Wheat straw pretreatment with KOH for enhancing biomethane production and fertilizer value in anaerobic digestion☆

2016-06-01MuhammadJaffarYunzhiPangHairongYuanDexunZouYanpingLiuBaoningZhuRashidMustafaKoraiXiujinLi

Muhammad Jaffar,Yunzhi Pang,Hairong Yuan,Dexun Zou,Yanping Liu,Baoning Zhu,Rashid Mustafa Korai,Xiujin Li

Department of Environmental Science and Engineering,Beijing University of Chemical Technology,Beijing 100029,China

1.Introduction

Sustainable biogas production plays a vital role in tackling the environmental issues such as global warming and climate change,as it can reduce the consumption of fossil fuels by waste treatment plants in addition to producing viable organic fertilizers[1].China is one of the largest agricultural countries in the world and has abundant biomass resources,which can be classified into four major categories:crop straw, firewood,various organic wastes,and agricultural residues.Amongst these,the crop residue is the largest group accounting for about 72.2%of the total biomass[2].Approximately 0.8 billion tons of various crop residues are generated annually in China,of which corn and wheat straw are 216 and 135 million tons,respectively[3].Anaerobic digestion(AD)offers multiple benefits for treating organic wastes,for instance,in wheat straw AD,biogas is a main product and solidstate digestate residue is a by-product[4].The digestate is a semidegraded organic matter comprised of residual nutrients including minerals and inorganic compounds,and can be used as soil conditioner on farmlands[5,6].

Feedstock substrates such as wheat straw,which is a lignocellulosic material,are resistant to biodegradation with low biogas conversion due to their complex structure[7].Lignocellulose is a complex and rigid matrix of plant cells resistant to any enzymatic attack due to tight association between cellulose,hemicellulose and lignin inhibiting their biodegradability[7].Pretreatment of lignocelluloses is necessary in terms of solubilization and biosorption of hemicellulosic and lignin components for better biogas production[8].Multiple treatments have been attempted including physical(hot water,steam explosion,extrusion),chemical(alkaline,acidic,oxidative)or biological(fungal,microbial and enzymatic)methods[7,8].In addition,pretreatment of wheat straw is mostly done with NaOH and other chemicals such as NH3and Ca(OH)2;but it is not conducive to generate the digestate good fertilizer value[9,10].Current researches focus on pretreatment of wheat straw with potassium hydroxide(KOH)to improve biomethane yield and digestate fertilizer value.Fertilization with fermented or digestate residual with good fertilizer value will have better effect on the soil,since the residual nutrients in the digestate are in mineralized state and could be taken up more effectively[11].For optimum cropping output,nutrients nitrogen,phosphorus and potassium should be supplied with a ratio of 1.2:1:1.5 for wheat production,1:1:1.8 for potato production and 2.4:1:1.4 for grass production[11],which may vary with the climatic and soil conditions of the region.Potassium(K)plays significantrole in enhancing the crop quality butlarge agriculturalareas in the world are reported to be deficientin Kincluding three-fourth of the paddy soils of China and two-third of the wheat belt of southern Australia[12].Sufficient K improves the soil profile in terms of physical characteristics,disease resistance,and shelf life of fruits and vegetables while deficiency of K,especially during critical developmental stages,will cause serious losses[12].

2.Materials and Methods

2.1.Wheat straw collection and characteristics

Wheat straw used in this study was collected from Changping District,Beijing City,China.The straw was air-dried in an open crop field after harvesting to final moisture contents of 7%-8%and then collected to store in a laboratory.For its size reduction the straws was air dried chopped to a length approximately 3 cm in a paper chopper(PC500,Staida Co.,Tianjin,China)and ground to 5-10 mm particles by a hammer mill(FE130,Staida Co.,Tianjin,China).The samples were sealed in plastic bags and kept under 62%±1%relative humidity and ambient temperature for further use.Table 1 shows the characteristics of wheat straw.

Table 1Characteristics of wheat straw

2.2.Pretreatment with KOH

Wheat straw was pretreated with different concentrations of KOH based on dry matter.The pretreatment experiments were classified into five groups according to KOH doses,1%(K1),3%(K2),6%(K3),9%(K4)and a control out KOH(K0).For preparation of each group,wheat straw(WS)was placed in glass bottles with KOH at a ratio of 1:6:(0.01-0.09)(WS:H2O:KOH)[13].The bottles were covered with plastic films,closed with plastic rings and placed in the lab at ambient temperature for three days before anaerobic digestion.

