双栅非晶InGaZnO薄膜晶体管有源层厚度对电学性能的影响*

2016-10-29蔡旻熹姚若河

蔡旻熹 姚若河

(华南理工大学 电子与信息学院, 广东 广州 510640)

双栅非晶InGaZnO薄膜晶体管有源层厚度对电学性能的影响*

蔡旻熹姚若河†

(华南理工大学 电子与信息学院, 广东 广州 510640)

双栅非晶InGaZnO薄膜晶体管(DG a-IGZO TFTs)具有比单栅a-IGZO TFTs更优良的电学性能.文中基于a-IGZO/SiO2界面缺陷态呈指数型分布的模型,讨论了在界面缺陷态影响下双栅驱动的DG a-IGZO TFTs有源层厚度对电学性能的影响.研究结果表明:随着有源层厚度的减小,双栅驱动模式下DG a-IGZO TFTs两栅极的耦合作用增强,有源层上、下表面的导电沟道向体内延伸,使器件的场效应迁移率显著增加;界面缺陷态对DG a-IGZO TFTs场效应迁移率的影响随着有源层厚度的减小而降低,对亚阈值摆幅的影响随着有源层厚度的减小而增大.

双栅非晶InGaZnO薄膜晶体管;界面缺陷态;场效应迁移率;亚阈值摆幅

与传统非晶硅薄膜晶体管(TFTs)相比,非晶InGaZnO(a-IGZO)TFTs因能在接近室温条件下制备、有较高的迁移率及柔性等优点而逐渐应用于高速和高分辨率的有源矩阵液晶显示器及柔性透明有源矩阵有机发光二极管显示器[1-5].为进一步提高器件性能和在电路中的驱动能力,近年来双栅(DG)驱动的a-IGZO TFTs备受关注[6-13].研究表明,DG a-IGZO TFTs具有比单栅结构更高的开关电流比,更低的亚阈值摆幅以及更强的器件稳定性.

近年有文献报道,随着有源层厚度的减小(小于30 nm),相比于单栅器件,DG a-IGZO TFTs的开启电流能提高两倍以上[11-13].文中通过建立DG a-IGZO TFTs模型分析了有源层的电子浓度、电势及电场强度的分布,讨论有源层厚度对器件电学性能的影响,并进一步研究了随着有源层厚度的降低,界面缺陷态对DG a-IGZO TFTs电学性能的影响.

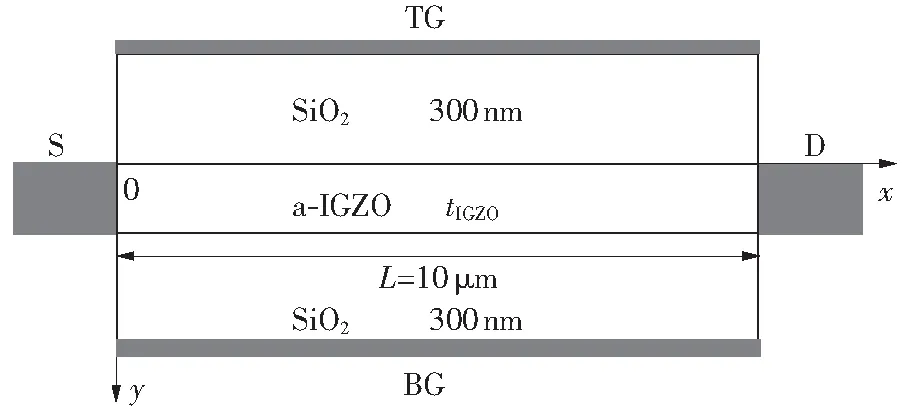

1 器件模型及工艺参数

图1为DG a-IGZO TFTs的结构示意图,采用Atlas仿真器建立器件模型,顶栅电极(TG)和底栅电极(BG)均采用Mo电极,源端(S)和漏端(D)为欧姆接触,顶栅和底栅绝缘层为300 nm的SiO2,a-IGZO的厚度tIGZO为变量,器件的沟道长度L和宽度W分别为10、140 μm,定义a-IGZO上表面源端处为起点,沿沟道长度方向为x轴,垂直于沟道长度方向为y轴.由于文中研究重点为有源层厚度的影响,故与器件性能相关的其他参数(掺杂浓度、宽长比、源漏电压及栅源电压等)的设置参考了文献[6-7,10-11,14]中的典型值.

