Design of Portable Super-audio Induction Heating Power

2016-09-03WANGHongGUShiyouWANGXiaomingLIXiaojieWANGFujingStateGridShandongElectricPowerResearchInstituteJinan000ChinaJinanJunqiInformationTechnologyCoLtdJinan000ChinaLaboratoryofGridMaterialsCorrosionandProtectionJinan000China

WANG Hong,GU Shiyou,WANG Xiaoming,LI Xiaojie,WANG Fujing(.State Grid Shandong Electric Power Research Institute,Jinan 000,China;.Jinan Junqi Information Technology Co.,Ltd.,Jinan 000,China;.Laboratory of Grid Materials Corrosion and Protection,Jinan 000,China;.Shandong Topower Engineering Consulting Co.,Ltd.,Jinan00,China;.Huaneng Zibo Bai Yanghe Power Generation Co.,Ltd.,Zibo 00,China)

(1.国网山东省电力公司电力科学研究院,济南 250003;2.济南峻齐信息技术有限公司,济南 250100;3.电网金属材料腐蚀与防护技术实验室,济南 250003;4.山东拓能工程咨询有限公司,济南 250012;5.华能淄博白杨河发电有限公司,山东 淄博 255200)

·专题论述·

Design of Portable Super-audio Induction Heating Power

WANG Hong1,GU Shiyou2,WANG Xiaoming3,LI Xiaojie4,WANG Fujing5

(1.State Grid Shandong Electric Power Research Institute,Jinan 250003,China;

2.Jinan Junqi Information Technology Co.,Ltd.,Jinan 250100,China;

3.Laboratory of Grid Materials Corrosion and Protection,Jinan 250003,China;

4.Shandong Topower Engineering Consulting Co.,Ltd.,Jinan250012,China;

5.Huaneng Zibo Bai Yanghe Power Generation Co.,Ltd.,Zibo 255200,China)

Induction heating technology has been widely used in metal smelting,casting,welding and so on.The traditional supersonic frequency induction heating power supply has larger volume and lower heating influence to weld dissimilar materials.As a consequence,a portable super-audio induction heating power supply is introduced,which is easy to carry and can be used to weld dissimilar materials.

induction heating;super-audio power supply;IGBT inverter

(1.国网山东省电力公司电力科学研究院,济南250003;2.济南峻齐信息技术有限公司,济南250100;

3.电网金属材料腐蚀与防护技术实验室,济南250003;4.山东拓能工程咨询有限公司,济南250012;

5.华能淄博白杨河发电有限公司,山东淄博255200)

0 Introduction

Inductionheatingtechnologyhasadvantageof high thermal efficiency,good frequency selectivity,and little environmental pollution,which is widely used in metal smelting,casting,welding and so on[1-2].The general trend of induction heating power is higher frequency,higher power,and smaller size.Intelligence and digitization is becoming a development goal as well[3-8].

Thetraditionalsuper-audioinductionheating power supply has larger volume and lower heating influence to weld dissimilar materials.Therefore,a portable super-audio induction heating power is introduced,which is easy to carry and can be used to weld dissimilar materials[9].

1 Characteristics and Parameters

Portable super-audio induction heating power employs IGBT to invert energy,which has small size and high efficiency.It adopts high-frequency resonant capacitors,modular filter capacitors,a touch screen and other components,which are instead of a large number of electrolytic capacitors,buttons,and instruments.Meanwhile the layout of the entire equipment is rational and compact.Handheld super audio transformer uses 1J22 soft magnetic material as cores,which has high saturation and low loss.Primary coil is winded by a high temperature wire about 1 mm2,and can withstand up to 150 A byforced water-cooling.Water-cooling cables between power supply and the transformer can be extended to 30 meters or longer.With the handheld super audio transformer and coaxial water-cooling cables,you can easily move welding.4~20 mA control signal interface is used to adjust the power automatically within the specified range.Technical parameters of IGBT power supply are listed in Tab.1,and the internal assembly is shown in Fig.1.

