花生荚果气力输送设备参数优化与试验

2016-03-21谢焕雄胡志超颜建春刘敏基徐弘博农业部南京农业机械化研究所南京210014

魏 海,谢焕雄,胡志超,颜建春,刘敏基,徐弘博(农业部南京农业机械化研究所,南京 210014)

花生荚果气力输送设备参数优化与试验

魏海,谢焕雄※,胡志超,颜建春,刘敏基,徐弘博

(农业部南京农业机械化研究所,南京 210014)

摘要:针对现有气力输送设备对花生荚果输送损耗大、裂荚、破碎率高等问题,改进关键部件结构,在分离筒内壁安装硅胶缓冲板,改进锁气器。通过对比,改进后锁气器能更好适应荚果输送。根据花生荚果在输送过程中受力破损机理,选取分离筒内壁硅胶缓冲板厚度、风机转速、花生荚果含水率三因素,以白沙花生为原料进行气力输送正交优化试验,考察上述三因素对荚果生产效率、裂荚率、破碎率的影响。结果表明,硅胶缓冲板厚度对目标因素影响最大,风机转速次之,花生荚果含水率影响最小。当硅胶缓冲板厚度为5 mm,风机转速2 700 r/min,花生荚果含水率10%时输送效果最佳,裂荚、破碎率降低明显。该研究可为花生气力输送设备的结构优化提供参考。

关键词:机械化;优化;农作物;气力输送;花生荚果;低损;试验分析

魏海,谢焕雄,胡志超,颜建春,刘敏基,徐弘博. 花生荚果气力输送设备参数优化与试验[J]. 农业工程学报,2016,32(2):6-12.doi:10.11975/j.issn.1002-6819.2016.02.002http://www.tcsae.org

Wei Hai, Xie Huanxiong, Hu Zhichao, Yan Jianchun, Liu Minji, Xu Hongbo. Parameter optimization and test of pneumatic conveying equipment for peanut pods[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(2): 6-12. (in Chinese with English abstract)doi:10.11975/j.issn.1002-6819.2016.02.002 http://www.tcsae.org

Email:weihgs@163.com

Email:xhxnq@163.com

0 引 言

花生作为极具国际竞争力的优质油料作物和经济作物,其价值早已引起国家的高度重视,并作为重要出口创汇、农业结构调整重点发展和扶持的农产品[1-3]。在花生收获及加工过程中,输送设备的优劣是影响花生质量和自动化程度的主要因素之一[4-7]。

目前,花生主要采用带式、斗式及螺旋等方式输送,但由于输送环境条件及配套作业机具结构复杂多样,上述输送方式不能有效满足作业场合需求,而国外上世纪80年代从冶金、化工领域发展起来的气力输送技术[8],因其结构简单、配置灵活、易操作,已广泛应用于稻谷、小麦、玉米等主要颗粒散料输送[9-13]。但由于花生自身物料属性的原因,气力输送设备作业原理对花生荚果损伤较大,不仅对后期生产造成影响,更会在储运过程中增加霉变风险,极易产生黄曲霉毒素[14-16],因此气力输送未能在花生输送领域得到有效应用。在国内外农产品输送领域未见花生荚果气力输送的相关报道。

本文通过改进分离筒内壁材料配置、锁气器结构并通过正交试验,分析影响花生荚果损伤的重要参数,确定使花生荚果裂荚率、破碎率和生产效率加权最优的结构参数和作业参数,以期为花生荚果气力输送设备设计提供参考。