图1 DG a-IGZO TFT结构示意图

基于已有实验数据[15],a-IGZO的体缺陷态Dbulk设置如下:导带底的带尾态和深能级态密度分别为NTA=1018cm-3eV-1、NDA=1017cm-3eV-1,特征能量分别为kTTA=0.03 eV、kTDA=0.19 eV,k为玻尔兹曼常数;高斯分布的氧空位缺陷态密度峰值NOV=1016cm-3eV-1,平均能量EOV=2.9 eV,标准差kTOV=0.1 eV.a-IGZO在非掺杂情况下呈n型,故定义其背景掺杂浓度为7×1017cm-3.a-IGZO带隙中呈指数分布[15]的界面态密度Dit定义如下:顶栅绝缘层/a-IGZO界面处的界面态密度NitA1=3×1012cm-2eV-1,a-IGZO/底栅绝缘层界面处的界面态密度NitA2=2.38×1012cm-2eV-1,其特征能量kTitA=0.19 eV.

2 结果及分析

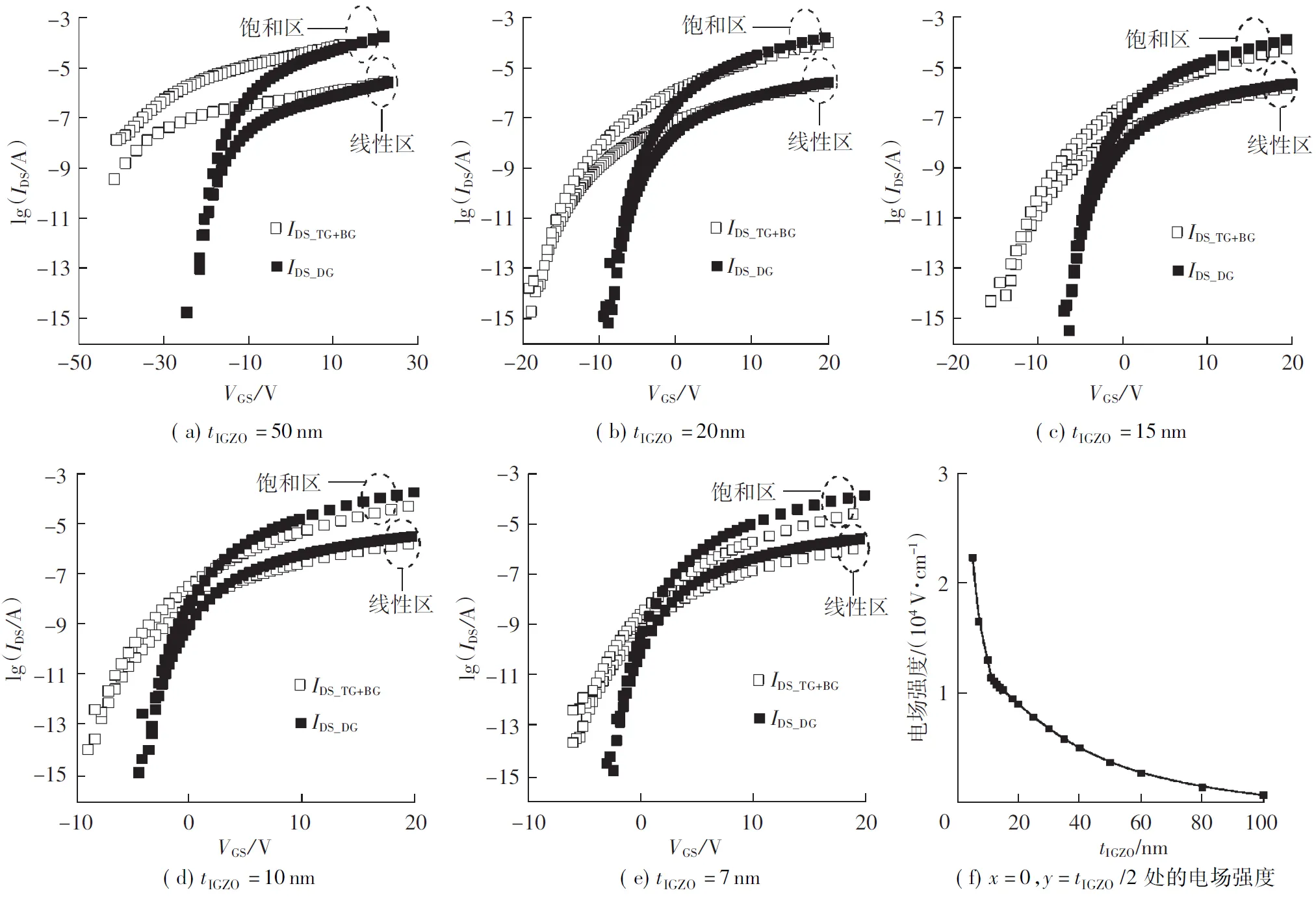

由仿真得到tIGZO分别为50、20、15、10 及7 nm时,3种工作模式(DG模式:两个栅极短接后共同驱动器件;TG模式:TG驱动器件而BG接地;BG模式:BG驱动器件而TG接地)的器件位于饱和区(漏源电压VDS=20 V)和线性区(VDS=0.1 V)的转移特性曲线.

将单栅a-IGZO TFT器件在TG和BG模式下的漏极电流相加,得到IDS_TG+BG,并与相应tIGZO的DG模式下的漏极电流IDS_DG进行比较,如图2所示.DG模式的器件开启后在a-IGZO的上、下表面同时形成的导电沟道可看作相互并联[8],其等效单位面积栅绝缘层电容可表示为CGI=CTI+CBI,CTI和CBI分别为顶栅和底栅绝缘层的单位面积栅电容,因此双栅驱动的器件开启后位于线性区和饱和区的漏极电流分别为

