Effect of cutting parameters on tool wear in diamond turning of new optical aluminium grade

2016-10-26OTIENOABOUElHOSSEIN

OTIENO T, ABOU-El-HOSSEIN K

(Precision Engineering Laboratory,Department of Mechatronics,>Nelson Mandela Metropolitan University,Port Elizabeth 6031,South Africa)*Corresponding author, E-mail:khaled.abou-el-hossein@nmmu.ac.za

Effect of cutting parameters on tool wear in diamond turning of new optical aluminium grade

OTIENO T, ABOU-El-HOSSEIN K*

(Precision Engineering Laboratory,Department of Mechatronics,>NelsonMandelaMetropolitanUniversity,PortElizabeth6031,SouthAfrica)*Correspondingauthor,E-mail:khaled.abou-el-hossein@nmmu.ac.za

Critical components in optical devices and optical measuring systems are mainly produced through the ultra-high precision machining. Aluminium alloys have been proven to be advantageous and very commonly used in the photonics industry. This ever-increasing use and demand in optics have led to the development of newly modified grades of aluminium alloys produced by rapid solidification in the foundry process. The newer grades are characterised by the finer microstructures and can improve mechanical and physical properties. Their main inconvenience currently lies in their having a very limited machining database as there is not enough adequate research contributions on their performance in terms of machinability when diamond turned. This paper investigates the machinability of rapidly solidified aluminium RSA 905 by varying diamond cutting parameters and measuring the diamond tool wear over a cutting distance of 4 km. The machining parameters varied were cutting speed, feed rate and depth of cut. The results show that the cutting speed is the most influential parameter on the diamond tool wear. The highest tool wear of 12.2 μm was achieved at the spindle speed of 500 rpm, the feed rate of 25 mm/min and the depth of cut of 15 μm. The lowest tool wear of 2.45 μm was recorded at the spindle of 1 750 rpm speed, the feed rate of 5 mm/min and the depth of cut of 5 μm. Generally, a combination of higher cutting speeds, lower feed rates and smaller depths of cut caused less diamond tool wear. Statistical analysis was performed to develop a model for the diamond tool wear. Wear maps were generated from the model to identify zones where the cutting parameters produced the least wear. The results prove the rapidly solidified aluminium is a superior alternative to traditional aluminium alloys and can also provide a reference for machinists using this material.

rapidly solidified aluminium;ultra-high precision manufacturing;wear;diamond turning;optical engineering

1 Introduction

Ultra-high precision machining(UHPM) can be defined as the process by which the highest possible dimension accuracy is achieved[1]. The dimensions of parts produced can be of the order 1 nm with dimensional tolerances of the order 10 nm and a surface roughness as small as 1 nm. Satisfying such requirements requires machines with a resolution and repeatability in the order of 10 nm. Ultra-high precision machining is used intensively in the photonics, aerospace and automobile industry for the production of optical devices and components[2-3]. Single point diamond turning(SPDT) is one of the precision machining techniques used for the fabrication of optical moulds. Single crystal diamond is employed as the cutting tool due to its high hardness, low tool-chip friction and high wear resistance.

Optical moulds made from non-ferrous optical grades are widely adopted in plastic lens production. They are typically manufactured from ultra-high precision machining of materials with high hardness in order to maintain a surface finish that will not degrade under the heat and pressures experienced during the moulding process. Optical mould inserts are manufactured as negatives of the final component shape. The inserts are fabricated by diamond turning or diamond grinding to produce high quality surface finish. Aluminium alloys have been proven to be advantageous in this regard[4]. They are most commonly used over other materials as they exhibit less tool wear and are relatively cheaper in comparison to other optical materials.

Newly modified grades of aluminium alloys that are characterised by finer microstructures and improved physical properties have recently been developed. These newer aluminium alloys are produced by the rapid solidification in the foundry process. Rapidly solidified aluminium alloy, RSA 905, is produced through solidification in the range of 106K/s resulting in fine microstructures with the enhanced mechanical and physical properties. This process produces a superiorly finer grain structure[5-6]. The grain size in rapidly solidified aluminium is approximated to be in the range of 1 μm. Machining material with smaller grain sizes would be advantageous in achieving lower surface roughness values without additional production steps and the use of expensive and vulnerable plating. RSA 905 exhibits better mechanical and physical properties compared to traditional aluminium alloys[7]. The mechanical properties and chemical composition of rapidly solidified aluminium(RSA 905) and traditional optical grade aluminium alloys(AA 6061-T6 and AA 6082-T6) are compared in Tab.1.