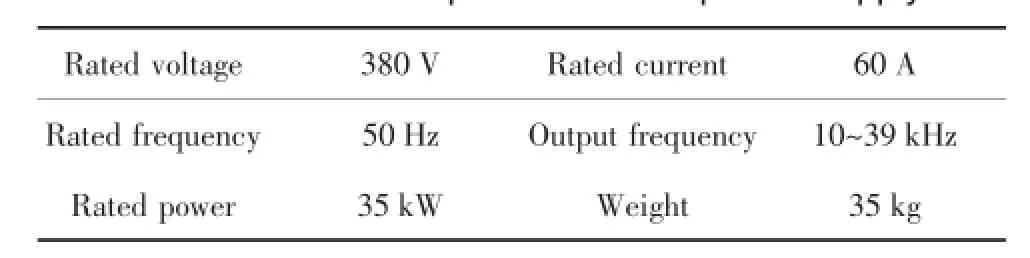

Tab.1 Technical parameters of power supply

Fig.1 The internal assembly of power supply

2 Power Supply Design

2.1The electrical design

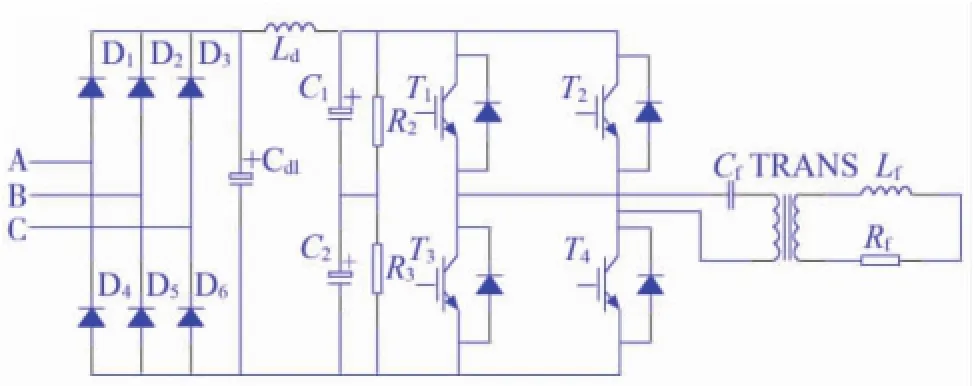

Fig.2 Power supply electrical schematic diagram

The main electrical circuit of induction heating power is shown in Fig.2.50 Hz three-phase current is rectified by uncontrolled rectifier bridge,and is transformed into 10~39 kHz single-phase super-audio current by IGBT inverter bridge after a filter.Then the current is input to a series resonant circuit which is composed by a transformer,an inductor and compensation capacitors.As a result, the work piece in the inductor is rapidly heated by super-audio eddy current.With the increase of the current frequency,the heating depth of the work piece is reduced.

As shown on above figure,Cd1,Ld,C1and C2constitute Π type filter.C1,C2are connected in series to reduce the voltage of a single capacitor.R2,R3equalize effect.Inverter bridge is composed of eight 300 A fast IGBT,in which two IGBT are in parallel to increase current.IGBT models are FF300RKS4,and each IGBT is connected by an anti-parallel diode.The role of the transformer is electricalisolationandloadmatching.Changing transformer ratio appropriately can adjust the resonanttankparameters,sothatdifferentload impedances are performed.

The resonant capacitor in common super audio induction heating power uses polypropylene film as a medium,the metal foil as electrodes,and capacitor oil potting.The capacitor which needs water cooling is large,so that the power size is up to 400 mm×500 mm×400 mm.Portable Super audio induction heating power supply employs high-frequency resonant capacitors,which size is only Φ65 mm× 45 mm.Those can withstand large high-frequency current with low equivalent series resistance and inductance,and only natural cooling is needed.DC filter uses modular industrial filter capacitors.They have aluminum heat sinks,very low equivalent series resistance,large RMS current and peak-peak current tolerance,and least inductance as possible.For the above reasons,they can replace the traditional electrolysis capacitors for long-life operation of the electrical system.High frequency resonant capacitor and modular industrial power supply filter capacitor greatly reduce the supply size and weight,and the weight of the power supply is only 35 kg,which is easy to carry.