图2tIGZO取不同值时器件在饱和区和线性区下的IDS及在x=0,y=tIGZO/2处的电场强度随tIGZO的变化

Fig.2IDSof devices at saturation and linear regions with different values oftIGZOand electric field variation withtIGZOatx=0,y=tIGZO/2

(1)

(2)

式中,μeff,lin、μeff,sat、VTH,lin、VTH,sat分别为线性区和饱和区的有效场效应迁移率和阈值电压.由以上分析,器件在DG模式下的开启电流ION_DG应等于其在TG和BG模式下的开启电流之和ION_TG+BG,但在图2中,随着tIGZO的减小,ION_DG与ION_TG+BG的差别明显增大.这是因为在DG模式下,两栅极的耦合作用在a-IGZO较厚时很弱,甚至不存在耦合作用,导电沟道分别在a-IGZO的上、下表面形成,且载流子的输运受界面态的影响很大,此时ION_DG与ION_TG+BG处于相同水平.随着tIGZO的降低,两栅极的耦合作用逐渐增强,a-IGZO中的导电沟道不再局限于上、下表面,开始向有源层体中延伸,载流子受界面态的影响也因此变小,器件的场效应迁移率显著上升,因此在tIGZO很小的情况下ION_DG>ION_TG+BG,DG模式下器件的开启电流能得到很大的改善.