Extensive research on tool wear associated with diamond machining of modified aluminium alloys is very limited. Zhongetal.[11]compared the performance of rapidly solidified aluminium with beryllium copper and aluminium alloy 6061 in the making of mould inserts. They found that high precision SPDT of RSA produced a finer surface quality compared to the traditional AA 6061 and BeCu. Abou-El-Hosseinetal.[12]looked into diamond tool wear when precision machining RSA 905 while varying the feed rate. The machining tests were stopped after cutting a distance of 17 km. The speed and depth of cut were kept constant at 2 000 rpm and 25 μm, respectively. The feed rates used were 5, 15 and 25 mm/min and tool wear of 3 μm, 12 μm and 10 μm were observed for the three feed rates, respectively.

Majority of the past studies have focused on the surface quality with very little attention given to the wear of the diamond tool. There is also a lack of adequate studies on the machinability of RSA grades over a range of cutting parameters. However, it is important to note that the results found in the literature show a trend of improved machining performance for the modified aluminium alloys compared to the traditional aluminium grades.

Cutting conditions are vital to study on the design of machining operation in order to satisfactorily meet the end product requirements. The importance of achieving the desired surface profile accuracy by using the diamond tool optimally cannot be overemphasised in the ultra-high precision machining. Past researchers have proved the potential of newly modified aluminium alloys in diamond machining optical surfaces[11,13-15]. However, none of the research has adequately addressed the diamond tool wear experienced with varying cutting conditions.

This paper investigates the machinability of rapidly solidified aluminium RSA 905 by identifying cutting parameter combinations that will minimise tool wear to aid in optical manufacture. The work makes use of statistical methods to develop a predictive model that can be successfully used to approximate the wear of diamond tool edge for a range of combinations of single-point diamond turning parameters.

