to modify the ordinary paving asphalt instead of the ordinary polymer modifiers. At the same time, three different types of combined modification technologies were studied to reveal the modification mechanism and provide a theoretical basis for the preparation of the low-priced modified asphalt.

2 Materials and experiments

2.1Materials

The recycled WPE bags whose main component was linear low-density polyethylene (LLDPE) were cleaned and dried. The ordinary industrial asphalt was SK-90 produced in petrochemical factory in Xi’an and its main properties are shown in Table 1. PANCFs are made by Institute of Coal Chemistry, Chinese Academy of Sciences. And the carbon fibers are 6 K and cut into 5 mm.

Table 1 Main properties of ordinary asphalt.

2.2Preparation

The recycled WPE bags were washed to remove impurities and dried in a vacuum drying oven until the water content was less than 1%. PANCFs were cut into a length about 5 mm. The compositions of the samples in the experiment are listed in Table 2.

Table 2 Compositions of the modified asphalt samples in the experiment.

Before the WPE and short-cut PANCFs were added into the asphalt, they were mixed in the following three methods. In the method A, WPE and PANCFs were weighed separately according to the formulations in Table 2. In the method B, WPE and short-cut PANCFs were added into xylene, heated to 90 ℃ and stirred by a blender for 100 min. The mixture was flocculated in alcohol, filtered and dried at 90 ℃ in a vacuum drying oven. In method C, WPE and short-cut PANCFs were mixed, crushed at high speed by double roller and extruded by an extruder at 170 ℃.

The asphalt was heated to 170 ℃ until completely melted. To the melted asphalt, the blends of WPE and PANCFs produced in the above three methods were added in the completely melted raw asphalt at 170 ℃ in a reaction kettle. Keeping the temperature constant, the mixture was stirred for 30 min with a glass stirring rod, and then sheared by a shearing machine at a high-speed of 4 000 r/min for 80 min.The temperature of the mixture was then reduced to 130 ℃ and left undisturbed for 50 min for swelling. After fully swelled, the mixture was sheared again by a shearing machine at a high-speed of 3 800 r/min for 60 min until WPE and PANCFs were dispersed uniformly in the asphalt.

2.3Performance test of the modified asphalts

The softening point, the penetration degree and the ductility degree of the modified asphalts were measured according to the standards of China, GB/T0606-2000, GB/T0604-2000 and GB/T0605-1993, respectively. The penetration degree of the modified asphalts was measured with a GS-IV type automatic asphalt penetrometer (China). The softening point of the modified asphalts was tested with a SLR-C type digital softening point tester (China). The ductility was tested with a STYD-3 type digital ductility testing machine (China). The softening point, the penetration degree and the ductility degree of the modified asphalts were measured three times at different positions and averaged.

Besides, a JSM-6390A scanning electron microscope (Japan) was employed to observe the microstructure of the modified asphalts at 5 kV. The modified asphalt samples were obtained at -5 ℃, and coated with gold/pallladium alloy before observation. An Olympus CX40-RFL32J fluorescent microscope was used to investigate the microstructure of the modified asphalts. FT-IR spectra were obtained using a Shimazu FTIR-8400S infrared spectrometer with a scanning range of 400- 4 000 cm-1and a frequency of 20 Hz.

The samples for softening point were prepared according to GB/T0661-2000. First, three kinds of modified asphalts were put into three test tubes. Next, the test tubes were layered for 48±1 h in an incubator at 163±5 ℃. The test tubes were first cooled to room temperature, then to -5 ℃ for 4 h[9]. Finally, the softening points of the asphalts were measured. The softening points of the samples were measured three times at different positions to get an average value.