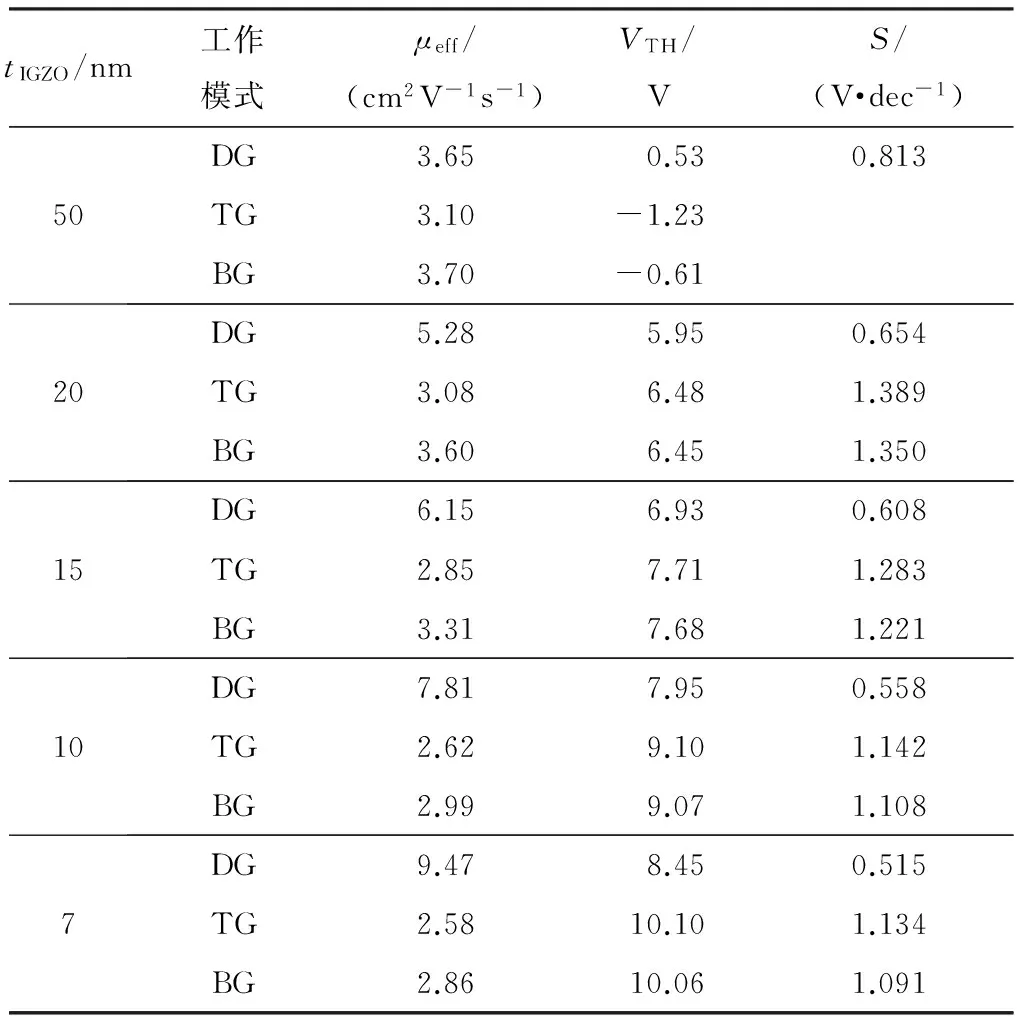

器件的有效场效应迁移率μeff和阈值电压VTH可由式(2)提取,亚阈值摆幅

S=[dg(lgIDS)/dg(VGS)]-1

由转移特性曲线最大斜率处提取得到.不同工作模式下器件的性能参数如表1所示,单栅驱动模式下器件的μeff随tIGZO的减小变化不大,略有降低,当tIGZO为50 nm时,双栅驱动的器件的μeff与单栅模式下相比并无较大的差别,但随着tIGZO的降低,μeff开始显著增加,当tIGZO下降到7 nm时,器件的μeff上升到9.47cm2V-1s-1,是同等tIGZO下TG和BG模式时μeff的3倍多,约为DG模式下tIGZO为50 nm时μeff的2.6倍.此外,DG模式下器件的亚阈值摆幅S比TG和BG模式下小,这主要归因于DG模式下栅极对沟道中载流子的控制能力的增强.

表1不同模式下器件的性能参数

Table 1Performance parameters of device under different modes

tIGZO/nm工作模式μeff/(cm2V-1s-1)VTH/VS/(V·dec-1)50DG3.650.530.813TG3.10-1.23BG3.70-0.6120DG5.285.950.654TG3.086.481.389BG3.606.451.35015DG6.156.930.608TG2.857.711.283BG3.317.681.22110DG7.817.950.558TG2.629.101.142BG2.999.071.1087DG9.478.450.515TG2.5810.101.134BG2.8610.061.091

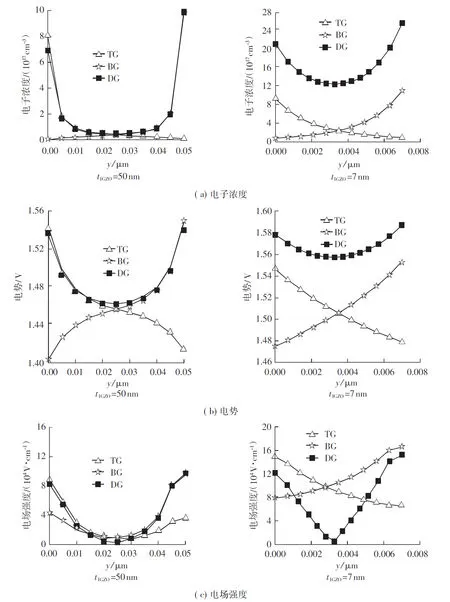

当VDS=0.1 V、VGS=20 V时在x=L/2处沿图1中y方向作切线,得到3种模式(DG、TG及BG)下tIGZO分别为50 和7 nm时有源层的电子浓度、电势及电场强度随y方向的变化,如图3所示.