2.3.Anaerobic digestion

In the anaerobic digestion(AD)the seeding sludge was collected from a wastewater treatment plant(WWTP)in Beijing.AD was carried outin 1 L glass bottles at(35±1)°C with a working volume of0.8 L and a loading rate of 65 g·L-1for untreated and KOH-treated wheat straw(K1-K4).The loading rate was based on the dry mass of pretreated wheat straw(total solids,TS)per liter effective volume(g·L-1).The straw was placed into each bottle in terms of the loading rate by experimental design.Each bottle was seeded with 15 g·L-1of the activated sludge as procured from the WWTP[14].The sludge contained 49.2 g·L-1(TS),29.5 g·L-1volatile solids(VS)and mixed liquor suspended solids(MLSS,34.8 g·L-1).The C/N ratio is an important macronutrient parameter in achieving stable anaerobic digestion,which was different for wheat straw pretreated with different doses of KOH[15].In order to have a stable C/N ratio of 25:1,an appropriate amount of urea was added to each bottle for the optimal growth of anaerobic bacteria.The samples were then placed in incubatortank for anaerobic digestion tests at the mesophilic temperature of(35 ± 1)°C.

2.4.Sampling and analytical methods

Biogas volume generated was monitored everyday via water displacement method.The biomethane yield is calculated using ideal gas equation at STP for biomethane contentand biogas production.The theoretical methane potential(TMP)is calculated by Eq.(1)[16]and Eq.(2)[17].According to the mass content and molar mass of each element,the chemical formula of wheat straw was determined and the TMP(ml·g-1)then calculated by Eq.(2).

In order to measure the production of CH4and CO2in the anaerobic digestion,gas samples of 0.25 ml were withdrawn regularly from each bottle.The methane content of biogas was analyzed everydayviaGas Chromatograph(SP-2100,BeiFenRuiLi Co,Beijing China)equipped with a molecular sieve(TDX-01)packed 2 m×3 mmstainless-steelcolumn and a thermal conductivity detector(TCD).The temperatures of oven,injector port and TCD were 140,150 and 150°C,respectively.Argon was used as the carrier gas at a flow rate of 30 ml·min-1.The methane production is the product of biogas production multiplying by methane content.

2.5.Chemical composition analysis

(TS),(VS),and(MLSS)of wheat straw,sludge and their mixture were measured according to the standard methods[18].The total carbon(TC)and total nitrogen(TN)were determined by TC analyzer(Vario EL/micro cube elemental analyzer,Germany)and the total Kjeldahl nitrogen analyzer(Model KDN-2C,Shanghai)for calculating the C/N ratio.The pH value was determined by pH meter(CHN868,Thermo Orion,America)and alkalinity was determined according to APHA standard methods[18].The contents of lignin,cellulose and hemicellulose were determined using a fiber analyzer(ANKOM,A2000I,USA).For the elemental assessment,the samples were pretreated with a mixture of HNO3/H2O2followed by the analysis of resultant clear solution by inductively coupled plasma atomic spectrometry(ICP-OES,Thermo Fisher iCAP 6200)according to standard procedures.Scanning electron microscope(SEM,S-3500N,Hitachi High Technologies,American,Inc.Pleasant on,CA,USA)was used to examine the microstructures of treated and untreated digestate residues.The digestate residue was dried in oven at 105°C for 24 h prior to SEM analysis.Samples were coated with a 100 nm layer of platinum with a Hummer6.2 sputtercoater(Anatech,CA,USA).Imaging was performed at 20 keV acceleration voltages.

2.6.Data analyses

Each analytical result was the mean of three measurements.The standard deviations and significant differences were determined by means of ANOVA using MetLab 7.10.0.