2 Experiment

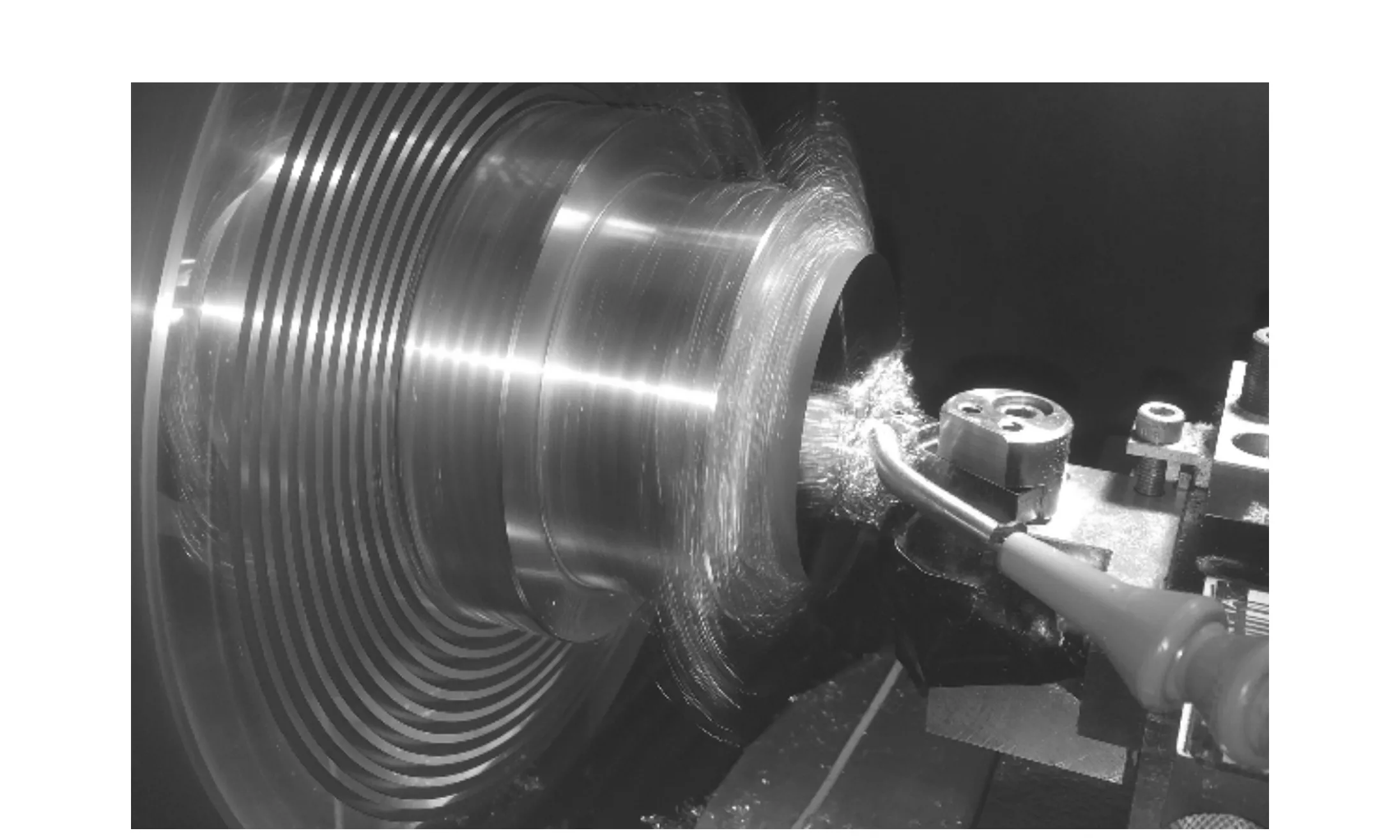

The diamond turning experiments were carried out on the Precitech Nanoform 250 Ultragrind machining centre, a high performance four axis ultra-high precision machine designed for turning and grinding applications. The setup was as shown in Fig.1. Mono-crystalline diamond with a -2.5° rake angle, 5° clearance and 0.5 mm nose radius was used as the cutting tool on the insert. Machining was carried out on the flat RSA 905 workpieces with 60 mm diameter produced by RSP Technology. The diamond tool wear was observed using scanning electron microscopy(SEM) after 4 km of cutting. The wear land on the cutting edge was measured for each experiment.

Fig.1 Diamond turning setup

The Box-Behnken method[16]was applied to create a design of experiments and the response surface method was used to investigate their effects and produce a model. The cutting parameters being investigated were cutting speed, feed rate and depth of cut. The selected machine parameters ranges were as follows: spindle speed was 500-3 000 rpm; feed rate was 5-25 mm/min; and depth of cut was 5-25 μm. The output was tool wear measurement. The parameter ranges were selected to cover the reasonable extremes of commonly used cutting conditions in machining aluminium alloys based on the previous work. A new tool insert was used for each experiment. The face turning tool path involved the tool nose engaging the workpiece at a set depth of cut and moving towards the centre at a set feed rate where it disengaged, while the workpiece rotated on its own axis at the desired spindle speed. The machining tool path was repeated to reach the required cutting distance(4 km) by performing multiple passes.