从图3(a)可知:当tIGZO为50 nm时,DG模式下a-IGZO上、下表面的电子浓度分别与TG和BG模式沟道中的电子浓度水平相近,且有源层体内电子浓度远低于表面;当tIGZO减小到7 nm时,由于两栅极间很强的耦合作用,a-IGZO中不仅表面处电子浓度水平比TG和BG模式下高,并且沟道中电子浓度也与表面处电子浓度处于相近水平(大于1.2×1018cm-3),说明电子在整个有源层中积累,这意味着tIGZO为7 nm的DG模式比TG和BG模式受界面态的影响更小.

由图3(b)可知,当tIGZO为7 nm时,DG模式下a-IGZO中的电势比TG和BG模式下更高,并且从表面到有源层变化不大,说明器件已经发生明显的体导通.

由图3(c)可知,当tIGZO为7 nm时,由于两栅极很强的耦合作用,在靠近上、下界面处DG模式下的电场强度显著低于TG和BG模式下沟道一侧界面处的电场,界面处削弱的电场一方面将减小载流子陷入栅绝缘层的概率,另一方面也能减少由于电场导致的a-IGZO表面对外界氧分子和水分子的吸附及解吸附[16].

图3VDS=0.1 V、VGS=20 V时图1中x=L/2处在3种模式下a-IGZO的电子浓度、电势和电场强度随y方向的变化

Fig.3Electron concentration,potential electric field in a-IGZO alongyaxis atx=L/2 in Fig.1 under three modes andVDS=0.1 V,VGS=20 V