1 气力输送装置及花生荚果损伤原因

1.1气力输送设备构造及工作原理

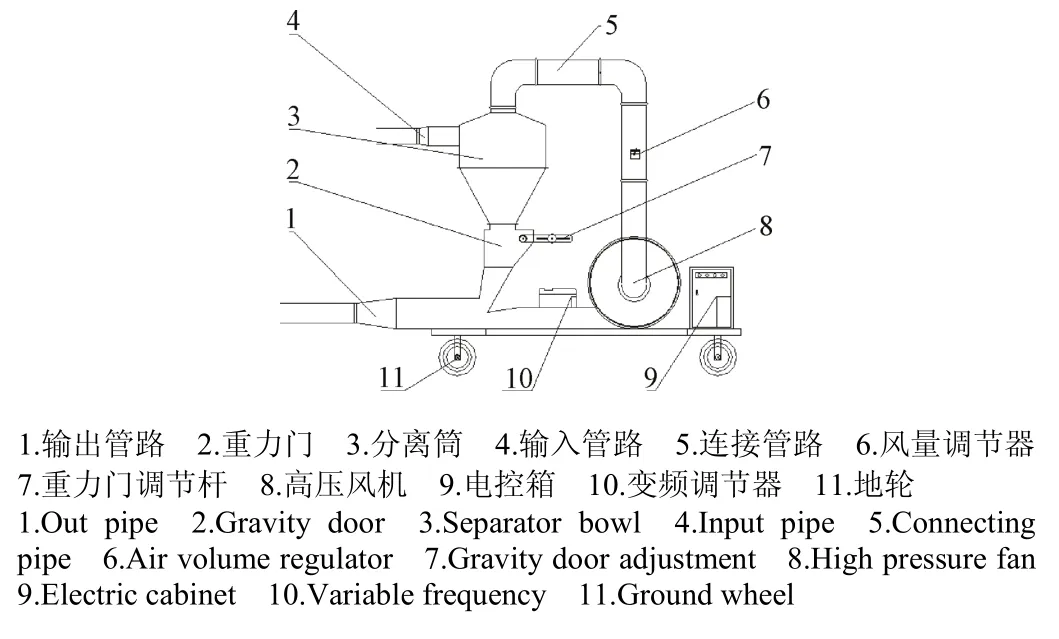

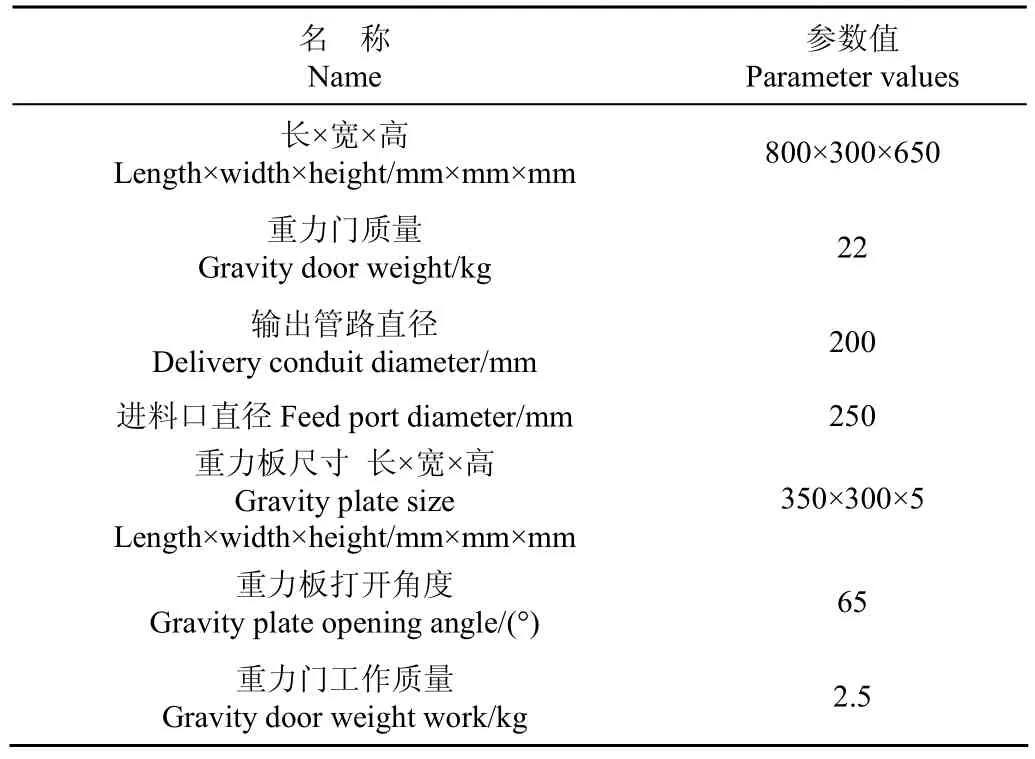

气力输送设备由机架、高压风机、变频调节器、风量调节阀、分离筒(旋风式分离器)、重力门(翻板式锁气器)、连接管路、输送管路、卸料器及控制箱等关键部件组成,主要结构及性能参数见表1,气力输送设备结构图如图1所示。

表1 气力输送设备结构及性能参数表Table 1 Structure and performance parameter for pneumatic conveying

工作原理:打开控制开关,电机带动风机,通过变频调速器调节电机转速(调节范围0~3 100 r/min)及输送管内风速。负压气流经过吸嘴、输入管路将物料吸入,通过分离筒由过滤筛网筒将空气与物料分离,物料在分离筒壁旋转下降落入重力门,当达到设定质量时重力门打开,物料下落至风机出风口处,由正压气流通过输出管路压送到卸料器,卸料器将物料与空气二次分离后卸出。

图1 气力输送设备结构图Fig.1 Structure schematic of pneumatic conveying

1.2荚果损伤的因素及机理

从力学角度来看,输送设备采用旋风式分离器,花生荚果进入分离筒后会受到比较明显的撞击与挤压作用;荚果在管道内被输送时,受到物料与管壁的撞击与摩擦作用;还有物料与物料之间产生的撞击与摩擦作用。这些作用构成了花生荚果之间的压力和剪切力,当这些压应力和剪切应力超过花生荚果的许可应力时,荚果就会产生破损。

1.3影响花生荚果损伤因素

在气力输送过程中,由于花生荚果外壳易破损的几何形态和生物力学特性,在携带气流作用下,荚果与机具内壁、荚果之间剧烈碰撞,锁气器作业时对荚果的剪切作用,极易产生裂荚和破碎,故影响荚果损伤的主要因素有荚果形状、输送气流速度(风量)、荚果与分离筒内壁产生的撞击力、荚果含水率及受压强度、锁气器结构原理。

1.3.1荚果形状

荚果几何形状对裂荚、破碎率的影响比较明显,衡量物料形状的参数主要是球形度φw为颗粒物料等体积球体表面积/颗粒物料表面积。φw值越大,物料颗粒表面的曲线越复杂,在输送过程中更容易破碎。