1096 巴马小型猪头颈部动脉的磁共振血管成像研究 李 帅,王立鹏,景国东,王铁功,陈录广,弓 静,彭雯佳,陆建平

3.Results and Discussion

3.1.Effect of KOH pretreatment on wheat straw

The pretreatment of wheat straw with an alkali source such as potassium(K)is based on the pretext that most of K is not plant-available.Crops need supply with potassium-soluble fertilizers and the demand is expected to increase significantly.In k-deficient crops,the supply of sink organs with photosynthates is impaired in accumulation of sugars in source leaves,which affects the yield.Kplays a crucialrole in a number of physiological factors vital to growth,yield and quality of the crop in addition to resistance to drought,salinity,high light or cold as well as pests and pathogens[19].

Pretreatment with KOH induces desired changes in wheat straw characteristics in terms of physical and chemical properties,and enhances the process biodegradability and biogas production[20].Table 2 shows the result KOH-treated gives higher TS and VS reduction,86%and 89%respectively.The characteristics of wheat straw are related to the reductions of overall size and process-oriented shape.The pretreatment breaks lignocelluloses into three major polymeric constituents:lignin,cellulose and hemicellulose(LCH)[21].The first step is to break the lignin sealand hemicellulose sheathing over cellulose and disruptthe crystalline structure of cellulose.After KOH pretreatment,cellulose contents of KOH pretreated wheat straw were reduced by 3.2%,6.3%,10.1%and 12.6%,while LCH contents were reduced by 10%,14%,22%,and 26%for K1,K2,K3 and K4,respectively.These results suggest that KOH pretreatment of wheat straw yields better microbial degradation of cellulose and hemicelluloses with the likely influence of higher pH value by 34%compared to untreated wheat straw.

3.2.Biogas production

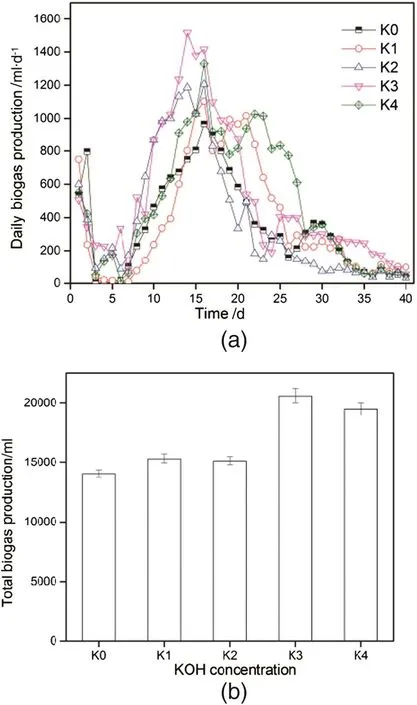

Fig.1(a)shows the daily biogas production atmesophilic temperature of(35±1)°C.Biogas production is normal until the fifth days,while on day six the production is slower.It is probably due to saturated of lignocellulose in wheatstraw,which degrades ratherslowly.Anotherprobable factor that the pH value decreases down to 4,and the accumulation of unionized NH3-N causes acidification of the medium[21].The influence of pH reduction on the process efficiency is reflected from day 7 to day 15 of digestion with higher biogas after the pH is regulated with calcium hydroxide.The maximum biogas production in a day was 1103,1207,1515,1330 and 967 mlwith K1,K2,K3,K4 and K0 respectively,indicating significant difference(P<0.05)between K3 and K0.This upsurge in biogas production may be attributed to the partial consumption of soluble organic substances during pretreatment increasing fermentative microorganisms in the medium.

Fig.1(b)also shows the totalbiogas production(TBP)at STP accrued from anaerobic digestion of wheat straw.The TBP for pretreated wheat straw with K1,K2,K3 and K4 was 15.3,15.2,20.6 and 19.5 LNrespectively in comparison to 14.1 LNfrom control run(K0).The TBP results indicate that wheat straw pretreatment with more KOH(K3 and K4)produces significantly higher TBP yield.The TBP value with biogas yield of 668 ml·(g VS)-1obtained with K3 is comparatively better than that by Liuet al.[22],who pretreated wheat straw with 30%KOH and obtained biogas yield of 548 ml·(g VS)-1.The results imply that the TBP for wheat straw pretreated with K3 is increased by 45%(P<0.05)compared with untreated wheat straw.

Fig.1.Daily biogas production(a)Total biogas production(b).