3 Results and discussion

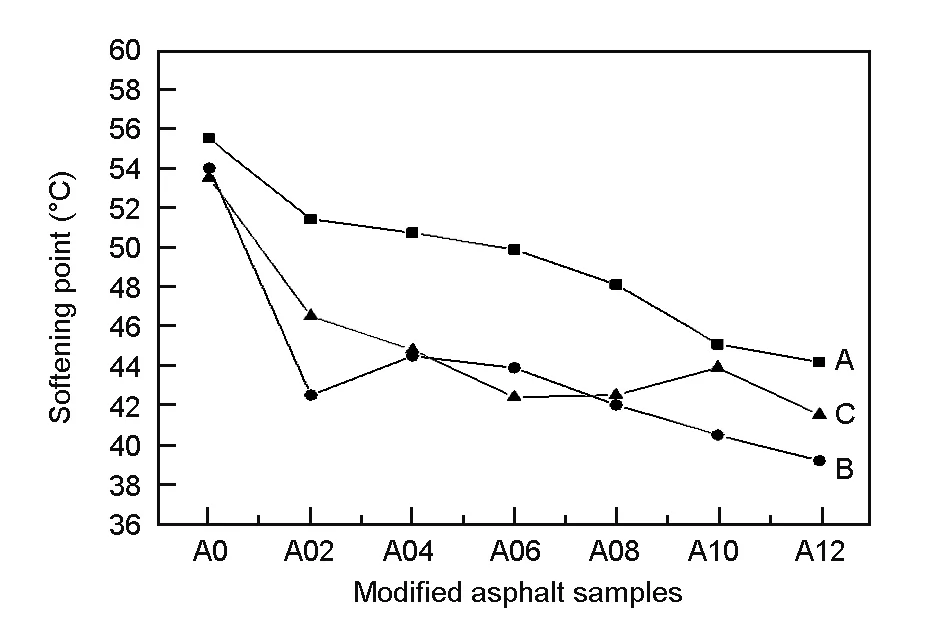

3.1Softening point

The softening point of asphalt is the temperature when asphalt changes from a state of being uneasy to flow to a liquid state in the presence of some external force and heat, reflecting the high temperature performance of the asphalt[10-12]. Fig.1 shows the softening point of the three types of modified asphalts. It can be seen that high temperature performance of the asphalts modified by WPE and PANCFs was greatly improved. Besides, the modification methods have great effects on the high temperature performance of the modified asphalts. The softening points of the WPE-modified asphalts with the method B and C are higher than that with the method A, because the particle sizes of WPE with the method B and C are much smaller than that with the method A. The softening points of the modified asphalts all increase with the amount of PANCFs below 0.1 wt% regardless of the method used. When the amount of PANCFs exceeds 0.1 wt%, the softening points of the modified asphalts slightly decrease. The reason for this might be that the dispersion degree of PANCFs reaches saturation in the modified asphalts[13-16]. Too much PANCFs might lead to agglomeration that forms large particles and affects the performance of the modified asphalts.

Fig. 1 The softening points of the three types of

3.2Penetration degree

The penetration degree of asphalt is a representation of asphalt viscosity, reflecting the rheological properties of asphalt[10-12]. Fig.2 shows the penetration degree of the three types of modified asphalts. It can be seen that the penetration degree of the modified asphalts decreases with the increasing amount of PANCFs. The penetration degree declines sharply and levels off when the amount of PANCFs was over 0.02 wt%. It is found that the penetration degree of the modified asphalts with the method A decreases most slowly because the dispersion of PANCFs is better for the method B and C[17,18].

3.3Ductility

The ductility of asphalt reflects the rutting resistance properties of asphalt. The changes in ductility of the three types of modified asphalts at 5 ℃ are shown in Fig. 3. It can be found that the ductility of all the three types are higher than those without PANCFs, indicating that PANCFs can improve the rutting resistance of the modified asphalts[19-22]. The ductility of samples prepared by the method A are lowest while those by the method C are highest under the same formulation of the modified asphalts. For the samples prepared with the method B and C, the ductility increases obviously when the amount of PANCFs is below 0.02 wt%, then increases slightly with the amount from 0.02 to 0.1 wt% and decrease with a further increase of the amount beyond 0.1 wt%. The reasons might be that the network of the modified asphalts is destroyed by the agglomeration of the PANCFs.

Fig. 2 The penetration degree of the three types of modified asphalts.

Fig. 3 The ductility of the three types of modified asphalts.