通过试验对比白沙和4粒红2种花生品种,白沙荚果长度集中在30~35 mm,宽度为10~14 mm,厚度为11.3~14.0 mm,果壳厚度范围为0.5~1.3 mm,平均为0.94 mm;4粒红荚果长度集中在33.3~50.0 mm,宽度为12~14 mm,厚度为12~14 mm,果壳厚度范围为0.8~1.7 mm,平均为1.28 mm。为得出设备最优工作参数,选用颗粒表面曲线复杂、果壳较薄的白沙品种作为试验物料。

1.3.2输送气流速度

用于输送物料的气流速度是影响花生荚果裂荚和破碎率的最重要的参数。气流速度越高,被输送物料的运动速度就越高。根据已有的研究资料记载,物料速度和破碎率成幂次关系[2,4],其关系式的具体参数主要是由颗粒的物理性质、输送管道的管径、管道路径、输送方式等参数决定。从能量角度分析,颗粒物料的速度越快,启动能就越大,在颗粒物料与分离筒发生碰撞时,颗粒物料的动能很容易达到破碎所需能量,从而发生破碎。

1.3.3荚果与分离筒内壁产生的撞击力

在输送过程中,由于负压作用,输送管路风速高,荚果通过进料管进入分离筒时运动速度极快,与分离筒壁撞击接触时间短,产生撞击大,直接导致荚果裂荚、破碎。

为降低荚果与筒壁之间撞击,在分离筒内壁粘贴硅胶缓冲板,既降低荚果进入筒内时产生的撞击力,也减少物料下落过程中与筒壁之间产生的摩擦。在转速2 700 r/min、荚果含水率40%的条件下进行试验。与未粘贴硅胶缓冲板相比,粘贴5 mm厚硅胶缓冲板,花生荚果裂荚率由15.33%降低至8.41%,降低了45%;破碎率由10.37%降低至4.83%,降低了53.5%,表明在分离筒内壁粘贴硅胶缓冲板可有效降低花生荚果破损,提高输送机作业性能。

1.3.4荚果含水率及耐压强度

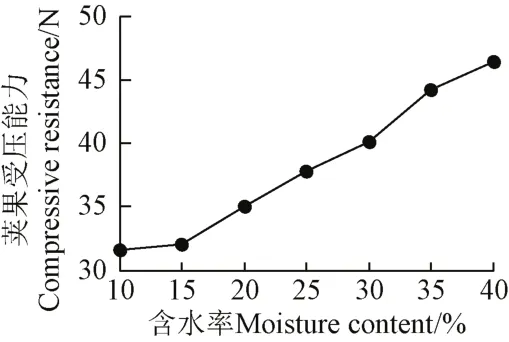

含水率是决定输送过程中荚果受压能力的重要参数,压力越低,输送过程荚果越容易破损。采用深圳三思纵横WDW-200型微机控制电子万能试验机,对烘干前含水率约40%,晾晒过程中含水率约25%和烘干后含水率约10%的花生荚果进行受压试验分析,得出水分含量越高,受压能力越强,当荚果受压力达到峰值时,荚果破碎。图2为不同含水率花生荚果受压能力测试结果图(采用试验机对不同含水率花生进行受压能力试验,没有其他因素固定值)。

图2 不同含水率对花生荚果受压能力的影响Fig.2 Influence of different moisture content on peanut pods compressive resistance

1.3.5锁气器结构及工作原理

锁气器是气力输送设备的关键组成部件,主要是为了在输送过程中防止气流回流、定量供料和卸料。锁气器的选择也直接影响气力输送花生荚果的整体效果。

现有农作物气力输送设备主要采用闭风器(旋转式锁气器),多用于稻谷、小麦、玉米等外形规则、表壳坚硬的颗粒物料。闭风器内主要采用叶轮旋转进行物料输送,为防止叶轮与机壳产生磨损,两者之间留有间隙,叶轮旋转过程中会对物料产生挤压,旋转到与机壳相切位置时,还会对物料产生较大的剪切作用。这种作业原理极易导致花生荚果裂荚和破碎,不适用于花生荚果气力输送。

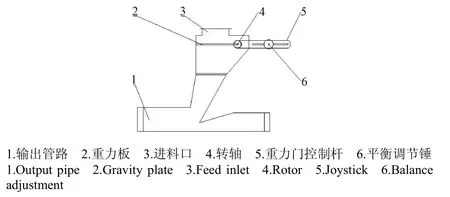

根据力平衡原理,采用翻板式重力回转机构,研发设计重力门锁气器,作业时对物料无挤压作用,还有效降低对物料产生的剪切作用,结构如图3所示。输送前调节平衡调节锤,输送过程中物料通过输入管路进入分离筒,当分离筒内荚果质量达到设定质量后,重力门自动打开,物料通过重力门下落至输出管路,再由风机将物料吹出。重力门主要采用重力板开闭进行物料输送,为防止重力门半开闭状态及荚果摩擦自锁造成物料拥堵,在设计中将重力门仓室和出料口尺寸优化,既降低风压压差,避免重力门出现半开闭状态;又防止花生荚果之间摩擦造成物料拥堵。输送过程中,当荚果质量达到设定值时,重力门才会打开,既减少重力板开闭对荚果产生的剪切力,又能避免机械能对荚果产生挤压作用。当输送物料量不稳定时,重力门可调节输送量,避免输出过程中气料混配比减小,加速度增大,在卸料器内产生撞击,造成花生荚果二次破损。重力门结构及性能参数见表2。