3.3.Cumulative biomethane yield

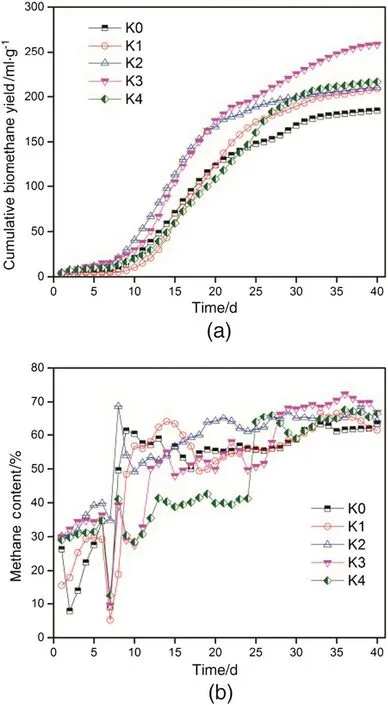

Cumulative biomethane yield was determined in terms of VS to compare energy conversion efficiency and improvement in substrate biodegradability.According to mass content of each element listed in Table 1,the chemical formula of wheat straw can be expressed by C3.48H5.53O3.21N0.065.The(TMP)was calculated as 361 ml·(g VS)-1while the maximum biomethane yield obtained with K0,K1,K2,K3,and K4 were 184(50%),208(57%),210(58),258(71%),and 217(60%)ml·(g VS)-1respectively[Fig.2(a)].These results show that there is a significant difference as between biomethane yield with K3 and those with other treatments as well as K0(P<0.05)implying efficient bioconversion of wheat straw pretreated with K3,while higher concentration of KOH(K4)gave lower bioconversion.

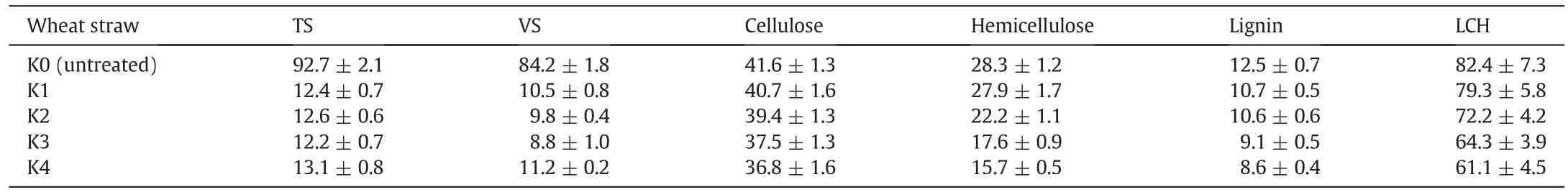

Table 2Changes of main composition after KOH-pretreatment(%dry matter)

Fig.2.Cumulative biomethane yield(a)Methane content(b).

The maximum biomethane yield is in line with that reported by Liuet al.[22],who obtained 210 ml·g-1from wheat straw pretreated with 20%KOH.The biomethane yield from wheat straw pretreated with K3 is 41%higher than that of untreated wheat straw(K0).Higher biomethane yield treated wheatstraw with respectto untreated wheatstraw is due to the efficient decomposition of cellulose and hemicellulose substances.

Overall methane content(OMC)profile of the biogas is also shown in(Fig.2(b)).The OMC value increased from 32%-50%in early digestion phase of15 days to 60%-65%after digestion for 40 days.The OMC values for case K1,K2,K3,and K4 were 67%,69%,70%and 68%,respectively,compared to that of 60%for control(K0).The OMC values are in agreement with those in literature in the range of 40%-70%[23,24].Higher OMC value of pretreated wheat straw is probably resulted from the adsorption of carbon dioxide gas into the substrate due to upsurge in alkalinity with the addition of KOH.

3.4.Influence of KOH pretreatment on digestate

Table 3 shows chemical analysis on the digestate residue with standard deviation.The digestate residue samples show low content of dry matter of around 5%after anaerobic digestion of wheat straw.The elemental profile of digestate samples is in agreement with the earlier results for wheat straw digestion.The digestate samples with K3 present lowest contents of carbon(32%)and nitrogen/total Kjeldahl nitrogen(TKN)/(2.1%/442 mg·L-1)showing that better biodegradability in digestion leaves less carbon and nitrogen[25].This effect confirmed by the carbon and nitrogen contents in the digestate samples with K1,K2 and K4.