3.4Segregation

Fig.4, Fig.5 and Fig.6 show the softening points of the upper, the middle and the lower parts of the three kinds of modified asphalts after segregation, respectively. It can be seen from Fig. 4 that change in the softening point of the upper parts is the most obvious, indicating that the segregation phenomenon of modified asphalts without any cross-linking agent is obvious. Because the density of WPE is lower than of asphalt, the content of WPE in the upper part is higher, resulting in a significant increase (by 20-40 ℃) of the softening points. The softening points of the upper parts of modified asphalts with method B and C change slower than those with the method A. Because the upper parts of modified asphalts with the method B and C have a better dispersion of PANCFs in WPE, which prevents segregation obviously. From Fig. 5 and Fig. 6, it can be seen that the softening points of the modified asphalts in the middle and lower parts slightly decrease after segregation. The segregation become weakened when the amount of PANCFs increase.

Fig. 4 The softening points of the upper

Fig. 5 The softening points of the middle

Fig. 6 The softening points of the lower

3.5Effectiveness of the modification

It can be seen from Fig.7 that, there are no changes in the FT-IR spectra of the modified asphalts by the three different modification methods, indicating that no chemical reactions take place during the modification. So the performance improvement of the modified asphalts comes from physical dispersion of PANCFs and WPE into the asphalts and the swelling of WPE by asphalt.

Fig. 7 FT-IR spectra of raw and modified asphalts.

3.6Microstructure

Fig.8 shows the SEM images of the three modified asphalts with the amount of PANCFs of 0.08 wt%. The dispersion of WPE and PANCFs in the modified asphalts is significantly different. Although the dispersion of WPE and PANCFs in the asphalts with the method A is uniform, no network structure is

formed. By contrast, a net structure is formed with the method B and C and the network structure is more uniform with the method C. The net structure prevents the segregation largely and greatly improves the comprehensive performance of the modified asphalts.

3.7The relationship between the CFs and WPE in asphalts

Fig.9 shows the microstructures of PANCFs and WPE in the modified asphalts with the method A when the amounts of PANCFs are 0.04 and 0.08 wt%. In the modified asphalts, PANCFs and WPE exist in several forms. PANCFs are wrapped by WPE as “1” shows. The “2” and “6” show that some short-cut PANCFs are dispersed into asphalt and the “7” shows some long-cut PAN-CFs are dispersed into asphalt too. From “3”, it can be seen that part of PANCFs are wrapped by WPE and the rest are dispersed into asphalt. “4” shows that the PANCFs pass through WPE, but both ends of the PANCFs are dispersed in asphalt. The PAN-CFs are adsorbed by two particles of WPE in “5”. By comparing the existing forms of CFs and WPE in asphalt, it is found that the compatibility between the modifiers and the asphalt is better in the cases of “1” ,“3”,“4” and “5”. Under these conditions, the PANCFs promote not only the swelling of WPE but also the dispersion of WPE.

Fig. 8 SEM images of the three types of modified asphalts with the method (a) A, (b) B and (c) C.

Fig. 9 Microstructures of PANCFs and WPE in the modified

A model is proposed to reveal the relationship between PANCFs and WPE in the modified asphalts as shown in Fig.10. This model is simplified as a rigid model. The WPE adsorption to PANCFs, the mixing extent between WPE and PANCFs, and the dispersion of PANCFs and WPE in modified asphalts are the worst in the method A, and best in the method C. In the modified asphalts, if the PANCFs are too long, their homogeneous dispersion in asphalt and WPE is difficult, WPE adsorption to them is weak and aggregation takes place, which are unfavorable for the modification. If the PANCFs are too short, their dispersion in WPE and asphalt is also not good, resulting in floating and suspension of PANCFs in the modified asphalts, which is unfavorable for the swelling of WPE. Experiment results verify that a length of 5 mm is the best for the short-cut PANCFs.

Fig. 10 The relationship model of PANCFs and WPE in the modified asphalts (a) the method A, (b) the method B and (c) the method C.

PANCFs have a good chemical stability and do not react with the components in the asphalt. The adsorption or insertion of PANCFs to WPE particles promotes the swelling and dispersion of the WPE in asphalt. In the modified asphalts, a higher swelling degree of the WPE and thicker adsorption layer of the asphalt on the surface of the WPE will make the WPE disperse more evenly in the asphalt and form more easily a spatial network structure. The thicker adsorption layer on the surface of the WPE particles prevent their aggregation in the modified asphalts. The network structure of the modified asphalts is able to inhibit the flow of asphalt at high temperature and also enhance the ability to resist external forces. So, for the modified asphalts with a network structure, only large external force can make the asphalt to bring forth phase displacement, and the ability to resist deformation at high temperature and the stability of hot storage are improved.