图3 重力门结构图Fig.3 Structure schematic of gravity door

表2 重力门结构及性能参数表Table 2 Structure and performance parameter for gravity door

2 试验方法

2.1试验因素

根据上述分析,风机转速影响输送气流速度,决定物料在输送机内部动能大小;硅胶缓冲板厚度影响物料与筒壁之间撞击缓冲程度;荚果含水率影响花生抗压能力。因此控制该三因素,从损伤机理方面可有效降低荚果裂荚率和破碎率。选择花生品种白沙作为试验材料。选择分离筒内壁粘贴硅胶缓冲板厚度、风机转速和荚果含水率作为试验因素,探讨这些因素对花生荚果破损的影响规律,并在降低裂荚率和破碎率的基础上减少对输送设备生产效率的影响。

2.2试验方法

通过对比试验考察不同锁气器对不同含水率花生荚果裂荚、破碎率的影响。采用正交试验分析硅胶缓冲板厚度、风机转速和荚果含水率对裂荚、破碎及生产效率加权最优的试验参数组合。参考目前生产上采用的参数值,试验因素变化范围为:粘贴硅胶缓冲板厚度3~7 mm;风机转速3 100~2 700 r/min;含水率10%~40%。

2.3试验测试内容

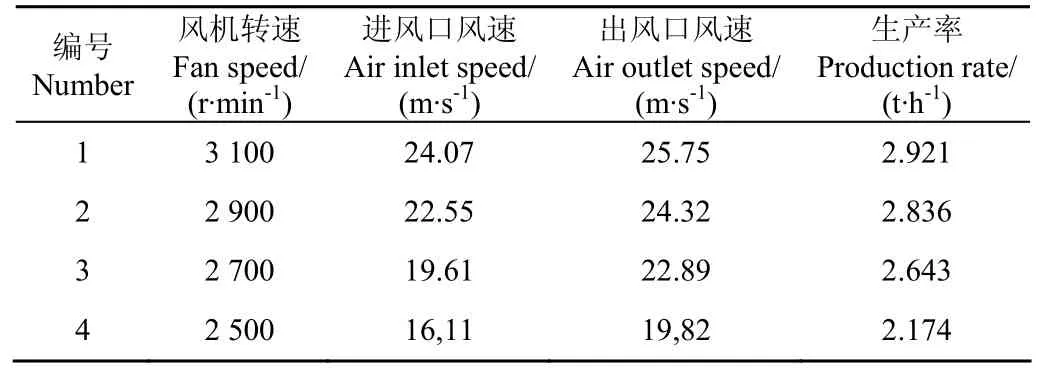

试验前对花生进行清选,去除裂荚和破碎荚果后称质量,每批次试验用量100 kg;采用烘箱法测试花生荚果含水率;使用西门子6SE6420变频调速器和优利德UT371转速计调节测试风机转速。在试验过程中需要测定的参数有风机转速、气流速度和花生荚果输送生产率等。花生荚果气力输送参数表如表3所示。

试验测试过程:接通电源,将变频调速器调节至最小,缓慢调节频率,使电机转速逐渐加大,到达设定转速后让风机工作平稳;测定进、出料口风速;通过吸嘴将花生荚果吸入输送设备,同时用计时器计时,测定输送时间,完成试验后计算生产率(设备生产率2.5~3 t/h)。

表3 花生荚果气力输送参数表Table 3 Parameter for peanut pods pneumatic conveying

由表3可知,输送气速由风机转速控制,转速越高,气速越快。在设定的4个转速下,只有转速≥2 700 r/min时,实际生产率符合设备生产率2.5~3 t/h要求,满足正常生产需要。

2.4性能评价指标

为评价输送效果,以生产效率、裂荚率、破碎率作为评价指标,各指标参数具体定义如下。

1)生产效率

2)荚果裂荚率

3)荚果破碎率

2.5气力输送设备关键参数正交优化试验

根据上文选定的试验因素,确定如表4所示的因素和水平表,每组试验随机取5个试样,重复3次取平均值,选用L9(34)正交表进行试验。

表4 花生荚果气力输送试验因素水平表Table 4 Experimental scheme of peanut pods pneumatic conveying

3 试验结果及分析

3.1不同锁气器输送试验结果对比分析

不同锁气器对不同含水率花生荚果输送试验结果评价指标值如表5所示。

表5 不同锁气器对不同含水率花生荚果裂荚率和破碎率的影响Table 5 Comparison of different air locks effect on dehiscence and broken rate of peanut pods with different moisture contents

由表5可知,与闭风器式锁气器相比,采用重力门式锁气器花生荚果裂荚率降低了4.86%~9.25%,破碎率降低了2.57%~7.42%,表明采用重力门进行花生荚果气力输送试验具有较好的适应性。