Since anaerobic biodegradability of organic matter is related to its composition[26],alkalinity is an ideal parameter to monitor anaerobic digestion process[27].For biomethane production with ideal degradation of digestate residue into methane and carbon dioxide,the digestate residue must be in neutral pH range of around 6.5 to 7.4[28].The alkalinity profile of the digestate samples suggest that the digestate from wheat straw treated with higher KOH is in the desired pH range.These observations are in line with literature[24].

3.5.SEM of digested residue samples

Fig.3 shows the surface images of pretreated and untreated wheat straw samples to examine their physical difference.The image of untreated wheat straw present clear flat and smooth surface with slight pores.Digestate residue samples pretreated with K2,K3 and K4 have the surface seemingly damagedviastructural friction with many micro pores,most likely caused by the biodegradation during anaerobic digestion.The surface analysis indicates that the pretreated samples consisted of many small particles with relatively few larger,partly covered fragments.A number of small holes are also observed indicating biodegradation of hemicellulose fibers.Liaoet al.[29]reported that the small holes in the manure fibers meant that part of hemicellulose was degraded from the backbone of fibers.The structural changes in fiber improve methanogenesis.

3.6.Fertilizer value of the digestate

Fig.4 shows the fertilizer value of digestate samples in terms of biogenic elements.Magnesium and phosphorus values ranged from 0.99%to 1.15%and 1.17%to 1.45%,respectively.Higher magnesium(1.15%)and phosphorous(1.45%)values are found in the samples with K3 and K1 compared to 0.99%and 1.17%with K0 and K4.The residual proportions of calcium and potassium in the treated digestate residue samples ranged from6.62%to 7.6%and 2.75%to 9.57%,respectively,considerably higher than those required for calcium(0.4%-2.5%)and magnesium(0.1%-0.4%)in cropping[30].These results are in agreement with those reported[11],with the residual calcium in the digestate between 2.72%and 3.2%.

The elementalpro file with K3 shows phosphorus,magnesium,calcium,and potassium 6.6%,16%,22%,and 138%higher than those with untreated digestate.Higher potassium contents in the digestate beneficial for soils,increasing their micro shear resistance and presenting positive effect on their waterholding capacity[31].Higher concentrations of calcium and magnesium in the residual digestate may be associated with a number of changes during the digestion process,indulging substantial removal of TS and an increase in ash content resulted from the conversion of organic and inorganic substances in pretreated wheat straw.It is expected that digestate with lower solid content will improve surface in filtration of the soil slurry,which is helpful to conserve nitrogen contents in the slurry[32].Another indirect indicator of saturated concentration of calcium and potassium is the digestate pH,since higher concentrations of basic cations such as Ca2+and K+in the digestate reduce the concentration ofH+[33].In addition,non-alkalimetals such as calcium and magnesium from soluble ions pairs with a number of anions such as carbonates,bicarbonates,hydroxides and sulfates[33].No such ionic pairing was observed in the process,which may contribute to increase the concentration of these cations.

Sufficient potassium in the soil also plays and active role in activation ofenzymes for healthy plant growth,the pH profile can be adjusted for desired enzymatic reactions[31].However,the digestate saturated with magnesium and calcium may be more effective for stabilizing soil structures with the relative flocculating ability of these cationic substances in the digestate[12].

Table 3Chemical analysis of digestate residue.

Fig.3.SEM image of untreated digestate wheat straw K0(a)pretreated digestate wheat straw K2(b)pretreated digestate wheat straw K3(c)pretreated digestate wheat straw K4(d).

Fig.4.Magnesium,and phosphorus elemental profile of digestate(a)Calcium and potassium elemental profiles of digestate(b).

Conventional fertilizer are only for the purpose of increasing food production while value-added digestate as a biofertilizer in cropped lands serves multiple purposes indulging less emissions of greenhouse gases and less NH3-N losses due leaching or denitrification processes,which are common in raw manure fertilization[28].The digestate with desired fertilizer value will be one of the important components in integrated nutrients management cost-effective and renewable source of plant nutrients for sustainable agriculture[5].