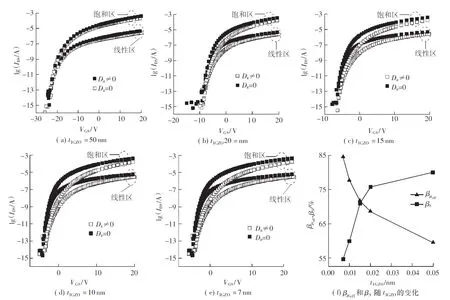

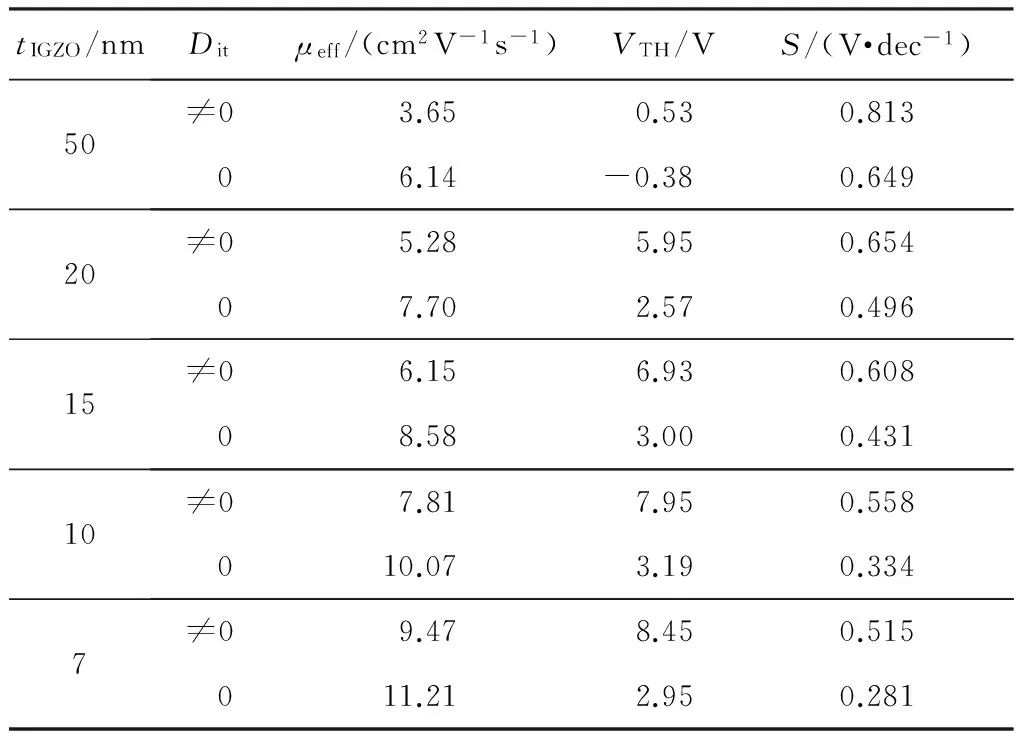

DG模式下Dit≠0以及Dit=0的器件在不同tIGZO下的转移特性曲线如图4所示,提取得到的性能参数如表2所示.将表2中Dit≠0与Dit=0时器件的μeff的比值定义为βμeff,1/S的比值定义为βS,βμeff和βS随着tIGZO的变化如图4(f)所示,随着tIGZO的降低,βμeff逐渐上升,即界面态对DG模式器件的μeff的影响会随着tIGZO的降低而减小.由图4(a)-4(e)可知,Dit≠0与Dit=0时器件的亚阈值特性的区别随着tIGZO的减小而越明显,在图4(f)中表现为βS随着tIGZO的降低而减小.器件在亚阈值区的特性主要由a-IGZO中的体缺陷态和界面缺陷态主导,其亚阈值摆幅S反映了a-IGZO中费米能级处带隙缺陷态的多少[17]:

(3)

图4tIGZO取不同值时Dit≠0和Dit=0的DG模式器件在饱和区和线性区的转移特性曲线及βμeff和βS随tIGZO的变化

Fig.4Transfer characteristic curves of devices withDit≠0 andDit=0 at saturation and linear regions under DG mode with different values oftIGZOand the variation ofβμeffandβSwithtIGZO

表2Dit≠0和Dit=0时DG模式器件的性能参数

Table 2Performance parameters of devices withDit≠0 andDit=0 respectively under DG mode

tIGZO/nmDitμeff/(cm2V-1s-1)VTH/VS/(V·dec-1)50≠03.650.530.81306.14-0.380.64920≠05.285.950.65407.702.570.49615≠06.156.930.60808.583.000.43110≠07.817.950.558010.073.190.3347≠09.478.450.515011.212.950.281

3 结论

文中通过仿真分析了DG a-IGZO TFTs的开启电流随有源层厚度降低而显著增加的效应,探讨了界面态影响下器件发生体导通的最佳有源层厚度范围.研究结果表明:在双栅驱动的器件中,适当降低有源层厚度可以使载流子在a-IGZO体中积累,改善器件的场效应迁移率、亚阈值摆幅和开启电流,增强器件的电学稳定性,使DG a-IGZO TFTs具有更优良的驱动能力.

[1]NOMURA K,OHTA H,TAKAGI A,et al.Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors [J].Nature,2004,432(7016):488-492.

[2]曹镛,陶洪,邹建华,等.金属氧化物薄膜晶体管及其在新型显示中的应用 [J].华南理工大学学报(自然科学版),2012,40(10):1-11.

CAO Yong,TAO Hong,ZOU Jian-hua,et al.Metal oxide thin film transistors and their applications to novel display technology [J].Journal of South China University of Technology(Natural Science Edition),2012,40(10):1-11.

[3]KIM B,CHO H N,CHOI W S,et al.Highly reliable depletion-mode a-IGZO TFT gate driver circuits for high-frequency display applications under light illumination [J].IEEE Electron Device Letters,2012,33(4):528-530.

[4]ITO M,MIYAZAKI C,ISHIZAKI M,et al.Application of amorphous oxide TFT to electrophoretic display [J].Journal of Non-Crystalline Solids,2008,354(19):2777-2782.

[5]LI F,SMITS E,LEUKEN L V,et al.Integration of flexible AMOLED displays using oxide semiconductor TFT backplanes [J].Sid Symposium Digest of Technical Papers,2014,45(1):431-434.

[6]SON K S,JUNG J S,LEE K H,et al.Characteristics of double-gate Ga-In-Zn-O thin-film transistor [J].IEEE Electron Device Letters,2010,31(3):219-221.

[7]LEE S,MATIVENGA M,JIN J.Removal of negative-bias-illumination-stress instability in amorphous-InGaZnO thin-film transistors by top-gate offset structure [J].IEEE Electron Device Letters,2014,35(9):930-932.

[8]BAEK G,ABE K,KUO A,et al.Electrical properties and stability of dual-gate coplanar homojunction DC sputtered amorphous indium-gallium-zinc-oxide thin-film transistors and its application to AM-OLEDs [J].IEEE Transactions on Electron Device,2011,58(12):4344-4353.