2.2Hardware design

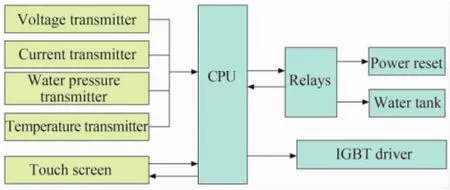

The connection of the hardware is shown in Fig.3.The output voltage and current are sampled by avoltage transmitter and a current transmitter,and then put into CPU.CPU adjusts PWM output signals,and drives the IGBT driver to control output power.Because of water cooling need,water pressure is detected.Once water pressure is low,the output power is shut down immediately.Components temperature is also monitored to avoid overheating.Itisconvenienttosetandshowparametersof power supply through the touch screen.Power reset and water tank are controlled by CPU through relays.

(2)对于建筑电气安装工程使用的关键材料而言,必须要确保电气安装工程材料的合格性与质量,且在发现电气材料无质量证明书与出厂合格书后,需要对材料进行退换操作,以使得建筑电气安装工程的施工材料合格性可以得到保障。

Fig.3 Hardware design of power supply

CPU control circuit is the core of the ultra-audio frequencypowersupply,includingCPU,voltage conversion unit,power supply unit,reset unit,debug unit and so on.

Super audio frequency range is 10~39 kHz,and the digital controller is necessary to achieve constant power control.It needs not only realize the digital phase-lockedfrequencytrackingfunction,but also have a state detection instruction,communication,interactive and other functions.High-frequency and multi-function operation requires that the controller has high operation speed,accuracy,and multiple analog sampling and analysis process.The controller also requires a strong parallel processing capability.For these characteristics,Luminary Micro Stellaris LM3S615 microcontroller family is chosen to be the main chip.32-bit LM3S615 controller is based on ARM CortexTM-M3,which the operating frequency is up to 50 MHz,with excellentcomputationalperformanceandexceptional systemresponsetointerrupts.LM3S615includes ARM CortexTM-M3 processor core,the nested vector interruptcontroller,pulse-widthmodulation (PWM)outputs,analog peripherals,serial communication peripherals,system peripherals,memory,andperipherals.ThePWMcontrolincludes three PWM generator modules.PWM generator generatestwoindependentPWMsignalswithprogrammable dead time delay,output PWM signal according to the operation counter and comparator output signal.It can realize each PWM signal output polaritycontrol,faulthandling,etc.,which meetstherequirementofIGBTinvertercircuit PWM controlling.