3.2花生荚果气力输送正交优化试验结果与分析

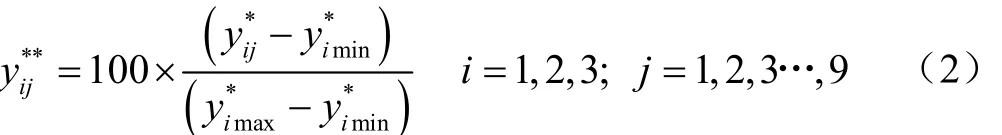

由于该试验属于多指标正交试验,为便于数据分析,选用综合加权评分法将多个性能指标的试验结果转化为一个单指标的试验结果,然后利用单指标试验结果的分析方法进行分析。

3.2.1确定各项试验指标的权值

根据各项指标的重要性,设定荚果输送生产效率、裂荚率、破碎率的权重W1、W2、W3分别为0.1、0.4、0.5。

3.2.2统一各项指标值的变化趋势

为保证综合加权平均值越大越好,应将变化趋势越小越好的指标值转化为越大越好,为此在其值前加以负号,如式(1)所示。对于花生荚果裂荚率和破碎率其值越小越好。

式中y2 j为花生荚果裂荚率指标第j号试验的评分值;y3 j为花生荚果破碎率指标第j号试验的评分值。

3.2.3统一各指标数量级和量纲

为了消除各指标数量级和量纲对其加权评分值的影响,使各指标的加权评分值具有可比性,需统一各指标的数量级和量纲。由式(2)可得到各指标的数量级、无量纲的评分值。

3.3试验结果分析

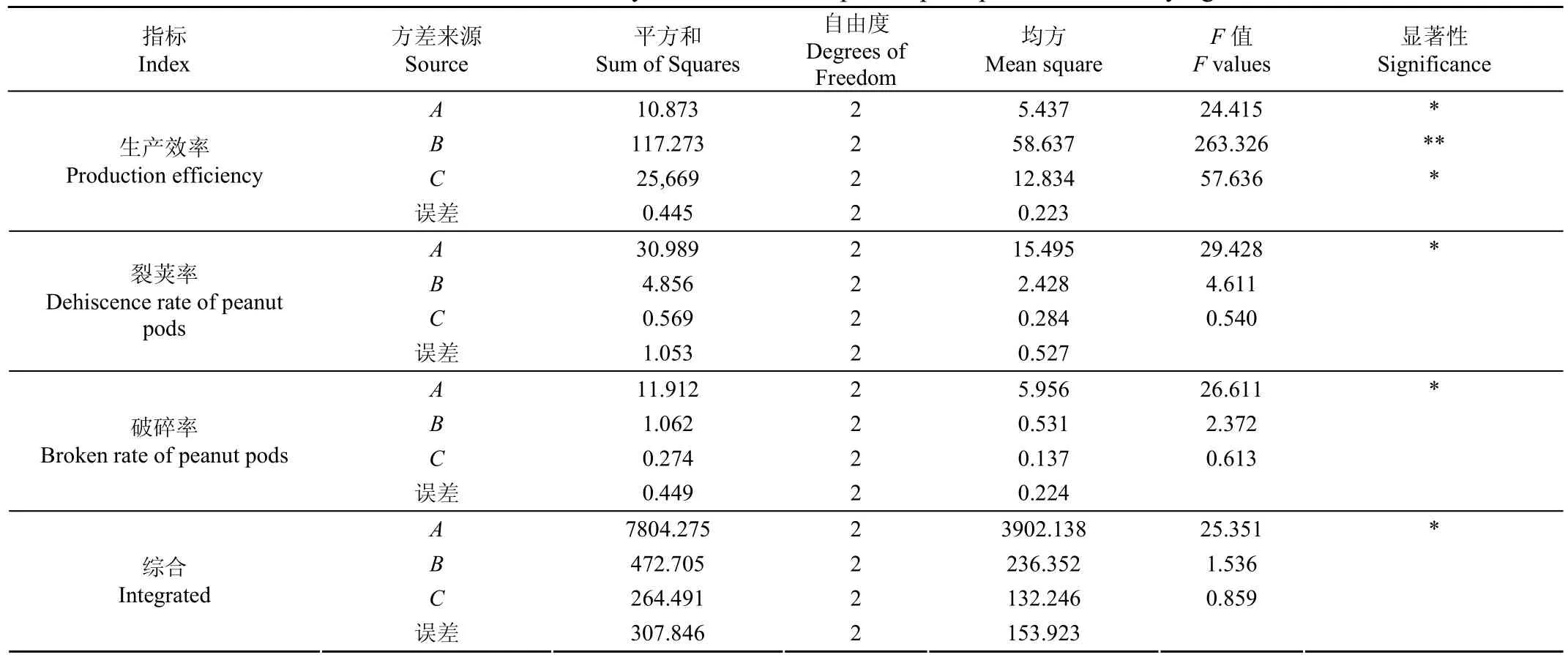

各项指标的综合加权评分结果如表6所示。将综合加权评分结果作为各次试验的结果进行方差分析,方差分析结果如表7所示:3个因素对气力输送花生荚果生产效率、裂荚率和破碎率影响程度顺序依次是A>B>C,即是否在分离筒内壁粘贴硅胶缓冲板对花生荚果输送效果的影响最大,风机转速次之,花生荚果含水率影响最小;由表6极差分析可知气力输送花生荚果效果最佳的组合方案是A2B3C3,即硅胶缓冲板为5 mm,风机转速2 700 r/min,花生荚果含水率10%时输送效果最佳。