3 Results and discussions

3.1Tool wear

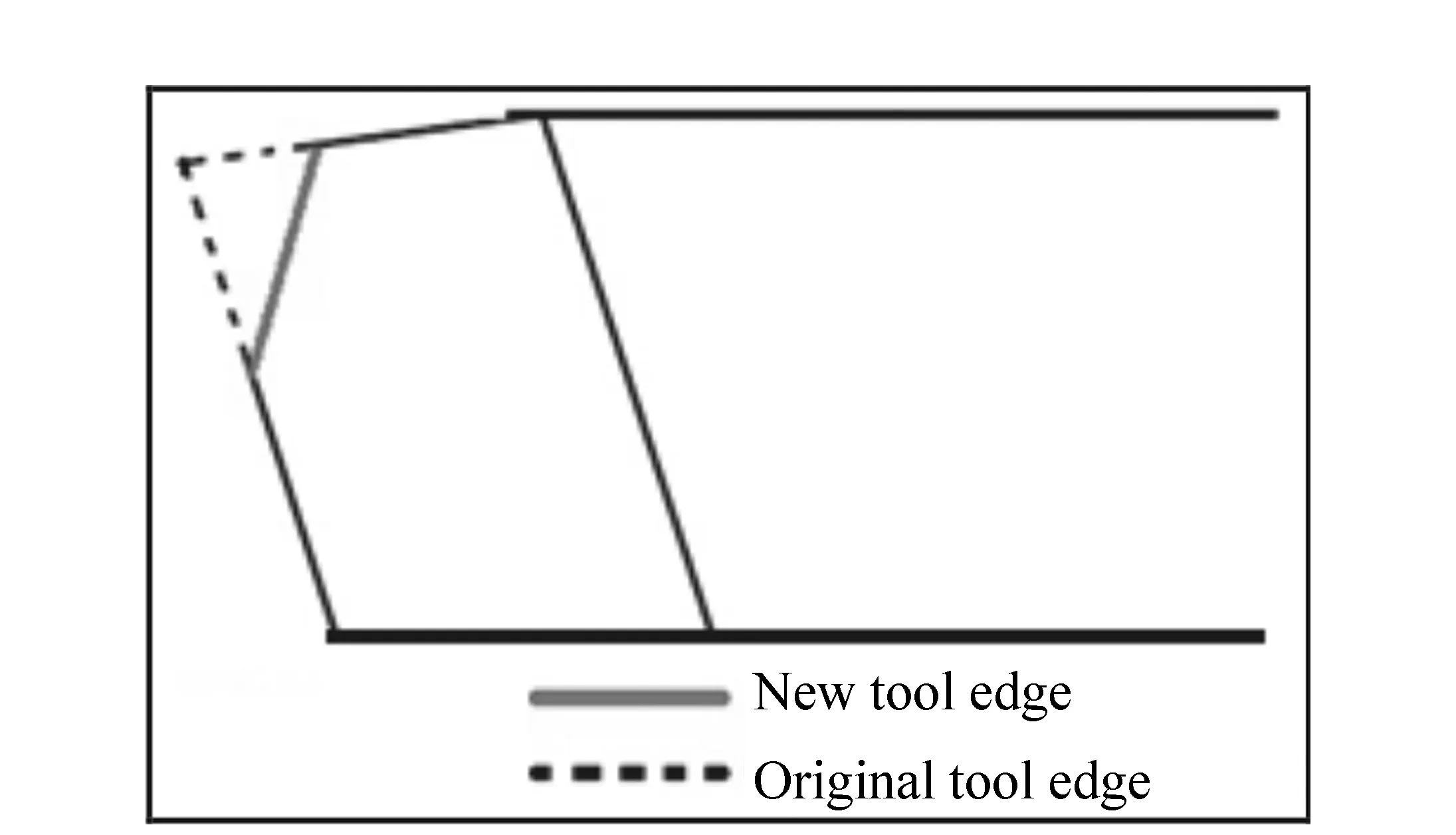

The diamond tool tip was found to wear as shown in Fig.2 and this wear land was measured under SEM and recorded for each experiment. Tab.2 shows the results from the measured tool wear of each experiment. The tool wear land was generally small after cutting for 4 km, within the 3-12 μm range.

Fig.2 Diamond tool tip wear area

The lowest spindle speed of 500 rpm generally produced higher tool wear, with 12.2 μm being the highest measured(Experiment 10 in Tab.2). The highest spindle speed of 3 000 rpm generally produced low tool wear as seen Experiments 8, 9 and 11(3.36 μm, 3.05 μm and 2.84 μm, respectively). This was also noticed when comparing Experiment 11 with Experiment 15, where the feed rate and depth of cut were constant at 15 mm/min and 5 μm, respectively. Generally, the higher spindle speed(3 000 rpm) resulted in less wear than that of the lowest speed(500 rpm).