4.Conclusions

Pretreatment of wheat straw with 6%KOH(K3)increased the biodegradability of the biomass significantly.This pretreatmentinduced a desired change in the characteristics of wheat straw so as to improve its efficient degradation in terms of total solids,volatile solids,and LCH by 86%,89%,and 22%,respectively.The anaerobic digestion of wheat straw pretreated with K3 enhanced cumulative biomethane yield to 258 ml·(g VS)-1and its total biogas production was 45%higher than untreated one.The digestate residue possesses enriched elemental profile in terms of calcium,magnesium,and potassium.Thus,the wheat straw pretreatment with 6%KOH effective to produce optimum biomethane yield and biogas production and is expected to be a good soil conditioner for crops.

[1]M.Pohl,J.Mumme,K.Heeg,E.Nettmann,Thermo-and mesophilic anaerobic digestion of wheat straw by the up flow anaerobic solid-state(UASS)process,Bioresour.Technol.124(2012)321-327.

[2]X.Zeng,Y.Ma,L.Ma,Utilization of straw in biomass energy in China,Renew.Sust.Energ.Rev.11(5)(2007)976-987.

[3]National Bureau of Statistics of China,China statistical yearbook 2012,China Statistics Press,Beijing,China,2013.

[4]S.Luste,H.Heinonen-Tanski,S.Luostarinen,Co-digestion of dairy cattle slurry and industrial meat-processing by-products:Effect of ultrasound and hygienization pre-treatments,Bioresour.Technol.104(2012)195-201.

[5]H.I.Owamaha,S.O.Dahunsi,U.S.Oranusi,M.I.Alfa,Fertilizer and sanitary quality of digestate biofertilizers from the co-digestion of food waste and Human excreta,Waste Manag.34(2014)747-752.

[6]S.Lansing,J.Martin,R.Botero,T.Nogueira da Silva,E.Dias da Silva,Wastewater transformations and fertilizer value when codigesting differing ratios of swine manure and used cooking grease in low-cost digesters,Biomass Bioenergy34(2010)1711-1720.

[7]Z.Weizhang,Z.Zhongzhi,Y.Luo,S.Sun,W.Qiao,M.Xiao,Effect of biological pretreatments in enhancing corn straw biogas production,Bioresour.Technol.102(2011)11177-11182.

[8]A.S.Nizami,T.Thamsiriroj,A.Singh,J.D.Murphy,Role of leaching and hydrolysis in a two-phase grass digestion system,Energy Fuel24(8)(2010)4549-4559.

[9]T.Mohsen,Z.Hamid,Improving biogas production from wheat plant using alkaline pretreatment,Fuel115(2014)714-719.

[10]Y.Dongyan,P.Y.Zhi,Y.Hairong,C.Shulin,Jingwei,Y.Lian,Enhancing biogas production from anaerobically digested wheat straw through ammonia pretreatment,Chin.J.Chem.Eng.22(5)(2014)576-582.

[11]N.Voca,T.Kricka,T.Cosic,V.Rupic,Z.Jukic,S.Kalambura,Digested residue as a fertilizer after the mesophilic process of anaerobic digestion,Plant Soil Environ.51(6)(2005)262-266.

[12]V.Römheld,E.A.Kirkby,Research on potassium in agriculture:Needs and prospects,Plant Soil335(2010)155-180.

[13]Y.Z.Pang,Y.P.Liu,X.J.Li,Improve biodegradability and biogas production of corn stover through sodium hydroxide solid state pretreatment,Energy Fuel22(4)(2008)2761-2766.

[14]R.Zhang,Z.Zhang,Biogasification of rice straw with an anaerobic phased solids digester system,Bioresour.Technol.68(1999)235-245.

[15]H.Bouallagui,H.Lahdheb,E.Ben Romdan,B.Rachdi,M.Hamdi,Improvement of fruit and vegetable waste anaerobic digestion performance and stability with cosubstrates addition,J.Environ.Manag.90(5)(2009)1844-1849.

[16]A.Buswell,H.Muller,Mechanics of methane fermentation,J.Ind.Eng.Chem.44(3)(1952)550-559.