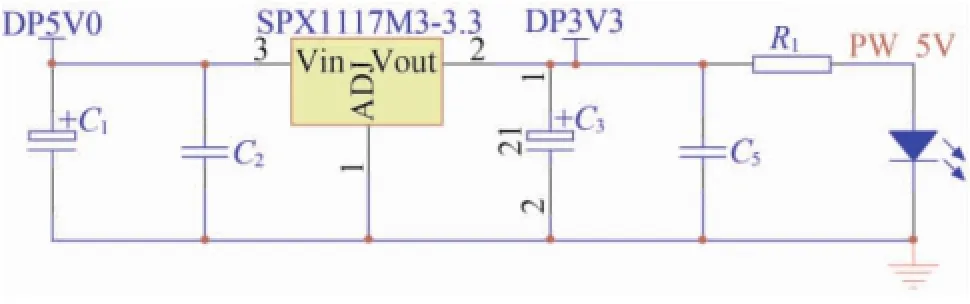

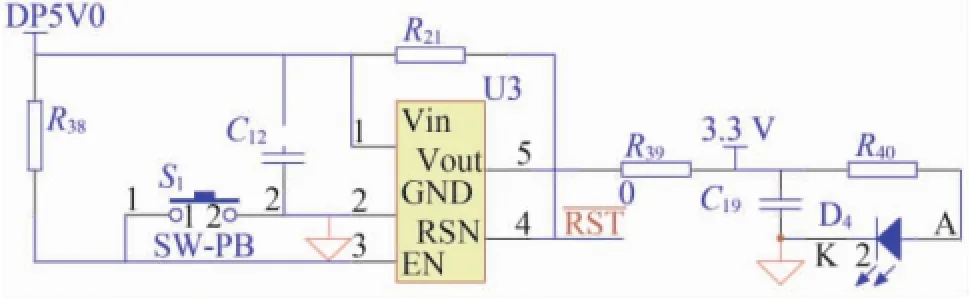

Signal interface circuit is used to determine the grouping of digital signal connection in order to avoid interference.Due to different supply voltage,voltage conversion circuit(as shown in Fig.4)realizes 5 V to 3.3 V signal conversion.Debug circuit is used to detect the performance of the CPU and debug the program.Reset circuit(as shown in Fig.5)is used to the power reset operation.

Fig.4 Voltage conversion circuit

Fig.5 Reset circuit

Because IGBT Inverter Bridge adopts two IGBT paralleling,itisdrivenbyeightPWMsignals.Special IGBT protection driver board is connected to the output PWM signals.IGBT driver board isolates the input signal and output signal electrically,and provides over-current protection.Detecting theover current signal,the driver board reduces the grid voltage first,and then delays triggering.When short circuit occurs,it executes a soft shut off,and blockades the input signal to perform a complete protectioncycle.Otherwise,itrestoresthe output to avoid the interference signal caused by frequent start.Only the short circuit threshold resistors Rn and grid resistance Rg need setting,and the rest of the driver protection parameters accept the default values.

2.3Software design

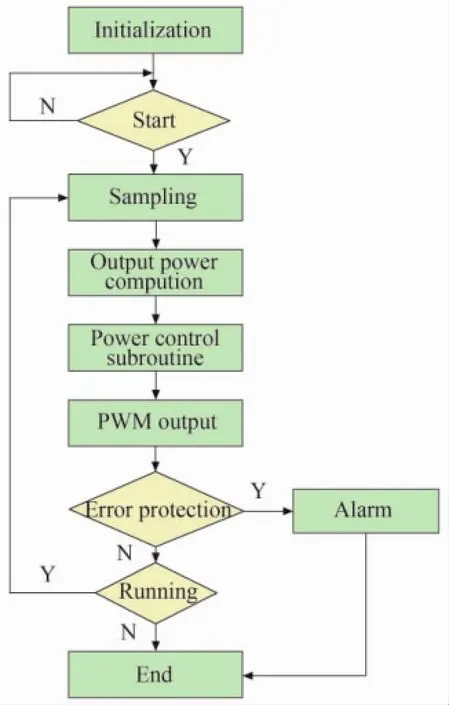

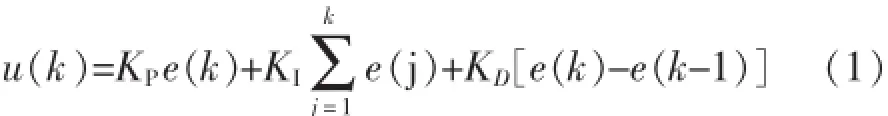

Program of induction heating power is developed by C language,and the main program flow chart is shown in Fig.6.The initial set of each register is carried out first.And then the initial value of output power is set after start signal was detected.Analog sample signals conclude current,voltage,capacitance temperature,cooling water temperature,water pressure,and temperature in the shell of the device.These parameters which have been put into a digital filter are monitored to keep operation stabilization.The product of inverter current and inverter voltage is output power.The central control strategyofpowercontrolsubroutineisdigital phase-locked loop control and constant power control algorithms.The program uses a digital PID algorithm to realize constant power control.Regulated by power control subroutine,inverter frequency of PWM signals is used to control the output power.If any error protection has been detected,CPU will stop running and alarm.