Tab.2 Wear results

Comparing Experiment 1 with Experiment 6, where cutting speed and depth of cut were constant at 1 750 rpm and 25 μm, respectively, the higher feed rate of 25 mm/min led to 1.36 μm, more wear than the lower feed rate of 5 mm/min. Similarly, lower feeds per revolution also resulted in lower wear which was noticed when comparing the same two experiments(experiment 1 at 14.29 μm/rev and Experiment 6 at 2.86 μm/rev). Feed per revolution, being a combination of spindle speed and feed rate, must have a high spindle speed and a low feed rate to achieve a low feed per revolution. When comparing experiments with approximately equal feeds per revolution and equal depth of cut, such as Experiment 4 and Experiment 8 at 8.57 μm/rev and 8.33 μm/rev, respectively, it was seen that the spindle speed plays a significant role in the resulting tool wear. Experiment 8 had a higher spindle speed at 3 000 rpm(meeting the criteria) but a higher feed rate at 25 mm/min(against the criteria) in comparison to Experiment 4 at 1 750 rpm and 15 mm/min, still managed to produce a less wear.

Comparing Experiment 1 with Experiment 2, where the cutting speed and feed rate were constant at 1 750 rpm and 25 mm/min, respectively, it is noticed that the smaller depth of cut 5 μm led to 0.3 μm less tool wear than the larger depth of cut 25 μm. The smaller differences in wear results with cutting speed and feed rate suggest that depth of cut has a smaller effect on the tool wear.

In order to achieve a high material removal rate(MRR), the depth of cut and feed rate must be high. The experiments show that a high material removal rates can be achieved with the minimal wear provided the spindle speed is high and the feed rate is moderate. Experiments 7, 8, 9 and 10 had the same MRR of 70.69 mm3/min, but Experiment 8 and Experiment 9 resulted in minimal wear due to a spindle speed of 3000 rpm. In addition to the low wear, the time taken was also the least. Experiment 9 proved to be the most efficient cutting parameters(3 000 rpm spindle speed, 15 mm/min feed rate, 25 μm depth of cut) in terms of MRR and associated wear.

The low wear could be attributed to the ultra-fine microstructure of RSA. This means smoother cutting process with less abrasive effect between the workpiece and the diamond tool. Generally, a combination of higher cutting speeds, lower feed rates and smaller depth of cuts resulted in less diamond tool wear. The small grains of RSA cause less of an impact on the tool and low tool deterioration rates. These parameters produced finer cutting and less impact on the tool. The high hardness of the diamond tool is also attributed to the lower wear rates. This combination also meant less overall cutting time and less tool-workpiece contact time. In addition, the total number of passes required is also reduced and there is less tool-workpiece engagement reducing impact on the tool. The highest tool wear of 12.2 μm was recorded for Experiment 10 at 500 rpm speed, 25 mm/min feed rate and 15 μm depth of cut. The lowest tool wear of 2.45 μm was recorded for Experiment 13 at 1 750 rpm speed, 5 mm/min feed rate and 5 μm depth of cut.

Fig.3 shows the SEM image of the tool edge with the wear measurements for Experiment 3. RSA 905 debris and hints of gold plating that were used for SEM imaging are also seen on the images. This flattening of the tool and the nature of the wear land seen in the images is the evidence that the wear was mainly attributed to abrasion. Fig.4 shows the chip build-up that was also noticed during low speed cutting which also contributed to the built-up edge(BUE) wear.

Fig.3 SEM image of wear land measured for Experiment 3 tool

Fig.4 Chip build-up during the low speed cutting

3.2Statistical Analysis

The tool wear results from the experiments were entered into Design Expert software and the response surface method was employed to develop and evaluate the model. The selection of a suitable polynomial equation was done by performing lack of fit tests. The lack of fit tests produced the results shown in Tab.3. From the table it can be seen that a quadratic model should be developed.Analysis of variance results are shown in Tab.4. The insignificant terms(p-value >0.05) were eliminated to produce a reduced model for tool wear.

Tab.3 Lack of fit tests for tool wear model

Tab.4 Analysis of variance for tool wear model

The final model to determine tool wear is defined as:

T=(-0.41202+0.0006541v+0.1176f+

0.1609a-0.00004356vf-0.00001656va+

(1)

wherevis the spindle speed in rpm;fis the feed rate in mm/min;ais the depth of cut in μm andTis the tool wear in μm.

The normality of residuals in Fig.5 verifies the adequacy of the model by the close proximity to the probability line.