[9]MÜNZENRIEDER N,ZYSSET C,PETTI L,et al.Flexible double gate a-IGZO TFT fabricated on free standing polyimide foil [J].Solid-State Electronics,2013,84(6):198-204.

[10]LI X,GENG D,MATIVENGA M,et al.High-speed dual-gate a-IGZO TFT-based circuits with top-gate offset structure [J].IEEE Electron Device Letters,2014,35(4):461-463.

[11]MATIVENGA M,AN S,JIN J.Bulk accumulation a-IGZO TFT for high current and turn-on voltage uniformity [J].IEEE Electron Device Letters,2013,34(12):1533-1535.

[12]JIN S,KIM T W,SEOL Y G,et al.Reduction of positive-bias-stress effects in bulk-accumulation amorphous-InGaZnO TFTs [J].IEEE Electron Device Letters,2014,35(5):560-562.

[13]XU Y,LIU C,AMEGADEZ P S K,et al.On the origin of improved charge transport in double-gate In-Ga-Zn-O thin-film transistors:a low-frequency noise perspective [J].IEEE Electron Device Letters,2015,36(10):1040-1043.

[14]FUNG T C.Amorphous In-Ga-Zn-O thin film transistor for future optoelectronics [D].Ann Arbor:University of Michigan,2010.

[15]KIM Y,BAE M,KIM W,et al.Amorphous InGaZnO thin-film transistors—Part I:complete extraction of density of states over the full subband-gap energy range [J].IEEE Transactions on Electron Device,2012,59(10):2689-2698.

[16]SON K S,JUNG J S,LEE K H,et al.Highly stable double-gate Ga-In-Zn-O thin-film transistor [J].IEEE Electron Device Letters,2010,31(8):812-814.

[17]KAMIYA T,NOMURA K,HOSONO H.Present status of amorphous In-Ga-Zn-O thin-film transistors [J].Science & Technology of Advanced Materials,2010,11(4):044305/1-23.

[18]NOMURA K,KAMIYA T,IKENAGA E,et al.Depth analysis of subgap electronic states in amorphous oxide semiconductor,a-In-Ga-Zn-O,studied by hard x-ray photoelectron spectroscopy [J].Journal of Applied Physics,2011,109(7):073726/1-8.

[19]CHEN T L,HUANG K C,LIN H Y,et al.Enhanced current drive of double-gate a-IGZO thin-film transistors [J].IEEE Electron Device Letters,2013,34(3):417-419.Effects of Active Layer Thickness of Dual-Gate Amorphous InGaZnO Thin Film Transistors on Their Electrical Characteristics

Supported by the National Natural Science Foundation of China(61274085)

CAIMin-xiYAORuo-he

(School of Electronic and Information Engineering, South China University of Technology, Guangzhou 510640, Guangdong, China)

Dual-gate amorphous InGaZnO thin film transistors (DG a-IGZO TFTs) have better electrical characte-ristics than single-gate a-IGZO TFTs. In this paper, on the basis of a model describing the exponential distribution of defect states of a-IGZO/SiO2interface, the effects of the active layer thickness of DG a-IGZO TFTs on their electrical characteristics are investigated by taking into consideration the interface defect states. The results show that, as the active layer becomes thinner, the two gates of DG a-IGZO TFTs get coupled more strongly, which causes the conduction channels initially locating at the front and back interfaces of active layer to extend into the bulk of a-IGZO, thus greatly increasing the field effect mobility of DG a-IGZO TFTs. In addition, with the decrease of the active layer thickness, the field effect mobility of DG a-IGZO TFTs gradually becomes immune to the interface defect states, while the subthreshold swing becomes more sensitive to the interface defect states.

dual-gate amorphous InGaZnO thin film transistors; interface states; field effect mobility; subthreshold swing

1000-565X(2016)09-0061-06

2016-03-04

国家自然科学基金资助项目(61274085)

蔡旻熹(1992-),女,博士生,主要从事非晶InGaZnO薄膜晶体管的建模和仿真研究.E-mail:eecaiminxi@mail.scut.edu.cn

姚若河(1961-),男,教授,博士生导师,主要从事集成电路系统设计、半导体物理及器件研究.E-mail:phrhyao@scut.edu.cn

TN 321

10.3969/j.issn.1000-565X.2016.09.009