[17]D.Li,Y.Sun,Y.Zhang,The study on anaerobic digestion of produce methane for eight organic fraction of municipal solid waste,International conference on biomass energy technologies,Guangzhou 2007,pp.361-363.

[18]APHA-AWWA-WEF,Standard methods for the examination of water and wastewater,20th ed.American Public Health Association,Washington,DC,1998.

[19]P.Kaparaju,M.Serrano,A.Belinda,P.Kongjan,I.Angelidaki,Bioethanol,biohydrogen and biogas production from wheat straw in a biorefinery concept,Bioresour.Technol.100(2009)2562-2568.

[20]K.Gray,L.Zhao,M.Emptage,Bioethanol,Curr.Opin.Chem.Biol.10(2006)1-6.

[21]A.J.Ward,M.S.Kumar,Bioconversion rate and optimum harvest intervals for Moina australiensis using digested piggery effluent and chlorella vulgaris as a food source,Bioresour.Technol.101-7(2010)2210-2216.

[22]L.Xiaoying,M.Steven,Zicari,L.Guangqing,L.Yeqing,Z.Ruihong,Pretreatment of wheat straw with potassium hydroxide for increasing enzymatic and microbial degradability,Bioresour.Technol.185(2015)150-157.

[23]X.Yonglan,C.Zhizhou,Y.Xiaomei,X.Rong,D.Jing,C.Guangyin,Methane production from wheat straw with anaerobic sludge by heme supplementation,Bioresour.Technol.172(2014)91-96.

[24]C.Zhifang,S.Jian,L.Yebo,Solid-state anaerobic digestion of spent wheat straw from horse stall,Bioresour.Technol.102(2011)9432-9437.

[25]W.Powers,H.Van,A.Wilkie,C.Wilcox,R.Nordestedt,Effects of anaerobic digestion and additives to effluent or cattle feed on odor and odorant concentrations,J.Anim.Sci.77(1999)1412-1421.

[26]L.Li,X.Yang,X.Li,the influence of inoculum sources on anaerobic biogasification of NaOH-treated Corn Stover,Energy Sources Part A33(2011)138-144.

[27]T.Fernandes,Klaasse,G.Bos,G.Zeeman,J.Sanders,L.B.Van,Effects of thermochemical pre-treatment on anaerobic biodegradability and hydrolysis of lignocellulosic biomass,Bioresour.Technol.100(9)(2009)2575-2579.

[28]R.Chaussod,G.Catrouz,C.Juste,Effects of anaerobic digestion of organic wastes on carbon and nitrogen mineralization rates:Laboratory and field experiments,Applied Science Publishers,1986 56-60.

[29]W.Liao,C.Liu,S.Chen,Optimizing dilute acid hydrolysis of hemicellulose in a nitrogen-rich cellulosic material-dairy manure,Bioresour.Technol.94(2004)33-41.

[30]D.Hillel,Soil in the environment.Crucible of terrestrial life,Academia Press,New York,2008 1121.

[31]D.Holthusen,S.Peth,R.Horn,Impact of potassium concentration and matric potential on soil stability derived from rheological parameters,Soil Tillage Res.111(2010)75-85.

[32]P.Rengasamy,M.E.Summer,Processes involved in sodic behavior,in:E.Summer,R.Naidu(Eds.),Sodic soils-distribution,properties,management and environmental consequences,Oxford Press,New York 1998,pp.35-50.

[33]J.Syers,W.Sheldrick,J.Lingard,Nutrient depletion in Asia:How serious is the problem?Proceedings of the 12th world fertilizer congress of the CIEC,2001.

猜你喜欢

杂志排行

Chinese Journal of Chemical Engineering的其它文章

- Influence of synthesis parameters on the properties of LiFePO4/C cathode material☆

- Controlled release and enhanced antibacterial activity of salicylic acid by hydrogen bonding with chitosan☆

- The structure,tensile properties and water resistance of hydrolyzed feather keratin-based bioplastics☆

- Preparation of dendritic bismuth film electrodes and their application for detection of trace Pb(II)and Cd(II)☆

- Performance evaluation of a modified step-feed anaerobic/anoxic/oxic process for organic and nutrient removal

- Biodiesel synthesis via metal oxides and metal chlorides catalysis from marine alga Melanothamnus afaqhusainii