The output power control strategy is pulse frequency adjustment mode(PFM).Intheinductionheating process,the closer IGBT inverter frequency is to the resonance frequency,the smaller the equivalent impedance of the load becomes.At the same time,the output power is larger,and the efficiencyishigher.Otherwise,powerbecomes smaller.Moreover,the resonant frequency of the load changes with temperature which is constantly changing.So output power can be changed by adjusting the frequency of the IGBT inverter,which needs following the resonant frequency.When the seriesresonancecircuitisinductive,theoutput current lags behind the voltage.Make sure the inverter frequency is slightly higher than the resonant frequency,and it will cause a dead zone in the lag time.As a consequence,IGBT and anti-parallel diode can be turned on and turned off in very smallcurrent,whichcaneffectivelyreducethe switching loss,and soft turn-off becomes true.

Fig.6 Main program flow chart

Where KPis the proportional gain,KP=1/P;P is the proportion constant;KIis the integral gain,KI=KPT/TI;TIis the integral time constant;KDis the differential gain,KD=KPTD/T;TDis the differential time constant;e(k)is the error;u(k)is the controller;T is the sampling period.

3 Conclusions

Compared to the traditional super-audio induction heating power,the portable IGBT super-audio power has higher heating efficiency,smaller size,and lighter weight.Handheld super-audio transformer is convenienttotransportation,whichcanreplace similar imported products.

References

[1]PAN Tianming.Modern induction heating equipment[M].Beijing:Metallurgical Industry Press,1996.

[2]WANG Hong.The design and implementation of the Customer Relationship Management System for Tobacco Industry[D].Jinan:Shandong University,2014.

[3]ZHU Shiliang,ZHANG Zhongdian,TIAN Xiubo,et al.Large size electrical contact the flexible design of induction heating power supply[J].Electric Welding Machine,2015,45(5):43-49.

[4]YU Yongxiang,CHEN Huiming.The development of induction heating power supply[J].Heat Treatment of Metals,2000(8):28-31.

[5]EGALON Julie,CAUX Stephane,Maussion Pascal.Multiphase System for Metal Disc Induction Heating:Modeling and Rms Current Control[J].IEEE Transactions on Industry Applica tions,2012,48(5):1 692-1 699.

[6]DUAN Haiyan.Digital control of induction heating power supply[D].Jinan:Shandong University,2007.

[7]ZHANG Surong.High frequency induction heating power supply control system based on DSP[D].Xi’an:Xi’an University of Technology,2004.

[8]NI Xuliang.Development of 50 kHz IGBT Series resonant in duction heating power supply is developed[D].Xi’an:Xi’an University of Technology,2008.

[9]WANG Xuegang.Copper aluminum transient liquid diffusion weldingmicrostructureandpropertiesresearch[D].Jinan:Shandong University,2015.

Accepted date:2015-11-20

WANG Hong(1981),receivedmasterdegreeinEngineering fromShandong University in 2012.She is now working in State Grid Shandong Electric Power Research Institute.Her main research interest is induction heating power supply and protective relaying.

便携式超音频感应加热电源设计

王宏1,顾士友2,王晓明3,李晓捷4,王福晶5

感应加热技术广泛应用于金属的熔炼、铸造、焊接等。传统的超音频感应加热电源体积、重量都较大,异种材料焊接加热效率低。设计一种便携式超音频感应加热电源,体积重量都较小,易于携带,并且可以进行异种材料的焊接。

感应加热;超音频电源;IGBT逆变器

TM92

A

1007-9904(2016)01-0033-04