Fig.5 Normal probability plot for the tool wear model

The effect of varying each input variable on tool wear was assessed. Fig.6 shows the cutting speed linear relationship with tool wear. As the cutting speed increases, the tool wear decreases. Fig.7 shows the feed rate also has a linear relationship with tool wear. Increase in feed rate leads to increase in the tool wear. Fig.8 shows the tool wear has an increasing curved profile with increasing depth of cut, and the highest tool wear occurs at approximately 18 μm. The plots show that the changes to cutting speed and feed rate within their respective ranges will have a similar level of impact on the resulting tool wear while the depth of cut will have a seemingly lower impact. These statistical results further verify the initial findings from the assessments of Tab.2.

Fig.6 Effect of the cutting speed on the tool wear model

Fig.7 Effect of the feed rate on the tool wear model

Fig.8 Effect of the depth of cut on the tool wear model

Fig.9 Wear map for 5 m depth of cut

Fig.10 Wear map for 15 m depth of cut

Fig.11 Wear map for 25 m depth of cut

The wear maps(Fig.9, Fig.10 and Fig.11) show the lower wear area was concentrated at equal extremes of the cutting speed and feed rate scale, high cutting speed/feed rate and low cutting speed/feed rate. These parameters are prevalent with the smooth material removal and cutting resulting in less impact on the tool edge. As the depth of cut increased, this low wear area covered a smaller area and became more concentrated on the higher end of the cutting speed and feed rate scale as more of the tool are engaged into the workpiece.

4 Conclusion

Single point diamond turning of rapidly solidified aluminium resulted in the low tool wear in the range of 3-12 μm after 4 km of cutting. The low tool wear measured was attributed to the ultra-fine microstructure of RSA 905 and the high hardness of the diamond tool. The small grains of RSA caused less of an impact on the tool and low tool deterioration rates. The tool edge wear was measured using SEM for each experiment that was carried out according to the Box-Behnken design of experiments. Abrasive wear and built-up edge were found to be the prevalent wear mechanisms. RSM and ANOVA were utilised to develop a predictive model to calculate resulting tool wear and analyse the effect of the variable cutting parameters. The analysis shows the combination of high cutting speed, low feed rate and small depth of cut produces low tool wear and less damage to the diamond tool edge. The results also show that a high material removal rates can be achieved with minimal wear provided the spindle speed is high and the feed rate is moderate. The work demonstrates RSA 905 as a viable alternative in optical mould manufacture with regard to the tool performance. Additionally, the results can provide a reference for machinists using this material.

[1]TANIGUCHI N. Current Status in and future trends of ultra precision machining and ultra-fine processing[J].AnnalsoftheCIRP,1983,32(2):573-82.

[2]SCHAUB M,SCHWIEGERLING J,FEST E,etal..MoldedOptics:DesignandManufacture[M]. USA:CRC Press,2011.

[3]BEICH W S. Specifying injection-molded plastic optics[J].PhotonicsSpectra,2002,36(3):127-8.

[4]VANCOLIIE E,XIANGDONG L,LING Y,etal.. Materials selection for durable optical inserts used in plastic lens moulding[R]. SIM Tech,Singapore,2000,DD/00/009/OTC.

[5]ZHANG L,JIANG Y,MA Z,etal.Effect of cooling rate on solidified microstructure and mechanical properties of aluminium-A356 alloy[J].J.MaterialsProcessingTechnology,2008,207:107-111.

[6]SALEHI M,DEHGHANI K. Structure and properties of nanostructured aluminum A413 produced by melt spinning compared with ingot microstructure[J].J.AlloysandCompounds,2008.457:357-361.

[7]KARAKO′SE E,KESKIN M. Structural investigations of mechanical properties of Al based rapidly solidified alloys[J].Materials&Design,2011,32(10):4970-9.

[8]RS Alloys Overview:RSP Technology[EB/OL]. [2015-06-01]. http://www.rsp-technology.com.

[9]Aluminium Alloy 6082 - T6~T651: Aalco Metals Ltd[EB/OL]. [2015-06-01]. http://www.aalco.co.uk.

[10]Aluminium Alloy 6061 - T6: Aalco Metals Ltd[EB/OL]. [2015-06-01]. http://www.aalco.co.uk.