3.4验证试验与分析

根据正交试验结果,硅胶缓冲板为5 mm,风机转速2 700 r/min,花生荚果含水率10%时进行验证试验,每组试验随机取5个试样,重复3次取平均值,试验测得生产效率为89.42%、裂荚率为0.738%、破碎率为0.185%,通过综合加权评分得值为91.135%,试验结果明显优于正交试验结果90.115%,因此A2B3C3为最优组合。

表6 花生荚果气力输送正交试验结果Table 6 Results of orthogonal experiment of peanut pod pneumatic conveying

表7 花生荚果气力输送方差分析结果Table 7 Results of analysis of variance of peanut pods pneumatic conveying

4 结 论

1)与闭风器式锁气器相比,采用重力门式锁气器花生荚果裂荚率降低了4.86%~9.25%,破碎率降低了2.57%~7.42%,表明重力门式锁气器能有效适应花生荚果气力输送。

2)对影响输送效果的关键结构参数和运动参数进行正交优化试验,输送结果表明:3个因素对花生荚果低损气力输送效果影响程度由大到小的顺序为硅胶缓冲板厚度、风机转速、荚果含水率;在硅胶缓冲板厚度为5 mm,风机转速为2 700 r/min,花生荚果含水率10%时,花生荚果气力输送损失最小。

3)与采用闭风器式锁气器、风机转速2 700 r/min、不粘贴硅胶缓冲板时,含水率10%的花生荚果输送效果相比,采用最优组合A2B3C3方案时,裂荚率从15.326%降低至0.738%,破碎率从10.375%降低至0.185%。

[参考文献]

[1] 吴建章,李东森. 通风除尘与气力输送[M]. 北京,中国轻工业出版社,2009.

[2] 杨伦,谢一华. 气力输送工程[M]. 北京,机械工业出版社,2006.

[3] 谢焕雄,王海鸥,胡志超,等. 箱式通风干燥机小麦干燥试验研究[J]. 农业工程学报,2013,29(1):64-71.Xie Huanxiong, Wang Haiou, Hu Zhichao, et al. Experiments of wheat drying by bin-ventilation dryer[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(1): 64-71. (in Chinese with English abstract)

[4] 高天宝,李勇. 气力输送过程中的粮食颗粒破碎问题[J].粮食与饲料工业,2006(12):13-15. Gao Tianbao, Li Yong. The problem of food stuff particle breaking during pneumatic conveying[J]. Cereal & Feed Industry, 2006(12): 13-15. (in Chinese with English abstract)

[5] 马冬云,周乃如,朱凤德. 小型移动式粮食气力输送装置产量影响因素的研究[J]. 粮食与饲料工业,2003(1):17-19. Ma Dongyun, Zhou Nairu, Zhu Fengde. Study on the factors affecting the capacity of small portable pneumatic grain conveyors[J]. Cereal & Feed Industry, 2003(1): 17-19. (in Chinese with English abstract)

[6] 张小刚. 物料输送技术与设备[J]. 黑龙江冶金,2013,33(2):33-34. Zhang Xiaogang. Material conveying technology and equipment[J]. Heilongjiang Metallurgy, 2013, 33(2): 33-34. (in Chinese with English abstract)

[7] 陈思林,杨旭东,秋实,等. 气力输送设备管道中物料的速度特性研究[J]. 交通信息与安全,2012,30(3):71-73. Chen Silin, Yang Xudong, Qiu Shi, et al. Velocity characteristics of the pipeline in pneumatic conveying equipment materials[J]. Journal of Transport Information and Safety, 2012, 30(3): 71-73. (in Chinese with English abstract)

[8] 王明旭,秦超,李永祥,等. 气力输送过程中粮食颗粒的输送特性研究[J]. 农机化研究,2014(9):18-22. Wang Mingxun, Qin Chao, Li Yongxiang, et al. Study on transport characteristics of grain particles in pneumatic conveying[J]. Journal of Agricultural Mechanization Research,2014(9): 18-22. (in Chinese with English abstract)

[9] 钱东平,程庆会,李国昉,等. 降低气力输送小麦能耗的试验研究[J]. 农业工程学报,2003,19(3):108-111. Qian Dongping, Cheng Qinhui, Li Guofang, et al. Experimental research on reducing power consumption of pneumatic conveying of wheat[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2003, 19(3): 108-111. (in Chinese with English abstract)

[10] 楼建勇,林江. 气力输送系统的研究现状及发展趋势[J].轻工机械,2008,26(3):4-7. Lou Jianyong, Lin Jiang. Study status quo and development tendency of pneumatic system[J]. Light Industrial Machinery,2008, 26(3): 4-7. (in Chinese with English abstract)

[11] 高连兴,杜鑫,张文,等. 双滚筒气力循环式花生脱壳机设计[J]. 农业机械学报,2011,42(10):68-73. Gao Lianxing, Du Xin, Zhang Wen, et al. Double-roller peanut sheller with pneumatic circulating[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(10): 68-73. (in Chinese with English abstract)

[12] 贾华坡,武文斌,管华威,等. 粮食输送机械的创新技术[J].粮食流通技术,2013(4):12-14. Jia Huapo, Wu Wenbin, Guan Huawei, et al. Innovation technology of grain conveying machinery[J]. Grain Distribution Technology, 2013(4): 12-14. (in Chinese with English abstract)