4 Conclusions

The modification of asphalt with PANCFs and WPE is physical. The of PANCFs with a proper length could promote the swelling and the dispersion of WPE in asphalt.

The content of PANCFs in the modified asphalts should not exceed 0.1%. Too much CFs form aggregation and have a negative effect on the comprehensive performance of modified asphalts. The modification by WPE and short-cut PANCFs can obviously improve high temperature performance and resist deformation of the modified asphalts. WPE and short-cut PANCFs are best dispersed into asphalt by an extrusion method at 170 ℃.

In the modified asphalts by the extrusion method, a network structure is well formed by PANCFs and WPE, which prevents segregation and improves the hot storage stability, high temperature performance and resistance to external force.

[1]Airey G D. Styrene butadiene styrene polymer modification of road bitumen[J]. Journal of Materials Science, 2004, 39(3): 951-959.

[2]Xiao C, Ling T Q, Qiu Y J. Optimization of technical measures for improving high-temperature performance of asphalt-rubber mixture[J]. J Mod Transport, 2013, 21(4): 273-280.

[3]Sun L, Xin X T, Ren J L. Pavement performance of nanomaterial modified asphalt mixture[J]. Journal of southeast university, 2013, 43(4): 873-876.

[4]Fang C Q, Zhou S S, Zhang M R, et al. Optimization of the modification technologies of asphalt by using waste EVA from packaging[J]. Vinyl and Additive Technology, 2009, 15(3): 119-203.

[5]Mohammad J K, Ahmed K, Hashim R R. Characterization of carbon nano-fiber modified hot mix asphalt mixtures[J]. Construction and Building Materials, 2013, 40: 738-745.

[6]Sayyed M A, Mohammad S, Sayyed M H. Fiber-reinforced asphalt-concrete-A review[J].Construction and Building Materials, 2010, 24: 871-877.

[7]Che D M, Saxena I, Han PD, et al. Machining of carbon fiber reinforced plastics/polymers: A literature review[J]. Journal of Manufacturing Science and Engineering, 2014, 136: 034001-1-22.

[8]Burri F, Fertl M, Feusi P, et al. Copper coated carbon fiber reinforced plastics for high and ultra high vacuum applications[J]. Vacuum, 2014, 101: 212-216.

[9]Fang C Q , Zhang Y, Yu R E, et al. Effect of organic montmorillonite on the hot storage stability of asphalt modified by waste packaging polyethylene[J]. Journal of Vinyl & Additive Technology, 2014, 10: 1001-1005.

[10]Cong P L, Yu J Y, Wu S P, et al. Laboratory investigation of the properties of asphalt and its mixtures modified with flame retardant[J]. Construction and Building Materials, 2008, 22: 1037-1042.

[11]Industry standards of the People's Republic of China. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering[S]. Issued by the Ministry of Transport of the People's Republic of China JTJ 052-2000.

[12]Fang C Q, Yu R E, Zhang Y, et al. Combined modification of asphalt with polyethylene packaging waste and organophilic montmorillonite[J]. Polymer Testing, 2012, 31: 276-281.

[13]Kesavan K, Ravisankar K, Senthil R, et al. Experimental studies on performance of reinforced concrete beam strengthened with CFRP under cyclic loading using FBG array[J]. Measurement, 2013, 46: 3855-3862.

[14]Tang B M, Ding Y J, Zhu H Z, et al. Study on agglomeration variation pattern of asphalt molecules[J]. China Journal of Highway and Transport, 2013, 26(3): 50-56.

[15]Hassan Firoozifar S, Foroutan S, Foroutan S. The effect of asphaltene on thermal properties of bitumen[J]. Chemical Engineering Research and Design, 2011,10: 698-703.

[16]Haddadi S, Ghorbel E, Laradi N. Effects of the manufacturing process on the performances of the bituminous binders modified with EVA[J]. Construction and Building Materials, 2008, 22: 1212-1219.