[11]ZHONG Z,LEONG M,LIU X. The wear rates and performance of three mold insert materials[J].Materials&Design,2011,32(2):643-648.

[12]ABOU-EL-HOSSEIN K,OLUFAYO O,MKOKO Z. Diamond tool wear during ultra-high precision machining of rapidly solidified aluminium RSA 905[J].Wear,2013,302(1):1105-1112.

[13]HORST R T,HAAN M D,GUBBELS G,etal.. Diamond turning and polishing tests on new RSP aluminium alloys. Modern Technologies in Space and Ground Based Telescopes and Instrumentation II[C]. Proceedings of the SPIE,Amsterdam,Netherlands,2012,8450:84502M-11.

[14]GUBBELS G P H,VENROOY B W H V,BOSCH A J,etal.. Rapidly solidified aluminium for optical applications. Advanced Optical and Mechanical Technologies in Telescopes and Instrumentation[C]. Proceedings of the SPIE,Marseille,France,2008,7018:70183A-9.

[15]OTIENO T,ABOU-EL-HOSSEIN K,HSU W Y,etal.. Surface roughness when diamond turning RSA 905 optical aluminium.Optical Manufacturing and Testing XI[C],Proceedings of SPIE,San Diego,USA,2015,9575:957509-6.

[16]FERREIRA S L C,BRUNS R E,FERREIRA H S,etal.. Box-Behnken design:an alternative for the optimization of analytical methods[J].AnalyticaChimicaActa,2007,597:179-186.

2016-04-21;

2016-05-30

Supported by the National Research Foundation, South Africa through the National Equipment Programme and the Technology Innovation Agency

2095-1531(2016)05-0579-09

切削参数对新型光学铝级金刚石车削刀具磨损的影响

OTIENO T, ABOU-El-HOSSEIN K*

(南非纳尔逊·曼德拉都市大学机电系精密工程实验室,伊丽莎白港 6031)

光学器件和光学测量系统的关键部件主要通过超精密加工制造。铝合金具有很多优势,通常用于光子产业。光学领域对铝合金使用和需求的不断增加,促进了在铸造过程中采用快速凝固技术对铝合金等级重新改良的发展。优异的微观结构和改进的机械和物理性能是新型铝合金等级的特点。目前主要问题在于采用金刚石车削时,由于在切削性方面缺乏对铝合金性能的充分研究,导致机械加工数据库非常有限。本文通过改变金刚石的切削参数,测量切齿安装距超过4 km时金刚石刀具的磨损,研究了快速凝固铝合金RSA 905的切削性能。改变的机械加工参数为切削速度、进给速度和切削深度。结果表明切削速度对金刚石刀具的磨损影响最大。主轴转速为500 rpm、进给速度为25 mm/min、切削深度为15 μm时,刀具磨损达到最大值12.2 μm;主轴转速为1 750 rpm、进给速度为5 mm/min、切削深度为5 μm时,刀具磨损达到最小值2.45 μm。通常,较高的切削速度、较低的进给速度和较短的切削深度的组合可以减少金刚石刀具磨损。建立了模型统计以分析金刚石刀具磨损。通过该模型可以生成磨损图,从而确定切削参数产生最小磨损的区域。结果证明,快速凝固铝是更好的选择,为机械工程师使用这种材料提供了参考。

快速凝固铝;超精密制造;磨损;金刚石车削;光学工程

TH752

Adoi:10.3788/CO.20160905.0579

Biographies:

Timothy Otieno is a PhD Engineering student at the Nelson Mandela Metropolitan University. He received his BEng and MEng degree in Mechatronics from Nelson Mandela Metropolitan University in 2011 and 2012, respectively. His research focuses on the ultra-high precision machining of rapidly solidified aluminium alloys.E-mail:timothy.otieno@nmmu.ac.za

Prof. Khaled Abou-El-Hossein, is the Director of the School of Engineering at the Nelson Mandela Metropolitan University. He obtained his PhD in Manufacturing Engineering from the National Technical University of Ukraine in 2000. His current research focuses on the ultra-high precision machining of optical materials. E-mail:khaled.abou-el-hossein@nmmu.ac.za.