[13] 魏飞,张林海,侯书林. 秸秆物料除杂及气力输送系统的设计[J]. 农机化研究,2013(8):80-83. Wei Fei, Zhang Linhai, Hou Shulin. System design of straw material impumatic conveying[J]. Journal of Agricultural Mechanization Research, 2013(8): 80-83. (in Chinese with English abstract)

[14] 陈冠益,方梦祥,骆仲泱,等. 稻壳的气力输送特性研究及各种输送方法的比较[J]. 农业机械学报,1998,29(3):73-78. Chen Guanyi, Fang Mengxiang, Luo Zhongyang, et al. The studies on gas transportation ofrice husk and comparison of others tran sortation ways[J]. Transactions of the Chinese Society for Agricultural Machinery, 1998, 29(3): 73-78. (in Chinese with English abstract)

[15] 王泽南,张鹏,尹安东. 临界风速气力输送模糊控制仿真[J].农业机械学报,2003,34(5):116-118. Wang Zenan, Zhang Peng, Yin Andong. Simulation of pneumatic conveyance process with critical wind velocity by a fuzzy controller[J]. Transactions of the Chinese Society for Agricultural Machinery, 2003, 34(5): 116-118. (in Chinese with English abstract)

[16] 颜建春,胡志超,谢焕雄,等. 花生荚果薄层干燥特性及模型研究[J]. 中国农机化学报,2013,34(6):205-210. Yan Jianchun, Hu Zhichao, Xie Huanxiong, et al. Studies of thin-layer drying characteristics and model for peanut pods[J]. Journal of Chinese Agricultural Mechanization, 2013, 34(6): 205-210. (in Chinese with English abstract)

[17] 李云克,邸坤. 气力输送在稻谷烘干系统中的应用[J]. 粮食流通技术,2012(1):17-20. Li Yunke, Di Kun. Application of pneumatic in rugh rice drying system[J]. Grain Distribution Technology, 2012(1): 17-20. (in Chinese with English abstract)

[18] 李长友,马兴灶,程红胜,等. 荔枝定向去核剥壳机设计与试验[J]. 农业机械学报,2014,45(8):93-100. Li Changyou, Ma Xingzao, Cheng Hongsheng, et al. Design and experiment of litchi denucleating and decorticating machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(8): 93-100. (in Chinese with English abstract)

[19] 尚书旗,刘曙光,王方艳,等. 花生生产机械的研究现状与进展分析[J]. 农业机械学报,2005,36(3):143-147. Shang Shuqi, Liu Shuguang, Wang Fangyan, et al. Current situation and development of peanut production machinery[J]. Transactions of the Chinese Society for Agricultural Machinery, 2005, 36(3): 143-147. (in Chinese with English abstract)

[20] 邓春香,陶栋材,高静萍,等. 气流清选风车中谷物的动力学特性和影响因素的研究[J]. 农业工程学报,2006,22(4):121-125. Deng Chunxiang, Tao Dongcai, Gao Jingping, et al. Dynamic characteristics and factors affecting perform ance of air-stream cleaning windmill[J]. Transactions of the Chinese Society for Agricultural Machinery, 2006, 22(4): 121-125. (in Chinese with English abstract)

[21] 黄远东,陈林兴. 水平悬浮气力输送在不同约束条件下的临界风速方程及求解分析[J]. 流体机械,2006,34(6):11-21. Huang Yuandong, Chen Linxing. Equations of critical velocity for horizontal pneumatic transport under different constraint conditions[J]. Fluid Machinery, 2006, 34(6): 11-21. (in Chinese with English abstract)

[22] 杨磊,田素芳. 脉冲式气力输送装置在小麦粉压运中的应用[J]. 粮食与饲料工业,2010(11):8-10. Yang Lei, Tian Sufang. Application of pulsating pneumatic conveying device in pressure conveying of wheat fiour[J]. Cereal & Feed Industry, 2010(11): 8-10. (in Chinese with English abstract)

[23] 程红胜,李长友,鲍彦华,等. 荔枝柔性去核刀具的设计与试验[J]. 农业工程学报,2010,26(8):123-129.Cheng Hongsheng, Li Changyou, Bao Yanhua, et al. Design and experiment for flexible cutter of litchi denucleating machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010,26(8): 123-129. (in Chinese with English abstract)

[24] 吴建明,陶菊春. 用综合加权评分法优化钻进泥浆配方的研究[J]. 农业工程学报,2002,18(2):45-48. Wu Jianmin, Tao Juchun. Experimental study on optimizing mud prescription for well drilling by using comprehensively weighted grading method[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE),2002, 18(2): 45-48. (in Chinese with English abstract)

[25] 王中营,武文斌,曹宪周. 粮食颗粒对输送管道的磨损机理分析及解决措施[J]. 粮食与饲料工业,2013(10):12-15. Wang Zhongying, Wu Wenbin, Cao Xianzhou. Analysis on the wear mechanism and solving measures of grain particles on the pipeline[J]. Cereal & Feed industry, 2013(10): 12-15. (in Chinese with English abstract)

[26] 谢灼利,黎明,张政. 水平管气力输送的数值模拟研究[J].高校化学工程学报,2006,20(3):331-337. Xie Zhuoli, Li Ming, Zhang Zheng. Numerical simulation of horizontal pneumatic conveying[J]. Journal of Chemical Engineering of Chinese Universities, 2006, 20(3): 331-337. (in Chinese with English abstract)