[17]Ye Y, Yang X H, Chen C H. Viscoplastic behaviour of asphalt mixture in compression[J]. Materials Research Innovations, 2011, 15: 45-48.

[18]Vandellos T, Huchette C, Carrère N. Proposition of a framework for the development of a cohesive zone model adapted to Carbon-Fiber Reinforced Plastic laminated composites[J]. Composite Structures, 2013, 105: 199-206.

[19]Schreiner C A. Review of mechanistic studies relevant to the potential carcinogenicity of asphalts[J]. Regulatory Toxicology and Pharmacology, 2011, 59: 270-284.

[20]Chockalingam K, Saravanan U, Krishnan J M. Characterization of petroleum pitch using steady shear experiments[J]. International Journal of Engineering Science, 2010, 48: 1092-1109.

[21]Adhikari S, You Z P, Hao P W, et al. Image analysis of aggregate, mastic and air void phases for asphalt mixture[J]. Journal of Traffic and Transportation Engineering, 2013, 2(13): 1-9.

[22]Caro S, Masad E, Bhasin A, et al. Micromechanical modeling of the influence of material properties on moisture-induced damage in asphalt mixtures[J]. Construction and Building Materials, 2010, 24: 1184-1192.

Modification of asphalt by dispersing waste polyethylene and carbon fibers in it

ZHANG Mao-rong1,2,FANG Chang-qing1,2,ZHOU Shi-sheng1,2,CHENG You-liang2,HU Jing-bo1,2

(1.SchoolofMechanicalandPrecisionInstrumentEngineering,Xi’anUniversityofTechnology,Xi’an710048,China;2.FacultyofPrinting,PackagingEngineeringandDigitalMediaTechnology,Xi’anUniversityofTechnology,Xi’an710048,China)

Recycled waste packaging polyethylene (WPE) and chopped polyacrylonitrile-based carbon fibers (PAN-CFs) were dispersed in molten asphalt at 170 ℃ with a shearing machine at 3 800 r/min for 60 min to modify its properties to meet the demands of motorway paving. WPE and PAN-CFs were mixed by three methods before the dispersion: (a) simple blending, (b) first dissolving WPE in xylene, then mixing and evaporating and (c) blending and extrusion to rods of 1mm diameterat 170 ℃ which were fed directly into the hot asphalt. The PAN-CF content was varied in the range 0 to 0.12 wt% while the WPE content was constant(4 wt%). Results indicate that WPE and PAN-CFs are dispersed in asphalt to form a network structure by the xylene-assisted mixing or blending-extrusion methods. The softening points, penetration degree and ductility are improved with increasing content of PAN-CFs up to 0.1 wt%. Aggregation of the two modifiers occurs beyond 0.12 wt% of PAN-CFs, which degrades the properties of the modified asphalts. A fiber length of 5 mm is optimum for their best dispersion in the asphalt. Segregation of the modifiers from the modified asphalts can be prevented by increasing the content of PAN-CFs. The blending-extrusion method is best to form a fine network structure, which achieves a best performance. A model is proposed to explain the observed dispersion behavior in asphalt.

Waste packaging polyethylene; Carbon fibers; Composite modification; Asphalt

date: 2016-03-19;Reviseddate: 2016-07-27

National Natural Science Foundation of China (51172180, 51372200); Program for New Century Excellent Talents in University of Ministry of Education of China (NCET-12-1045); Local Service Program of Shaanxi Provincial Education Department (2013JC19); Excellent PhD dissertation Foundation of XAUT (102-211208).

introduction: ZHANG Mao-rong, Ph.D Candidate. E-mail: zmr.1234@163.com

FANG Chang-qing, Professor. E-mail: fcqxaut@163.com

1007-8827(2016)04-0424-07

TQ342+.74

A

国家自然科学基金(51172180, 51372200); 新世纪优秀人才支持计划(NCET-12-1045); 陕西省教育厅服务地方专项计划项目(2013JC19); 西安理工大学优博基金资助项目(102-211208).

方长青,教授. E-mail: fcqxaut@163.com

10.1016/S1872-5805(16)60022-7

作者介绍:张茂荣,博士生. E-mail: zmr.1234@163.com

English edition available online ScienceDirect ( http:www.sciencedirect.comsciencejournal18725805 ).