[27] 马爱纯,Williams K C,周孑民,等. 气力输送管道压降预测影响的数值模拟研究[J]. 武汉理工大学学报,2010,32(23):13-16. Ma Aichun, Williams K C, Zhou Jiemin, et al. Numerical simulation of some effects on pressure drop predicting in pneumatic transport[J]. Journal of Wuhan University of Technology, 2010, 32(23): 13-16. (in Chinese with English abstract)

[28] 鹿鹏,陈晓平,梁财,等. 不同煤粉高压密相气力输送特性实验研究[J]. 中国电机工程学报,2009,29(5):16-20. Lu Peng, Chen Xiaoping, Liang Cai, et al. Experimental study on the characteristics of high-pressure and dense-phase pneumatic conveying of different pulverized coal[J]. Proceedings of the CSEE, 2009, 29(5): 16-20. (in Chinese with English abstract)

Parameter optimization and test of pneumatic conveying equipment for peanut pods

Wei Hai, Xie Huanxiong※, Hu Zhichao, Yan Jianchun, Liu Minji, Xu Hongbo

(Nɑnjing Reseɑrch Institute of Agriculturɑl Mechɑnizɑtion, Ministry of ɑgriculture, Nɑnjing 210014, Chinɑ)

Abstract:As the internationally competitive oil crop and cash crop, peanuts have attracted great attention in China, and become an important export commodity and the key to the agricultural structure adjustment. Transportation equipment has directly affected the peanut quality after harvest and the degree of automation. Nowadays, people are increasingly concerned about food safety, and the quality risk of peanut pods during the process of conveying, such as dehiscence and break, has drawn more attention. Due to various factors, the peanut pods are easy to break in the process of conveying, which not only affects the later production, but also increases the risk of aflatoxin in the process of transportation and storage. Pneumatic conveying has great advantages for granular materials because of its simple structure, flexible operation and stable production efficiency and so on, which is widely used in the areas of agricultural product processing. Aiming at the problems of power loss, peanut pod’s dehiscence and break, crushing rate and unstable production efficiency, the structure and parameters of the existing pneumatic conveying equipment were improved and optimized. Besides, the experiments were conducted in main production areas of peanut. Through analyzing, the pod’s damage elements, including pod physical characteristics, fan speed,pod moisture content and air lock structure, were determined respectively. In the process of conveying, the impact of various forces on peanut pods would cause damage easily. To avoid these damages, the silicone buffer plate was installed on the wall of separate cylinder, which reduced the force between the material and the separate cylinder effectively. In order to adjust airflow velocity, the frequency conversion governor was installed on the conveyor equipment to control the fan speed, which could reduce the impact force to achieve the best conveying effect without the decrease of production efficiency and the break of peanut pods, when materials entered the equipment. By using WDW-200 type computer-controlled electronic universal testing machine, the compression capabilities of different peanut varieties were contrasted, and we selected white sand peanuts as the test materials, whose shells are coarse and thin. Then, we measured the moisture content of this kind of peanut in different drying periods. Afterwards, the rotate plank type air lock was designed to replace the original rotation type air lock,which would remain to be closed until the weight of peanut pods reached the set value. This kind of air lock could not only reduce the shear force to the pods when the gravity plate was opening and closing, but also avoid the squeezing action to the peanuts. At the same time, when the conveyed material quantity was unstable, the gravity door of the air lock could adjust the conveying quantity, which avoided the reduction of gas material mix proportion and the increase of peanut pod’s acceleration,and thus avoided the second break by relieving the strike of peanut pods in the unloader. According to the contrast test, the rotate plank type air lock caused a minor injury compared with the rotation type air lock. On this basis, pneumatic conveying orthogonal optimization test was conducted with the improved equipment. The influences of silicone buffer plate thickness, fan speed and peanut pod moisture content on productivity, dehiscence rate and broken rate were considered respectively. According to the comprehensively weighted evaluation and variance analysis, the results showed that the silicone buffer plate thickness had the most obvious influence, followed by the fan speed and peanut pod moisture content. When the thickness of silicone buffer plate was 5 mm, the fan speed was 2 700 r/min and the moisture content of peanut was 10%, the dehiscence and broken rate of peanut pods reached the minimum, which achieved the best conveying effect. This study can provide reliable evidence for structure optimization of pneumatic conveying equipment of peanuts.

Keywords:mechanization; optimization; crops; pneumatic conveying; peanut pods; reduce breakage; test analysis

通信作者:※谢焕雄,男,广西浦北人,研究员,主要从事农产品加工技术与装备研究。南京农业部南京农业机械化研究所,210014。

作者简介:魏海,男,甘肃兰州人,助理研究员,主要从事农产品加工技术与装备研究。南京农业部南京农业机械化研究所,210014。

基金项目:国家花生产业技术体系专项基金(CARS-13-产后加工机械);中国农业科学院科技创新工程(农产品分级与贮藏装备创新团队);公益性行业(农业)科研专项(201203037)

收稿日期:2015-07-22

修订日期:2015-12-09

中图分类号:S229+.2

文献标志码:A

文章编号:1002-6819(2016)-02-0006-07

doi:10.11975/j.issn.1002-6819.2016.02.002